Home Insulation

Date of publication: 23.10.2015

2

7030

- Comparison with other materials

- How is styling done

- Phased insulation

In order for the house to be warm, it must be properly insulated with special cotton wool or expanded polystyrene. A frame building can be insulated with various materials, but mineral wool is a versatile tool. It has the best qualities, while it is easy to fit with your own hands and has an affordable price.

Thermal insulation of a house with mineral wool

The choice of insulation

A frame house is a lightweight construction, therefore, the material for insulation should not have a high density. In this case, the best option would be a density value not exceeding 500-600 kg / m³. Given this indicator, it is worth opting for three types of thermal insulation materials:

- cellulose wool;

- expanded polystyrene;

- mineral wool - slabs, mats

Consider the peculiarity of each type of insulation.

Cellulose wool

If you plan to build the most ecological house, then this is the best option, because the raw material is 80% cellulose. Ecowool is not susceptible to mold and mildew, it also does not burn and does not emit toxic substances. Another undoubted plus is the invariability of its structure for a long time under any climatic conditions.

Installation is carried out dry and wet. In the first case, pressed briquettes are used - you can fill them yourself. It must be loosened immediately before work. After this operation, the volume of the heat insulator is tripled.

Do-it-yourself installation in the second way is possible only with the use of special equipment and the help of specialists. But in the end, you get a high-quality seamless insulation.

Expanded polystyrene

This material is popular due to three factors - low cost, lightness and ease of installation. The performance indicators of the material are at a sufficient level, but its use threatens to release toxic substances in the living room. It also burns with the formation of a black pungent smoke.

Therefore, if you decide to choose expanded polystyrene for insulation, then you need to give preference to the extruded version. It works over a wider temperature range. Also, extruded polystyrene foam is resistant to combustion, does not emit toxic substances and has a denser structure.

Mineral slab

Mineral insulation is used much more often than the products described above. It is given preference not only because of its low thermal conductivity, but also because of its good soundproofing qualities. When choosing this material, you need to take into account the negative aspects - toxic discharge and fear of moisture.

To solve the first problem, the insulation layer must be completely insulated with polyethylene. This will prevent formaldehyde from entering the air. You also need to prevent moisture from entering the insulation, because the insulating properties of a wet material deteriorate. This requires additional ventilation.

The easy path to comfort

Advertising

If the family has "men with hands" who know how to work with simple tools, the frame house can be assembled on your own in a suburban area. But in order to live in a frame house all year round, without fear of cold weather and heat, its walls will need to be insulated with heat-insulating materials.

Wall insulation in a frame structure can be made with expanded polystyrene, ecowool, a mixture of straw and clay, sawdust concrete, expanded clay and other bulk materials. Basalt fiber slabs are one of the most popular insulation materials for frame houses today.

The reason for its popularity is simple: firstly, this material is non-combustible, which is very important for a wooden house. Secondly, it keeps heat well, while being vapor-permeable, environmentally friendly (completely harmless to humans and animals), and also very durable (manufacturers give a product guarantee for at least 50 years). Another advantage is the ease of working with this insulation. Mineral wool slabs are lightweight, easy to cut, not flowing during processing, do not emit any harmful odors, retain their shape well, do not sag or wrinkle over the years.

Basalt insulation is not susceptible to mold, attacks by rodents and insects, and therefore is well suited for insulating floors along logs, insulating walls and roofs.

Modern thermal insulation based on basalt fiber reduces construction costs, since the installation of lightweight heat-saving slabs does not require strengthening the foundation and supporting structures.

Basalt insulation maintains a comfortable microclimate inside the premises: the air warms up evenly in all rooms, natural ventilation of the air layers occurs. In the summer, the walls, insulated with stone wool, keep the coolness inside the building well, saving residents from the heat; in winter, they keep heat for a long time, saving the cost of heating the home.

Basalt fiber thermal insulation protects the load-bearing envelope from temperature extremes, extending the service life of the building, and also performs a sound-insulating function.

If the listed advantages seem attractive to you, and you want to insulate the walls of a frame house on your own, we recommend that you familiarize yourself with the tips for the use of new generation GreenGuard thermal insulation materials from TechnoNICOL, created on the basis of a biopolymer binder.

Installation rules

You can reliably insulate the wooden walls of a country house by observing the following sequence of layers:

The first layer from the inside - a reinforced vapor barrier film - is designed to protect the insulation from internal moisture. It is rolled out of a roll and fixed with a stapler from the inside of the wooden frame to butyl rubber tape - at the points of contact with the wooden beams. The joints of the vapor barrier are glued with tape.

Note that the vapor barrier of the insulation from the side of the room is a strictly mandatory element of the proposed system. The main task of this layer is to protect the insulation mats from the penetration of moist warm air into the material. Therefore, it is important that the vapor barrier layer is airtight and continuous, without cracks and breaks. Films must be glued to each other; the vapor barrier must fit snugly to the adjacent elements and structures. During installation and during interior decoration, this thin layer should be protected from any mechanical damage, punctures and scratches.

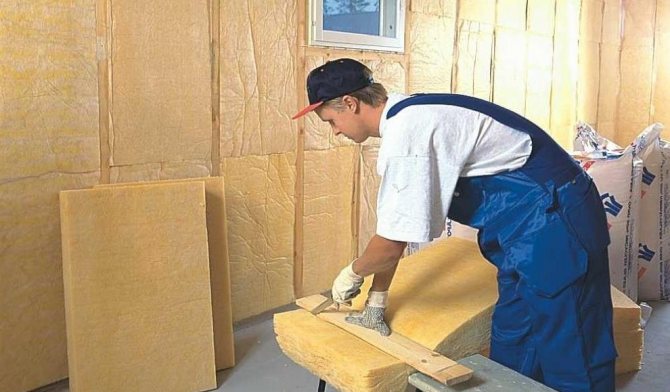

At the second stage, GreenGuard thermal insulation boards are laid, which are tightly fixed between the wooden frame posts (the master makes measurements and cuts the boards to the desired size). The width of the cut material should be 1-2 cm wider than the distance between the frame posts. Due to their elasticity, stone wool slabs stand up well and do not require additional fixation.

For better heat retention, such insulation is usually installed in two layers, with the plates of each new layer shifted relative to each other by half their length (to eliminate cold bridges). The calculation of the thickness of the insulation takes place depending on the region of construction.

To protect against external influences, GreenGuard slabs are covered with a TECHNONICOL hydro-windproof membrane, which is attached to the frame racks with a stapler. The membrane layers at the joints are fixed to each other with adhesive tape.

Before installing the facade cladding material, a counter-lathing is fixed to the working surface, a marker is made according to the level for installing the finishing. At the end, the facade is clad with any decorative panels (siding, block house), the installation of which takes place from the bottom up.

Installation can be carried out both from the inside to the outside and vice versa: first install the outer casing, and then mount the thermal insulation from the side of the room. The latter option is most preferable in the Russian climate - because of the danger of sudden rain. During the installation process, it is recommended to protect the thermal insulation boards from the effects of atmospheric precipitation.

Stone wool slabs should be protected from moisture also during storage. Therefore, it is necessary to store packs of basalt insulation strictly under a canopy, or in covered warehouses. Installation is best done after the outer walls have already been sheathed with a wind-, moisture-proof film and finishing material. In the case of installation from the outside of the building, it is important to work with grippers in order to exclude the possibility of products getting wet during precipitation.

The solution described above from the TechnoNICOL company with an environmentally friendly, fireproof, excellent heat-saving material made of GreenGuard stone wool is easy to implement with your own hands; it is easy to operate and will last for many years without repair.

IMPORTANT! Recommended thicknesses of stone wool slabs for a residential building, depending on the region:

| Construction area | The thickness of the insulation for the wall of the frame house |

| Central region of the Russian Federation, North-West | 200-250 mm |

| Southern region of Russia | 150-200 mm |