Varieties of mineral wool

There are varieties of mineral wool: glass and basalt. The latter is made from rock - gabbro-basalt. During production, carbonates are added to it, which allows you to regulate its acidity.

Basalt wool

A factor such as acidity is of great importance for mineral wool. The more acidic cotton wool is, the less sensitive it is to water.

The type of cotton wool in which the acidity is higher is considered more durable. Synthetic, bituminous or composite clays are added to shape. Glass wool does not require any special explanations, its name speaks for itself.

This is a mineral composition, for the manufacture of which the same components are used as for glass (this can be broken glass).

The two types of cotton wool differ in their properties. Glass wool is usually 15 microns thicker (from 3 microns), but basalt wool is several times longer.

The conclusion suggests itself: glass wool is a more durable material that can withstand more aggressive environmental factors than basalt. Also glass wool does not burn.

Thermal insulation of the roof with mineral wool is difficult when working on roof slopes with a rafter structure. In such cases, it is better to use thick cotton wool. To prevent moisture from accumulating under the roof, you need to use cellulose wool.

Mineral wool cutting video

In the video - cutting the mineral wool with a special tool.

Intensive use of the machine and cutting tool automatically leads to its wear. The processing of glass wool, mineral wool and other abrasive materials has a particularly strong effect on those parts of the tool that come into contact with these materials.

A common problem when cutting mineral wool and glass wool is blade wear under the carbide tooth.

The problem is as old as the world ...

One of the well-known problems in the processing of glass and mineral wool is the rapid wear of tools, especially cutting. This consumable needs to be replaced regularly. For this reason, maintenance costs are high and production interruptions occur frequently. The constant friction with rock wool takes its toll on the main saw blade very quickly. Such abrasion invariably leads to a loss of quality.

In the traditional approach, inserts are applied to the main disc and the area under the insert is abraded. Abrasion causes destruction of the main disc. Due to this destruction, the cutting inserts very quickly deteriorate and break. Even if the inserts are not damaged, they cannot be used in the future.

Disadvantages of the traditional approach

- Rapid wear on the saw blade body

- Fast breakage of carbide teeth

- Regular production stoppages

- Significant maintenance costs

... a modern approach

The modern approach to carbide tooth brazing eliminates all the disadvantages of the traditional method. This technological solution emerged as a result of negotiations with suppliers and manufacturers and was the result of many years of development.

New soldering method

By combining a 2.5-fold widening of the contact surface and a new method of setting a carbide tooth, the wear on the saw blade body is significantly reduced.Tests have shown that the saw blade body and carbide tooth last much longer thanks to the new method.

This new technology has been developed specifically for the processing of insulating materials with saw blades for both low and high density materials. For high density materials, milled saw blades are recommended, while for low density materials it is better to use blades with a solid edge. The new brazing method can be applied to discs of different diameters.

Benefits of new technology

- Consistent and long-term cutting quality

- Longer blade life

- Carbide tooth lasts longer

- Saw blades need to be replaced less frequently, which means less downtime

- Maintenance costs are reduced

Our company offers a wide range of saw blades and circular knives specially designed for cutting mineral wool, glass wool and other insulating materials.

All our discs can be supplied in any diameter and size up to 1100 mm. at the request of the customer. All saw blades and saws are equipped with carbide teeth and hardened blades. We manufacture all types of discs with or without cooling slots.

Cutting insulating materials is challenging and requires top quality saws and blades. We offer the best quality circular knives and saw blades and are constantly working to improve them. We are trying to make our discs as durable as possible and are working on dust reduction when cutting with our discs.

Our company started working in a new direction, namely, a cutting tool for sawing mineral wool, based on basalt fiber, glass wool.

Cutting tools

Mineral insulation has a fibrous structure, the violation of which leads to a decrease in thermal insulation properties. This makes it ineffective to use scissors for heavy fabrics or cardboard, as well as table or office knives for cutting it. Therefore, the answer to the question of how to cut mineral wool correctly, without disturbing its structure, will be useful for novice builders.

What will we cut

On an industrial scale, special machine tools are used to cut mineral insulation. Consider how to cut mineral wool insulation yourself at home.

Often, an assembly knife is used to cut mineral wool. But it has one drawback - a short blade, which is not suitable for working with thick sheets of insulation. In addition, the blade dulls quickly and needs to be replaced.

Sometimes a special hacksaw is used for wood or metal, and craftsmen have found how to cut mineral wool at home - with a kitchen serrated knife for cutting bread.

But still, when choosing how to cut stone, glass or slag wool, it is better to use special tools.

There are always a lot of questions about what and how to cut mineral wool. Especially for those who are going to build housing on their own (for example, frame, which involves assembly on their own). Indeed, in its structure, this material is fibrous, moreover, having a certain thickness. Ordinary table knives or scissors designed for cutting cardboard or thick fabrics will not work at all.

However, before you start cutting the mineral wool, it is important to deliver it correctly to the construction site. Indeed, otherwise, the material, brought to a state of marriage, will not have to be cut, but simply changed to a new one. And this is an additional cost.

Science is simple, but very important. So:

- plates and mats are transported in a horizontal position;

- the truck must have a protective awning;

- transportation is carried out only in packaged form;

- during transportation, loading and unloading operations, it is important not to squeeze the insulation too much;

- unpack the mineral wool immediately before the start of insulation work.

What will we cut

This can be done with different devices, depending on the thickness of the mineral wool.

Thin materials (no more than 50 mm):

- scalloped kitchen bread knife;

- assembly construction knife;

- stationery knife.

Denser and thicker materials:

- special knives with a length of about 300 mm. Often they are offered by manufacturers of insulation materials. This tool has teeth of different sizes for cutting mineral wool of different thicknesses and densities;

- saws with undivided teeth;

- hacksaw for metal;

- cutting machines. Used when cutting complex shapes. However, for self-construction of your own house, that is, for one-time use, it is impractical to purchase such expensive equipment - you will have to adapt to the capabilities of other tools.

How to cut

When cutting mineral wool, it is important to preserve the shape and density of the material, not get injured and do not too expensive purchases. Therefore, it is important to follow these tips:

- for self-construction, when the workers do not have sufficient experience, it is advisable to consult with specialists before starting cutting, especially if the presence of pieces of complex shape is expected. This will help prevent unnecessary consumption of insulation;

- the cutting tool must be well sharpened so that the mineral wool does not break into fibers and less dust;

- when cutting insulation, it should be borne in mind that to ensure a tight overlap of the insulated space with mineral wool, it is necessary to leave allowances of about 2 cm;

- it is better to cut rolled mineral wool before unfolding it;

- mineral wool boards must be removed from the packaging and cut one by one;

- it is not recommended to cut the mineral wool "for future use" - at once for the entire volume of work. This increases the risk of accidental damage to its shape during additional shifting from place to place or folding the pieces on top of each other.

This is really important. As in any business, adherence to simple safety procedures will help maintain health, carry out work at the optimal time and at a high quality level. What you need to pay attention to:

- it is better to cut the insulation in cold weather, since for work it is necessary to wear a protective suit made of dense fabric, which will prevent skin contact with mineral wool fibers and its irritation;

- to protect hands, wear special gloves - with silicone or rubber dusting on the palms;

- special glasses will be needed to protect the eyes;

- respiratory organs will be protected by a respirator.

Such measures must be observed, since when the insulation is cut from under the knives, particles of the material rise into the air. May get in the eyes, respiratory tract, and cause skin irritation.

In addition, it is important to remember:

- when working with this type of insulation, you need to periodically take a break, during which to ventilate the room;

- it is necessary to transfer the cut pieces carefully, without throwing, in order to reduce the amount of fibrous suspension in the air;

- there should be no children on the construction site at this time, even in protective equipment.

As you can see from the above, there is nothing super complicated in cutting mineral wool. Subject to the indicated rules, it will not be difficult to perform the work efficiently and safely.

Mineral wool processing is not very difficult, which allows you to do all the work yourself. You can cut the insulation with several tools:

- Stationery knife. Suitable only for thin sheets of material.

- Hacksaw for metal.With its help, you can process wool with a thickness of more than 50 mm.

- Special knives. Outwardly, they look a lot like fine-toothed saws. But at the same time, they are not divorced to the side and are located in one line.

- Bread knife. In the absence of any other tool, this product also copes well with mineral wool.

It should be noted that all blades must be very sharp. This will minimize fiber pulling from the mat structure. Experts recommend cutting before the roll is unrolled.

If you need to obtain elements of complex shapes, then it is better to use special cutting machines. They can process cotton wool not only in a straight line, but also in a circle. This is very important, especially in industrial production. If this is a one-time task, then the purchase of such a tool will be impractical and it is better to use the material at hand.

Before cutting, it is important to consult with a professional to minimize the cost of the sheets used.

Are there any nuances in transportation and storage?

Manufacturers recommend storing mineral wool in an intact package, and it is better if the pack is on a flat surface. Each stack of packages should not be higher than 2 meters. The optimal storage conditions are closed spaces that are resistant to moisture ingress. It is not recommended to store the insulation on the street, but if this happens, then you need to cover it with a tarpaulin or film.

You need to store cotton wool only in a horizontal position.

When transporting, you should follow the same rules: transport cotton wool horizontally and in a dry truck body. You also need to provide the material with protection from mechanical stress and from atmospheric precipitation. When loading and unloading material, it must not be strongly compressed.

Unpacking mineral insulation also requires certain nuances. The material should be removed from the packaging only before starting work, which will minimize the various risks associated with damage to the insulation. When laying out material for cutting, use its packaging as a bedding. Thus, the product will not get dirty. Also, the packaging can be used to collect other waste at the construction site.

Operational features of basalt wool

Mineral wool has the following advantages:

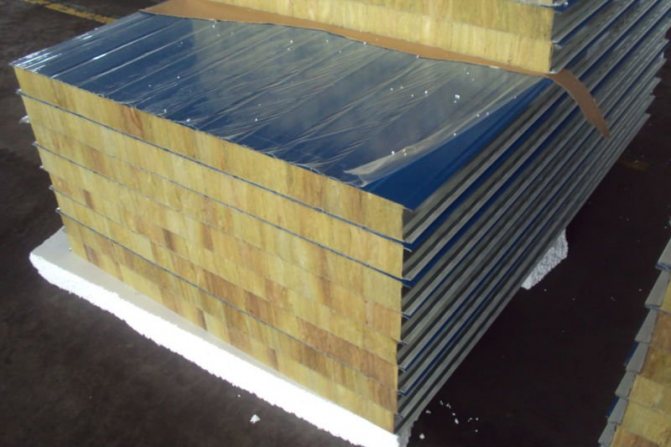

- a wide range of products. Mineral wool is produced in the form of slabs, rolls or mats. Due to this, it is possible to choose the option that is best suited for the thermal insulation of a certain section of the building. Also, the types of mineral wool differ in density: the material in the form of slabs has a high density, and the roll insulation is lighter;

- has high thermal insulation characteristics. Mineral wool has a porous structure. This material is made up of small layers. Due to this, it retains heat well, and also provides excellent sound insulation;

- fire safety of the material. Minvata does not burn and does not spread fire. For this reason, it is often used for thermal insulation of interfloor ceilings. Mineral wool manufacturers claim that this material can withstand temperatures above 900 degrees Celsius;

- mineral wool does not deform, and this is a very important advantage. This material does not shrink, therefore, there is no formation of "cold bridges" that cause heat loss;

- frost resistance. This property allows the use of mineral wool for thermal insulation of the external elements of the building;

- mineral wool is an environmentally friendly material. It is used for thermal insulation of health resorts and medical institutions, as well as children's rooms.

This insulation is produced in various forms - plates, cylinders, mats; you can buy cotton wool covered with foil.

Mineral wool has features that cannot be called positive. These include:

- low strength.This is due to the high porosity of mineral wool;

- to ensure a high level of thermal insulation, this material should be used together with a waterproofing film and a vapor barrier membrane;

- when using mineral wool with fiberglass, it becomes unsafe, since formaldehyde is added to it;

- high hygroscopicity (therefore, high waterproofing is done).

To fasten such insulation, planks are nailed to the inner side of the rafters (they make a lattice), to which cotton wool will be attached. From the outside, the cotton wool is laid in one layer (the layers depend on the thickness of the cotton wool).

After laying the insulation, waterproofing is applied. The important thing in this step is not to confuse the sides of the insulation. The upper layer does not allow moisture to pass through, and the lower one is an obstacle to steam.

The waterproofing is not stretched, there is an air space between it and the cotton wool. There should be some air space in front of the skate, which will create additional traction.

Basalt insulation scheme.

- thermal insulation and hydrophobization. The first parameter ranges from 0.042 to 0.048 W / mK. Other well-known insulation materials (for example, expanded polystyrene, polyurethane foam) have approximately the same characteristics. Minvata is not able to accumulate moisture (hygroscopicity is less than 1%), which makes its weight unchanged. A distinctive feature can be called vapor permeability, which guarantees insulation and, at the same time, intensive moisture exchange between the external environment and the walls of the building;

- density, strength. The insulation has a sufficient density (from 30 to 100 kg / m3), which guarantees high thermal insulation properties with optimal strength. The rigidity of the material is ensured by the direction of the fibers; they are located horizontally and vertically;

- soundproofing. Good noise protection characteristics are achieved due to the porous structure of the cotton wool;

- resistance to aggressive environment. Vata is "indifferent" to alkali, acids; does not rot, is not affected by the fungus. Rodents also bypass this insulation side;

- fire resistance. Basalt wool is able to withstand heating up to 700 ° C. This protects the structure from complete destruction in the event of a fire and gives time for the evacuation of residents;

- health safety. Resins containing harmful substances (formaldehyde, phenol) are used in the production. However, compliance with the technology involves their introduction into the composition of the insulation in a chemically bound state. Substances become completely neutral in relation to the environment and do not pose a danger to humans.

Material characteristics and properties

Mineral wool is produced in the form of slabs and rolls

Before starting construction or repair work, the owner of the premises thinks about what criteria should be used to choose materials. Currently, the assortment of sale is replete with a variety of canvases that differ from each other in raw materials, price, scope, operation characteristics.

The term "mineral wool" means three types of materials, namely:

- basalt (stone);

- slag;

- glass wool.

Glass wool (fiberglass) has a low density and high hygroscopicity. The material does not have moisture resistance properties, and one should not expect heat resistance from it: when a high heating temperature (about 300 degrees) is reached, the wool fibers melt, and the material no longer performs the function of insulation. Glass wool on sale in rolls.

Glass wool is produced by blowing: an industrial centrifuge creates streams of air that go directly into the raw material. Due to the flow of air, fibers appear from the threads, moreover, they can have different lengths, directions and thicknesses.

Mineral wool has low thermal conductivity, allows steam to pass through due to the cells in the structure, and almost does not absorb water. In addition to the base, there are few binding elements in the composition, which allows it to withstand high temperatures. The material is widely used as sound insulation and insulation for various substrates and surfaces. It is produced with canvases that vary in strength.

Slag wool for room insulation

Slag wool is the cheapest option for insulation. The material consists of fibers that are waste of blast furnaces, it is not dense and does not have good heat resistance. If slag wool is overheated, it will sinter. Therefore, the material is not suitable for insulating premises adjacent to heat sources, and is also not recommended for the construction of houses.

The structure of a horizontal layer of any kind of mineral wool is created in the direction of the grain. The formation of vertical sections occurs due to elements that are located chaotically. Each type of material has its own characteristics and external differences.

External wall insulation technology

It is best to use a cutting knife to cut basalt insulation.

- a vapor barrier film is attached to the wall; it should release moisture to the outside under the slabs of mineral wool and not let cold air inside the house;

- further, wooden bars or a metal profile are attached to the wall in a vertical position. Their width should correspond to the thickness of the insulation. The spacing between the posts should be such that the mineral wool is inserted with little effort;

- the insulation is fixed by means of glue and special dowels, if the wall is stone, or by means of nails (self-tapping screws) with large washers, if the surface is wooden. For 1 sq. m you need 5-6 pieces;

- it is recommended to lay a windproof membrane on the fixed basalt wool, the joints of which are glued with adhesive tape;

- to ensure ventilation under the subsequent decorative coating, it is advisable to make a counter-lattice of wooden bars or a metal profile with a height of 10-15 mm over the slabs.

Thermal insulation scheme using basalt wool.

This technology is suitable when facade insulation is required for siding. However, in some cases, for example, in multi-storey buildings, it is required to fix the insulation more rigidly. In this case, it is additionally fixed to the surface with glue, while reinforcement is carried out. This operation strengthens the structure, dampens the thermal expansion of the material, which can contribute to the formation of cracks and increase thermal conductivity.

Reinforcement is carried out on the already installed insulation using special glue and a mesh resistant to alkali. First, glue is applied, on which the mesh is laid, then it is covered with another layer of adhesive. The final decorative finish can be done with facade paint, decorative plaster.

To start insulating the roof with mineral wool, you need to cut (if necessary) it so that it fits in size to the inter-rafter distance.

If cotton wool is used, for example 10 cm, and the thickness of the thermal insulation is more than 10 cm, then another layer of wool is laid already perpendicular to the rafters. There are two ways to strengthen the roof of non-residential premises.

The first is to insulate the floor, and the second to strengthen the roof slopes. The first case does not require any special preparation or special expenses.

There is no need to bypass the rafters, as in the second case. Thus, it is costly to strengthen the roof slopes of non-residential premises. A large amount of cotton wool will be required, which must be strengthened by bypassing the rafters.

To insulate the roof with mineral wool, it is necessary to install steam, hydro and thermal insulation. The pitched part of such a roof is a multi-layer cake.It is mounted both inside and outside the roof.

To create high-quality roof insulation, you must perform the following steps:

- carry out the installation of a vapor barrier layer. It will protect the insulation from moisture saturated air;

- use mineral wool as an insulating material;

- to protect the rafter system and insulation from precipitation, a waterproofing layer should be installed;

- it is necessary to provide a ventilation gap. It is created by installing a counter-lattice;

- at the last stage, the roofing material is laid.

Laying the waterproofing membrane

- When insulating the roof of a building with mineral wool, it is necessary to ensure that it does not block the ventilation hole.

- If a superdiffusion membrane is used during installation work, then the heat insulator should be laid tightly on it. This is necessary in order not to block the ventilation gap.

- If a conventional roofing film is used, then two gaps must be made: at the top and at the bottom.

- When laying mineral wool slabs in rows, make sure that the joints do not coincide with each other.

- In order for the insulation to fit snugly to the surfaces of the rafter legs, it is necessary to choose mineral wool of such a size that its width is slightly larger than the distance between the rafters.

- Mineral wool slabs must fit very tightly together.

- When insulating the roof with mineral wool, it is necessary to install a waterproofing layer. In this case, it is necessary to monitor the quality of the connection of the waterproofing film.

Pitched roof insulation

To insulate the roof with mineral wool, it is necessary to install steam, hydro and thermal insulation. The pitched part of such a roof is a multi-layer cake. It is mounted both inside and outside the roof.

To create high-quality roof insulation, you must perform the following steps:

- carry out the installation of a vapor barrier layer. It will protect the insulation from moisture saturated air;

- use mineral wool as an insulating material;

- to protect the rafter system and insulation from atmospheric precipitation, a waterproofing layer should be installed;

- it is necessary to provide a ventilation gap. It is created by installing a counter-lattice;

- at the last stage, the roofing material is laid.

Laying the waterproofing membrane

- When insulating the roof of a building with mineral wool, it is necessary to ensure that it does not block the ventilation hole.

- If a superdiffusion membrane is used during installation work, then the heat insulator should be laid tightly on it. This is necessary in order not to block the ventilation gap.

- If a conventional roofing film is used, then two gaps must be made: at the top and at the bottom.

- When laying mineral wool slabs in rows, make sure that the joints do not coincide with each other.

- In order for the insulation to fit snugly to the surfaces of the rafter legs, it is necessary to choose mineral wool of such a size that its width is slightly larger than the distance between the rafters.

- Mineral wool slabs must fit very tightly together.

- When insulating the roof with mineral wool, it is necessary to install a waterproofing layer. In this case, it is necessary to monitor the quality of the connection of the waterproofing film.

How to properly transport the insulation?

Mineral wool is one of the best, simplest and most common materials for insulation and sound insulation of walls and ceilings today, and is also known in several other fields of application. In addition, it is easy to mount, that is, you can independently insulate the premises.

Many people do not know how to cut mineral wool correctly without violating its structure, in this material we will consider all the ways to properly cut mineral wool,and we will also advise the tools that are best suited for this.

Mineral wool is usually classified according to the principle of the material from which it is made. Hence it follows that the mineral wool made from different raw materials also differs in structure - fibers, and, accordingly, in the type of cutting. So there are the following types of mineral wool:

- Glass mineral wool. Consists of glass melts.

- Stone mineral wool. It is made most often from various rock melts.

- Slag mineral wool. The starting material is blast furnace slag.

In fact, you should pay attention to the fact that sometimes mineral wool is harmful. This is due to the fact that it contains dust and phenol-formaldehyde resins. Therefore, it is necessary to treat this material selectively, although mineral wool cannot be classified as carcinogens for humans.

Cutting of mineral wool can be carried out both independently at home and using various equipment. The equipment for cutting mineral wool boards can be different. The question is scale. The rock wool cutting machine is suitable for large and large scale enterprises, manufacturers, etc. But a knife for cutting mineral wool will become an indispensable assistant in cutting insulating materials at home.

It is important that the cutting of mineral wool does not damage the fibers, so equipment must be selected carefully. The cut should be straight. At home, cutting rolls of mineral wool (the so-called "50-ki") will be convenient with a cutting knife, but for large ("100-ki") a special hacksaw for heaters will be convenient.

If you do not know how to cut mineral wool at home, we can advise you on excellent tools that are best suited for cutting mineral wool.

So, for cutting mineral wool, a good, sharp stationery knife or a hacksaw for metal is best suited, carefully trim the mineral wool in the right directions, for greater accuracy, you can draw lines with a pencil or cut straight along the ruler. The process of cutting mineral wool is somewhat similar to cutting paralon, only you need to apply a little more effort, pressing a little harder on the tool for cutting mineral wool.

How to cut mineral wool in a roll

To insulate the house with mineral wool, they cut it, cut the material up and down. Each type of cut has its own rules, observing which the work is much easier to do.

Longitudinal cut of material

Mineral wool in rolls is cut unpacked. The roll is placed on a hard, flat surface. The required length is measured with a tape measure. Labels are placed in three places around the packaging circle. The place of the cut, for accuracy, is wrapped with molar tape.

Then they take a saw and cut a roll of mineral wool in a circle. After the cut piece has been separated, remove the packaging film.

Important. Masking tape is wound on a roll from the opposite side of the workpiece so that after cutting the remaining part of the roll does not unwind.

Cross cut material

For cross-cutting, the rock wool roll is unpacked. Make markings on both sides. Then a flat bar is applied: a ruler, a piece of a profile or a bar.

A knife or hacksaw is carried out along the bar. If it did not work to cut off the insulation in one motion, the cut is repeated several times. The material is cut to the end so that it does not have to be torn off, in this case the geometry will be violated. We'll have to equalize the insulation.

Important. When the insulation is cut, they put a board so that the knife does not dull.

Mineral wool brands

Mineral wool is produced in the form of mats and slabs. It is used for thermal insulation of ceilings, partitions, roofs, partitions, as well as interior walls. When working with this material, as a rule, there are no special problems. Mineral wool can be laid not only on a flat, but also on a non-standard surface.

Mineral wool grade p-75

There are the following brands of mineral wool, which differ from each other in their density:

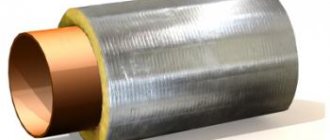

- P-75. Mineral wool of this brand has a density of 75 kg / m3. It is usually used for thermal insulation of horizontal surfaces that are not exposed to serious loads (some types of roofing, attic rooms). Also, cotton wool of this brand is used for insulating oil and gas pipes, as well as pipes for heating plants. Mineral wool of lower density is also produced, but it is used in cases where there is almost no load.

- P-125. This material has a density of 125 kg / m3. It is used for thermal insulation of partitions, ceiling, floor and interior walls of the room. Mineral wool of this brand creates good sound insulation. Therefore, when using it, you can not only insulate the building, but also create good sound insulation.

- PZh-175. It is a dense material with increased rigidity. It is used to insulate floors and walls made of profiled metal or reinforced concrete.

- PPZh-200. Mineral wool of this brand has increased rigidity. Used in the same cases as PZh-175. The difference between PPZh-200 and the previous brand is that it is fireproof.

How to work with mineral wool

To protect against small particles, it is better to work with mineral wool with gloves and a respirator

In the manufacture of glass wool, the same material is used as for the production of glass, as well as waste from the glass industry. If we take into account that limestone, sand, borax, soda and dolomite are used as raw materials for the production of glass wool, then the content of cullet in the structure of the material reaches up to 80%.

When working with glass wool, fragility of fibers is formed in the form of small sharp and small particles that fall on the human body, into the respiratory organs and eyes. Therefore, when working with glass wool, it is imperative to use protective equipment such as a respirator, goggles, heavy gloves, clothing that covers all parts of the body. If, nevertheless, for some reason, you have not saved yourself from adhering to the following rules:

- If dust gets on an open area, the body does not need to itch. Because by doing so, you will drive small particles further into the body.

- Be careful to shake off the glass wool. Moreover, if you are indoors, you need to do this over a dry bathroom, and if outdoors shake off in the direction of the wind.

- Take a cool shower, but never hot, without using a washcloth, soap and various sponges.

- After the shower, you can not dry off with a towel, wait until dry.

- If glass wool gets into your eyes, try rinsing them out with cold water. If all else fails and there is pain in the eyes, see a doctor. In case of a critical condition of the eyes, an ambulance should be called immediately.

- The same goes for the respiratory tract. If you have a persistent cough, difficulty breathing, or other problems after working with glass wool, see your doctor.

- It is best to throw out the clothes in which you worked. No matter how much you shake it out and wash it, particles of glass wool will still remain in it.

Mineral wool knife

Slag wool is produced from waste of blast-furnace slag during iron smelting. If we compare the slag wool with glass wool, then both in the one and in the other there are brittle fibers with the only difference that in the glass wool they have the nature of glass, and in the slag wool the nature of slag. Which ultimately makes the latter no less harmful than the first.

The same applies to stone wool, or as it is also called basalt, because it is made by melting basalt by heating it to 1500 º C. Here, the role of sharp and small fibers falls on solidified basalt threads.Among other things, the composition of slag wool and stone wool contains phenol-formaldehyde resins, which are also very harmful to health. Therefore, all precautions inherent in working with glass wool apply to both stone and slag wool.

All types of mineral wool are used to insulate the facades of buildings, but in no case should this material be used to insulate the walls and ceiling inside the premises.

a) it is most convenient to cut mineral wool with a sharp knife with a long blade; b) it is advisable to work with mineral wool together, because it is easier to handle it carefully; c) cover the cotton wool fixed on the wall with a protective plastic film, and only then fix the lining, MDF panels or something else.

It is important to create a safe working environment

This is really important. As in any business, adherence to simple safety procedures will help maintain health, carry out work at the optimal time and at a high quality level. What you need to pay attention to:

- it is better to cut the insulation in cold weather, since for work it is necessary to wear a protective suit made of dense fabric, which will prevent skin contact with mineral wool fibers and its irritation;

- to protect hands, wear special gloves - with silicone or rubber dusting on the palms;

- special glasses will be needed to protect the eyes;

- respiratory organs will be protected by a respirator.

Such measures must be observed, since when the insulation is cut from under the knives, particles of the material rise into the air. May get in the eyes, respiratory tract, and cause skin irritation.

In addition, it is important to remember:

- when working with this type of insulation, you need to periodically take a break, during which to ventilate the room;

- it is necessary to transfer the cut pieces carefully, without throwing, in order to reduce the amount of fibrous suspension in the air;

- there should be no children on the construction site at this time, even in protective equipment.

As you can see from the above, there is nothing super complicated in cutting mineral wool. Subject to the indicated rules, it will not be difficult to perform the work efficiently and safely.

During the installation process, slabs and rolls very often have to be adjusted to the appropriate dimensions. The absence of minimal gaps between the elements of the supporting frame and the material excludes the possible formation of small areas with increased and undesirable heat transfer. It is worth noting that the builders call these plots nothing more than cold bridges, and they know how to properly cut the insulation in order to avoid such problems.

Insulation cutting methods

- the most picky in this matter are polystyrene foam panels. Using a heated nichrome wire or a fine-toothed hand saw, you can easily and quickly cope with this task, while ensuring a smooth and clean cut. During cutting of expanded polystyrene, there will be practically no dust, and the work does not require special physical effort from workers; more problems will be with mineral fiber heat insulators, which are created on the basis of basalt wool and fiberglass. Despite the fact that modern dust-free technologies are used today, cutting these materials causes the formation of glass dust, which often causes irritation of the mucous membrane of the human eyes, as well as the upper respiratory tract;

- in order to reduce the amount of dust particles, experts recommend using only technically sound and proven tools that have well-sharpened working edges, special cutters and knives; to reduce the amount of dust, the material should be cut along the grain. In each version, the masters strongly recommend the use of personal protective equipment, and all work should be carried out in well-ventilated rooms.Mineral wool is minimally safe, but at the same time all recommendations regarding the use of protective equipment will necessarily remain in force;

- the developers of such materials are well aware of all their products and very often offer consumers proprietary methods of cutting and cutting rigid and flexible insulators. You can always familiarize yourself with the recommendations in the installation instructions attached to each package; - the properties of heaters completely depend on the integrity of their structures. For example, all mineral wool materials based on stone wool are strictly forbidden to deform and compress. In this case, the insulation can always restore its shape and volume, however, the heat preservation of such a site is greatly reduced. Finally, it is worth noting that if you are not confident in your abilities, then you better turn to qualified specialists - they know how to correctly and correctly cut insulation. In this case, you are guaranteed to get quality work, which will undoubtedly please you. And the material itself will serve you for many years.

How to cut mineral wool?

It is advisable to cut stone wool heaters with a special knife with a serrated blade or a hacksaw for metal. The tool used for these purposes must be well sharpened.

This is necessary so that the torn fibers of the insulation are as small as possible. Many manufacturers of thermal insulation materials offer special cutting tools to customers. These are knives, the length of which is approximately 300 millimeters, as well as saws with undivided teeth.

It is important to note that the insulating material must very tightly overlap the space to be insulated. Therefore, it is necessary to leave allowances before cutting.

How to cut

- for self-construction, when the workers do not have sufficient experience, it is advisable to consult with specialists before starting cutting, especially if the presence of pieces of complex shape is expected. This will help prevent unnecessary consumption of insulation;

- the cutting tool must be well sharpened so that the mineral wool does not break into fibers and less dust;

- when cutting insulation, it should be borne in mind that to ensure a tight overlap of the insulated space with mineral wool, it is necessary to leave allowances of about 2 cm;

- it is better to cut rolled mineral wool before unfolding it;

- mineral wool boards must be removed from the packaging and cut one by one;

- it is not recommended to cut the mineral wool "for future use" - at once for the entire volume of work. This increases the risk of accidental damage to its shape during additional shifting from place to place or folding the pieces on top of each other.

Floor insulation

Interfloor and attic floors are made of load-bearing beams or reinforced concrete. In the first case, the heat insulator is placed in the space between the floor beams, and in the second - on the surface of the slabs.

Insulation of the attic floor

First of all, it is necessary to install a vapor barrier. It will protect the insulation from moisture and steam. Before laying the vapor barrier film, it is necessary to study the instructions for its use. If the vapor barrier is installed incorrectly, then it will not fulfill its tasks.

Flat roofs are usually insulated with rigid slabs of mineral wool, the density of which is more than 150 kg / m3. A layer of waterproofing is laid on top of it. It is necessary to lay the slabs very tightly to each other. In this case, the seams should not be located on the same line. The optimum thickness of the mineral wool layer is 25 centimeters.

You can also insulate interfloor and attic floors with sawdust. They are used together with sand, clay, lime and cement. The composition provides good thermal insulation.

Expanded clay is also often used to insulate the attic.This material contains a large number of pores, due to which the function of thermal insulation is provided.

When using these materials, financial costs will be less, and the quality of thermal insulation is not worse than in the case of mineral wool insulation. When choosing a heater, one should take into account the height and area of the building, the materials from which it is built and other parameters.