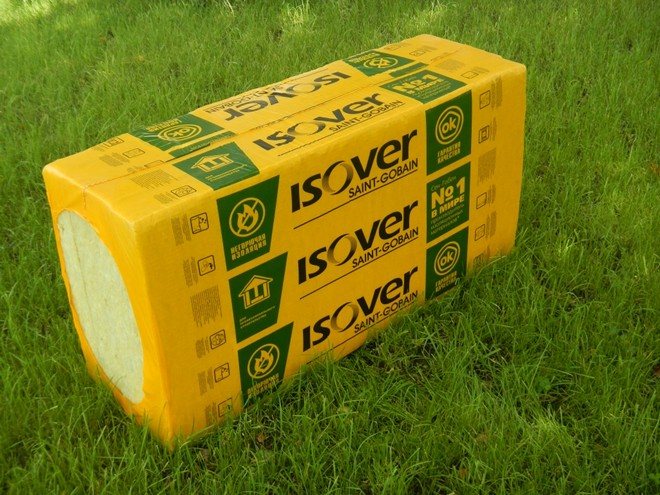

Izover facade is popular all over the world. first of all, he received his fame for the highest quality. In Europe, more than 30% of houses were insulated with Isover, both in hinged ventilated facades and plaster facades. Isover façade materials are increasingly used by companies and ordinary homeowners as exterior finishes, all thanks to their high quality and a long history of quality work.

Insulation Izover facade

Brand history

The rights to the brand belong to the firm of Saint-Gobain from France. Its main office is located in Paris, and the date of its foundation is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name of the insulation Isover was formed from the words "glass" and "insulation". In our country, the company's products were initially known under the brand name "Uteplyaev".

Initial production of Izover in Russia

For more than 350 years of history, Saint-Gobain has grown into an international industrial group, represented in 67 countries and with over 170 thousand employees. Sales in 2015 were € 39.6 billion. The company is included in the following ratings:

- 100 largest industrial enterprises according to Forbes.

- Top-100 innovative organizations in the construction sector.

- Best Employer - 2020

Experience and the latest technologies have made the company a world leader in creating comfortable living spaces. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by the brands ISOVER, ISOTEC, ISOROC in isolation; GYPROC in plaster solutions; dry mixes WEBER; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; PAM pipes.

- Distribution activity in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for over 20 years. Ten years ago, a plant was opened in the Moscow region (Yegoryevsk), and since 2011 in Chelyabinsk, a stone fiber insulation has been produced at the Minvata plant. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162 — ISO 9001.

Facade solutions from Isover

Plaster facade

The plaster facade of the Isover brand is unique in its own way. Mineral wool, which is often used as insulation, has a serious problem: the material is soft, which makes the slabs prone to deformation.

The manufacturer was able to achieve the required rigidity of mineral fiber boards thanks to an innovative technology developed by him. As a result, a cladding material for the facade was obtained from mineral wool, which does not require external cladding.

Product performance characteristics:

- The coefficient of thermal conductivity of the plaster facade is not higher than 0.038 W / (m * K).

- The service life of the material is 25 years or more. The material itself is almost eternal, and the tendency of the mineral wool to caking is almost completely solved by the manufacturer.

- The linear dimensions of the slabs are not prone to changes due to fluctuations in temperature and humidity, which makes the insulation especially valuable as a facade material.

- The vapor permeability of mineral wool makes it possible to realize a reasonable structure of the walls, when the resistance to moisture movement decreases from the inner layers to the outer layers of the wall as it migrates.

- The material is absolutely non-flammable.

- Plates are produced with a thickness of 50-200 mm and length / width characteristics - 60x120 cm.

Material description

It is a world famous mineral wool based insulation. Available in rolls, as well as rigid and semi-rigid plates. It consists of glass fibers 100-150 microns long, the thickness of which is 4-5 microns.

For manufacturing, only natural ingredients are used, since mineral wool is environmentally friendly. It can be used both horizontally and vertically. Different types are designed for both indoor and outdoor use.

Insulation is made of quartz sand and broken glass (80% of the total mass). Soda, dolomite, limestone, borax can also be used. The materials are poured into the hopper, where the mass melting process takes place. The filaments are formed by steam blowing molten glass that is ejected from the centrifuge. When soaked in aerosol, they fall on the rolls and level out, forming a “carpet”. Polymerization occurs at a temperature of 250 ° C. Then the mineral wool is cooled to ambient temperature and cut into mats and rolls.

Application area

Thermal insulation materials produced by the French company Saint-Gobain, in addition to excellent insulating functions, also have very significant sound-absorbing properties, which significantly expands the scope of their application.

Isover mineral wool slabs are widely used both in the field of industrial construction for the purpose of insulating interfloor floors and voids inside hollow walls, and for household thermal insulation of residential buildings and premises.

According to consumer reviews, Isover insulation materials in a practical aspect show themselves better than similar products produced by other competing manufacturers.

Mineral wool heaters of the Isover brand allow for thermal insulation of any surfaces. The company produces products that make it possible to insulate both internal and external wall surfaces, insulate attic ceilings, pitched and straight roof ceilings.

Significant advantages of French-brand heat-insulating mineral wool boards are their characteristics such as mechanical flexibility, resistance to deformation and tear resistance. This makes it possible to use them on structures of a complex geometric profile such as pipes, industrial equipment, structural elements of production lines and others.

As noted above, Isover mineral wool also has very high technical soundproofing performance, successfully protecting industrial premises and rooms in apartment buildings from any external noise.

The main characteristics of the insulation

Isover mineral wool thermal insulation materials inspire confidence and are in stable demand. Moreover, both slabs and rolls are rightfully considered one of the best thermal insulation on the market.

The main characteristics of the insulation include:

- Thermal conductivity.

- Soundproofing.

- Flammability.

- Water vapor permeability.

- Long service life.

- Environmental friendliness.

- Convenient release form.

- Low weight.

As a heat insulator, Isover insulation has managed to prove itself from the best side precisely due to the coefficient of thermal conductivity equal to 0.041 watts per meter per Kelvin. The coefficient does not change during the operation of the insulation throughout the entire period, the fibers do an excellent job with the accumulation and retention of air, preventing heat loss.

The material has excellent sound insulation performance. Air-spaced fiberglass insulation absorbs noise, guaranteeing an optimal level of silence, especially if specially adapted types of insulation are used for the soundproofing layer.

The flammability index is also important.Thermal insulation materials with technical characteristics indicating a density of up to 30 kilograms per cubic meter are classified as non-combustible. The materials are successfully used in premises of any type and purpose, without fear of spreading fire in the event of a fire.

Thermal insulation boards made of mineral wool with special technical characteristics indicating the presence of an additional layer based on aluminum foil or fiberglass are classified as low-flammable.

Such materials are used subject to certain restrictions, which in fact are nothing more than a convention. In practice, insulators are appropriate almost everywhere, the main thing is to follow the fire safety regulations of structures prescribed in SNIP.

An important point from the list of technical characteristics of thermal insulation is vapor permeability. Insulation is able to maintain functionality even after contact with moisture. Unlike many modern counterparts for thermal insulation, Isover products based on stone wool simply and effectively deal with the problem of moisture penetration inside the thermal insulation layer.

The insulation gives off the absorbed moisture as quickly as it receives, the main thing is to leave a small gap (2-3 cm) between it and the wall to maintain ventilation.

Failure to follow this simple rule will lead to a violation of the material's ability to remove moisture, which over time will negatively affect the ability to retain heat. Isover heaters have optimal vapor permeability values - from 0.50 to 0.55 mg / mchPa.

Analysis of the technical characteristics of the material implies the mention of such an important parameter as the operational life. The material not only does not allow heat to pass through, but is also capable of properly serving for several decades. The manufacturer claims an operating life of 50 years for thermal insulation boards and rolls with full functionality.

The peculiarity of the material is the water repellents included in the composition, capable of repelling moisture, preventing the reproduction of insects, fungi and the formation of mold, which in turn ensures safety throughout the entire period of use.

Advantages and disadvantages

Among the advantages of building materials, the following factors should be noted:

- High quality thermal insulation. Isover is used in particular for facade insulation, which can significantly save on heating the house in the winter season.

- Resistant to extreme temperatures.

- Fire safety. Minvata does not burn, so it is used for insulating multi-storey buildings, where the spread of fire would have very serious consequences, as well as for the roof and attic floor, the structure of which consists of wooden elements.

- Resistance to mechanical and chemical attack.

- Tensile strength and no compression deformation.

- Excellent sound insulation allows the products to be used in plasterboard partitions.

- Resistance to the negative effects of rodents.

- Ease of installation.

These technical characteristics of Isover insulation speak in favor of its use in a wide variety of construction areas.

However, this material has its drawbacks. During installation, a full set of personal protective equipment must be used: glasses, gloves, a respirator, long-sleeved clothing that completely covers the body.

Even if it is very hot outside, you cannot neglect the above means, because the fibers cause irritation and itching when in contact with the skin.

If the insulation is moistened by 1%, its thermal insulation properties deteriorate by 10%. Therefore, when using the material on the roof and attic, it is imperative to carry out waterproofing work, because getting wet will lead to a loss of thermal insulation properties. And when installing slabs on the facade of a building, it is necessary to immediately tighten it with a net or plaster to avoid moisture due to atmospheric precipitation.

Material parameters

Figure 1. Isover in blocks

Modern requirements for heaters imply fire safety, tight fit to the wall, good protection from heat loss and from the wind. In this case, the thermal insulation should not absorb moisture and deform from temperature fluctuations. Such a heater is French-made Izover.

Isover Facade refers to non-combustible materials. It has a tensile strength of at least 15 kPa and a water absorption of 1 kg / m2. The density of Isover insulation is 145 kg / m2, which gives high resistance to mechanical stress.

The main characteristic of the insulation is the thermal conductivity coefficient. This parameter shows how much heat the wall gives from the house to the outside environment. The lower the number, the better. For Isover Facade, the coefficient is 0.036 W / (m K).

Varieties

Manufacturer Izover produces mineral wool in rolls, mats and slabs.

Slabs

Plate models are of the following types:

- Isover Optimal, the density of which is 28-37 kg / m3. It is used for frame structures and installation of sound insulation for interior partitions and inter-floor ones. They can insulate the roof, floors, and walls. The dimensions of the slab are 60 * 100 cm, the thickness is 5 cm or 10 cm, in the package there are 4 slabs (10 cm) or 8 slabs (5 cm);

- Isover Standard. It is used to insulate walls from the outside before finishing them with siding or facing bricks. The slab geometry is identical to Isover Optimal. Among the characteristics of Isover Standard, it is worth noting low compressibility under a specific load of 2kPa - 10%;

- Isover Facade, with a density of 145 kg / m3, is used for facades with a thin plaster layer. Fire resistance, as well as the absence of the influence of rodents are the undoubted advantages of this model when insulating a building.

Rolls

Among the many roll options of this insulation, the following can be distinguished:

- Isover Warm Roof. The technical characteristics of this model make it possible to use it for pitched roofs, since this material has high water-repellent properties;

- Isover Warm House is convenient to use on large horizontal surfaces. It allows you to save 64% on heating your home;

- Isover Sauna combines a vapor barrier. The presence of a layer of foil allows you to maintain a high room temperature for a long time;

- Isover Karkas-M37 is used for serial construction;

- Isover Karkas-M40-AL has a layer of aluminum foil, which makes it possible to increase the heating rate of the room and save heat for a long time;

- Isover Karkas-M40 is used for thermal insulation of floors.

Mats

Pro - used inside and outside, a versatile material that is popular. Thickness 50, 100 and 150 mm. Classic - thickness 50 mm, 2 mats are wound in a roll. It is used for insulating floors, roofs on joists, ceiling on battens. M37 frame - thickness options 40, 50, 60, 100 and 150 mm. It is used to fill the inter-wall space when insulating frame houses. M34 frame - 50 mm thick, less dense than M37. M40AL frame - foil-clad insulation 50, 100 and 150 mm thick.

How to make insulation correctly?

In order to correctly carry out the installation on the facade of the isover insulation, you do not need special knowledge or skills, because this is not difficult to do and you just need to comply with the installation instructions. Doing everything according to the instructions, you will get a facade of excellent quality, and warm rooms in the house.

Installation of insulation under the ventilation facade

To begin with, the starting profile is mounted by leveling the plates and protecting them from below on the wall. Focusing on it, then the first row of the ventilation facade is laid down.

Each plate of insulation isover is first primed with an adhesive solution. Then the main part of the solution is applied, and only then press the slab against the wall.

Each subsequent row of insulation boards is laid with an offset relative to the vertical seams of the lower row. After the end of the laying of the slabs, the ventilation facade is bottom, the slabs are fixed to the wall.

Installation of a plaster facade

The next stage of work is to give the surface of the insulation rigidity in order to start applying the finishing coating. For this purpose, a thin layer of glue is applied to the izover plaster facade slab, on which a plastic or steel mounting mesh is laid and rolled with a roller.

When the reinforcing layer is dry, it must be primed and covered with a layer of decorative plaster. Depending on the location of the place that was insulated, its finishing is carried out.

Stamps

Isover thermal insulation product lines have several dozen items and are designed to solve specific problems. All of them differ in the form of delivery, thickness, density and size.

Note: since all brands have the same basis, they are interchangeable.

For general construction works

Isover Profi. A versatile material with increased elasticity. Provides the highest level of thermal insulation among the brand's retail materials.

Supplied in rolls, board thickness - 50, 100 and 150 mm. It does not require additional fasteners during installation; a raspor can be installed. Has earned positive reviews from builders.

It is used for insulation and sound protection:

- external walls from the inside and outside of the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic. Supplied in rolls, material thickness - 50 mm. A surprise can be set.

Application area:

- insulation of suspended ceilings;

- interfloor floors - the material lies between the lags;

- attic rooms.

Izover Classic stove. The shape of the mineral wool is a slab. Size - 610 * 1170 mm, thickness 50 and 100 mm. Packaged 5 and 10 m2.

The lineup

Like any building material, isover insulation is available on the market in several types. Each of them is designed for specific building structures:

Isover product line

- "Sound protection" intended for finishing partitions, walls.

- For frame construction, insulation of the model "Frame».

- "Profi" used for insulation of attics and pitched roofs. This is a high quality insulation. Profi is offered on the market in rolls with a thickness of 50, 100 and 150 mm.

- Classic used by wide applications. He has access to insulation for floors, logs, attic floors and other complex objects. Although the Classic is a roll material, it can be used to cover huge areas in one go. Usually, two layers of 50 mm are laid in a roll. So you can safely split it or use it as it is.

- Classic Plus... This heat insulator insulates the outer and inner surfaces of the walls. Possesses high thermal insulation characteristics. An excellent specimen.

Important... Many models are categorized as "interchangeable". That is, one is freely replaced by another. In this regard, Profi and Classic Plus are universal heaters.

The sound protection model is increasingly used in rooms where there is a need to reduce the penetration of noise from the outside. Sound protection is two in one. Therefore, those who do not want to hear the steps of neighbors over their heads anymore are recommended to install Isover Soundproofing under suspended or suspended ceiling structures.

Fiberglass construction wool from a Finnish manufacturer is today the leader in the “thermal insulation” category. Excellent quality characteristics plus affordable price for the mass consumer. This is enough to achieve the excellent qualities of a 100% insulated home.

Mineral wool insulation Isover (Isover) Venti 100

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 82 kg / m3

- Package area: 2.16 m2

792 rbl

Mineral wool insulation Isover (Isover) Venti 150

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 82 kg / m3

- Package area: 1.44 m2

775 rbl

Mineral wool insulation Isover (Isover) Light 100

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 38 kg / m3

- Package area: 2.88 m2

563 rbl

Mineral wool insulation Isover (Isover) Optimal 100

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 34 kg / m3

- Package area: 2.88 m2

117 rbl

Mineral wool insulation Isover (Isover) Optimal 50

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 34 kg / m3

- Package area: 5.76 m2

363 rbl

Mineral wool insulation Isover (Isover) Venti 30

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 103 kg / m3

- Package area: 5.76 m2

692 rbl

Mineral wool insulation Isover (Isover) Venti 50

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 85 kg / m3

- Package area: 4.32 m2

792 rbl

Mineral wool insulation Isover (Isover) Light 50

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 38 kg / m3

- Package area: 5.76 m2

563 rbl

Mineral wool insulation Isover (Isover) Facade 100

- Length (mm): 1200mm

- Width (mm): 600mm

- Density (kg / m3): 145 kg / m3

- Package area: 1.44 m2

854 rbl

Against the background of many proposals for new insulating materials, Isover Plaster Facade mineral wool and other types of Isover remain recognized as classics. Fiberglass is processed using a special patented technology to obtain insulating materials with strictly defined properties. If high adhesion to adhesives is required for external wall insulation, we recommend using Isover façade.

In addition to chemical resistance to plaster mixes, this type of material has a zero fire level. According to the area of application, Isover is divided into the following types:

- For light thermal insulation;

- For general construction insulation;

- For special purposes;

- Lightweight thermal insulation.

Almost weightless Isover mineral wool slabs exclude the load on the base. Plates are used in the reconstruction and construction of residential buildings and industrial facilities. It is a well-proven insulation material for floors, roofs, walls, attics, floors between floors. Plates are produced in optimal sizes. Thanks to this, installation time is 20% less. The specialists of our company will tell you what is better for you to buy - "Isover facade" or other products of this brand.

General construction insulation.

Fiberglass rolls "Isover" are mounted without fasteners, fit tightly to the base. They have proven to be excellent for thermal insulation of partitions, walls, floors and more. It is possible to buy Isover stone wool with an aluminum film for vaporization.

In the production of mineral wool of this class, they impart especially enhanced moisture resistance and fire safety properties. Insulation is widely used for the arrangement of pitched roofs of houses, floor insulation, insulation of water pipes and ventilation pipes. Isover sound protection is used to protect against external airborne noise. The level of protection is confirmed by acoustic tests.

Types of isover and its application

Isover slabs for a plaster facade have several types, we will consider the main ones.

Isover ventilated facade

Isover products are actively used for ventilated facades

During the production of Izover ventilation facades, a two-layer system is often used, which has a positive effect on energy saving in the house. This composition, in addition to mineral wool, also includes staple fiberglass. The insulation does not suffer from mechanical stress. Such insulation is often used in tall buildings. Fiberglass covers one of its sides. As a result, by purchasing this product, you become the owner of a reliable and durable insulation used in the facade.

Ventfasad izover niz

Ventfasad Bottom - ordinary insulation of medium hardness

Izover ventilation façade bottom serves as plastering of the interior walls of the premises. The main task is to fill the gaps. Be sure to use only when installing two-layer thermal insulation.

Ventfasad izover top

This type is used in the case of two-layer insulation and acts as an outer layer.Its distinctive feature is that the material practically does not absorb moisture and will serve as excellent heat retention.

Tool necessary for work

- Perforator;

- Hammer;

- Spatula set 60, 200, 400 mm;

- Paint roller;

- Hacksaw for wood;

- Paint brush;

- Scissors;

- Protective glasses;

- 2 buckets for mixing glue.

Wall insulation with ISOVER materials

The use of ISOVER insulation improves the quality of life for the whole family:

- increases the efficiency of heating and air conditioning systems,

- helps to reduce the associated costs,

- prevents noise from entering the house from the street.

ISOVER thermal insulation materials are non-flammable, they do not emit toxic substances even at the highest temperatures. Interesting to know Thermal insulation with a thickness of 10 cm in terms of the level of thermal protection can replace massive walls made of brick or timber. Insulation of the facades of Kiev houses will not be difficult with ISOVER products, since the materials have optimal geometric shapes and low weight.

8 advantages of ISOVER materials

| Thermal insulation Reliable thermal protection due to low thermal conductivity. |

| Service life - 50 years Retain operational ability throughout the entire shelf life. |

| Fire safety Reduces the risk of fire: materials do not burn even in direct contact with fire. |

| Environmental friendliness Materials are made from natural ingredients: sand, soda, limestone. Recommended for use in children's and medical institutions according to the EcoMaterial Absolute certificate. |

| Ease of installation Due to their flexibility and special dimensions, the slabs are easily assembled into the structure without requiring any fasteners. |

| Renewability After unpacking, slabs and rolls are guaranteed to be restored to the required size. |

| Convenience of delivery Materials are delivered in a compressed form, which allows to reduce the cost of delivery and storage up to 5 times. Plates are available in sealed packaging and can be stored outdoors. |

| Quality assurance Product quality is controlled according to the European standard EN13162, the international standard ISO 9001 and the standards of the Saint-Gobain group. |

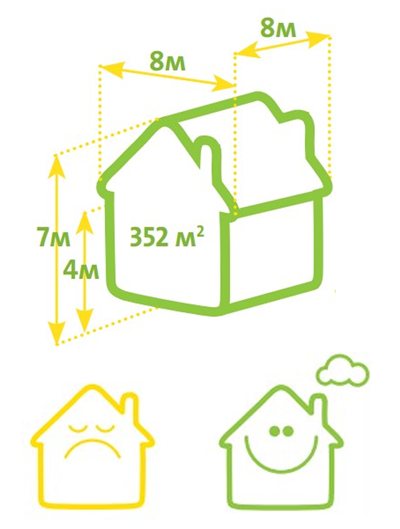

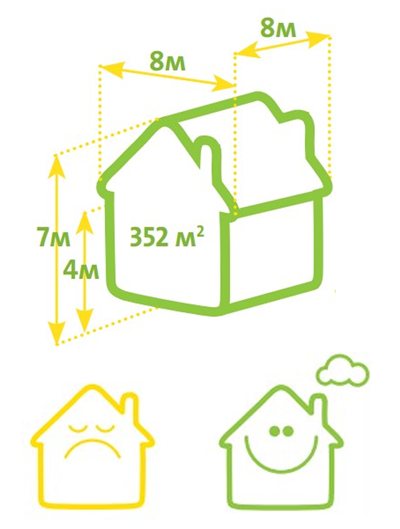

How quickly wall insulation will pay off

Before buying ISOVER insulation materials, you need to understand whether it is profitable to insulate the house at all and what kind of insulation is needed for the walls (from the inside or outside). Therefore, we conducted a small experiment - we compared the indicators of a gas and an electric meter in insulated and non-insulated houses with an area of 352 m2. And that's what came of it.

| In a non-insulated house: | In an insulated house: |

|

|

Materials used for insulation:

- Facade - 18 m3 of material ISOVER Profi (wall insulation in the Kiev house was carried out with slabs 150 mm thick).

- Roof - 20 m3 of material ISOVER Profi (insulation layer 120 mm).

- Floor - 7 m3 of material ISOVER Profi (insulation layer 100 mm).

In total, 45 m3 of material ISOVER Profi is needed ≈ 20 850 UAH. * At the price of gas for a private house 7 188 UAH / m3 (as of March 1, 2016). ** At the price of electricity for a private house 1.56 UAH / kW / year (as of March 1, 2020). You can calculate the savings on heating your home using an energy efficiency calculator. Insulation of facades - the price of warmth and comfort in your home.

Characteristics of Isover Facade

Insulation is marketed in rolls and slabs. The level of thermal insulation of the material, in comparison with analogues, highest... Also Izover Facade is distinguished by improved indicators of flexibility and density, environmental friendliness. Other advantages of the material:

- Easy transportation, the ability to compress the volume almost 3 times with the subsequent return of the original shape.

- Wide assortment - in the line of ISOVER insulation materials, you are guaranteed to select the right type of heat insulator.

- Elasticity - it is the maximum among the materials in this category.

- High heat dissipation - 5 centimeters of insulation works the same as 1 brick.

- Durability - 50 years warranty.

- Low weight - on average 45 kg / m3.

The insulation also has disadvantages - since cotton wool has a soft structure, its scope is limited. It is not allowed to install the heat insulator without a slight gap - otherwise moisture will begin to be absorbed into the material.

Important. The installation of the insulator is carried out strictly in goggles and special gloves.

Security

She speaks about the safety of stone wool for health natural origin, production method and sconclusion based on the results of product testing and enterprise audit... It is no coincidence that professional builders use mineral insulation during the construction or reconstruction of even children's, medical and sports facilities... ISOVER stone wool creates a comfortable temperature in the building of the federal center for cardiovascular surgery (Chelyabinsk), in the emergency hospital (Kazan), in many kindergartens in Moscow, St. Petersburg and other Russian cities. This material is chosen when it is important to use a safe product with a positive experience of use, the quality of which can be trusted. Fire safety Mineral wool belongs to the group of non-combustible materials. Therefore, it does not burn, does not spread fire and does not emit harmful substances, not only when in contact with an open fire, but also simply when heated.

Environmental friendliness and harmlessness

Fiberglass materials of this type are absolutely harmless to human health and life. During their operation, no harmful substances are emitted. For half a century, Finnish scientists have been verifying this fact. No danger was found - this verdict was repeatedly made by specialists from the Institute of Cancer Problems.

Rules for working with stone wool

Manufacturers of stone wool recommend installing stone wool in accordance with the rules for working with any building material, i.e. in gloves and a respirator.

Insulation weight

If we compare Izover with other heat insulators in terms of weight, it will turn out to be much lighter than the rest. Therefore, in those buildings whose walls are made of not very strong materials or excessive load is unacceptable, it is the use of Isover that will be an excellent way out.

Ventfasad Izover Verkh

The product is the outer layer for two-layer insulation.

Let's refer to the description of Ventfasad Izover Top by the manufacturer:

- The material, due to the minimum permeability coefficient, provides effective protection against heat leakage.

- The material belongs to the NG group, i.e. not flammable. But in the production of plates with a fiberglass layer, the insulation gets the G1 group.

- Slab parameters: thickness 30 mm, linear dimensions 1380x1190 mm.

Ventfacad Top is produced in two versions: without wind protection and with it.