So, the decision to build a house has been made, and then it is necessary to determine the most important thing: from what the future house will be built, its structure, size, what finishing materials to use, and most importantly; how to make it warm, or rather, how to insulate the house in order to avoid the high costs of heating it?

Of course, all other issues during the construction phase and during the construction process are important and deserve very careful attention. But we're talking about insulation. The search for the best options that will suit you in terms of quality, and even more so for the price, will take a lot of time, but we can help you with the choice of insulation. You don't have to read this article at all, but just call: 8(911) 9999812, and our insulation installer will answer your questions regarding the insulation of your home. And after spending a couple of minutes reading, you can make a decision yourself.

Minvata

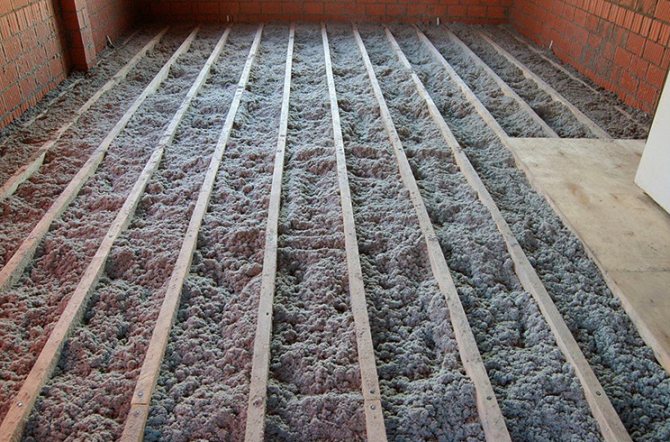

Mineral wool is one of the most common types of insulation for insulating various elements of a building, that is, the insulation is laid in the roof, interfloor and interior ceilings, floor, walls both inside and outside the room. Tiled or rolled mineral wool allows you to quickly insulate a house, a bathhouse, various utility and non-residential premises.

Such popularity of mineral wool is easily explained by a wide selection of varieties, brands, and availability in retail chains. Also, low cost, ease of installation, high heat and sound insulation characteristics. But there is another side - a negative one, which sometimes outweighs all the positive qualities of many varieties and brands of mineral wool. The use of formaldehyde resins as a binding component to form an insulating layer significantly reduces its environmental friendliness, but a decrease in the component reduces the moisture resistance of the finished insulating material. Only a few species based on basalt fiber do not contain harmful toxins. In its pure form, mineral wool is difficult to give the required density, there is a risk of dust from mineral fibers entering the air of the room to be insulated, therefore it is produced mainly in rolls or mats with already formed density and rigidity.

Disadvantages of tile and roll insulation

Yes, rolled and tile mineral wool is convenient for installation - they rolled out a roll or marked a plate, cut off the desired piece of a given size and insulated the available cavity. But the ease of installation is not the parameter that should be guided when choosing a heater. When cutting a roll of insulation, waste is inevitable, consumers overpay in advance for the surplus that still has to be disposed of.

Mineral wool is intended for insulating buildings made of various materials with different number of storeys and of various types, but when auditing its installation with a thermal imager or when opening it, dispersed joints and a loose fit are often found, and these, as a rule, are drafts and cold islands - the main reasons for the dampness of the insulation and , accordingly, loss of thermal insulation qualities. For this reason, mineral wool loses about 40% of its heat-saving properties already in the first years. And not always the reason for this is poor-quality installation. Subsidence of mats causes moistening, destruction of fragile stone fibers by ice crystals. And when the process is running: moistening - destruction - subsidence - the situation is getting worse every season. In such a house, keeping warm will be very, very costly, and do not forget that mice and rats in the mineral wool settle comfortably.

But there is an alternative that belatedly appeared on the Russian construction market in the 90s after it conquered low-rise construction in neighboring Europe and many more distant countries.

Composition and properties of insulation

In the manufacture of ecowool, the following components are usually used:

amount (%)

up to 80

Recycled paper (newspapers). Glossy and coated paper does not meet the specified characteristics, therefore they are not used.

12

Antiseptic. Prevents the penetration and development of pathogenic bacteria and fungi (mold)

8

Antipyrine. Reduces the level of fire hazard, makes the insulation unattractive for rodents and other pests

This composition determines the low price of thermal insulation and its environmental safety. In fact, there is no toxic component here, however, relatively good technical characteristics remain.

Now let's talk about properties. The performance characteristics of ecowool look like this:

Flammability class - G2... Under the influence of high temperatures, crystallized liquid is released from the fibers of the material, respectively, the insulation is poorly flammable and does not support combustion processes.

Biostability - high... The composition contains boric acid and drill, which neutralize almost any external factors and aggressive environment, make the material unsuitable for eating by rodents and other pests.

Thermal conductivity values: 0.032-0.041... The material reliably protects the interior from drafts and cold winds, reduces heat loss, and helps to save on heating in the winter season.

Density - up to 75 kg / m3. This ensures reliable sound insulation of the building, forms a reliable moisture insulating layer.

In addition, ecowool is not produced in sheets or rolls, therefore, during installation, monolithic thermal insulation is formed, completely eliminating cold bridges, seams and joints.

Ecowool

It's time to think about what influence we, willingly or unwillingly, have on the world around us and on ourselves and on our loved ones. Therefore, construction companies in Europe and the West are concerned not only with how to build a house at the lowest cost, but also strive to use environmentally friendly materials in construction. The demand from consumers of construction services for safe materials has also grown. Many are willing to overpay, but live in a clean environment at home and not pollute the surrounding space. This is the choice of modern man. There is no need to overpay for ecowool, as well as to doubt its environmental friendliness. Definitely a budget option available to many, but guaranteeing safety, energy conservation and care for natural resources.

What is ecowool

Remembering that suburban construction in Russia began to actively develop from the earliest times, then in St. Petersburg and the Leningrad region ecowool appeared relatively recently. Acquaintance with Ecowool in the low-rise suburban construction of St. Petersburg began in unfavorable conditions for her: it was not clear with the supply of cellulose insulation, not to mention equipment for installing ecowool, although in Europe it was used even in the pre-war period. But even in our time we still have to hear from construction crews, behind whose shoulders there is more than one erected country house: EKOVATA - and what is it?

Ecowool is an environmentally friendly material that consists entirely of natural ingredients:

- borax - 7%;

- boric acid - 12%;

- recycled cellulose - 81%.

The loose consistency of ecowool allows for seamless installation, after which there will be no drafts, mice and insects in the house. There is no problem with leftovers - there is no waste during installation, every gram of ecowool will reliably protect your home.

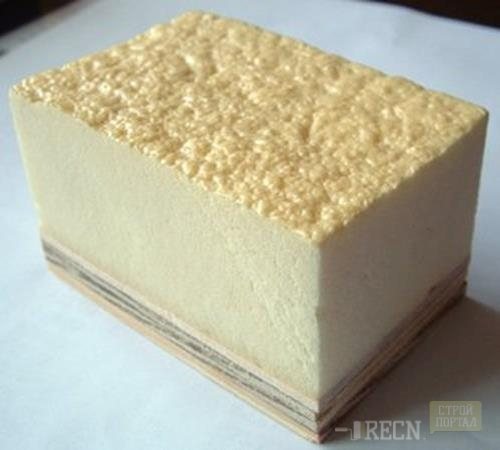

Polyurethane foam, characteristics

Elastic polyurethane foam is a general name for a group of materials that consist of inert carbonate gases and air (in this case, the proportion of the binder is from 5 to 15%, the rest is air space).

The commonly used name "foam rubber" appeared due to the fact that in the Soviet Union this product was represented by the products of the Norwegian company Porolon, which later merged with colleagues from Lithuania.

The following categories are used to determine the physical properties of a material:

- average density (kg / cubic meter) - 30-150,

- thermal conductivity coefficient (W / m * K) - 0.019-0.028,

- porosity - closed,

- service life - 20-30 years,

- working temperature (° С) - from -160 to +150.

The density index characterizes the foam rubber as a rather soft material that is easily deformable and does not lose its integral structure. It should be noted that the structure is more adapted to bending than to pressure. When squeezed, the polyurethane foam does not work correctly and quickly deteriorates. As a percentage, the allowable size reduction is 10%.

Thermal conductivity is the main trump card of foam rubber. The material has the smallest coefficient. This means that it warms up or freezes by only 2 mm, therefore, a layer of 5 mm will be enough for high-quality thermal insulation, and a layer of 10 mm will provide protection from the cold even in the most severe climatic conditions.

Closed porosity means that the polyurethane foam is a solid material, the pores of which are concentrated inside.

Carbon, which is the basis of foam rubber, is one of those elements that practically do not decay and only become stronger over time. In the case of polyurethane foam, this leads to crystallization of the structure and loss of heat-saving properties. Nevertheless, even for inexpensive manufacturers, the service life exceeds 20 years, if you buy modern products, then they are in operation for 50 years. Such a significant increase in service life is achieved due to a more thorough cleaning of various gas impurities. Such polyurethane foam, the price of which is not significantly higher, by the way, is produced in Japan.

The limiting operating temperatures, as well as the thermal conductivity, are the highest of all thermal insulation. This is largely due to the fact that the foam rubber heats up poorly and cools down, however, due to the presence of air in the composition, it burns very well and quickly. This is perhaps the only drawback of the material. Special inert gases-catalysts are introduced into the composition of modern foam rubber, which cause a carbonization reaction of carbon, therefore, ignition spreads to the material only under the action of an open flame. It is better to test this property by experience before buying.

Biological and chemical resistance should also be noted. In the first case, polyurethane foam is quite reliable, since it is not subject to decay, mold and the appearance of fungi, in addition, some components are harmful to rodents, so their appearance is excluded. The same is true for the roots of trees and grasses. For humans, foam rubber is no less dangerous, in small doses it causes "volvulus", in large doses - a lethal outcome. Therefore, small children should not be allowed to access the material.

Despite the fact that polyurethane foam is chemically neutral, acids and alkalis have a destructive effect on it, therefore it is not used at production facilities. Ingress of detergents has no consequences.

It is not customary to talk about sound insulation in terms of foam rubber, since the material suppresses (removes noise, high frequencies, makes it more deaf), but does not drown out the sound. This property is successfully used for the production of headphones, pop filters and other sound equipment.

Rid the house of rodents and insects

To permanently protect your house from the invasion of rats and mice, as well as insects, you do not need to use toxic chemicals - just insulate the house with ecowool, and these uninvited guests will lose interest in your home.

The fact is that both insects and rodents cannot live near ecowool in any way - they cannot tolerate the borates that are in its composition. Boric acid and its salts are not volatile, resist fire, and are safe for humans. Therefore, the use of cellulose insulation allows you to solve a number of important problems:

- increasing thermal insulation;

- increasing sound insulation;

- protecting the house from rats and insects;

- protection against drafts;

- natural regulation of humidity at home;

- lack of mold and mildew.

Frequently asked questions (FAQ) on ecowool:

How long does it take to insulate the house?

We insulate a house of 100-200 squares in two days. That is, we will arrive on Saturday morning, and on Monday morning your house will already be insulated. If you insulate a house of this size with your own hands and without professional equipment, then it may take one to two weeks. I hope now the question of how long the house is insulated with ecowool is closed for you.

How much does it cost to insulate a house with ecowool

I already wrote, but I will say it again. 2000 rubles per cubic meter (! Cubo, not square) of dry insulation and 3500 rubles per cubic meter of wet insulation (it is more technologically advanced and more complicated).

Is there a calculator of some kind?

Manual only! Here I have given you a calculation method, everyone can calculate himself easily and quickly the amount of ecowool he needs!

What is the wet insulation method?

The wet method (or rather the wet-glue method) of warming consists in using a special machine in which ecowool, water and glue are mixed, and then it feeds it with a jet under pressure to the right place. In my opinion, cotton wool can only be fed into the walls with a wet method, since if you use a dry one, then the ecowool will definitely sit down over time.

Does ecowool shrink?

Does not give! But there is one but. Ecowool does not shrink with proper installation: with wet insulation of vertical coatings (the horizon can also be made dry), as well as with the direct hands of the installer (therefore, call people with experience, for example, us).

What should be the density of ecowool for blowing?

If we are talking about overlapping, then the density should be about 35 kg per cubic meter, if about wall insulation, then the density of ecowool should be 65-75 kg per cubic meter.

Is it possible to insulate the house with ecowool in winter?

If the perimeter of the house is closed, then in winter until -15, you can insulate.

How much water should ecowool contain? (humidity)

Water takes 30 liters per cube of cotton wool.

Perfect wall and floor cake for ecowool

Ideal cake: ventilated facade-MDVP-ecowool-kraft paper, steam-limiting (or PE) -lattice-plasterboard.

How to plaster the outside on ecowool?

Plastering will not work. But you can plaster on MDVP

What is the durability of ecowool?

For the entire time of using ecowool (and it has been used abroad for a long time already) it was not noticed that at least something happened to ecowool. So you don't have to worry about its durability as a heater.

How much does a 15 kg bag of ecowool cost?

A bag of ecowool comes out at current prices of about 450-500 rubles. You can buy ecowool at special factories. But many factories make very low-quality raw materials, so you still need to know where you can buy and where not.

What is the sufficient thickness of the ecowool layer in mm for a permanent residence house?

For a permanent residence house, a sufficient thickness of ecowool is sufficient: 200-250 mm in the floor, 200 in the walls, 250-300 in the attic or attic. Carriers are becoming more expensive, so it's better not to save on insulation.

For a summer residence, a sufficient thickness of ecowool is sufficient: 150 mm in the floor, 100 mm in the walls, 150 mm in the attic.

Do you need a ventilation gap (ventilation gap) in the wall with ecowool?

The vent gap in the ecowool pie is optional, but it depends (as with other heaters) on the complete wall pie and especially on the facade materials. If the siding is outside, then the ventilation gap is not needed.If the exterior finish of the facade is wooden, then there is no way to do without a ventilation gap. That is, there are no special rules with regards to ecowool, unlike the same mineral wool or glass wool, all "pies" are classic.

Is it possible to insulate foam blocks from the outside with a wet method?

Oh sure. Usually foam blocks (aerated concrete and gas silicate blocks also) are insulated with ecowool from the outside with a crate of about 100 mm thick. After that, a siding facade is already made (most conveniently).

How much does it cost to insulate a 200m2 house with ecowool?

Depends on the area of the walls and floor, here I have given the calculation for a house of 100m2. But if you find it difficult, please contact us in the comments, by mail or by phone - we will count for you.

Do you need an ecowool waterproof film outside?

Yes, of course, as with any other insulation, a moisture and windproof film is needed on the facade after ecowool. The fact is that it protects a wooden or other facade and insulation not only from moisture, but also from blowing, and this is no less important.

Do you need a vapor barrier film with an ecowool inside?

Opinions differ here. Many people insist that PE is not needed inside, but I am still in favor of putting it. The classic frame house pies all contain a vapor barrier, and I am against the idea of bicycles.

Is it possible to insulate the bath.

Yes. It is not so afraid of moisture as basalt and mineral insulation and easily removes it both outside and inside. The only thing is that you need to very efficiently mount the vapor barrier in this case.

Does ecowool burn?

According to the certificate, ecowool belongs to the group G2 (moderately flammable), as well as B2 (moderately flammable) and D2 (with moderate smoke-generating ability) and T2 (moderately toxic). In practice, ecowool does not burn at all, there are many experiments on the Internet with attempts to set it on fire, all unsuccessful. She only burns a little and nothing further. Ecowool does not burn due to a special additive: borax five or ten water. When igniting ecowool, water is released from the borax, thereby contributing to a decrease in temperature in the hearth and attenuation. After that, a ceramic layer is formed on the surface of the ecowool, which does not allow the fire to spread deeper. In addition, ecowool is poorly blown by the wind, which also gives more chances when fighting fire.

And here are the photos from the real object. Found, as promised at the beginning of the post. Bottom line - ecowool does not burn:

Plywood and ecowool

How is plywood and ecowool combined? With her, the situation is the same as with OSB-3 (I described above how to get out of this situation)

How much ecowool should be in mm?

Slab, floor: 200mm or 250mm Walls: 150mm or 200mm Attic: 200mm or 250mm Attic: 250mm or 300mm

Is ecowool poisonous?

During the use of ecowool, no consequences for human health have been identified. The fact is that both an antiseptic (boric acid) and a fire retardant (borax) are natural sparingly soluble minerals that cannot release anything into the air during operation. Even allergy sufferers can live in a house insulated with ecowool.

The fastest insulation method. Which one?

The fastest insulation method is the wet-hot method. If you need to insulate the house very quickly, then hire specialists and everything will be very fast.

Is it possible to use drywall with ecowool?

Drywall with ecowool can be used. The only thing, I would first give a month of ecowool to release excess moisture into the environment, and then I would sew it up with gypsum plasterboard (drywall). You can also successfully sew up walls insulated with damp ecowool material GSP and DSP.

And what about ecowool with mice and insects? Do mice start in ecowool?

Mice do not eat ecowool, it is inedible for them. True, there are rumors that they can still make moves in ecowool, if they are put into it. But this can be said about any known insulation: basalt wool, glass wool or foam.

The main thing in the fight against mice: do not let them inside, and for this, steel nets are used at the points of access to the wall (in the ventilation gap), as well as closing the access to the ceiling from below. It is also desirable to have a cat, this removes all possible problems.

Films and ecowool

If your house does not have a rigid slab sheathing, but the film is simply stretched outside, then it will be unrealistic to insulate it from the inside with ecowool. Ecowool should stick to something and this something should be hard: board, MDF, etc. If you want to make a vapor barrier film between the main insulation layer and the additional cross layer, then you also cannot make the cross layer ecowool. It is better to take the vapor barrier inside the house, up to both layers of insulation. Moreover, you can also hide pipes and communication wires under the film.

Can Kraft Paper Be Used In Ecowool Pies?

Indeed, it is very often used with eco-friendly craft paper. It is used by adherents of the "partial vapor barrier" method. That is, kraft paper holds some part of the steam, and passes the rest into ecowool. And the ecowool is already releasing it further out. Plus, kraft paper retains dust from ecowool (if suddenly it wants to dust it).

The main thing is not to use kraft paper on the outside of the OSB pie. Then the steam will not be able to leave the ecowool and will remain in it. So the option of using kraft paper in a pie without OSB is possible.

Is ecowool dangerous for health?

In fact, in the modern construction market, almost all goods are somehow dangerous. Therefore, the normal thing is not to trust, but to check and investigate. As far as I could understand from my research - ecowool is not hazardous to health.

Boric acid does not get into the air (especially if we put a vapor barrier on the walls, but I still recommend it), plus the pores of the ecowool are large and there are no small particles that can get into the lungs of a person (unlike basalt heaters). So the answer to the question: “is it dangerous to inhale ecowool?" - No. Still, it is better to work with it in a mask, as with any other material, such as putty and other similar materials. It is better not to inhale anything unnecessary, even harmless.

A good video about ecowool, where this issue is revealed:

And this video is about how ecowool looks like in 10 years (nothing settled). So the answer to the question: does ecowool settle - no.

Maintaining humidity in the house

This property of ecowool is well known - the natural regulation of humidity in the house. The process is ensured due to the properties of the insulation: it accumulates moisture when there is an excess in the air and gives back moisture when it is lacking, for example, during the heating season. By the way, ecowool absorbs moisture into itself, that is, moisture is absorbed into the fibers themselves, leaving the air between the cellulose fibers minimally moist, unlike mineral wool, (if we return to the question: which is better - ecowool or mineral wool), and humid air is a conductor cold.

Comparison of heaters in terms of technical characteristics and properties. Differences between them

Air permeability

This property is of great importance, determining the effectiveness of the insulation during strong gusts of wind. The lower this indicator, the better the heat is retained in the room. For ecowool, this indicator is 75×m3 / m × s × Pa, for mineral wool - 120×m3 / m × s × Pa.

Flammability

Mineral wool belongs to the NG flammability group, that is, the material is not flammable (non-combustible). Ecowool belongs to the G2 flammability group, being moderately flammable. Therefore, it is not recommended to use it close to a fire source, as the material begins to smolder. Additional protection is required with ecowool made of asbestos-cement slabs or basalt fiber mats, which are sufficiently fire resistant.

Water absorption

Both materials tend to absorb moisture. But this has a completely different effect on their properties, as well as suitability. In the case of mineral wool, a set of 1% moisture leads to an increase in thermal conductivity by 8%which makes the material unusable. When moisture is absorbed, the thermal insulation properties of ecowool decrease slightly, but when it reaches 20% humidity, mold formation processes begin to occur in it.

Environmental friendliness

In this sense, ecowool has a great advantage, as it is an absolutely environmentally friendly material, unlike mineral wool.

Linear shrinkage

Mineral wool is characterized by the formation of interplate voids. For ecowool, there is a risk of shrinkage deformation on the vertical surfaces of structures, but only if low density ecowool is used (65kg / m3).

Life time

Ecowool is more durable with a lifetime from 65 to 100 years old... Minvata is inferior in durability, its average service life is 50 years.

Ease of installation

When installing mineral wool, personal protective equipment is required. It is also difficult to carry out installation in structures of complex shapes. When using ecowool, the application surface does not matter, but for the correct installation, highly qualified specialists are required, the presence of additional special equipment.

Disadvantages of ecowool - myths and reality

But ecowool is also not ideal, there is also a drop of ointment, a page of our site is dedicated to it. But we will try to dispel some misconceptions about toxicity here.

The first argument of opponents of ecowool from among competitors: “Boric acid belongs to the III class. danger "and cite GOST 18704-78 as a weighty argument. However, having opened GOST, one can easily understand that this is a technical specification for the production of boric acid and there is a direct link to the classification of chemicals - GOST 12.1.007-76, where it is explained in detail that the third class is moderately hazardous among chemicals. Along with boric acid, the list includes nickel, aluminum, manganese, iron, silver, etc. We hope that after these discoveries you will not want to throw away the family silver? And the dose of boric acid, taken internally 15-20 g (tablespoon) for adults and 4-5 g for children, is considered toxic.

The second argument is “ecowool is“ dusty ”during dry installation. But how many construction and finishing operations can be considered "clean"? There is no point in arguing here - a normal working moment.

The third argument against ecowool is essentially a cut newspaper, and ink is harmful. " The days when heavy metals were part of paints are long gone - expensive and not cost-effective. Today printers use pigment and mineral oils.

Another argument is that "small producers do not provide adequate quality." This is the fault of the manufacturers of many materials, and we always call for a careful choice, verification of certificates of conformity. We ourselves work only with reliable partners. And we boldly talk about the shortcomings of ecowool.

Ekovata or penoizol

Ecowool is not the only seamless insulation, but only it has a natural organic basis. None of the heaters that can be poured, sprayed and even glued into the cavity of structures: walls, pitched roofs, floors and various ceilings has such a unique opportunity - to be identical in nature to a tree and become one with wooden structures. Let's consider an example of a choice: "ecowool or penoizol"?

The main raw material in the production of penoizol is urea-formaldehyde resin - hazard class 2 - a product of polycondensation of urea with formaldehyde. When pouring, Penoizol releases these formaldehydes - substances hazardous to human health. The polymerization process is not always irreversible. When heated, reverse processes are inevitable - the poisonous smoke of modern fires is caused precisely by the toxins of burning polymers. But the choice: "ecowool or penoizol?" You will have to do it yourself, although our clients prefer not to risk it when there is natural natural material and reliable installers from the Teploservice Company.

Scopes of heaters

Mineral wool is effective for use:

- For insulation for pitched and flat roofs, or as an upper or lower layer of thermal insulation for a roofing cake.

- For external insulation with plastering.

- For insulation of industrial water pipelines, pipelines, heating networks, various equipment and tanks.

- As an insulating material in sandwich panels and three-layer reinforced concrete structures.

Ecowool is used even in the most inaccessible places and is suitable for any type of structure and premises, namely:

- Walls and partitions.

- Cherdakov.

- Floors and slabs.

- Attic.

Which insulation is better, who to entrust the insulation

When choosing between price and quality, it is not always worth focusing on cost, but as usual there are exceptions: an unrealized newspaper simply cannot be expensive, and competition does its job.

Therefore, let the builders build, and it is better to trust the insulation to independent teams. And let the electrician - pull the wires, the roofer - cover the roof, the plumber - supply the water, and the eco-sensor, which uses insulation that is safe for human health, insulates the house. "What is better ecowool or mineral wool" or "ecowool or penoizol" is still up to the one who makes the choice between these materials.