When building a dwelling on the territory of Russia, many owners ask themselves the question of insulation. The modern building materials market has a large assortment, which is represented by tile thermal insulation. Among them, the most popular are Penoplex and Technoplex. If you cannot choose: technoplex or penoplex - which is better, it is recommended to consider the photo and read the comparative description. Both materials are environmentally friendly, non-flammable and do not dissolve in soil or water. They are great for private construction, balcony insulation and underfloor heating.

What is extrusion

More than half a century ago, American engineers developed a technology for extruding polystyrene, which is now successfully used in the production of building materials with high thermal insulation properties.

Polystyrene granules under high pressure and temperature are mixed with foaming agents (a mixture of non-toxic light freons).

The material obtained at the exit of this process has a cellular structure. Remains of freons in the cells are quickly replaced by air. Microscopic closed cells are distributed evenly throughout the entire volume of the slab.

Various additives (graphite, flame retardant additives) are added to the expanded polystyrene produced by extrusion, which enhance the useful properties of the material.

Features and types of material

The most popular is the Ursa XPS series of insulation made of extruded polystyrene foam. They have excellent properties that guarantee good thermal insulation.

A special technology is used for production - the material is made from pre-melted polystyrene granules and a foamed agent. The granules are melted under pressure and the influence of elevated temperatures. The resulting mixture passes through an extruder, resulting in a strongest material with a closed structure that does not lose its excellent characteristics over time.

Ursa XPS boards are used for thermal insulation of various premises. Among its analogs, this material has the lowest thermal conductivity, besides, it has a low weight, accordingly, it gives a minimum load on the supporting structures. And working with such material is easy and simple.

Let's consider some of the most popular types of material.

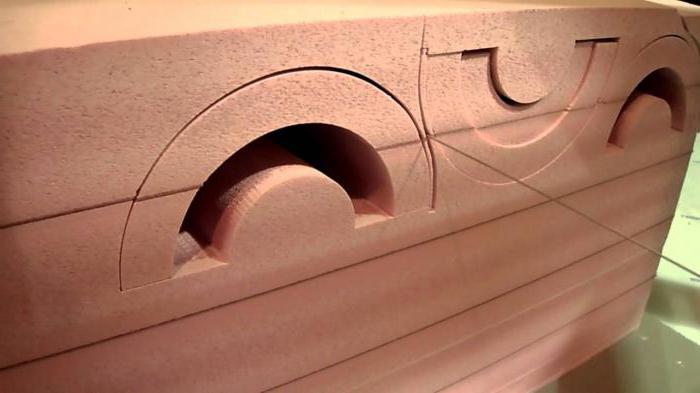

- Ursa XPS N-III - wide slabs used in construction. They are often used to insulate flat roofs of varying degrees of complexity. In the wall structure, they are used as a layer of insulation for "well masonry". These slabs have found their application for the insulation of floors, plinths, balconies and loggias. The surface of the slabs has textured unevenness and relief, which greatly simplifies the plastering work on the material.

- Ursa XPS N-III-G4 - boards with characteristics similar to those of XPS N-III products. This series is available in a wider range of thicknesses. Plates are cheaper, since there are fewer flame retardant additives in the composition, as a result of which the flammability class decreases. They are used for basements, foundations, facades, as well as floors with subsequent filling of the screed.

- Ursa XPS N-V - the most durable slabs that can withstand heavy loads. Designed for thermal insulation of deep-lying foundations, floors in rooms with high loads. These can be industrial buildings, roads, railways, and even runways. Slabs are not used for private construction.

General properties of heaters

The products of the two competing companies have similar properties:

- have the form of slabs of various sizes - their thickness ranges from 20 to 120 mm;

- high insulating properties due to the cellular air structure;

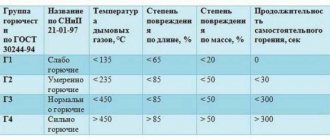

- high degree of fire safety - the material does not support combustion processes;

Note:

different products from the same company may have different degrees of fire resistance. Check this information on the product packaging.

- environmental friendliness, chemical and biological inertness. Expanded polystyrene boards do not rot, do not decompose, do not dissolve in water and soil. Their water absorption and thermal conductivity indicators are extremely small;

- the possibility of installation in any weather conditions;

- high strength and elasticity, both products have a long service life;

- easy handling and installation. The low weight of the boards greatly facilitates the installation process;

- good sound absorption.

Take a note:

you can use an ordinary clerical knife to cut the expanded polystyrene plates.

Common features

If you analyze the technical indicators of both heaters, you will notice that they do not have decisive differences:

- Temperature regime (taking into account the fact that in the CIS countries the temperature of -70 ° C is rare).

- These materials are heat insulating and also environmentally friendly.

- In fact, they are not susceptible to dissolution both in water and in soil.

- Used for individual construction and subsequent thermal insulation.

- They are destroyed when exposed to solvents and bitumen glue.

- Lightweight.

- They do not require special skills for installation work.

- Approximately one price segment.

Areas of use

Penoplex and Technoplex insulation boards can be used in the widest range of construction works and are generally interchangeable:

- civil and industrial construction;

- Walling;

- , thermal insulation of ceilings;

- internal thermal insulation and external insulation of facades;

- insulation of basements and foundations;

- roof erection;

- insulation of loggias and balconies;

- arrangement of terraces, verandas;

- arrangement of refrigerating chambers;

- isolation of septic tanks and pools;

- thermal insulation of soil in road construction, including railway;

- arrangement of gas pipelines and oil pipelines;

- any construction work in permafrost regions;

- thermal insulation equipment for airports and runways.

Foamed polystyrene insulating plates are irreplaceable when installing a warm floor system. It should be noted that the smooth and rough surface of the slabs provides excellent adhesion to finishing materials.

Insulation of a balcony or loggia ↑

In this case, we give preference to penoplex. With the use of these heaters of a small repair and construction building, a typical insulation of loggias of several houses of the microdistrict was made by order. In the course of the work, the builders, having worked with both materials, gave preference to penoplex. The latter seemed to them, in particular, more profitable than its counterpart in terms of saving the internal space of the room to be insulated - the thickness of the layer for optimal thermal insulation turned out to be somewhat thinner. As for such compact premises as a balcony or loggia, where almost every centimeter is saved, this turned out to be critical.

What is the difference between materials

- Some differences in the operational properties of Penoplex and Technoplex are due to slightly different production technology, different methods of cooling the extruded material. According to the manufacturer Technonikol, Technoplex is produced without the use of freon mixtures.

- The addition of various additives to enhance the properties of the insulation boards. Technoplex is distinguished by the presence of graphite nanoparticles in its composition, which increase the overall strength of the material.

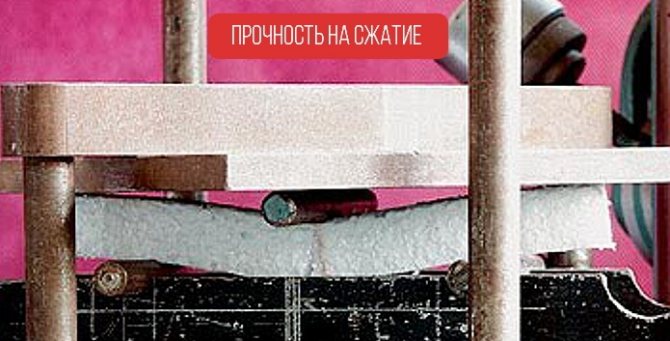

- The mechanical bending strength of Penoplex can reach 0.7 Pa versus an average value of 0.3 Pa for Technoplex. It should be borne in mind that these are serious values, both materials perfectly withstand the normal load.

- The declared operating temperature of Penoplex starts from -70 ° C, Technonikol guarantees the preservation of the properties of its product at a temperature of -50 ° C. The difference, of course, is significant, but irrelevant for central Russia.

- There is a slight difference in the price of these products, but it is not absolute and depends mainly on the region and the manufacturing plant.

Any capital construction at a certain stage needs insulation. The modern assortment is replete with materials of varying degrees of thermal conductivity and cost ranges. To choose the option you need, you should familiarize yourself with their fundamental qualities. The favorites in the thermal insulation market are heaters based on expanded polystyrene - an environmentally friendly non-combustible polymer. The most popular of them today are Technoplex and Penoplex.

The difference between brands is small, which can significantly complicate the choice in favor of one or the other. However, some differences in characteristics will help you to choose the right thermal insulation correctly.

Features and characteristics

Thermal insulation Penoplex is a board made of extruded polystyrene foam. A narrow-profile company that produces the material specializes specifically in the manufacture of synthetic insulation for various applications: roofing, foundations, walls and interior work. Penoplex 45, for example, is supplied only to industrial construction sites and is used as thermal insulation for loaded structures, railways and roads, and airport runways.

The presented series products have reliable durability, resistance to biological influences, low thermal conductivity and zero water absorption. Considering the manufacturer's description, such thermal insulation does not burn, it is made of environmentally friendly components without the addition of phenol-formaldehyde resins. Thus, it provides a healthy indoor climate, and a guaranteed service life of 50 years.

Insulation Technoplex is produced by a wide-profile company Technonikol, whose product range includes roofing materials, construction chemicals, special equipment and much more. Extruded insulation has proven itself well mainly for interior work - insulation of partitions, balconies, floors. It is even used in the installation of underfloor heating systems.

During the production of Technoplex, nanosized particles of graphite are added to the same expanded polystyrene, which in turn provides a decrease in thermal conductivity. Hence, according to the manufacturer, there is a stability of the Technoplex characteristics throughout the entire service life, a reduced level of water absorption and vapor permeability. Inert to moisture, bio-resistant, practically non-shrinking polymer material is afraid of gasoline solvents and bitumen glue. Well suited for plastering applications.

Comparison of basic parameters and prices

To choose the necessary thermal insulation, it is worthwhile to correctly navigate the purpose of this or that material, based on its composition and characteristics. For clarity, comparative technical characteristics of polystyrene foam heaters are shown in the table below.

| Specifications | Technoplex | Penoplex |

| Length, m | 1.18 and 1.20 | 1.20 and 2.4 |

| Width, m | 0.58 and 0.6 | 0,6 |

| Thickness, m | 0,02-0,1 | 0,02-0,1 |

| Compressive strength, kPa | 150-250 | 200-500 |

| Thermal conductivity, W / mK | 0,032 | 0,030 |

| Density, kg / m3 | 26-35 | 25-47 |

| Temperature range, ° C | from -70 to +75 | from -50 to +75 |

| Water absorption, no more,% | 0,2 | 0,4 |

| Thermal conductivity at (25 ± 5) ° C, W / (m * K) | 0,032 | 0,030 |

| Water vapor permeability, mg / m * hour * Pa | 0,018-0,02 | 0,02 |

A review of indicators indicates the similarity of heaters of this class. As for the difference between them, it indicates the immediate place of application.

Both heat insulators have a number of common properties:

- the thermal conductivity coefficient is better in comparison with stone wool or foam;

- lightweight and do not require special qualifications for installation work;

- are not afraid of attacks by rodents, insects, fungi or other biological agents;

- destroyed by solvents and bitumen glue;

- roughly equal price range.

The level of strength of materials, according to experts, is approximately the same. But, unlike Penoplex, due to the presence of nanoparticles in the composition, Technoplex is considered more resistant to mechanical stress. However, as practical studies show, with strong static bending, the strength coefficient of Penoplex is 0.4 - 0.7 MPa, and Technoplex is 0.3 MPa. Hence the conclusion: the resistance to high loads of the first is much better than that of the second insulation.

Another difference is the operating temperature range. For Penoplex, it is -50 - + 75 ° C, and for Technonikol, respectively, -70 - + 75 ° C. It is worth noting that in our latitude there are no values of -70 Celsius, so this difference is insignificant.

You can buy thermal insulation materials of both brands at the prices indicated in the following table:

For each specific case, the fundamental requirements for thermal insulation are pushing to choose Technoplex from Technonikol or Penoplex. The solution is based on the field of application and personal preference of the customers. So, if Technoplex is better to acquire for private construction, then Penoplex has a wider range of uses. Depending on the marking, it is equally well suited for industrial buildings and for road works.

Today, a large number of different heaters are presented on the building materials market. They differ in performance, cost and scope. Insulation materials can also be made from natural and artificial components. Both groups of materials are popular.

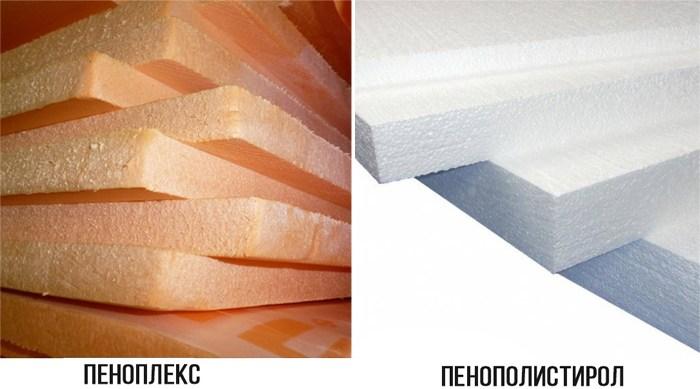

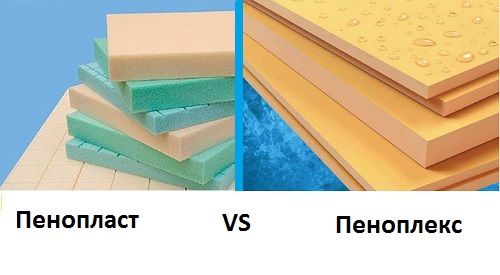

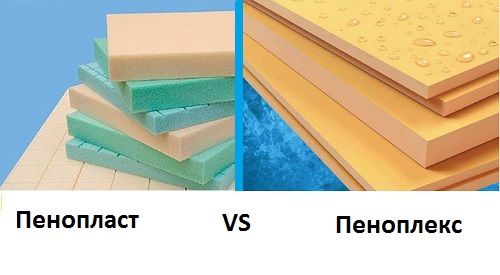

Many buyers are interested in what is better - polystyrene or penoplex? They belong to the category of fully synthetic substances. These materials and their differences will be discussed below.

Considering which is better - polystyrene or penoplex, you should consider the features of each of the heaters presented. They have a lot in common, as they are made from the same material. However, its handling is significantly different.

Both materials presented are lightweight. Heaters of this type do not absorb moisture. Also, artificial materials are not subject to decay, which allows them to be used in almost any weather conditions. These artificial heaters are afraid of exposure to solvents (acetone, gasoline).

It is very simple to use penoplex and polystyrene in construction work. They do not weigh down the structure. Also, the cost of the materials presented remains invariably affordable for all categories of buyers. This makes both heaters presented popular among buyers.

However, penoplex and polystyrene have a number of differences. Some buyers think that these are completely the same materials. However, this is not the case.

Water absorption and thermal conductivity

If you are faced with the question of which is better - penoplex or technoplex, then it is important to pay special attention to the ability to absorb water and heat conductivity. The first material is capable of conducting heat, depending on the variety and external conditions under which the operation takes place. This indicator ranges from 0.028 to 0.031 W / mK.

The opponent has a thermal conductivity in the range of 0.031 W / mK. This indicates that both materials are effective insulation materials. The water absorption of the technoplex is also important, it does not exceed 0.2% by volume during the day. Whereas, if we consider the 35th type of foam, water absorption is 0.1%. If this material is immersed in water for 28 days, then it will increase by only 0.2% by volume. Among other things, this heat insulator retains its original properties after an impressive number of freeze and thaw cycles. After 1000 cycles, the penoplex will change the thermal resistance by only 5%.

Foam creation

In our country, penoplex or polystyrene foam is widely used for insulation. What is better, will help to understand the consideration of their features. Polyfoam appeared before penoplex. It is made from polymeric materials.

To obtain polystyrene, polystyrene granules are first made. They are composed of isoprene and pentane. They are treated with gases, foamed until light balls are obtained. To obtain polystyrene, polystyrene is treated with water vapor. In this case, a chemical reaction occurs. The balls swell and increase in volume. Pentane leaves them.

The polystyrene beads are further processed. To form insulation plates, the balls are subjected to high pressure. They can also be processed at elevated temperatures. This material has balls in its structure. If you look closely, they can be easily seen.

Which is better to choose - polystyrene or penoplex?

Do you want to understand what is the difference between polystyrene and polystyrene foam? Although these materials are similar in their composition, they still have significant differences. After reading this article, you will learn about the manufacturing technology of both materials, their properties, advantages and disadvantages, as well as what are their differences.

The problem of choosing a heat-insulating material arises when the turn has come to insulate the walls. The insulated balcony, walls, even the ceiling and roof are the border that protects us from the effects of cold in the winter, and from the destructive heat in summer. The effectiveness of thermal insulation depends on the materials used in the construction. So that you do not have to "defrost" your summer cottage for a long time, and the heat in the house remains as long as possible, we advise you to insulate the surfaces using foam or polystyrene foam. Both materials are of synthetic origin, safe for human health, and can be used in the construction of industrial and residential buildings.

Penoplex production

There is an official opinion of experts on the question of which insulation is better. Styrofoam or styrofoam? They are very similar. The fact is that they are both made of polystyrene. Penoplex is a newer development of technologists. Thanks to a special production technology, this material has received certain advantages over foam.

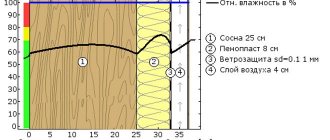

It is also a vapor barrier material. This property leads to moisture accumulation under the surface of the foam. This entails the development of decay processes, the appearance of a fungus. This leads to the establishment of an unfavorable microclimate in the apartment. Therefore, the foam is not recommended to be mounted indoors. They mainly insulate the outer walls.

Styrofoam specifications

You should also consider the technical characteristics of the materials, choosing between foam or foam. What is best for the facade, floor or other objects will help you understand the basic qualities of the materials presented.

Styrofoam is a combustible material. Its thermal conductivity is 0.04 W / m. This indicator is typical for many other types of thermal insulation. The presented material can be used at temperatures from +70 to -40 ºС. Styrofoam is characterized by a compression density of about 8 t / m². The material has a moisture absorption rate of 2.1%.

Polyfoam has a long service life. He reaches 30 years of age. At the same time, foam sheets of various sizes and thicknesses are on sale. This allows it to be used for different conditions. Most often, sheets with a thickness of 10 cm are purchased. The cost of foam is invariably acceptable. A sheet with a thickness of 5 cm and an area of 0.5 m² can be purchased at a price of 40 rubles.

Penoplex properties

For various construction work, foam or foam is used. What is best for floors, walls, façades, and more? The advice of professional installers will help you make a decision.

Penoplex is characterized by special qualities. It features a robust construction. Therefore, it is Penoplex that is used for floor insulation. Moreover, in this case, you do not even need to create an additional frame. The weight of the screed and structures in the room will be evenly distributed over the slabs. They will not be pressed through.

At the same time, penoplex has improved thermal insulation properties. This allows the slabs to be thinner. A sheet of foam plastic with a thickness of 3 cm is identical in terms of insulating qualities to a foam plastic with a thickness of 8 cm. Even in the Far North, plates of extruded polymer thicker than 10 cm are not used. All the positive qualities of foam plastic are not only inherited by this material, but also improved.

Comparative analysis ↑

Externally, penoplex differs little from polystyrene, except for its bright corporate, almost tangerine color

The thermal insulation properties of both materials are undoubtedly high. And in this practice does not disagree with theory.

If you decide to insulate, for example, walls or floors with foam or polystyrene foam, you need to take into account some of the nuances, because when using one or another insulation, there is some difference. Having stopped the choice on one of the heaters, we also use slightly different technology for performing the work... Although in relation to polystyrene (expanded polystyrene) and polystyrene foam, such differences in practice are insignificant and can relate only to very small nuances, they still exist. A few words about this below.

Negative qualities of penoplex

The owners of houses and apartments have a question, what is the best way to insulate the walls - with foam or foam? Both exhibit high thermal insulation properties. Extruded tough polymer has many advantages over foam. Why hasn't the more fragile material been taken out of production yet?

The fact is that the cost of foam remains invariably cheaper. Penoplex costs about 120 rubles. per sheet with an area of 0.6 m² and a thickness of 3 cm. Therefore, cheaper polystyrene is often purchased to insulate walls and ceilings.

In addition, expanded polystyrene has the same vapor permeability. It also causes moisture to build up inside the walls. This leads to the development of decay processes, the formation of a fungus. In this case, other insulation materials are more attractive for installation.

Penoplex technical characteristics

There are several recommendations about the best way to insulate your house. It is quite simple to decorate a facade, ceiling or other objects with polystyrene or polystyrene foam. However, before purchasing this or that material, you need to know its technical characteristics. Penoplex has a lot of advantages over foam.

Extruded insulation has a thermal conductivity of 0.029-0.03 W / m. However, it can be used at lower temperatures. Penoplex can withstand frost down to -50 ºС.

At the same time, the compression density will be much higher than that of the foam. This figure is about 21 t / m².

Also, the material has a lower water absorption rate. It is 0.5%.This indicates a much slower destruction of the material under the influence of moisture. Penoplex service life is 50 years. It is also a combustible material that should not be installed in rooms with increased fire hazard.

Useful and harmful properties

Those who use penoplex or expanded polystyrene for thermal insulation are interested in the question of possible harm to human health. Subject to the production technology, materials become safe. The installation does not require the use of personal protective equipment. If the service life of expanded polystyrene is exceeded, decomposition of the foam may begin with the release of harmful substances, for example, styrene, ammonia, benzene, which can adversely affect others. The real threat is posed by the use of low-quality material. In Moscow and other large cities, there is a large number of heaters offers. In order not to be mistaken, you should carefully study the accompanying documentation, consumer reviews, price compliance.

It is important to note that Styrofoam and Styrofoam are susceptible to fire. As a result of smoldering, heaters emit harmful substances that are dangerous to humans. Manufacturers are working to reduce the flammability level by additional processing and the addition of antiprenes to the composition of materials.

The useful properties of heaters are obvious - a warm house with a comfortable atmosphere inside. Penoplex and polystyrene perfectly retain heat, provide sound insulation. At the same time, working with them is convenient and simple. The processing of materials is simple, even an inexperienced person can cope with the insulation.