- 1 Watch the video how to reinforce foam plastic with mesh

- 2 Technological features of foam reinforcement

- 3 Stages of reinforcement of expanded polystyrene

- 4 Tips / tricks for work

Expanded polystyrene is one of the most popular materials used to insulate various surfaces. Its loose structure provides for subsequent finishing, which each master makes at his own discretion.

But there are technological requirements, non-observance of which leads to rapid wear of the protective layer and the formation of deformations on the finishing surface. To prevent such incidents, it is worth familiarizing yourself with the reinforcement rules and recommendations for the use of building materials.

Technological features of foam reinforcement

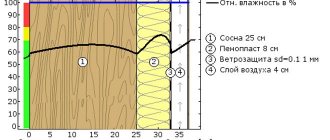

The process itself provides for the creation of a protective reinforcing layer. The barrier prevents the destruction of foam due to exposure to ultraviolet radiation, precipitation and other external factors. The reinforced surface needs further finishing, which is carried out in different ways, depending on the place of work and functionality.

The sequence of surface insulation by fixing the foam is performed in the following order:

1. Preparation of the surface for the installation of insulation boards (cleaning from dirt, sealing cracks and holes, dismantling protruding decorative elements).

Types of glue

Insulation glue is usually sold in a powdery state, and is diluted with water before use. Stirred by hand or using a drill with a construction mixer attachment. The quantitative ratio in each case is different, you must carefully read the instructions for use. It is necessary to prepare the glue before work, not in advance, the viability of the solutions is short-lived.

There are two types of glue for reinforcing mesh:

- universal;

- special (for a specific material).

When buying a universal glue, you can be inattentive, but when purchasing a special glue, you need to carefully look at the list of materials with which this adhesive can work.

About whether this composition can stick a reinforcing film should be written in the instructions. Glue for mesh on a synthetic basis, as well as on gypsum, cement is quite suitable for installing facade mesh.

What to consider when performing foam reinforcement.

Foam supplies across Krasnodar, Krasnodar Territory and Rostov-on-Don.

Surface preparation and fixing the mesh to the foam

Foam plaster includes several important stages, on the competent execution of which the durability of the finish depends. First of all, care should be taken to level the surface on which the foam will be fixed. If the walls of the house are already insulated, then you can skip this stage and move on.

Today, there are various building mixtures for foam plastering. The most common of them are bark beetle, bayramiks and others. By the way, you can read exactly how to apply the bark beetle to polystyrene by going to another section of the site.

Also, it is imperative that before the foam plaster is performed, you should take care of the right tool to do the job. First of all, you will need:

- Graters and metal spatulas;

- Master OK;

- Empty containers for solution;

- A drill with a mixer attachment for mixing the plaster mixture.

So, initially you will need to prepare the surface of the foam before applying the plaster. It is important to take into account the correct coincidence of the joints with each other and the absence of any gaps between them. If they are, then it is as easy as shelling pears to seal them up.

Next, you need to fix the reinforcing mesh on the foam. You should not refuse to use it, since dried plaster can simply fall off over time from the surface of the foam. It is best to use a strong foam mesh reinforcement, starting from the corners of the building.

After installing the reinforcing mesh, it is necessary to wait 2-3 hours, after which it will be necessary to rub the surfaces with a float or not too coarse emery.

Do I need to prime the styrofoam before plastering?

Priming the surface will increase the subsequent adhesion of the finishing material to it. Foam should be primed with a roller or wide brush. The tool should be light-nap, and it is best to use a foam rubber.

Be sure, after the primer is applied to the foam, you need to give some time for the surface to completely dry out. Only after that, you can start plastering on foam.

Fastening insulation sheets to the wall

Gluing foam to the facade is carried out on a special glue, for example, Ceresit CT83, Ceresit CT85, or their analogs. After that, the foam is fixed with umbrella dowels (fungi).

Work order:

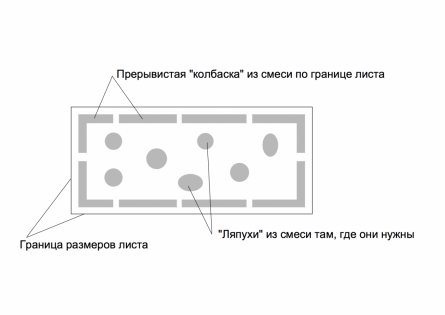

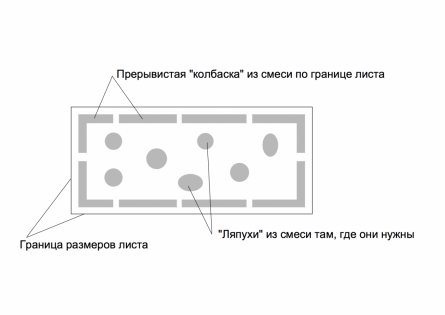

Figure 2. Scheme of applying the solution to foam sheets.

- Attach a starter profile to the bottom of the wall, which will hold the foam on the glue and prevent it from slipping.

- Apply the adhesive to the perimeter wall and a few cakes in some places in the middle of the styrofoam sheet. The thickness of the cakes can partially level out small irregularities in the wall.

- Press a sheet of Styrofoam to this spot and move on to the next. Sheets must be glued with a horizontal offset. In no case should the 4 corners converge at one point (see Fig. 2).

- When the entire facade is sealed with foam, you need to pause for 3 days. This is necessary in order to give the glue a good grip.

- After that, fix the foam with fungi. The dowels must be of such a length that they enter the main wall by at least 50 mm. They need to be located at the joints and in the center of the sheets. Drill holes with a diameter of 10 mm. Their depth should exceed the length of the fungi. The fungi should be placed at a distance of 50-100 mm from the corner of the wall. After installing the fungus, drive a nail into its sleeve. It is advisable to choose plastic nails, since metal ones will be additional cold bridges. Cut off the nails that have not been finished off with pliers.

- Slots larger than 5 mm must be foamed.If the gaps exceed 15-20 mm, then they need to be hammered in with strips of insulation, and then foamed. The foam should dry within 4-5 hours. After drying, the protruding foam should be cut off with a knife. Smooth out significant irregularities with a foam trowel.

- If you decide to insulate the facade in 2 layers, then the top layer must be fastened with overlapping seams - both horizontal and vertical. Then the seams of the lower layer do not need to be foamed.

- Putty the fungus caps using a large spatula. Sand the unevenness of the filler with sandpaper.

Reinforcing mesh adhesive

Adhesive for the reinforcing mesh allows you to reinforce the facade layer with fiberglass mesh, to glue polystyrene foam plates in various insulation systems. The material interacts perfectly with a variety of concrete compositions and is not picky about the texture of the treated surface.

It is intended for adhesive fastening of a heat-insulating layer of expanded polystyrene plates, as well as for the subsequent installation of a base reinforced plaster layer with an alkali-resistant facade mesh over the insulation for external thermal insulation of buildings and structures for various purposes.

Reinforced, crack-resistant plaster-adhesive mixture for gluing thermal insulation boards and creating a reinforcing layer. For manual application.

It is intended for adhesive fastening of heat-insulating layer made of mineral wool and expanded polystyrene boards.

OSNOVIT KAVERPLIX TS117 plaster-adhesive mixture is intended for installation of expanded polystyrene and mineral wool boards, creating a reinforced base plaster layer.

Adhesive for expanded polystyrene boards and reinforced protective layer devices

Adhesive for mineral fiber boards and reinforced protective layers.

Reinforced, crack-resistant plaster-adhesive mixture for gluing thermal insulation boards and creating a reinforcing layer.

Adhesive for fixing heat-insulating plates and the device of the base plaster layer of facade heat-insulating systems in low-rise construction.

Plaster and glue mixture for the installation of expanded polystyrene and mineral wool boards, creating a reinforced base plaster layer.

For the installation of all types of heat-insulating polystyrene foam and mineral wool boards inside and outside buildings.

Reinforced, crack-resistant plaster-adhesive mixture for gluing thermal insulation boards and creating a reinforcing layer. For machine application.

It is used when installing external thermal insulation systems for buildings (SNTI) for fastening heat-insulating materials made of various materials (expanded polystyrene, mineral wool and basalt fiber, etc.), as well as for applying a plaster layer reinforced with fiberglass mesh to their surface.

Adhesive mortar for installing a layer reinforced with a glass mesh on facade insulation boards made of expanded polystyrene, as well as for gluing expanded polystyrene boards to substrates.

Adhesive mortar for installing a layer reinforced with glass mesh on facade thermal insulation boards made of mineral wool, as well as for gluing these boards to substrates, prefabricated in the form of a dry mixture of binders, mineral fillers and modifying additives.

White reinforced plaster Osnovit Coverlix PC117 W is designed to create a reinforced base plaster layer.

Adhesive for fixing extruded polystyrene foam boards and base plastering layers.

White universal glue for gluing EPS and mineral wool boards and reinforced base layer.

A plaster-adhesive mixture for creating a reinforced base plaster layer of SFTK in a vandal-resistant zone: 1.5 m from the level of the base, as well as a reinforced layer of high quality.

Mineral dry mix for the preparation of glue - reinforcing mortar, for gluing expanded polystyrene and mineral wool boards.

Dry mix for gluing expanded polystyrene and mineral wool boards, as well as for a layer reinforced with glass mesh in thermal insulation systems.

A universal mineral dry mix for creating a base layer reinforced with glass mesh and gluing expanded polystyrene and mineral wool boards, as well as as a finishing putty layer on a smooth facade. For indoor and outdoor use.

Reinforcement glue can be purchased for gluing insulation boards to the following substrates:

- to ordinary concrete,

- to walls with ceramic, silicate, concrete elements,

- to concrete on lightweight aggregates,

- to aerated concrete.

Reinforced foam for the facade

Reinforced foam for the facade is made by cutting out a panel of the desired shape and size from a single foam block, followed by reinforcement with a putty.

The scope of use of reinforced polystyrene is very wide: it is used not only for the facade of buildings as thermal insulation, creating a basis for future painting, plastering and other finishes, but also for the manufacture of facade decor elements. If you have decided to insulate the facade using this material, you are probably interested in how reinforced foam is produced for the facade, the pros and cons of its use, as well as the nuances of installation.

First of all, it should be said that reinforced foam is in great demand due to the following advantages of the material:

- elasticity;

- waterproofness, which prevents the occurrence of dampness and fungus;

- breathability. At the same time, passing air, the material does not absorb water, which excludes the possibility of swelling and deformation;

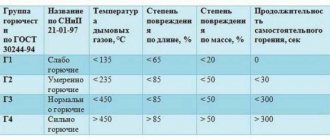

- incombustibility;

- environmental friendliness - the material does not emit any toxic substances even with strong heating, which makes it absolutely safe for use in construction;

- high rates of noise and sound insulation;

- light weight, so that the material does not put a lot of stress on the foundation. This property makes it possible to use it, including for the installation of hinged facades;

- affordable price.

Reinforcement technology is very simple. The foam board must be immersed in the reinforcing mixture, as a result of which the latter will cover the product with an even layer and give it additional strength. The reinforcement procedure increases the useful performance properties of the foam and significantly extends the overall service life of the building insulated with this material.