When thinking about building a new house or insulating an old house, any homeowner thinks first of all about the convenience and safety of his family.

The main question facing him is the safety of building materials for the health of residents. The first to be discussed are heat insulators, in particular, mineral-based insulation - is basalt wool really bad for health? To understand this issue, we will consider the manufacturing technology, the composition of the material, the subtleties of the installation process and the behavior of thermal insulation during operation.

Basalt - You Can't Think of it More Naturally

For the production of mineral wool, the rock is melted and crushed. This material is also called stone wool, as it is actually made from stone. Basalt-igneous rock is most often used, which is environmentally friendly and even used in medicine. Thus, the basis of the insulation is harmless to humans.

Then, resin is used to bond the resulting fibers together. The composition of the latter depends on whether mineral wool is harmful to the body. The manufacturer decides what type of this substance to use.

Some resins do not contain harmful components, and then the material is practically harmless. But sometimes phenol and formaldehyde are added to the composition - components harmful to health.

What materials is the insulation made of?

Today, the production of stone wool has reached colossal proportions. Many enterprises are engaged in its production, selling their products in various price categories. Depending on the manufacturing technology, products from different companies may differ significantly. It depends on the amount and composition of the joint resins that are used as the binder.

Today, stone wool is sold in the form of rolls and hard mats, the price range of which ranges from 500 to 2000 rubles. Moreover, the maximum cost of the material can be much higher.

Basalt wool is made from rocks. Due to its stone base, the fibers of the material are non-flammable, but the resin used to connect them can be easily flammable. In addition, the presence of formaldehydes and phenols in it can have a negative effect on human health, since the resin is gradually destroyed due to drafts and temperature fluctuations. In addition, external factors gradually destroy the fibers of the cotton itself, which become fine scree and dust, which subsequently settles on the lungs and other respiratory organs.

Harm to health of mineral wool microparticles

It is believed that the maximum harm to the body is caused by inhaling the fibers of the mineral insulation. It's true: getting micro-particles of basalt and resin in your lungs will not do anything good. When cutting the mineral insulation during construction work, fine dust is released, so you should work in a gauze bandage.

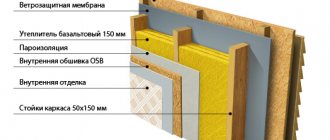

But when the insulation is already in place, it does not generate dust by itself. In addition, in most cases, the material is covered with a film to increase its thermal insulation properties and waterproofing. Thus, the safety of the mineral wool is ensured.

There is a mineral insulation of the latest generation, which does not prick and creates almost no dust.The reason lies in the elasticity of the acrylic contained in its composition: the fibers bound by this material do not break off and do not scatter in the form of microparticles. This is not the only advantage of the material, it has improved sound insulation characteristics also thanks to acrylic, which absorbs sound waves more efficiently. Thus, it is possible to completely avoid the appearance of dust when using mineral insulation.

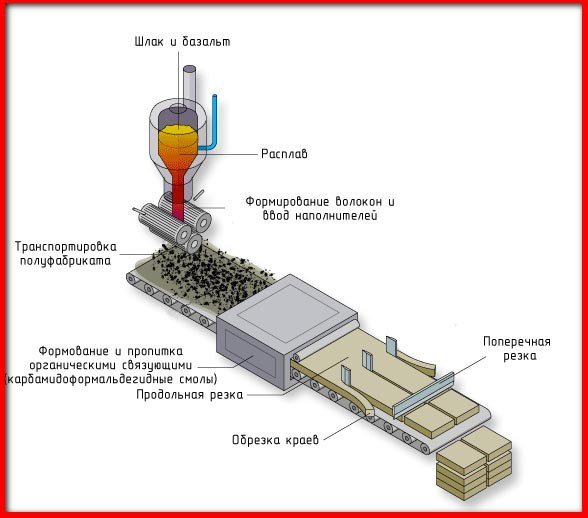

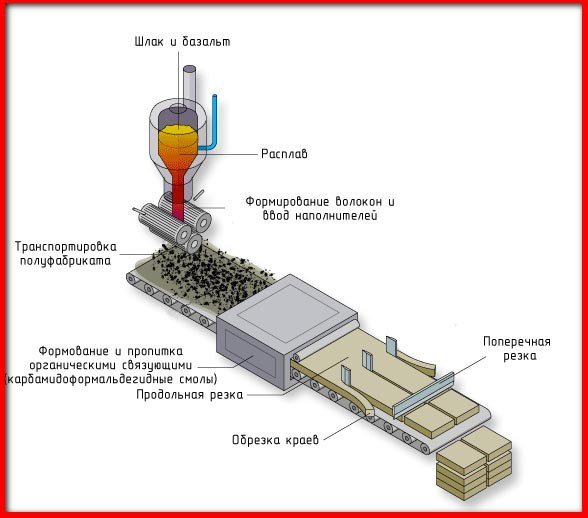

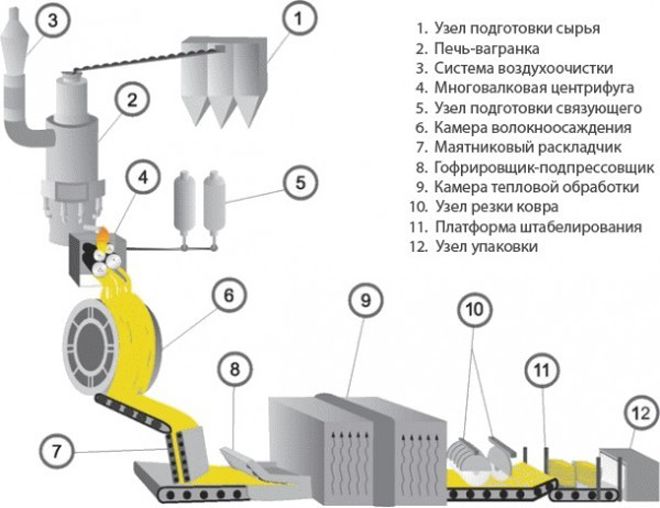

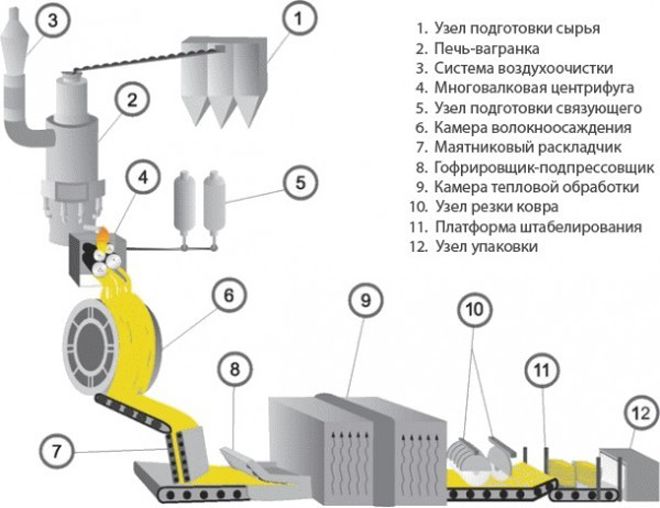

Manufacturing process

Basalt and gabbro rocks formed during volcanic activity serve as raw materials for mineral insulation. The material production technology consists in melting crushed stone with simultaneous blowing with a gas stream at a high temperature. As a result, the finest and most resilient threads are formed, which, using phenol-free glue, are converted into basalt fiber for the production of slabs or mats.

Since during the production process the finest threads can break and get into the respiratory tract and mucous membranes, the personnel work in protective suits, gloves, goggles and a respirator.

Formaldehyde resins

Many people want to know if mineral wool, which contains formaldehyde resins, is harmful. The amount of resin in any basalt insulation is 2-3%. This substance contains a very small amount of formaldehyde. Thus, the mineral insulation contains the minimum amount of substances that affect health.

If it is necessary to completely eliminate the harm of mineral wool, pay attention to manufacturers who do not use harmful substances in production.

When installing the insulation, cover it with foil and carefully seal the seams to avoid dust. Such mineral wool is not harmful to health.

Ingestion of basalt insulation fibers human lungs

Most users believe that the greatest threat of basalt wool slabs is when particles of their fibers penetrate into the lungs. It is quite possible to agree with this only on condition that construction workers use basalt-based insulators of low quality. Wherein such insulation is not capable of causing serious harm to healthif its fibers are located outside the boundaries of the house.

A great danger is the inhalation of air from particles of this material, which is why fragments of basalt fiber in significant quantities will gradually begin to accumulate in the lungs of a person. Sometimes this can cause the appearance of cysts, against which the development of harmful microorganisms can actively occur.

The danger of cysts is due to the possible appearance of trematodes in them, because of which there is a danger of their malignancy, which is a favorable factor for the development of malignant neoplasms.

There are many cases when people with solid tumors in their lungs found in their bodies were for a long time in rooms where the air was saturated with particles of asbestos or basalt slabs.

Is it harmful during installation

The harm of mineral wool during installation work is often mentioned. Handling this material with bare hands can cause tiny, sharp fibers to dig into the skin and cause irritation. Therefore, you should only work with it with gloves.

However, if stone wool gets on hands without gloves, there will be nothing terrible. You just need to thoroughly wash your palms with cool water (so as not to expand the pores), and then collect all the fibers from the skin by hand. Experienced installers use masking tape to remove these particles, applying it with the adhesive side to those areas of the skin that have come into contact with the mineral wool.

When working with basalt insulation, it is recommended to use a gauze bandage or at least a scarf to cover the respiratory system. This is especially true when you have to cut mineral wool. When installing a film for thermal insulation, there is no harm, so the gauze bandage can be removed.

Mineral insulation with acrylic is not harmful. In addition, it has increased elasticity. When installed inside structures, a “spring effect” occurs and the insulation fills the entire allotted space, leaving no cracks or gaps. Additional protection against dust scattering is not required.

Safety precautions - basic recommendations for work and material selection

In order to prevent damage to the insulation based on stone wool health during the installation process, elementary precautions should be observed. It is extremely important to protect mucous membranes and skin from contact with material particles with special clothing with long sleeves, a respirator, goggles and gloves.

If contact could not be avoided, in order to avoid even greater harm, the affected areas are urgently washed with running water. The problem is that if the fiber particles can be washed off the skin, although not so easily, then the elements trapped in the lungs will settle on their surface. That is why it is so important not to neglect the rule of using a respirator.

An equally important point is the choice of mineral (basalt) wool insulation. To insure against the consequences of using low-quality products with harmful impurities, you need to choose products from trusted suppliers who are ready to provide quality certificates.

The manufacturers Rockwool, Knauf, Leinrok and Teplit and some others are considered worthy of respect. Products manufactured under these brands have an impeccable reputation and will not cause serious harm to human health if the rules of installation and operation are observed.

Ursa pure one

Ursa Pureone mineral wool has the best thermal insulation properties. Moreover, it is environmentally friendly, does not contain any harmful substances. The use of phenol and formaldehyde in production is completely excluded. This is a material of the latest generation, which differs from simple mineral wool even in appearance: it is white, reminiscent of cotton or sheep's wool.

Quartz sand is used instead of basalt, which is the reason for the white color of the material. Instead of resin, acrylic is used as a connecting component - a safe polymer substance.

Harmful fumes from connecting elements

The technology for manufacturing basalt slabs provides for the use of certain types of resins containing a number of hazardous chemical compounds, which should include phenol and formaldehyde derivatives. These substances are necessary to bind basalt wool fibers one after another. But such compounds can seriously harm the life and health of people. It is possible to exclude the negative impact from this material, provided that at the stage of manufacturing the basalt insulator there are no violations of technology, including the use of high quality raw materials.

The finished product has a design in which the derivatives of phenol-formaldehyde resins are bonded to each other. As long as they are in a similar state, a person can feel safe. But, when raw materials of poor quality are selected as the basis for basalt wool, and its production is carried out in an artisanal way, then the created heat insulator will have significant deviations from the current standards.

Such plates may contain individual impurities that can greatly harm your health.Therefore, in order to avoid risk, consumers should give preference only to those versions of basalt slabs that have a high level of performance, which is confirmed by certificates of conformity.

Leading mineral wool companies

Rockwool stone wool has become so widespread thanks to its high quality, versatile products. There are many more companies that also supply their heaters to the CIS countries. Among them are the most famous and popular:

- TechnoNIKOL.

- Turkart.

- Nobasil.

- PAROC.

These companies are preferred by Russian builders. All these firms have an extensive assortment, where one type of insulation can be better than another, and vice versa. There is competition among manufacturers, so you shouldn't take everything from one organization. Better to explore building forums where people share their experiences. After all, stone wool is always chosen, the reviews of which are the most positive for a certain type of work. Now the insulation of buildings is so diverse in scale and execution that the material should be chosen for a specific narrowly focused work.

Another popular stone wool "Technonikol". It is used by both professionals and home craftsmen. There is also a wide range of not only stone, but also glass wool, as well as other materials for insulation. Their products can be found both in hardware stores and in the online store. However, you should always remember what harm this material can cause to health, so you always need to install it correctly so that dust and fumes cannot escape. This applies to any insulating materials, regardless of whether it is Technonikol stone wool or another.

What is Kaolin Wool?

Kaolin wool (also the accepted name of mullite-siliceous) is technically called MKRR-130. She has established herself as an excellent tool:

* simplification of installation,

* reducing the material consumption of the furnace structure,

* saving (reducing consumption) fuel.

Binders for MKRR-130 it is considered to be predominantly organosilicon. Among them are alumina cement, refractory types of clays, and silicate (liquid) glass.

It is an insulating, easily torn white padding material for thermal insulation under thermal conditions of 1100-1250 ° C.

The use of organosilicon and clay-containing connecting materials is not accidental. MKPP-130 is a derivative of natural natural raw materials: technical alumina, quartz sand and approximately 99% Al2O3. You can find highly alumina and zirconium types MKRR-130, corresponding to the thermal regimes of 1400 ° C and 1600 ° C.

Where is the MKRR-130 refractory fiber used?

Kaolin wool is characterized by a wide range of uses:

* As an insulator of expansion joints for ovens of all types, as well as windows;

* It is used in any heating units for filling thermocompensation seams, as well as their vaults and walls;

* As thermal insulation in metallurgy, due to its inertness to liquid metals.

Specifications

MKRR-130 highly effective. Produced by combining silicon and chromium oxide in an electric furnace and then blown into fibrous form, it has excellent heat resistance properties.

A high degree of resistance to thermal effects and deformations, vibration resistance, negligible mass, thermal capacity and density, increased heat resistance and thermo-chemical resistance, excellent sound insulation performance, elasticity and completeness of adherence of the texture to structures - all this ensures the MKRR-130 consumer popularity.

If we add to the exceptional physical and mechanical parameters perfect electrical insulating qualities that remain completely unchanged under conditions of up to 700-800 ° C, non-wettability with liquid metals, the ability to excellently withstand an aggressive environment (acid-base types of influences and environments, from neutral to acidic, inertness to water-containing liquids, water and its vapors, mineral types of oils - MKRR-130 is presented as an ideal and very safe insulator in operation.

You can see the price of kaolin wool by clicking here ...

Is modern basalt wool harmful to health?

November 03, 2016

Such natural heat-insulating material as stone wool mats is made by melting special rocks and then gluing the resulting fibers. Basalt is magma frozen on the surface of the earth. Note that this substance consists of many rocks.

The main positive characteristics of basalt wool are considered to be high resistance to combustion, a low coefficient of thermal conductivity, and good thermal insulation performance. This information is carefully masked by manufacturers, but the described products have one negative quality - it is harm to humans.

How harmful is stone wool made using modern technologies?

For many consumers, the environmental safety of building materials, including insulation, is considered a decisive choice parameter. In our article, we will get acquainted with the possible risks that may arise during the operation of basalt wool. The relevance of this issue is associated with the popularity of insulation among end consumers. Despite good thermal insulation performance, insulation boards can be used as sound insulation in the design and construction of apartments and private buildings.

As you can understand, many workers and residents of the house will be in contact with the insulation (if the finish is damaged), so the defeat can take on a massive nature. According to many experts, despite the damage caused, mineral wool has certain indicators of environmental friendliness. Such conclusions are confirmed when comparing the described products with glass wool, which was actively used to insulate buildings some 20-30 years ago.

Here you need to pay attention to one important nuance - this is the quality of raw materials and compliance with the technology of manufacturing the material. Harmfulness rates rise sharply in cheap products. Such insulation is obtained in violation of technology or from low-quality raw materials. High-quality basalt wool will differ from analogues in the following technical characteristics:

- low thermal conductivity;

- resistance to open fire;

- long period of operation;

- the ability to absorb extraneous sounds.

In addition to using cheap insulation, certain harm can be obtained if simple safety measures are not followed. The fact is that when laying thermal insulation mats, builders are constantly in contact with the substance. It should be noted that the plates of such products have a limited margin of safety. Under the influence of small efforts on the part of the workers, the fibers are destroyed. In this case, the smallest particles of thermal insulation fall under the folds of overalls, penetrate into the respiratory tract of a person. After that, the following happens:

- itchy skin;

- respiratory tract damage;

- the possibility of the appearance of oncological diseases;

- irritation of the mucous membrane of the eye;

- separate harm to the body is brought about by phenolic resins. Many of these substances are contained in thermal insulation called Isobox.

According to experts, high-quality stone wool with sufficient density, for which natural glue was used to hold the fibers together, will not be able to do harm. Especially durable materials will not collapse under load, so their smallest particles will not get on the skin and will not penetrate the human lungs.

When studying the information described, one can come to the simple conclusion that stone wool, produced without observing standards, by a handicraft method has a harmful effect on the human body. In this regard, it is necessary to buy only high-quality insulation that has the appropriate certificates and other accompanying documents.

Harm from the ingress of insulation fibers into the respiratory system

Many believe that getting particles of basalt wool into the lungs will cause irreparable harm to human health. Next, consider whether this is actually the case. Such a statement may be true, and especially if work is carried out with low quality insulation. At minimum strength indicators, with the slightest effort, the structure of the mats begins to collapse, the smallest fibers are released and the air is saturated with harmful particles.

When protecting the material with a finishing layer, as well as in cases where basalt wool is outside the house, such products will not harm human health. But here there is one thing, but when you inhale air next to the insulation, fiber particles will accumulate in the body. As a result of such an impact, cysts are formed in a person, which are the focus of the development of harmful bacteria. With the appearance of so-called trematodes, malignant tumors (oncology) may appear in the body.

Some people have been diagnosed with lung tumors that doctors associate with inhalation of asbestos or mineral wool. The particles of these materials are microscopic and sharp. When inhaled, such substances pass through large tubes and settle on small vessels, resulting in chronic damage and enzyme deficiency. Through the needle-like structure of small particles, small wounds appear in the lungs, which eventually turn into scars. In the future, areas with scars turn into swelling. Modern heaters, produced according to the requirements of state standards, have sufficient strength and good fiber bunch, which prevents small particles from entering the human lungs.

What harm to a person is brought about by the fumes of connecting substances

In the manufacture of basalt wool, hazardous substances such as phenol and formaldehyde are used to bind individual fibers. According to experts, such ingredients can be dangerous to humans, and especially if the conditions for the production of the material are not followed. Subject to the technology of work and the use of high-quality raw materials, there will be no harm from thermal insulation. The fact is that such products are also bonded using formaldehyde resins, but these components are in a coherent state.

In cases where stone wool was produced in an artisanal way, without observing any standards from low-grade raw materials, the resulting products will not meet the established quality standards. In the composition of such material, in any case, harmful additives will be present.

Work safety and first aid in case of poisoning with basalt wool

When laying insulation boards, you must adhere to safety rules. When small particles of insulation come into contact with unprotected human skin, scabies, redness and itching occur. Sharp, tiny particles of fibers get into micropores and cracks and remain there.

Microparticles can penetrate into the lungs, where they settle, which often leads to serious respiratory diseases. To prevent the negative impact of the material on the human body, use the following protective equipment:

- special glasses;

- rubberized gloves;

- respirator;

- overalls.

Important: after the insulation work, the overalls are thrown away, they are unsuitable for further use.

In case of accidental ingestion of fibers on unprotected areas of the skin, you do not need to itch, because this will lead to the penetration of the material deep into the pores. If microparticles hit the hairline, you need to gently shake your head over the bathtub and drain the water, but it is not recommended to wash off the insulation itself. When shaking, it is advisable to close your eyes tightly. After that, you can take a bath with a strong pressure of cold water without using detergents.Using a towel or washcloth, including hot water is also prohibited.

After a cold shower, the water in the bathtub should drain, and the human body should dry completely. Then they wash in the usual way using soap. Microparticles that have got into the eyes are also washed off with a jet of cold water under pressure. When the fibers of the insulation get into the lungs, a chronic cough occurs in a person. In such a case, you must consult a doctor.

You can buy many different heaters, but when choosing such a material, ask the seller for quality certificates for the products, and also use protective equipment and observe safety measures during installation.