Home / Boiler automation

Back to

Published: 24.05.2019

Reading time: 3 minutes

0

855

Modern scientists, together with engineers, are looking for an increase in the efficiency of heating systems in order to reduce the negative consequences of the environment affecting us. One of the ways to solve this problem is weather-dependent automation capable of controlling heating systems.

This group of devices is able to control fuel consumption in a running unit, taking into account the current weather changes. At the same time, it is possible to predict excessive cooling or excess temperature in the heated room in order to immediately compensate for possible deviations.

It is important to understand that the work carried out by weather-dependent automation is aimed at maintaining the optimal balance between a comfortable microclimate and an economical heating mode.

- 1 Weather-dependent automation device

- 2 How it works

- 3 Advantages and disadvantages

- 4 When weather-compensated automation comes in handy

The device and principle of operation of weather-dependent automation

The mechanical part of the heating automation is a pump with a control valve. The equipment is controlled by a computer based on data from 4 temperature sensors that respond to the temperature outside and in the room. The program for intelligent regulation of weather-dependent boiler control is embedded in the controller. The contour is adjusted according to the operating conditions and the type of room.

Existing regulatory schemes are based on three principles:

- The hydraulic elevator uses return water, mixing with the water heated in the boiler. The device is controlled by a weather-dependent heating controller, giving a command to move the cone valve according to the readings of the sensors.

- A circuit with a circulation pump and a three-position valve restricts the heated flow and returns the waste heat carrier to the system. The three-way valve is controlled by the processor according to a given program.

- The shut-off valve on the return line is closed by a valve. The device is controlled by a weather-dependent heating system controller according to temperature sensors.

Weather-dependent automatic sensors for heating systems of an apartment building (MKD) are installed in a living room.

The individual heating station (ITP) is located in the basement, where it is easier to maintain the equipment.

Advantages and disadvantages

Weather-dependent automation allows its users to avoid excessive heating of the room during warming periods and to avoid loading heating boilers in advance during cold snaps.

The presented system has a number of advantages that allow the heating to work in optimal mode:

- sudden changes in temperature outside do not affect the microclimate of the room;

- the most economical fuel consumption;

- smooth transitions between operating modes exclude prolonged loads on heating equipment;

- the amount of harmful emissions into the chimney is reduced;

- the service life of the heating system is increased.

Installation of automatic control over heating will significantly save money, get maximum comfort and not be distracted by self-adjusting heating modes.

However, one should also take into account the disadvantages of this equipment:

- High price.

- The indoor location of the sensor will seriously affect the overall performance of the system.

- Installation, adjustment and repair of automation is possible only with the help of qualified specialists.

Weather-dependent automation perfectly controls heating in high-rise apartment buildings, whose facades are accessible to all winds. The use in the private sector is highly dependent on the environment.

Types of automatic control systems

When using individual heating, apartment owners often have a problem with temperature control. The manual adjustment method is inaccurate and consumes excessive fuel. The use of automatic weather-compensated regulation of the heating system saves resources and frees up personal time.

Types of automation:

- a thermostat wired to a dependent mechanism;

- wireless control of the heat preservation system depending on the weather.

Functions of control devices:

- keeping the room temperature by the thermostat at a given level;

- programmed setting of the heating level by time of day for up to one week.

Types of devices:

- mechanical thermostat - turns on the electrical network when the ambient temperature changes;

- electronic device - precisely controls heating according to sensor signals;

- electromechanical device - a temperature relay controls the valve drive.

Heating control thermostats can be connected to a pump, boiler or mechanical shut-off actuator.

Methods for controlling the heating system with weather-dependent automation

Thermal automation

The most common method of temperature control is called "direct exposure". That is, in order to change the microclimate in the house, you need to go and change the indicators of the heat generator (heating boiler, stove, fireplace or electric heater) with your own hands. In this way, maximum control over the room temperature level is achieved. This approach is very effective, but quite inconvenient, since it takes effort to manage heat every time.

Rules for the operation of weather-dependent heating

Heating control systems have a self-diagnostic function. Error messages are sent to the display, and the owner is left with the choice of how to resolve them.

If the temperature controller does not work, you need to check the electricity first.

Frequent problems:

- crackling during operation - poor contact with the power supply;

- weak heating of the room at a high set level - an extraneous thermal effect on the sensor is possible;

- the device connected according to the rules does not turn on - the reason is in the design, replacement will be required;

- blinking of the LED - the temperature sensor is broken;

- the thermostat does not provide the set mode - the device is faulty.

For continuous operation without failures, it is sufficient to comply with the operating requirements established by the manufacturer. Installation and configuration of the system is carried out according to the instructions.

Using automatic heating control

Heating control systems differ in function and price. Simple models are controlled by a remote control or touch screen. Complex systems have their own software with remote control access. Weather-dependent automation is available in different types of heating boilers:

- wall-mounted, located in one of the rooms;

- floor-standing, installed in the boiler room;

- electric boiler.

In the controller program setting, the initial value is set when the inside and outside temperatures are the same. Then the calibration is carried out, the parameters of the coolant are selected for each type of weather. The manufacturer programs his own options by default, one of which can be selected for work.

To set up the system, you need to install temperature sensors outside and in the room so that the data is transmitted without distortion.

The advantages of management are the availability of autonomous operation, saving resources.Disadvantages of weather-compensated automation - maintenance and repairs can be expensive due to the replacement of faulty electronics.

The principle of weather-compensated heating control

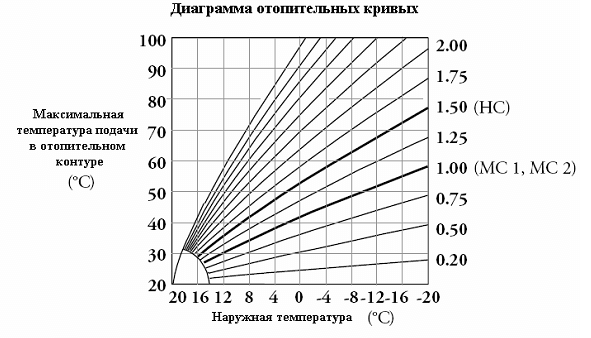

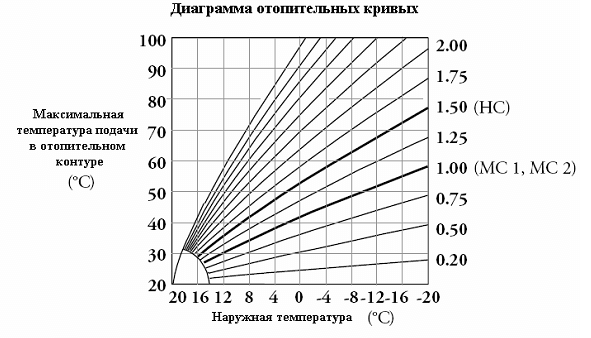

Let us explain how the maintenance of the room temperature is carried out taking into account the changes in the street temperature. When setting up the controller, a so-called temperature curve is set, which reflects the dependence of the temperature of the coolant in the heating circuit on changes in weather conditions outside. This curve is a line, one point of which corresponds to + 20 ° С outside (while the temperature of the coolant in the heating circuit is also + 20 ° С, since it is believed that under such conditions there is no need for heating). The second point is the temperature of the coolant (say, 70 ° C), at which, even on the coldest days of the heating season, the temperature in the room will remain set (for example, 23 ° C). If the building is not sufficiently insulated, a slightly higher temperature of the coolant in the heating circuit will be required to compensate for the heat loss. Accordingly, the slope of the curve will be steep. And vice versa, if everything is in order with the thermal insulation of the house. During the manufacture of the controller, many similar curves are entered into the memory of the device, so that you can then select from the entire family a suitable line specifically for the conditions of your home.

Typically, a single outdoor sensor is not enough to maximize thermal comfort and save fuel. Therefore, an additional sensor is often installed inside a heated room. The presence of two sensors at once, both indoor and outdoor, allows you to accurately monitor and quickly adjust the temperature in the premises of the house.

Typically, the room temperature sensor is installed in a so-called reference room - the temperature in it will correspond to your concept of a comfortable thermal background. This room should not be heated by direct sunlight or blown through by drafts. As a rule, nurseries and bedrooms are chosen as a reference. Installation of a room sensor makes it possible to activate the self-adaptation mode, in which the heating curve is automatically matched to the corresponding room - by the microcomputer of the control panel itself. In addition, the room sensor is often integrated into a thermostat, with which you can set the desired temperature and its average level throughout the house. Local temperature control in a separate room is achieved by installing thermostatic valves with thermal heads on the radiators.

A very important aspect of using a thermostat is again fuel economy. Let us explain how it is carried out. For example, in the room where the sensor is installed, guests have gathered and the temperature has risen by 2 ° C due to the natural heat release of people. The control panel detects these changes and gives a command to reduce the temperature of the coolant in this circuit, although an outdoor sensor may require just the opposite. Reducing heat consumption for heating this room naturally saves fuel. But there are also problems here. Flooding in a room with a thermostat, fireplace, or leaving a window open for a long time can cause temperature changes throughout the house. To take into account such factors in many systems, it is possible to amend the control algorithm by setting the coefficient of influence of the room sensor on the nature of the heating curve. But in general, experts simply do not recommend installing room temperature measuring devices near fireplaces, entrance doors, windows and other sources of heat or cold that can introduce an error in the measurement results.

It should also be noted that the installation of only one room thermostat, without an outside temperature sensor, significantly increases the inertia of the thermal control system. Changes in the heat background will occur with a delay, since the automation will start to operate only when the temperature in the house, for example, drops, and this will happen after the actual cold snap outside.

Modern controllers not only monitor the weather, but also have a fairly large number of functions, some of which are custom, and some are service. While the former are on guard for comfort, the latter monitor the state of the system and ensure the correct and safe operation of the equipment.

Weather-dependent automation Vaillant

Vaillant's Multimatic VRC 700 controls underfloor heating and up to 10 mixed heating circuits.

Vaillant VRC 700 Multimatic specifications:

- setting of parameters with a rotary knob;

- work with solar heating of the coolant and forced ventilation;

- preset heating curves Vaillant - night, guest, day and ventilation;

- recording of an individual control program;

- remote diagnostics of the system by service.

VRC 700 weather-compensated automation control schemes:

- One direct heating circuit and recirculation pump with additional module.

- Two mixing lines, expansion VR 70, boiler pump.

- Direct heat carrier flow control.

- Circuits - straight and mixed, with two VR 70 modules, recirculation pump.

- Control of two heating medium mixing lines with expansion VR 70, module VR 91 regulates the process.

- Regulation of two mixing circuits by means of a VR 70 expansion and a boiler via a condensing boiler board.

- Three mixing lines with VR 71 module and a recirculation pump.

- Controls more than 3 contours, one of which is straight. The scheme includes extensions VR 60, VR 32, VR 90.

The version of the Vaillant VRC 700/6 weather-dependent automation can connect several boilers to work, and with the VR 900 unit, control the cascade remotely in a special application.

Pump control from an external signal

Connecting the controller to the “smart home” system significantly expands the heating control capabilities. In addition to heating operation under the control of a weather-dependent automation controller, the system gives owners the opportunity to remotely adjust the temperature regime in the premises.

The main condition here is the connection of the controller to the Internet and the installation of a special application on mobile devices for managing life support systems at home.

Baxi weather-controlled boilers

Gas boilers consume fuel even in normal mode, since the burner continues to work when there are no people in the house. With good insulation of the house, turning off the heating reduces the temperature by 2 ° C in 6 hours, and turning on heating gives an increase of 2 ° C in one hour. Boilers of the Baksi Luna 3 Comfort model are remotely controlled via a mobile application. A script for automatic heating control can be linked to a calendar.

Boilers of the Baxi Slim series have the following functions:

- remote inquiry of temperature in the apartment and on the street;

- remote control of water temperature in the direct and return circuits;

- reading of gas meter readings;

- control of pressure in the system;

- notification of errors and emergency stop of the boiler;

- remote activation of the boiler.

Advantages of wall-hung boilers:

- separate heating and water heating circuit;

- constant temperature of the coolant;

- silent work;

- electronic modulation of the flame;

- boiler operation at reduced gas pressure in the system;

- the ability to connect underfloor heating.

The Italian manufacturer Baxi boilers are unpretentious.

Manual control of the heating boiler

Until a certain moment, the most common way to control a heating boiler was manual regulation of the temperature of the coolant (many boilers are still controlled in this way). The automation was simple - the thermostat built into the boiler was manually adjusted to a certain temperature of the coolant circulating in the system, for example, 50 ° C. But manual control is effective only under stable external conditions. Let's say that it is necessary to maintain a certain temperature in the room - 23 ° C. When the temperature of the coolant reaches 50 ° C, the thermostat will give a command to turn off the gas burner, and if the temperature drops, then turn it on. This cyclical process explains the “waviness” of the orange flow temperature graph and the green room temperature graph. If it gets colder outside and the thermostat continues to work in the same mode (50 ° C), then the temperature in the room will inevitably drop. To correct this situation, the participation of a person is required, who must increase the temperature of the coolant to higher values.

The disadvantages of this method of regulation are obvious - this is the involvement of a person in the operation of the heating system and the continuous operation of the automatic ignition of the burner.

Benefits:

- High accuracy of maintaining a stable temperature in the house at a constant temperature outside;

- There is no need to pay extra for control automation, because it is included in the price of the boiler.

Disadvantages:

- The need for constant manual adjustment of the temperature regime of the boiler;

- Due to the constantly running pump, increased energy consumption occurs;

- Frequent on / off cycles wear out the boiler automation faster.

Automatic control of boilers Protherm

Boilers without regulation turn on heating depending on the parameters of the heat carrier. Protherm weather-dependent equipment controls heating based on data from outdoor and indoor sensors. Thermostats save up to 30% of fuel by reducing the frequency of the boiler switching on.

Room regulators that are used with the Proterm Skat electric boiler:

- Instat Plus with wired connection, maintains temperatures from 5 to 30 ° C, there is a night mode for reducing heating.

- Termolink B - room regulator for air heating in the range from 8 to 30 ° C, programmable operating mode for 24 hours, frost protection function.

Electric heating is a safe and emission-free source of heat in your home. No ventilation system required for installation. The equipment of an electric Protherm boiler is simpler than a gas one.

With the floor-standing cast-iron boilers Protherm Bear, thermostats on the eBus are used:

- Termolink P - there is a modulation mode, regulation of air and hot water heating, heating control curve depending on temperature sensors.

- Termolink S - can change the boiler operating mode by time of day, programmable for a week. Vacation mode and frost protection are preset.

Medved series boilers change the water temperature with an injection burner. The heating element is made of cast iron. The display on the panel informs about the parameters of the coolant.

Description of controller operation:

Depending on which of the hydraulic circuits is activated, the potential-free contact R1, the power contacts R2 ... R8, as well as the low-voltage contacts of the temperature sensors T1 ... T8 receive a corresponding place in the hydraulic circuit. Free power contacts can be assigned to control any additional device (boiler or mixing pumps, terminals of the 2nd stage of the burner, solar pump, heating element, etc.). The number of additional devices connected is limited by the number of free power contact terminals.

The expansion of the circuit in terms of the number of controlled heating circuits is carried out by connecting the required number of additional (slave) EH controllers to the EH master controller via the eBUS (2-core cable with a cross-section of 0.5 ... 0.75 mm2). Any of the EH controllers can act as a master or slave controller.

The outside temperature sensor can be connected either one to several controllers, or each controller can have its own outside temperature sensor (T2).

In hydraulic circuits with mixing circuits, you can select the type of heating devices used: radiators or underfloor heating. For example, when you select “underfloor heating”, the corresponding low-temperature heating curve is activated, the time programs are shifted taking into account inertia, it becomes possible to start the screed drying program, etc.

The DHW tank circuit can be loaded according to priority, or in parallel with the heating system. It is possible to operate the controller in systems with combined tanks (heating + hot water supply) of storage or flow type.

Power contact R5 can be used to control a recirculation pump in the DHW system. In this case, the signals from the temperature sensors T1 or T8 are used (if they are free in the selected hydraulic circuit).

Power contact R6 has the ability to control the speed of rotation of the pump connected to it. It is also possible to set the minimum preset pump rotation speed on this power contact.

Functional capabilities of EH-7, EH-17, EH-52 controllers

| EH-7 | EH-17 | EH-52 | |

| Number of relays (mechanical / electronic) | 6/0 | 6/1 | 7/1 |

| Number of temperature sensors | 6-7 | 6-7 | 6-7 |

| Number of hydraulic circuits | 7 | 17 | 52 |

| Number of heating circuits | max 1 | max 2 | max 2 |

| Number of connected thermostats | 2 | 2 | 2 |

| Time programmer | Yes | Yes | Yes |

| Switching between two boilers | not | not | not |

| Heating by heat pump | Yes | Yes | Yes |

| DHW heating with a heat pump | not | Yes | Yes |

| DHW preparation by solar system | not | Yes | Yes |

| System expansion via eBUS | Yes | Yes | Yes |

| Functions "Holiday", "ECO", "Vacation", DHW boiler temperature control | Yes | Yes | Yes |

| Advanced heating functions | Yes | Yes | Yes |

| Periodic activation of the pump and valves outside the heating season | Yes | Yes | Yes |

| Boiler overheating protection, solar collectors, and a water heater | Yes | Yes | Yes |

| Remote control option from a smartphone | Yes | Yes | Yes |

| Legionella protection | Yes | Yes | Yes |

| Frost protection | Yes | Yes | Yes |

| The function "drying the screed is warm. gender " | Yes | Yes | Yes |

| Current day temperature overview | Yes | Yes | Yes |

| Overview of temperatures over several days | Yes | Yes | Yes |

| Error and overheating indication | Yes | Yes | Yes |

| System simulation | Yes | Yes | Yes |

| Settings change log | Yes | Yes | Yes |

| PC connection | Yes | Yes | Yes |

Weather-dependent automation Meibes

The HZR-M Meibes weather-compensated thermostat controls the heating medium mixing circuit independently, complete with other controllers. Characteristics of the Maybes device:

- interface with icons;

- built-in heating programs;

- integration with other regulators on the eBUS bus;

- autonomous power supply with batteries;

- display backlight;

- connector for connecting a computer.

Weather-dependent automation for heating systems of a private house - devices with remote access Meibes LE HZ of German production.

The thermostat controls two circuits or a cascade of 2 boilers, recirculation pumps. Meibes LE HZ features:

- connecting controllers remotely;

- expansion of control by 8 loops via eBUS;

- symbolic menu;

Advantages - easy installation on the wall.

When weather-dependent automation comes in handy

In private houses, if they are of medium or smaller size, the need to install these automation mainly appears during long absences of the owners in the house.In other cases, adjustments are not difficult to make manually or with the help of gadgets.

A different situation develops in large cottages or mansions, as well as in public buildings with a large area. Here, the organization of automatic heating control by means of automation for boilers becomes a direct necessity.

According to the results of the control test, which checked the operation of the new system, it was found that the fuel consumption for heating in a high-rise apartment building with a large number of glazed surfaces was reduced by 2 times.

In addition, weather-dependent automation has produced high efficiency in the central heating boiler house of the residential sector, tuned to service a number of buildings.

ZONT thermostat

The weather-dependent heating controller ZONT H-1 is an intelligent system that is remotely controlled via GSM or the Internet. The device is connected via a mobile application, a personal account on the manufacturer's website or by SMS commands. Thermostat features:

- 2G SIM card management;

- transmission of readings from temperature sensors and boiler operation mode;

- selection of the heating control curve;

- room heating programming for a week;

- notification of errors and emergency cases;

- a message about a power outage in the house;

- history of operations for 3 months;

- software update via the Internet.

The thermostat is connected in 2 ways - via the terminals on the boiler or via an adapter to the digital bus. Heating control can be performed in relay mode, with periodic switching on of the gas burner. Digital control via adapter is possible - electronic flame modulation.

Specifications ZONT H-1:

- operating voltage 10-28 V;

- analog and digital inputs;

- connection of 10 wired and radio channel sensors;

- operating range from –30 to + 55 ° C;

- exit to the mode - 50 seconds;

- plastic housing, universal surface mount.

The advantages of weather-dependent regulation of the heating system of a country house

First, you need to determine what functions the automation of the heating system is designed to perform. Let's highlight two main ones: ensuring the most comfortable conditions for residents and saving heat energy.

Comfortable conditions are provided not only by weather automation. A whole range of engineering solutions is used to ensure the optimal air temperature of the interior premises, and weather automation is one of the essential components of this complex. The fact is that the microclimate parameters, as a rule, are responsible for room thermostats that operate on internal air temperature sensors and provide direct control of the heating system. However, it has already been understood that the use of thermostats alone (if we are talking about a purely automatic mode) is not entirely justified, since there is always a delay between a change in the outside air temperature and the subsequent change in the internal air temperature, as well as the inertia of the heating system itself (this is especially true underfloor heating). Considering all of the above factors, it turns out that the system begins to operate in an intermittent pulse mode with a periodic delay. And here the same weather-dependent automation comes to our aid, which includes a controller, which, using an outdoor temperature sensor, will constantly adjust the temperature of the coolant and provide the necessary parameters.

Comfort is, of course, good, but the question arises whether it is advisable to constantly adjust the temperature of the coolant. It is often possible to come across such an opinion that it is necessary and sufficient to adjust the system once for a period, or when the outside temperature changes abruptly.At the same time, the adjustment can be made manually and, using various remote control systems, to avoid unnecessary "bells and whistles" in their engineering systems, simplifying their operation. In order to understand this issue in more detail, I propose to move on to the second functional part of weather-dependent regulation - saving energy resources.

Of course, if you ask: "What kind of regulation of the coolant supply will be the most energy efficient?", Then you can immediately, without hesitation, answer: "Automatic!" and thus finish this article. But a question immediately arises, not just associated with energy efficiency, but with how much the real costs of generating heat energy from the use of weather-dependent automation are reduced and how expedient these measures are.

Many manufacturers give different figures when talking about savings, but there are practically no real data, confirmed by calculation or experiment. Perhaps this is due to the fact that it is rather difficult to calculate in advance what the real effect will be from this system, because a large number of variables are included in the calculation.

All these variables are associated with the actual operating mode of the hot water heating system and the number of hours people spend in the house.

Thus, we can determine the effect of the use of weather-dependent regulation in two ways. The first method is experimental, the second is calculated.

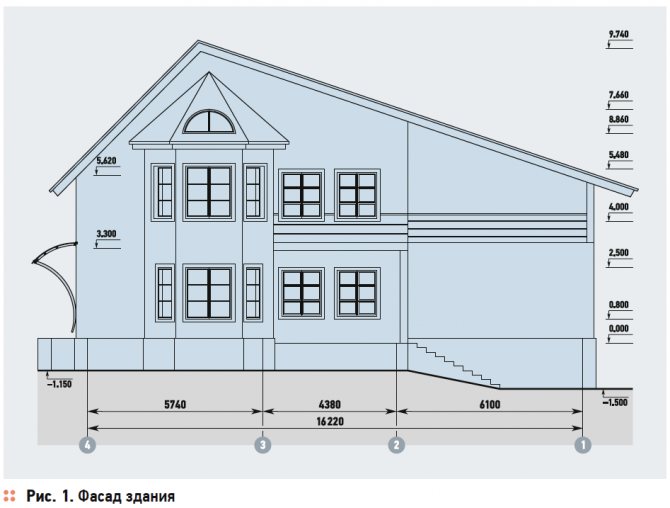

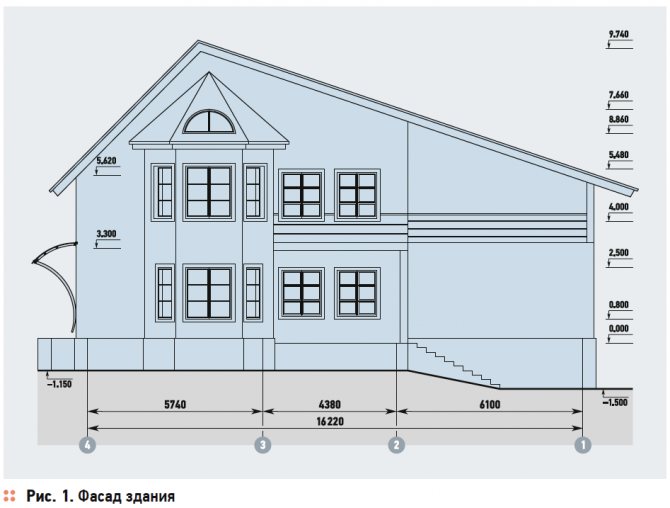

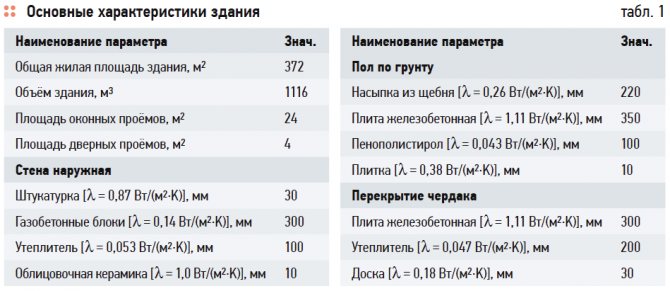

In this article, we will just use method # 2, and for this we will set the initial data. For example, take a house (Fig. 1), located in the Leningrad region, which has the design characteristics given in table. one.

To begin with, let's determine the heat loss [W] of our building at an outdoor temperature tн = –26 ° C. Calculation of heat losses through each enclosing structure is carried out according to the formula:

where k is the heat transfer coefficient of the enclosure, W / (m² · K); A - the area of the enclosing structure, m²; tв and tн - temperatures of indoor and outdoor air, respectively, ° C; n - coefficient of reduction of the calculated temperature difference; β is a coefficient that takes into account additional heat losses in excess of the main ones.

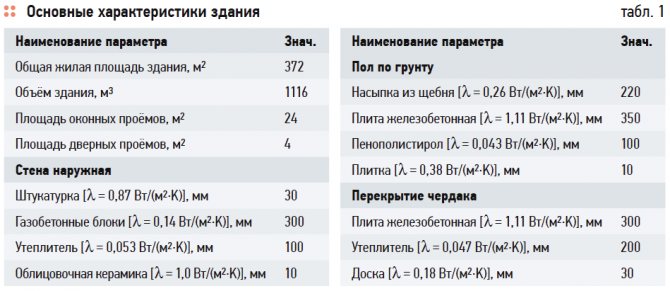

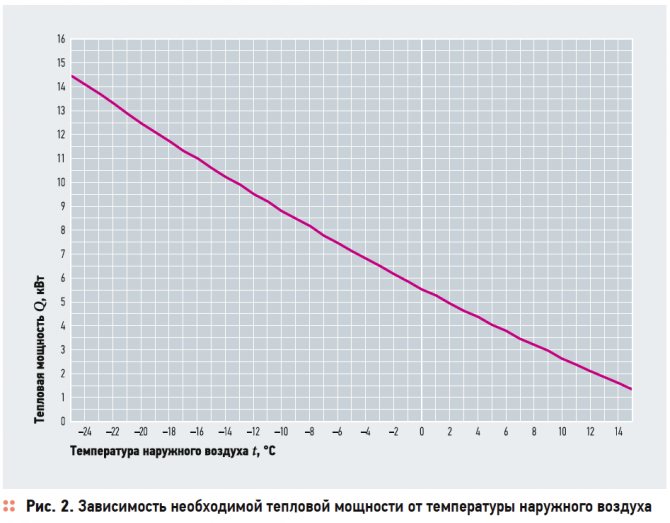

Thus, the value of the maximum value of the heat loss at the minimum outside temperature will be 14 891 W or 14.9 kW.

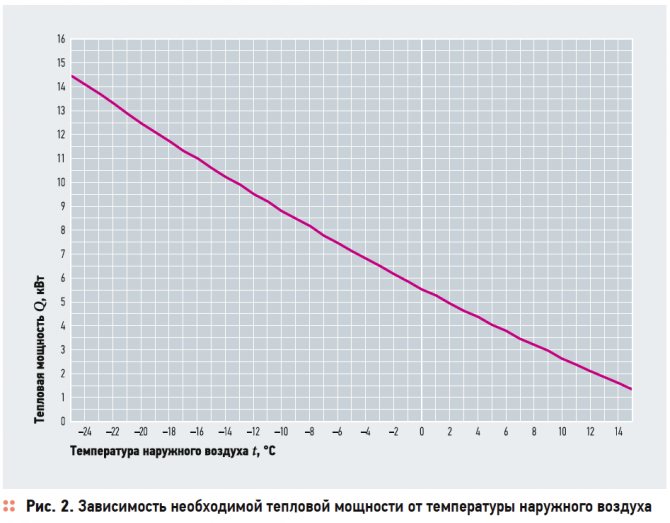

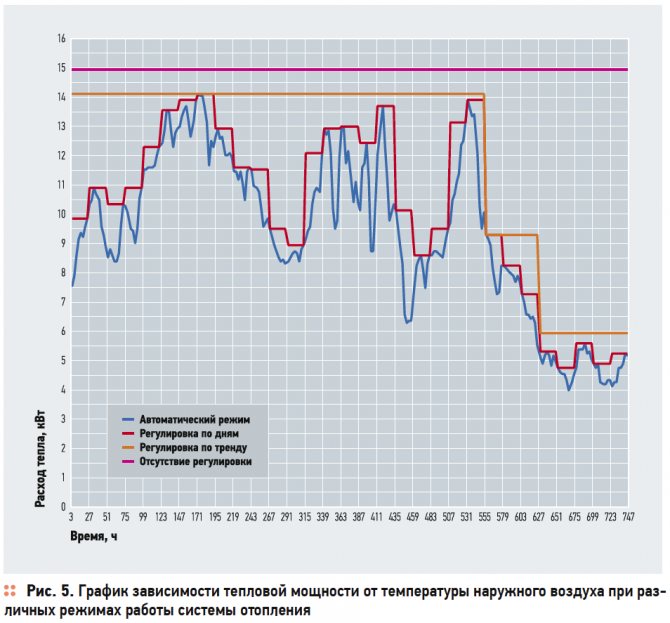

However, due to the change in the temperature of the outside air, the heat transfer process turns into dynamics. In order to estimate the required heat load for our building, depending on the outside air temperature, it is proposed to make a number of calculations, sequentially substituting variable values of the outside air temperature into the initial formula, as a result of which we can obtain the dependence shown in Fig. 2.

Please note that this graph has some bending, which indicates a non-linear relationship between temperature and power. This non-linear dependence will be different for each building due to its individual design features.

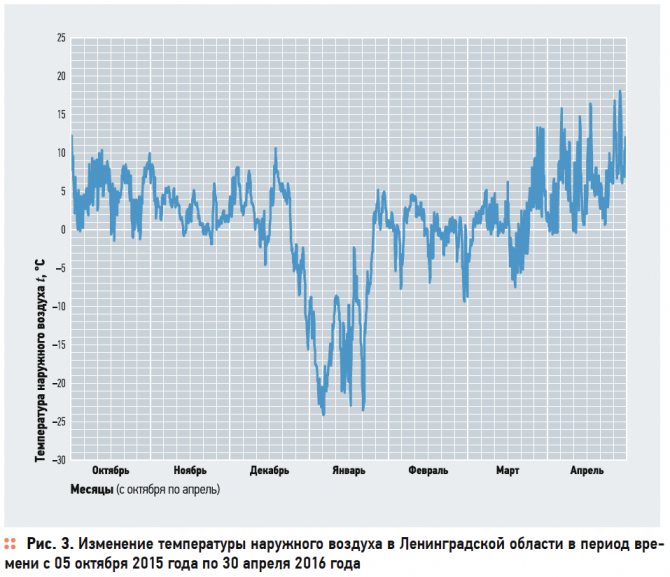

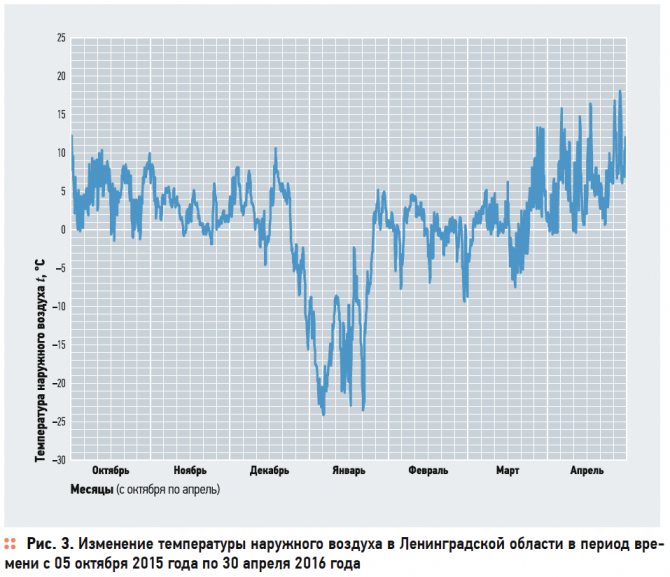

In addition to the characteristics presented above, we will need the values of the outside air temperatures during the entire heating period. To do this, we will use the data archive for the Leningrad Region in the period 2015–2016. Of course, there are norms, based on which every year at a certain time the heating season begins, however, if we are considering a private house, then it occurs, as a rule, at the first sharp cold snap. After analyzing the change in temperature over the course of the year, it was concluded that the heating period presumably started on October 5, 2020 and ended on April 30, 2020. Thus, the duration of the heating period was seven months, which is quite a normal indicator for this region.

In fig.3 shows a graph of air temperature changes during the entire heating period. Having secured the initial data, we proceed to calculating the effect of the use of weather-dependent automation.

The principle of operation of this type of regulation is as follows. The outdoor temperature sensor detects temperature changes and sends a signal to the controller.

The controller processes the information received and, according to a certain algorithm, calculates the required temperature of the coolant in the heating system. The signal from the controller goes to the mixing valve actuator, which, in turn, opening or closing, provides the required coolant temperature in the serviced circuit. Note that in this case, a high-quality adjustment occurs, in which the total flow rate of the coolant in the system remains constant, since the regulation consists in the degree of mixing the hot coolant with the cooled one. A decrease in the mixture of hot coolant leads to an increase in the temperature of the coolant returned to the heating (boiler) circuit. This will either cause the burner to shut down or reduce the fuel supply to the burner. This is how energy savings are formed, which I would like to evaluate.

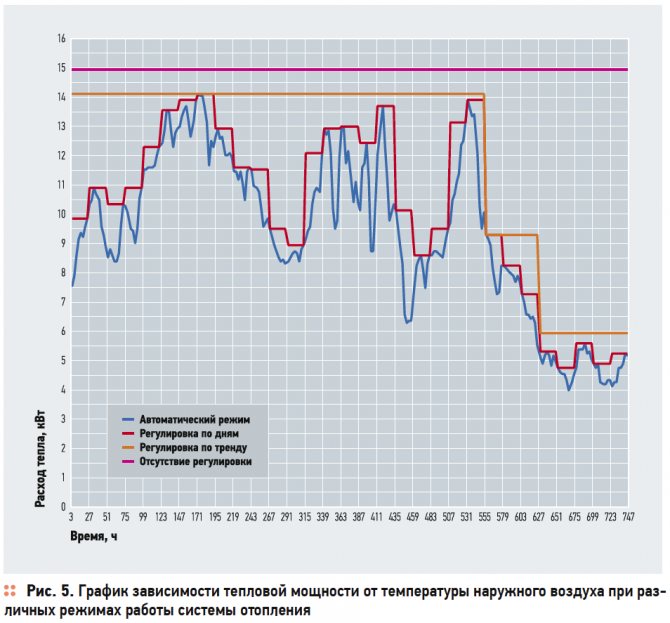

For direct calculation, let us set the following operating modes of the heating system:

1. First mode of operation - constant correction of the coolant temperature by the outside air sensor (automatic mode). To calculate the consumed heat energy, we will carry out the calculation, taking into account the changes in the outside air temperature every three hours.

This calculation will be made for every day during the entire heating period.

2. Second mode of operation - in this mode, we will take into account the changes in the outdoor temperature by day during the month. It is assumed that this is the same mode when the owner has the ability to manually or remotely adjust the temperature of the coolant every day. The logic of this regulation is as follows. When viewing a weather forecast or real feeling of coldness, a person sets the required temperature, however, the main criterion will not be saving resources, but the desire not to freeze. However, when the temperature rises by 2–4 ° C, the probability that the owner immediately goes to cover the regulator tends to zero. Thus, the calculation of this type of regulation will be based on the minimum outdoor temperature during the day. The calculation is carried out in the same way for all days of the heating period.

3. Third mode of operation - involves manual adjustment of the system at the time of a sharp change in the outside air temperature. For clarity, let us refer to the graph shown in Fig. 4. It can be seen from the figure that in the interval from the first to the 23rd, inclusive, the outdoor air temperature fluctuated in the range of –20… –10 ° C, with an average value of –15 ° C. Then the trend went up and we see an average value around +2.5 ° C.

It is obvious that it is at such a moment that any sane person will try to reduce the temperature of the coolant by the method that is available to him, for example, by adjusting the boiler power. So, when calculating the third operating mode of the heating system, we will be set by the minimum values of the outside air temperature within the trend.

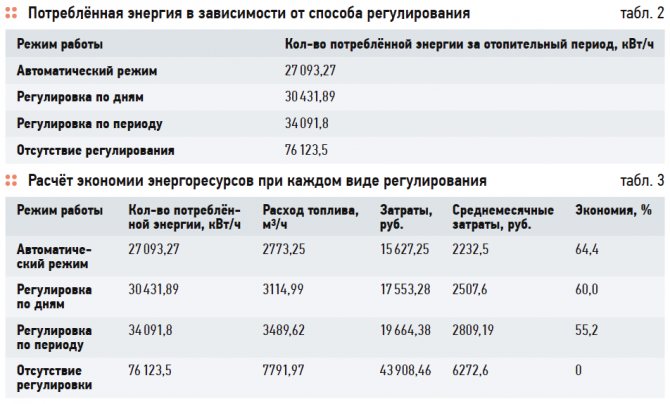

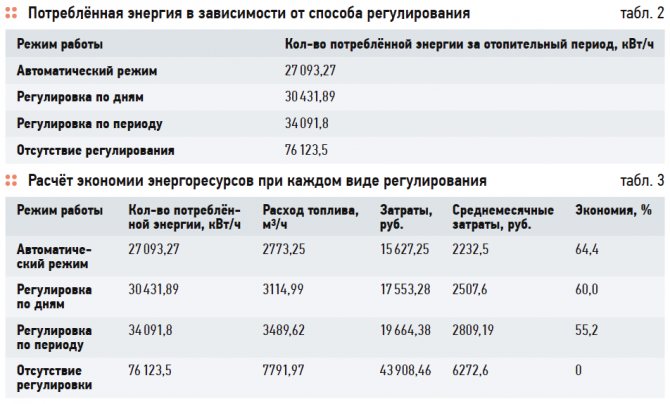

4. Fourth mode of operation - complete absence of any regulation of the temperature of the coolant. It is assumed that the heating system operates at full capacity during the entire heating period. The results of calculating the consumed thermal energy for the heating period for various types of regulation are summarized in table. 2 and the graph shown in Fig. 5. Further it is possible to calculate the fuel consumption:

where Q is the heat consumption for the heating period, kW / h; qн - the lowest heat of combustion of gas, kW / m³; η - boiler efficiency.

For the calculation we take the average value of the net calorific value for natural gas - 10.619 kW / m³ and the average value of the boiler efficiency equal to 0.92.

The calculation of financial costs is carried out by multiplying the resulting fuel consumption by the cost of 1000 m³ of natural gas, taken according to retail gas prices for the period 2015–2016. The cost of 1000 m³ of gas was 5636.09 rubles.

To determine the average monthly costs, it is necessary to divide the value obtained from us by the number of months in the heating period we are considering:

where Gg - fuel consumption during the heating period, m³ / h; B - the cost of 1000 m³ of natural gas; n is the number of months in the heating season. The results are summarized in table. 3. As can be seen from the above table, the operating mode, in which there is no regulation, is taken as 100%. The savings in fully automatic mode were 64.4%. It should be noted that the increase in the economic effect will be carried out through the use, for example, of the operating mode for the periods of presence / absence of residents, which are configured individually.

Having analyzed the above calculations and schedules, it should be noted that weather-dependent regulation is a completely justified measure that allows not only to increase the degree of comfort, but also to save a fairly significant percentage of money. Of course, this calculation was carried out taking into account a number of assumptions and assumptions, but all of them were taken within the framework of adequate values, which allows us to estimate the order of prices. In any case, weather-dependent automation is a full-fledged justified solution that moves in step with the times.

Boiler operation with underfloor heating

For comfort, a warm floor system is used in the house, where the heat carrier is water or liquid with a low freezing point. The circulation pump is regulated by weather-dependent automatic equipment.

The composition of the underfloor heating scheme:

- weather-compensated controller;

- outdoor temperature sensor installed in the shade;

- mixing unit servo drive;

- circulating water temperature sensor;

- underfloor heating pipeline;

- thermostat in a heated room.

The Russian-made TRTs-03 controller maintains the temperature along the heating control curve.

Warm floors are used with other types of room heating. There are four types of weather controllers designed to work together:

- Main - controls 8 types of hydraulic circuits, 6 of which include a boiler.

- Expansion for 2 hydraulic systems in addition to the main regulator.

- Independent mixing circuit control, can independently regulate one system.

- Heating control unit with buffer tank and timer.

Warm floors have significant inertia, so the room thermostat reacts more accurately to the weather.

Pump schemes

The second popular scheme for the operation of a circulation pump in a weather-dependent heating system is its use in the underfloor heating circuit. Installing underfloor heating makes it possible to raise the room temperature for a short time. The essence of this scheme is to use a circulation pump to pump hot coolant in the underfloor heating system during the period of lowering the outside temperature. The controller, by reading the readings from the temperature sensors, calculates how much the room will cool when the outside temperature drops. After processing the information and making the necessary calculations, commands are given to open the valves and switch the pump to the desired mode. The coolant fills the collector and enters the beams of the warm floor.

The advantages of this scheme are the rapid creation of a comfortable temperature in the room for staying in it, while, after warming up, the controller again blocks the supply of the coolant and switches to normal operation.

Weather-dependent automation for greenhouses

Growing agricultural products year-round in northern climates is a difficult task. To ensure the vegetation of plants, weather-dependent heating is used. The best option is a piped soil heating system that stimulates root development and reduces energy consumption.

The temperature in the greenhouse is different at night and during the day, and the soil should be warmer by 2-3 ° C. Aries TRM-32 automation or Aries PLC 100 controllers, combined into a system with a control center, will cope with such a task.

Characteristics of the control system Aries TRM-32:

- control of heating of the coolant based on the signal of four external sensors;

- connection to a computer via an adapter;

- control range from –50 to + 200 ° C;

- wire communication length - 1200 m;

- the temperature in the greenhouse is from +1 to + 50 ° C;

- push-button control, information display;

- programming the heating schedule at a given temperature value;

- switching from day to night operation.

Remote control of the microclimate in greenhouses is carried out by ventilating and changing the speed of the pumps.

DIY automatic regulation

Weather-dependent regulation is used to maintain comfort and economy. They install weather-dependent heating with their own hands in small private houses and dachas. Factory-assembled devices are suitable for stable operation of the system. Self-made devices will not work stably, they are unsafe.

A universal boiler Ochag, which runs on solid fuel, is suitable for a country house. In the control circuit there are three temperature sensors - the coolant in the boiler, waste gases and water in the boiler. Actuators - air flow damper and damper on the pipeline. Automatic control is organized using the Arduino Nano controller.

Heating controller device

Consumers and generators

It is very important to understand why automation is needed at all for heating a private house, and how it works. Automation can work with both consumers and heat generators. In this case, consumers include heating devices (radiators, "warm floors", etc.). To control heat transfer from consumers, separate control elements are used, which regulate heat. These controls can include pumps, taps or mixers. An important nuance: with a decrease in the number of consumers on the circuit, the control accuracy increases.

The heat generator in the system is usually a boiler. Automation for a heating boiler can work in both directions, increasing or decreasing the temperature, which allows precise control of the temperature of the coolant in the pipeline. If you set a program to the system once, then it will run all the time, without the need for constant monitoring.

How necessary is a weather-compensated heating system

Heat management automation is not always necessary. Regulation takes place with a deviation of 2 ° C from the norm in the room with the sensor, in other rooms the spread is greater. The cost of installing separately installed automation reaches 2 thousand euros.

If the equipment is supplied with a heating boiler, the use of weather-dependent automation is justified. In other cases, the costs will not cover the possible savings.

Thermostatic radiator heads are enough to regulate the heating.

Benefits of automatic heating control

Due to its high cost, weather-dependent regulation is more often used in apartment buildings and industrial buildings, where it is economically justified. Automation advantages:

- constant temperature;

- reduction in fuel consumption with temperature drops;

- automatic control of the environment by sensors;

- maintaining a low temperature;

- lack of a human factor.

Boilers of new models are equipped with automatic regulation.The functions of these systems are sufficient for comfort in the house without extra investment.

Types of control devices

To ensure control over the temperature regime of the heat generator or consumer, the same device equipped with a temperature sensor is used.

These devices are divided into three categories, which can work either singly or in conjunction:

- Thermostat

... This device is the simplest control device in the heating system. Located in a building, it monitors changes in air temperature. When the required temperature is reached, the thermostat sends a signal to the boiler or the radiator valve, as a result of which the heating of the coolant stops or the supply of liquid to the radiator is blocked. Self-installation of the thermostat is not particularly difficult: just look at the photo, which shows a diagram of its connection and operation, to make sure that this design is simple. - Heating agent temperature regulator

... Such a device can work independently or together with a thermostat. The design works by means of temperature sensors that are installed inside the heating circuit. They constantly monitor changes in temperature in the system and transmit this data to the control module, which controls the mixing valve of the circuit. If an increase in temperature is required, the regulator can perform this task using a valve. - Weather-dependent automation of heating systems

... This type of device can be classified as the most complex, since such a system has to work not only with the heating circuit, but also with the environment, due to which the most accurate and rational temperature control is provided.

The basic design of the weather-dependent automation includes an outdoor thermometer, a thermal circuit regulator and a thermostat located in the room. Despite the high cost, such a system is considered the most in demand, since it is able to provide the maximum comfort that can only be squeezed out of heating. Weather-dependent automation of heating systems uses sophisticated software systems, which allow you to ensure maximum efficiency and economy.

For calculations, these systems use the outside temperature, on the basis of which the weather-dependent controller of the heating system makes a decision to increase or decrease the temperature of the heating medium. Profitability is ensured through competent and balanced use of fuel.

Weather-dependent automation can be controlled both from its own remote control and remotely by installing the necessary software on a smartphone or tablet (in more detail: "How to choose a remote heating control - characteristics, capabilities"). In this case, you can regulate the temperature in the house from a distance from it.

Conclusion

Automation for heating boilers is expensive, but immediately after installation, these devices will begin to save fuel, which will affect the economic situation after a while. In addition, it is the automatic temperature control system that ensures maximum comfort in the house.