Pros and cons of polyurethane foam

Benefits

Judging by the reviews and technical properties of polyurethane foam, there are a number of advantages that this material has for insulation:

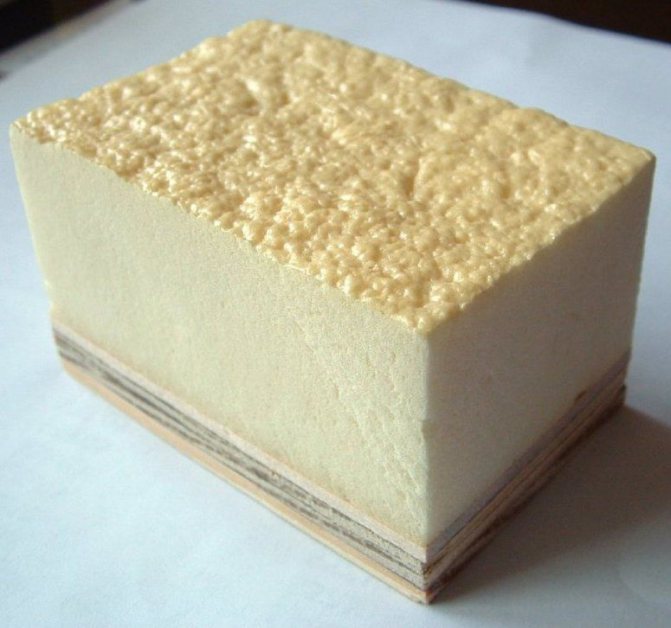

- When processing the surface with polyurethane foam for its insulation, seams and cracks are not formed. As a result, the heat loss coefficient is much lower than that of boards made of extruded polystyrene or other similar material.

- Polyurethane foam for insulation, judging by the reviews of both experts and ordinary owners of buildings with such a treatment, provides excellent sound insulation.

- In most cases, a polyurethane foam layer of 50 mm is sufficient to provide high-quality thermal insulation.

- The transportation of the substance is much cheaper than the slabs. It's all about the compactness of both the installation and the material.

- PPU can be used at temperatures from -150 to +220 degrees Celsius. Therefore, it can be used in construction anywhere in the world. Moreover, scientists are actively using this substance in the creation of aerospace technologies.

- The use of the material allows you to significantly strengthen the roof.

- The high thermal inertness allows the polyurethane foam for insulation to retain heat inside the room, even in the strongest winds. This is evidenced by numerous reviews of home owners from cold regions.

- Polyurethane foam has a low water absorption coefficient. It is not surprising that it is often used to create reliable waterproofing. Due to this property, the substance has found wide application in roofing.

- When applying polyurethane foam, special equipment is used. An important part of it is the gun, with which you can adjust the spraying speed. This greatly speeds up the installation and makes it more economical, at least as the reviews say.

- The substance has high heat resistance and biological neutrality. It is safe both for the environment and for humans, but spraying must be carried out with a mask and goggles. Otherwise, there can be serious consequences. What you can see from the reviews.

- The service life of polyurethane foam for insulation can reach 50 years.

According to reviews and expert opinions, PU foam insulation has many advantages. If we talk about those that gave it a key advantage in the market, it is the speed of installation and ease of transportation.

Separately, it is necessary to talk about the benefits that industrial facilities receive. Take grain storage and vegetable storage, for example. These objects are often attacked by rodents and insects. But the biological properties of polyurethane allow it to be an insurmountable obstacle for the former and for the latter.

disadvantages

Unfortunately, despite the more than outstanding advantages, polyurethane foam insulation has its drawbacks:

- The material is vulnerable to UV rays. Under their action, accelerated destruction of the structure is observed. However, you can find out about this from the reviews.

- It is not recommended to use polyurethane when it is necessary to insulate a roof consisting of a profiled sheet or metal tile. The fact is that due to the lack of a gap, condensation begins to form. As a result, the roof surface is destroyed. But the reviews on this issue are largely contradictory.

- The price of the material itself is not that low. Moreover, for its spraying, you will need to rent or purchase special equipment.

At first glance, the disadvantages of polyurethane foam, which is used for insulation, are much less than advantages. But it's not that simple. Judging by the reviews, most of the disadvantages of this substance are leveled out or quite simply eliminated.

Take, for example, rapid degradability under ultraviolet light. It is enough to take paint and apply it on polyurethane for insulation, so that the life of the substance will last for several decades. Moreover, there are other alternative methods of protection. Suffice it to recall the plaster.

Now about the price. If calculated in cubes, then polyurethane foam for insulation is required much less than the same extruded polystyrene. On average, the savings are about 20 percent. If you think about reducing the cost of transporting and hiring workers, then the level of savings will be even higher.

The fact is that if you use polyurethane foam for insulation, then judging by the reviews with an area of 400 square meters, you can handle it in about 8 hours. If you process it with extruded polystyrene plates, you need at least three days. This is taking into account that about seven workers with the appropriate qualifications will work for you.

That is how much, if you look at the reviews, you need workers to get the job done as soon as possible. In turn, one person can handle the spraying of polyurethane foam for insulation. This is also evidenced by reviews.

Scope of polyurethane

The area of application of polyurethane insulation is widespread and tends to grow. Applications include automotive and construction. Spraying with polyurethane foam is used everywhere for the following types of houses: • panel and panel houses • wood and timber • gas silicate and brick • buildings made of concrete slabs or blocks.

The reason for such a successful application in polyurethane insulation is the excellent adhesion of the material. Therefore, for complex architectural forms and elements, be it arches, projections or columns, the application of the material is carried out without difficulty. This material adheres equally well to vertical and horizontal surfaces, forming a monolithic heat-insulating layer.

Insulation of the roof with polyurethane, repair work on damage to the roof, located at any angle of inclination, will allow insulation to be carried out quickly and with significant savings in material costs. For example, covering and insulating the roof with polyurethane will save about 70 percent of the time compared to the old traditional methods of insulation.

But polyurethane is in great demand for wall insulation.

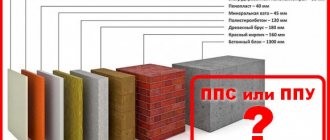

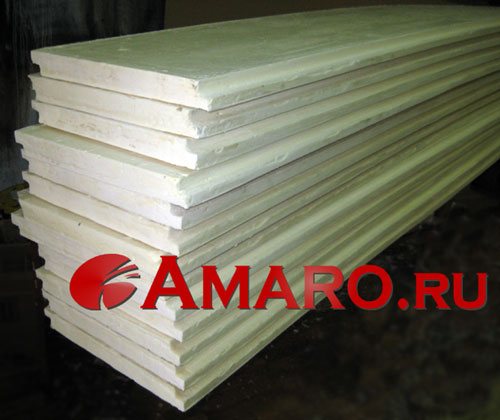

Arrangement of the roof. The thermal insulation of the roof will be even better and more economical if rigid polyurethane foam boards are used. Fastening plates - mechanical or adhesive. If the roof structure is inclined, then the slabs are placed in the rafters.

Wall insulation. For the insulation of the outer walls, rigid polyurethane foam boards are used as an insulating material. Their thickness varies from 50 to 100 millimeters. It is also possible to use the slabs as covering elements on the external masonry under the plaster.

Floor insulation. This material is used for insulation and soundproofing of a concrete floor. Arrangement of underfloor heating is possible (laying of heating systems into the floor structure).

Technical characteristics of polyurethane foam

Insulation of PPU, judging by the reviews, has both its pluses and minuses. Fortunately, all of these can be eliminated if the correct actions are taken. But for this to be possible, it is necessary to understand in detail the technical properties of the material.

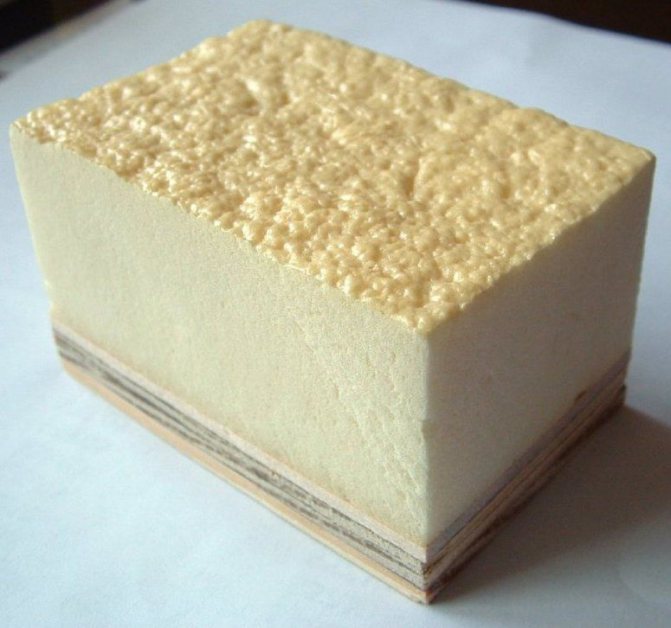

All polyurethane can be roughly divided into hard and soft.For construction work, in most cases, the first is used, judging by the reviews. It is excellent for insulation and at the same time is resistant to mechanical influences of various kinds.

The important technical properties of the material, judging by the reviews, include corrosion resistance. Moreover, polyurethane foam does not allow water to pass through and is able to withstand the influence of an aggressive chemical environment.

It is necessary to learn about the thermal conductivity of polyurethane foam for insulation from specialized literature, and not from reviews. This parameter directly depends on the size of the cells that make up the main structure of the substance.

Attention! The thermal conductivity of polyurethane foam ranges from 0.02 to 0.04 W / m.

This is a good indicator if you need to insulate a room. This is evidenced by numerous reviews. It is enough to look at expanded clay to understand how high the PPU indicators are. The thermal conductivity of expanded clay is about 0.14 W / m. For foam glass, it is even higher. Even mineral wool cannot be compared to polyurethane foam.

The ability to absorb sound depends on several parameters:

- elasticity,

- bandwidth,

- thickness.

Damping properties should be mentioned separately. This information is also confirmed by the reviews of professionals who have been insulating rooms and houses with polyurethane foam for many years.

Advice! You consider PPU semi-elastic type to be the best for noise protection.

Separately, it is necessary to talk about the properties of polyurethane foam, which are manifested in contact with chemicals. Polyurethane foam, if you believe the reviews of experts, cannot destroy even caustic chemical reagents. Moreover, it easily tolerates the influence of gasoline, oil, plasticizers, alcohol and acid.

Another important property of polyurethane foam, based on the reviews, is the protection of metal from corrosion. It is enough to apply polyurethane foam to the metal, and you will receive not only high-quality insulation, but also protect the building from destruction.

An important property of polyurethane foam for insulation, judging by the reviews, is low moisture absorption. The performance of this material is impressive. For a day, the structure will not stretch more than three percent of moisture. This is a good indicator.

Attention! The higher the density of polyurethane foam for insulation, the less its water absorption. However, you can find out about this from the reviews.

disadvantages

When choosing a mattress, one should take into account the existing shortcomings and try to avoid them in order to get the maximum satisfaction from the purchase after:

- Non-compliance with production technologies. It is very important here that the manufacturer observes them, is guided by state standards and technical conditions, otherwise the product will quickly become unusable: it will be deformed and will not be able to properly provide ventilation. Sometimes, to increase the thickness of the mattress, an additional layer of foam rubber is used, this leads to a rapid loss of shape, crushing and the formation of dips in certain places.

- Increased absorption. This is perhaps the main drawback that a polyurethane foam mattress has, the reviews about which are often not true and which, moreover, cannot be corrected. The mattress absorbs liquid, air vapors, even odors. And at home, cleaning will not work, for this you will have to contact service companies.

Classification of mattresses

Polyurethane foam mattresses are classified as follows:

- To size:

- Single (120x200 cm) - the most popular type, filled with high-density polyurethane, a very practical model, ideal for a long stay. Available in a variety of colors.

- One and a half mattress made of polyurethane foam, reviews of which are no less positive (140x200 cm), is similar to the previous sample, it differs only in size.

- Double (160x200 cm) - in this model, the mattress can be of different density on both sides. Or, for a double bed, it is possible to purchase two mattresses measuring 80x200 cm with different characteristics of elasticity and density, suitable for sleeping for people with different complexions.

- Non-standard - made by the manufacturer on an individual order in accordance with the size of the bed.

Difference by species:

- Spring - produced in two models: with bonnel springs (strong, but without orthopedic properties) and with independent springs (silent, orthopedic, but require delicate use). In mattresses of these types, polyurethane foam serves as an upper cover, the main load falls on the springs, on which the degree of comfort of the products depends.

- Springless - equipped with a Euro frame (side border made of more durable polyurethane foam), which keeps the shape of the product.

Technology features

Polyurethane foam is obtained by mixing a polyol and a diisocyanate. Individually, these components are quite toxic, but in the course of a chemical reaction they lose their harmful properties. During the production process, a large volume of carbon dioxide is released, the bubbles of which are enveloped in a thin polyurethane foam shell. The resulting mass is applied to the surface with a special pistol, in the air it foams and hardens.

Polyurethane foam is divided into two main types:

- Lightweight open cell... In terms of its characteristics, it is similar to mineral wool, but it is more expensive. When applying it, it is imperative to use vapor and waterproofing films.

- Closed-cell with different density levels... PPU with low density (up to 32 kg / m 3) is used for internal insulation of walls and ceilings, with medium (up to 40 kg / m 3) - for filling cavities, with high (up to 80 kg / m 3) - for surface treatment, which will be subjected to serious mechanical stress.

The application technology is not difficult, but the process uses components hazardous to health and expensive equipment. Therefore, it is better not to risk it and entrust this task to professionals.