Winter colds always come unexpectedly. It is more pleasant to meet them in a circle of loved ones behind warm walls than under a warm blanket, turning off the heating at night in order to somehow save some money.

Polyurethane foam for wall insulation will quickly cover residential and non-residential buildings. It is sprayed onto surfaces of any inclination with pneumatic devices or pistols. The most popular type of such insulation is foam rubber.

Features of insulation

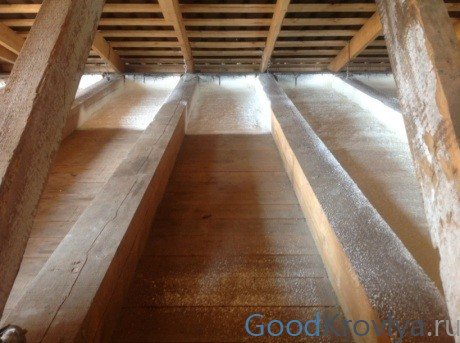

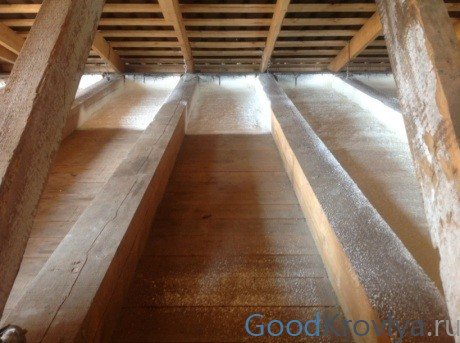

To carry out insulation with liquid polyurethane foam, you need to wear a protective suit. Polyurethane foam is often used as a material. Next, you will spray the foam all over the facade. The material needs to be filled in the void between the rafters, the wall and the beams.

Advantages of wall insulation with foam:

- the ability to increase volume;

- the upper temperature limit is within +80 ° C;

- vapor permeability;

- resistance to mechanical stress;

- refractoriness.

Tip: Residual foam with a polyurethane component can be used to seal the gaps left by reinstalling plastic windows.

To insulate which objects you need to use a pneumatic gun:

- window;

- insulated external walls;

- foundation;

- balconies outside;

- loggias;

- pipes.

The facade after insulation with foam will remain without seams, joints. One cylinder contains 600-700 ml of insulation, it is enough for one square meter for a layer 4-8 cm thick. To start insulating walls with polyurethane foam, you need to insert the cylinder into the gun, pull the trigger, pointing it at the wall. The setting time is 24 hours.

The video shows the insulation of the hangar PPU.

Types of foam insulation

Foam is distinguished by its composition and structure, regardless of the field of application. There are the following varieties:

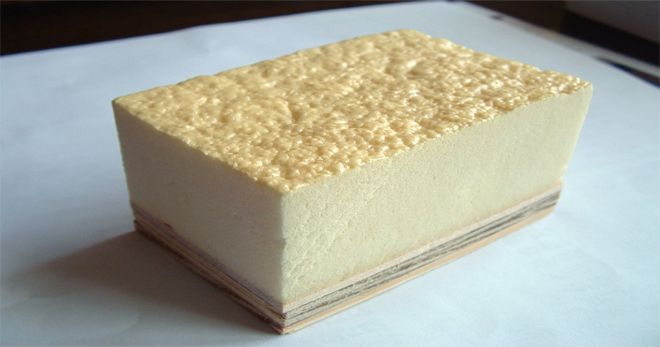

- Penoizol - contains aldehydes, which is potentially hazardous to health, which is denied by manufacturers. Due to its structure, it dries longer than polyurethane - up to three days. It is used for insulating load-bearing structures, walls, attics. Available in liquid form, in the form of finished slabs;

- Foam concrete and ecowool are produced in liquid form for pouring the facade. Practically not used in the decoration of the facade due to the large weight, which gives a strong load on the walls, and the high price;

- Polyurethane foam is inferior to the previous types of foam in relation to the main characteristics. It is intended only for sealing holes, joints and seams, as it cannot pass steam, moisture, which is critical for insulating material. Interaction with air increases the volume twenty times with a minimum amount of air bubbles inside. Produced in small cylinders;

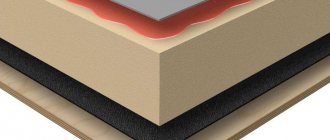

- Polyurethane or PU foam is the most common type of foam due to its versatility. Polyurethane insulation is recognized as the most effective insulation for the facade. Its structure is a polyurethane compound of two components, which are machine-mixed before application. Expansion of foam based on polyurethane occurs 30-40 times from the initial volume, forming small balloons inside. Thanks to this, polyurethane performs well at home insulation.

How to choose from all varieties

The choice of the type of insulation depends on the situation, as well as the area of application, we will consider some common cases in which foam insulation is used:

- You can use polyurethane if you need to repair cracks or other defects on the walls. Do not expose it to direct sunlight.

- To fill a large volume, use Penoizol. In this case, it is necessary to purchase a special high-pressure apparatus, since a conventional cylinder will not be enough for this.

- To seal cracks and insulate a small surface area, select mounting specimens in cylinders. It does not ignite when interacting with fire, does not support combustion, has an ecological composition and hardness after solidification.

Remember! For insulation of the entire building, polyurethane foam is categorically not suitable, since it does not have the appropriate characteristics.

To eliminate defects that were found outwardly, foam, which contains polyurethane, is applied using direct technology, using an apparatus or a special balloon. Errors within the layer that creates the foam insulation require a long hose to push the material through. To fill the air spaces inside the insulation, holes are made in the wall.

The main advantages and disadvantages of the material ↑

Polyurethane foam, despite the demand and prevalence, is characterized not only by its advantages. There are also some negative aspects that can significantly affect the final choice of PPU as a roofing insulation.

Significant advantages of polyurethane foam insulation ↑

If we consider the strengths of this type of heat insulator, then first of all it is worth noting that roof insulation with polyurethane foam offers the following advantages:

- the ability to use in a wide temperature range;

- excellent adhesion performance in contact with a wide variety of substrate materials;

- high tightness of the formed thermal insulation layer, regardless of the geometry of the roof and its complexity;

- minimum parameters of thermal conductivity;

- insignificant mass of the frozen composition;

- excellent resistance to biological influences;

- inertness in relation to influences of a chemical nature;

- good compressive and tensile strength;

- no need to equip an additional layer of vapor barrier;

- minimal moisture absorption;

- excellent characteristics of noise isolation and absorption of external noise;

- service life of about 50 years, provided that there is no mechanical damage.

Absolute tightness of the heat-insulating layer

Weaknesses of using thermal insulation material ↑

As for the shortcomings, in the opinion of users and specialists, the following deserve special attention:

- all work should be carried out in protective uniforms, protecting the eyes and respiratory tract, otherwise there is a high risk of causing significant harm to health;

- the process of insulating the PPU roof itself requires a certain amount of experience and knowledge, in the absence of which it is not always possible to obtain a truly effective and efficient heat-insulating layer;

- despite the incombustibility, when in contact with areas of fire, the material emits a certain amount of smoke - quite harmful to humans;

- the resulting coating is unable to withstand the negative effects of UV rays. That is why it is preferable to carry out work indoors, immediately covering the material as it hardens;

- rather high cost, and here we are talking not so much about the polyurethane foam itself, but about the equipment for spraying it. Household kits save the situation to some extent, but they are disposable and not suitable for permanent use.

External insulation requires immediate protection from ultraviolet radiation

Roof insulation with polyurethane foam is an effective and reliable way to reduce heat loss to a minimum, and sometimes even eliminate them completely.At the same time, it should be recognized that carrying out the procedure on your own is very problematic and requires the use of special equipment. That is why it is worth entrusting the work to professionals - it is beneficial for a number of factors, including from the standpoint of financial savings.

Pros and cons of the warming process

The advantages that you get if you insulate your house with this material:

- Insulation speed, regardless of the surface.

- It is not subject to biological effects, fungus and mold are unlikely to appear on such a wall.

- Hardly flammable material, but it can melt when exposed to temperatures over 80 degrees.

- Does not need to fasten the frame to the facade, membranes, films, steam and waterproofing.

- Forms a monolithic surface without seams, excluding cold bridges.

- When insulating pipes and other metal elements, it creates a dense layer, excluding the penetration of moisture, the appearance of corrosion.

Among the disadvantages that foam insulation creates are:

- Impossibility of constant interaction with water.

- Do not expose to direct sunlight.

- The high cost of the material requires the purchase or rental of special equipment for application before insulating the building.

- An insufficient level of vapor permeability of the insulation requires installation inside artificial ventilation.

- To carry out the warming process, you must wear a respiratory mask with goggles, a canvas suit and gloves that not every owner has, so you will have to buy them too.

Despite the fact that people have been insulating houses with foam for a long time, the perfect ideal means for this has not yet been invented. The owner of a private house, who opted for foam insulation, will not deny its effectiveness. The main thing is to buy materials and equipment for installation, and the process itself will not take much time and effort.

Attention! Be careful, if you do the insulation with your own hands, be sure to use protective equipment. After application, treat your façade with a special coating. It is designed not only to protect the insulation, but also your health.

Procedure for applying polyurethane foam and safety ↑

It is important to insulate the roof with polyurethane foam in compliance with the established sequence of actions, while adhering to the basic safety rules. This is the only way to guarantee the receipt of a high-quality insulation layer without harming the health and well-being of the residents.

Safety at work ↑

When working with a PPU spraying tool, you should adhere to the following rules and recommendations:

- work is carried out without fail in goggles and clothing that completely covers the body;

- in the process of spraying, a respirator should also be used, which will protect the respiratory tract from penetration into the small components of the composition. Its use is especially important when spraying at a height or positioning the sprayer at an angle to the surface to be treated;

- hands should be protected with gloves. As a rule, one pair is included with the equipment, but you should stock up on a few more for a change if necessary.

Substrate must be clean before application

Stages of work and their features ↑

Thermal insulation measures are carried out in the following sequence:

- Starting insulation of a roof or roof with polyurethane foam, first of all, the base is prepared and cleaned of unstable old coating - it can be peeling paint and varnish materials, plaster, etc.

- They arrange a crate made of a steel profile or a wooden bar. The thickness of the structure must correspond to the height of the required thermal insulation layer.

- Stir the working composition to bring it to the desired consistency.

- The first layer of polyurethane foam is applied, making sure that the composition completely closes all the available cracks to obtain the most sealed coating - spraying is carried out from the lowest point to the top, without much rush. Practice shows that an ordinary household spray can cover about 150 sq. foundations in 8 hours.

- If necessary, re-spraying is carried out to achieve the required thickness of the heat-insulating layer (work is performed as the previously applied composition polymerizes).

- After the heat-insulating layer is applied and completely solidified, the protruding excess polyurethane foam is cut off, after which the roof insulation is continued with the finishing of the coating. The options can be very different - lining, panels, plastering and other materials - it all depends not only on the choice of the owner, but also on the purpose for which the attic or attic room will be used in the future.

- In the case of PPU plastering, the base is pre-tightened with a mesh-netting, fixing it by means of guides on the crate. Throw a cement mortar onto the surface and wait for its initial setting. After that, any kind of self-leveling plaster coating is applied - it fits just perfectly on such a basis.

Mesh-netting as an excellent base for plaster