According to experts, about 15% of the heat can go through the roof and attic of a residential building even with basic insulation. If you do not use insulation at all, then the remaining cold bridges in the winter neutralize the effect of the heating systems. At the same time, modern roof structures and roofing provide ample opportunities for improving the energy efficiency of a building. A properly arranged warm roof will not only provide microclimatic comfort, but also extend the service life of the attic materials.

Constructional features of the insulated roof

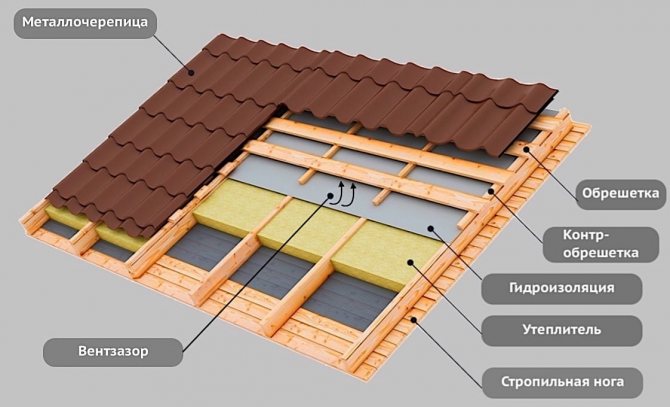

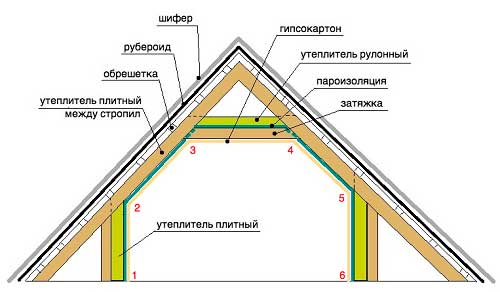

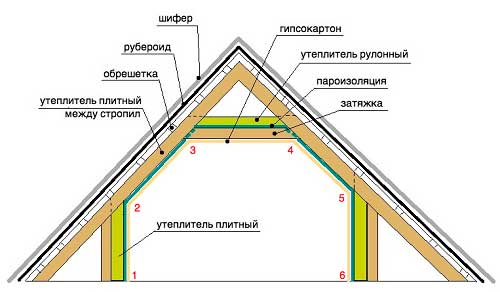

In its pure form, an ordinary pitched roof is a supporting frame formed by beams, Mauerlat, support posts and battens, on which the roof is laid. The configurations of the rafter system may vary, but the most important thing is that even when assembled and in use, they can be insulated. The insulated roof structure is characterized by the presence of several layers of insulation in the transition areas. The lowest level is the floor that separates the attic from the living space. This is followed by the direct insulation of the slopes from the rear sides and in the layer between the crate and the roofing deck. In addition, the construction of a warm roof provides for technological ventilation zones. They can have a different design, but the task of the ventilation gaps is the same - to exclude the accumulation of condensate in the under-roof and attic space.

How to get the right ramp shape for a warm roof

Warm roofing technology is reminiscent of a layer cake.

To get the correct shape (and it is needed for high-quality insulation and appearance), you first need to measure the width, length, height and diagonal of the building. As you measure, you can find out a lot of unpleasant things, because of which it will not be possible to start the roofing immediately.

For example, opposite walls can have significant drops, and the building itself can unexpectedly take the shape of a trapezoid or diamond. All these troubles can arise for various reasons: due to the usual negligence or due to the lack of work of carpenters or masons.

If errors on opposite walls of the masonry, even by 1 cm, will give 1 mm in the seam of the masonry, due to the inconsistency of the workers, this will already give noticeable differences, up to 1 cm per 1 m of the height of the walls. This is in the case of the usual inconsistency of professional workers, and if I work as amateurs, the difference can be much greater.

Wall defects should be eliminated as far as possible to facilitate roof insulation work. In order to achieve strict horizontality of the ridge of the roof and laying the roof slope in the same plane with the horizon, it is necessary to carry out the device of the rafter system.

- The bed for wall rafters and pads for hanging rafters plus the Mauerlat are set at the water level. The bed must necessarily lie horizontally, it does not matter whether it is above or below the Mauerlat. The Mauerlat and pads must also be flush around the entire perimeter of the building.

- The distance between the bed and the Mauerlat must be the same. If necessary, it is adjusted by adjusting the structure.

- Racks are fastened only after installing the bed. They should be initially planned exactly the same, their verticality should not be in doubt.

- After installing the racks, a run is laid on them, which, if the previous steps are performed correctly, should lie horizontally.

- Once you have installed the wind struts, the rafter legs can be installed. The thickness of the insulation layer directly depends on the choice of the thickness of the rafter legs.

The choice of thermal insulation material

The layout of the insulation will largely determine the effectiveness of the thermal barrier, but if the wrong material was initially used, then the highest quality installation will not solve the task of heat saving. Roofers recommend paying attention to the following types of heat insulators:

- Glass wool is a cheap and easy-to-install material with acceptable insulation values. Its strong point will be the complete elimination of biological degradation processes, and its weak point is the loss of insulating qualities after moistening.

- Basalt slab. It is also a moisture-sensitive insulator, but it is fire-resistant, which is also important for the place of operation in question.

- Mineral wool. A variety of designs and durability can be put among the main advantages of this insulation. A warm roof with mineral wool retains its characteristics for 50 years. But this material should be protected from any contact with moisture.

- Styrofoam. Another option for a budget insulation, which has decent insulating properties, but a lot of structural flaws. Use foam only with good mechanical protection.

- Polyurethane foam. Foam insulation with low thermal conductivity. It is difficult to do without it when spot sealing hard-to-reach cracks and gaps.

Roof preparation

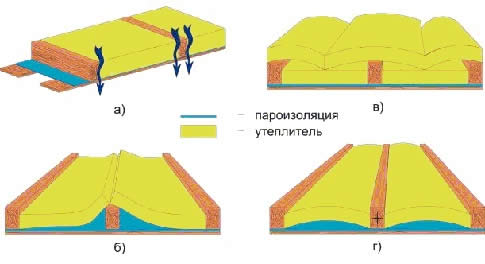

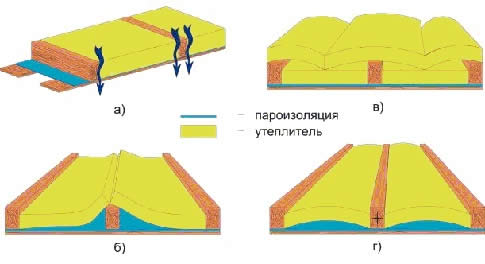

Insulation installation diagram.

When insulating a roof with your own hands, first of all, you need to draw up a work plan and decide on thermal insulation materials. Any roof, regardless of the type of construction, consists of an external and an internal part. The roof from the outside (from the street) is called the roof, and the inside is made up of a frame of rafters and floor slabs. In order for the roof to be warm and to serve for a long time, before starting work, if necessary, it is necessary to carry out repair work, get rid of moisture and all its manifestations on the roof structure: rust, mildew or mold. In this case, the metal parts are cleaned with a metal brush and covered with anti-corrosion agents, and the areas affected by mold or fungus are treated with antiseptic compounds.

Regardless of the type of roof, in the absence of insulation, the loss of heat at home can be 25%

Based on this, it is important to choose a suitable thermal insulation material. To simplify the installation of insulation with your own hands, the width of the slabs should correspond to the distance between the rafters

Otherwise, cold zones will form in the unfilled areas, which will lead to a decrease in the quality of the insulating structure. If you use a roll of insulation (instead of a slab), then you can set any width by cutting the roll with a regular saw on wood. This will be relevant if the distance between the rafters is different. To keep the roof warm, today there is a wide selection of heaters. Each of them has its own pros and cons:

Scheme of a pitched roof with insulation.

- Glass wool is relatively cheap, easy to install, and has good thermal insulation characteristics. It must be used together with waterproofing, as it can lose up to 60% of its thermal insulation properties when wet. It is not a favorable environment for the life of rodents and insects.

- Mineral wool - similar in characteristics to glass wool, but has a long service life (up to 50 years). It is very convenient for do-it-yourself installation, as it is produced in rolls or in the form of plates.

- Basalt slabs - the main advantage of this insulation is its high fire resistance. When wet, it loses its insulating properties, therefore, like other fibrous insulation, it is worth protecting from moisture.

- Polyfoam is one of the cheapest, but no less effective insulation materials. The variety of slab sizes allows it to be used for any roof structure. The disadvantage is the fragility of the plates, so you need to be careful during installation. In this case, the roof can become a habitat for rodents when using foam as insulation.

- Expanded clay - the main advantage is the environmental friendliness and fire resistance of the material. Moreover, it is resistant to biological effects. But the application technology mainly extends to horizontal surfaces (roof slabs, ceiling), which limits its application. It is also heavier than mineral wool.

- Polyurethane foam is a liquid insulation with a rather low thermal conductivity. It is applied by spraying onto the prepared waterproofing layer. Suitable in cases where you need to quickly carry out insulation measures.

Heat insulator installation

Insulation is built into the construction of the slopes from the inside. Typically, the form of roof insulation is a slab or thick roll material such as mats. Laying is carried out on a prepared surface with profile bearing strips. On the beams of the rafter system, a crate of wooden bars is mounted, to which a heat insulator is subsequently fixed. Fastening can be done with mounting brackets, screws or adhesive. This is not fundamentally important, since the slab or mats should be covered with a counter-grill, the strips of which are nailed to the rafters of the warm roof. Insulation is carried out using the method of solid sheathing with full sealing. Slots, technical gaps and joints are sealed with either moisture-resistant sealants or the aforementioned polyurethane foam. For greater structural reliability, it is advisable to continue the outer crate up to the Mauerlat beams, where the walls of the house begin.

Do-it-yourself roof insulation

Roof insulation work does not have to be done with the help of a specialist, everything can be done with your own hands. The whole process should start with the selection of the necessary materials and the creation of a plan and work scheme. Any roof consists of an outer (roof) and an inner (ceiling and rafter frame) parts.

All insulation work is carried out only after checking these components, and, if necessary, they are repaired. Then they remove excess moisture and get rid of dampness and mold.

House roof insulation scheme

To prevent bacterial damage to wooden structures, the inner surface of the roof is treated with an antiseptic, and to protect metal structures from rust, such surfaces are treated with anti-corrosion compounds.

Laying hydro and vapor barrier

A review of heat insulators showed that without reliable protection from moisture, the material will simply get wet and stop performing its main function. Therefore, the next step is to take care of hydro and vapor barrier. For this, membrane film materials are used, which do not require a supporting structure for fastening. In particular, for arranging a warm roof, it is recommended to use Uniflex, Linokrom and Technoelast waterproofers. In some modifications, they also perform the function of a vapor barrier. Laying is done on a surface with a fixed heat insulator by gluing. There are self-adhesive films, but universal building compounds can also be used to fix insulators with a water-repellent effect. Without fail, the film is closed from the outside with strips in increments of 20-30 cm.

Installation options for arrangement

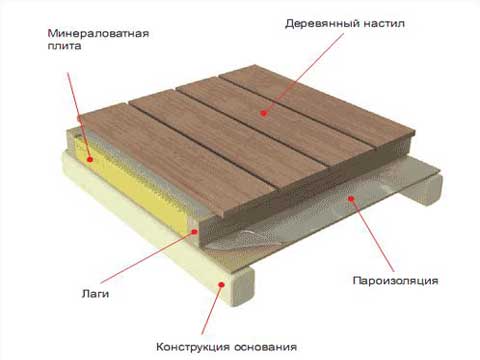

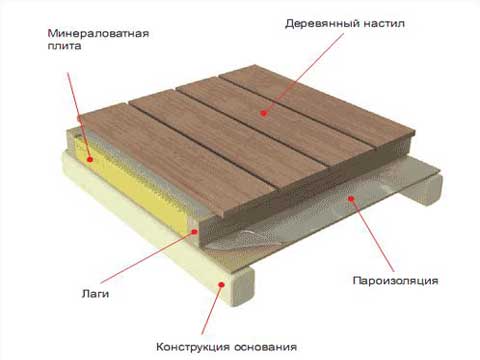

Insulation of an unheated attic

The simplest type of roof insulation device is the thermal insulation of an unheated attic, since the insulation of roof slopes is irrational.The most reasonable thing in this case is to insulate the attic floor. Structurally, it is performed as follows:

- attaching a vapor barrier with an overlap from below to the lags, create an obstacle for the moving steam;

- place insulation between the lags;

- so that one can move along the thermal insulation, either it is covered with a continuous flooring, or "paths" of boards are laid.

The thermal insulation must be constantly dried, therefore, ventilation holes are provided in the gables, and waterproofing is installed under the roofing material to protect against possible leaks.

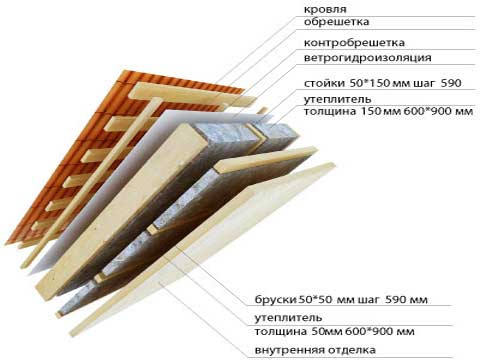

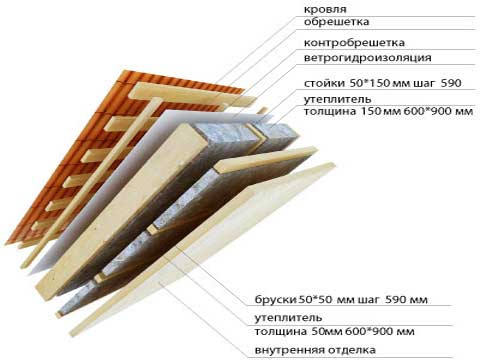

Insulation of a warm pitched roof

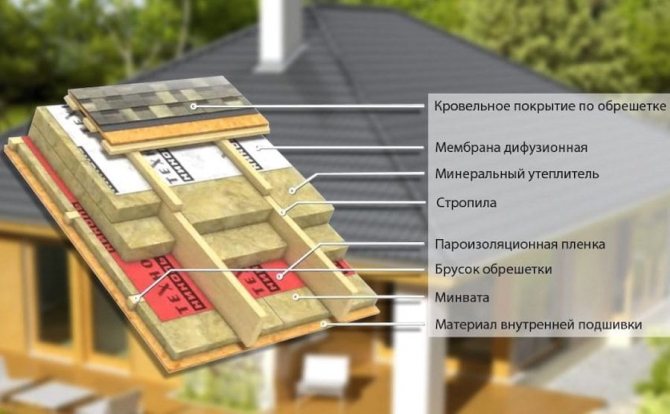

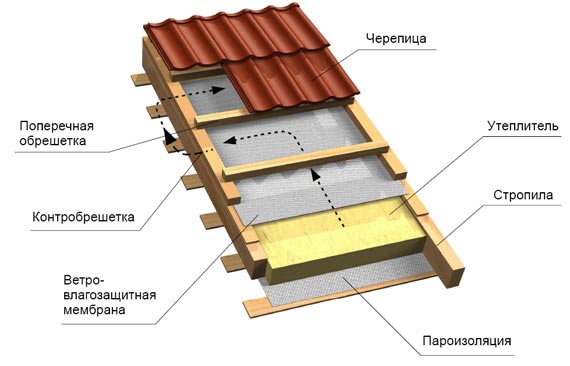

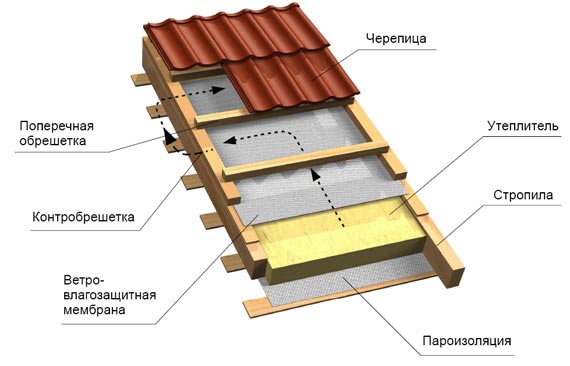

The thermal insulation of the used attic or residential attic is somewhat more complicated. The insulation design, which also includes the thermal insulation of the slopes, is as follows:

Vapor barrier

It is necessary to minimize the penetration of vapors from residential premises into thermal insulation. The vapor barrier film consists of several layers of polyethylene in several layers and a reinforcing mesh made of polyethylene or polypropylene. Fastening is performed either with a stapler or straps.

At the same time, it is important to glue the joints with construction butyl tape.

When installing a vapor barrier, special attention is required for the junction points. They are also glued with butyl tape.

Roof insulation

Insulation of the calculated thickness is filled in the space between the rafters

The calculations take into account the thermal conductivity coefficient and the operating conditions of the pitched roof. Quite often, mineral wool acts as a heater (density - 30-50 kg / cubic meter

m) and staple fiberglass. For additional fastening of fibrous materials, extensions from fishing line or rope are also used. If the height of the rafters is not enough for laying the insulation of the required thickness, it is increased by additionally filling the timber to the rafters.

Insulation waterproofing

The main function of this layer is protective: firstly, from leaks of the roof covering, and secondly, from condensate that forms on some of its types. For waterproofing, apply:

- a hydro-barrier made similarly to a vapor barrier made of PE layers with a reinforcing grid with the difference that additional microperforation and tapered punctures are made on it to remove steam. During installation, a gap of several centimeters is maintained between the thermal insulation and the hydro-barrier.

- superdiffusion membrane, the vapor transmission capacity of which is very high in comparison with a film hydro-barrier. It is laid directly on the heat-insulating layer without any gaps.

Ventilated gap

Above the waterproofing layer, an air gap must be provided for ventilation, by means of which the steam that escapes through the waterproofing from the insulation is removed. The air is placed on the eaves and ridge.

Substructure for roofing

As a rule, for laying the roofing, it is necessary to arrange the lathing - solid or lattice with a certain step.

Creating a ventilated gap

Condensation removal from under the roof space is not only a measure of protection of the heat insulator. The wooden truss system is also sensitive to dampness and if you do not think over the air circulation channels, then in the very first months of operation you can find foci of development of fungus and mold. How to make a warm roof with a ventilation gap? The best option is to use perforated eaves on the overhangs. These are special plastic boxes that are installed along the edges of the slopes, forming a buffer zone with air heat exchange. Thus, effective ventilation of the space from the bottom will be ensured without the risk of rainfall.

Roof insulation: preparatory stage

Types of insulation fastening.

Let's get down to business and figure out how to make the roof warm.The roof is the uppermost structural part of any building; it is designed to protect the structure from all kinds of external influences. The installation of roof insulation is made taking into account the local climate, the structure of the building. The technology of roof insulation does not depend on the material from which the house is built: the roofs of both brick and wooden buildings are insulated using the same technology. If the premises are residential, then it is recommended to make the roof insulated both from the outside and from the inside, and if the building is used as non-residential, then the last point can be skipped.

Before carrying out work on roof insulation, it is necessary to inspect the roof structure and eliminate all faults (if required, replace the damaged areas with new ones). In addition, it is necessary to remove mold on the entire surface of the roof, treat it with an antiseptic or other special agent that would prevent the appearance and spread of mold and mildew. Eliminate all faults in the wiring, plumbing and other communications. Completed? Then it's time to warm up your roof.

Choosing a warm roof

Roof decking can have different heat-saving qualities. The roof in this sense plays a decisive role, but it is far from always possible in principle to use a dense cover with good sealing. For example, bituminous shingles, due to their severity, are contraindicated for installation on weak rafter systems in many private houses. The way out will be a multi-level warm roof - a roof, the upper level of which is formed by several technological layers. The first layer along the slopes can be laid out with a vapor barrier, and then wind and waterproofers will follow. The task of thermal insulation in this part is not the most important, since the already mounted rear skin will be responsible for the regulation of heat flows. In the structure of the roofing system, it is important to provide protection from physical influences, including wind, precipitation, snow, etc.

The choice of material for a cold roof

However, it is impossible to mount a heater close to such a film. The fact is that when it comes into contact with the insulation, the film loses its insulating properties and the insulation actually gets wet. So, if in the future it is planned to equip or insulate the attic or attic, it is better to use a waterproofing membrane.

When installing a cold roof, you can use all traditional materials as a covering, for which a solid base is not required. However, the optimal solution, according to experts, is a profiled sheet or metal tile, which are technologically advanced, durable and reliable roofing materials.

Steel profiled sheet

The simplest solution for a cold roof in the case of a non-residential building is to use a steel profiled sheet with an anti-condensation coating. This material, which has the structure of synthetic felt, is applied to the reverse side of the profiled sheet directly during the manufacturing process.

Between the interwoven fibers of synthetic felt, there are many tiny air cavities, due to which the coating accumulates and retains a certain amount of moisture (up to 1 l / m2). As the air temperature rises, it begins to vigorously evaporate. At the same time, there is virtually no need to install a counter-lattice or lay a waterproofing film.

The installation of a roof made of a profiled sheet with an anti-condensation coating is carried out in the same way as the installation of a conventional flooring. For installation work, neither specialized tools nor additional accessories are needed. This material achieves a 30% cost savings on the estimated cost.

The anti-condensation coating reduces the noise of wind, hail and rain, prevents the formation of mold and mildew, and is easily cleaned from dirt under pressure with water.

2019 stylekrov.ru

Floor insulation

The main barrier to the outdoor cold from the upper part of the house is the floor that separates the attic from the lower rooms. In this area, there are many more opportunities for insulation. They should be used to their maximum benefit. A layer of expanded clay or sawdust can be poured into the very niche of the warm roof overlap. These are bulk heat insulators, the advantages of which include environmental friendliness and affordable cost. However, expanded clay gives a large weight load, and sawdust is a combustible material and is prone to biological damage. Well, then, already on the surface of the floor, a horizontal crate is mounted, in the cells of which heat-insulating plates are also laid. If the design allows for height, then you can make a double lathing with the location of different insulation fibers in a criss-cross pattern.

How to choose insulation

Thermal insulation of the roof with a "pie" is the same for any roof options

The technology itself, by which the roof insulation will be carried out, depends on various climatic factors of a particular region.

So, the thickness of the material for insulation is calculated based on the lowest temperature in this area. To get the maximum effect, during the device of roof insulation with your own hands, it is recommended to combine materials.

When making a choice of those, it is necessary to take into account such nuances as:

- the climate of the region;

- the thickness of the walls of the structure;

- the level of strength of the roof, as well as its shape and angle of inclination.

To insulate the attic roof, it should be covered with good thermal insulation materials. But in order to create thermal protection for the attic floor, you can already use cheaper bulk options in the form of sawdust or expanded clay. At the same time, it is important to remember that the correct thermal insulation of the roof will help to maintain the reliable state of the structure of the entire building longer.

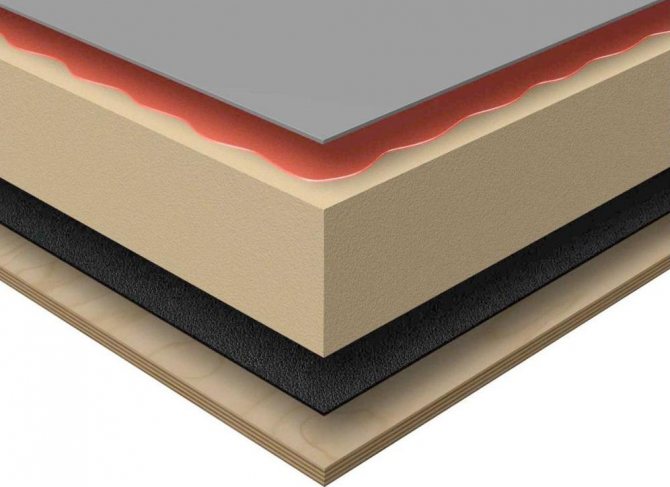

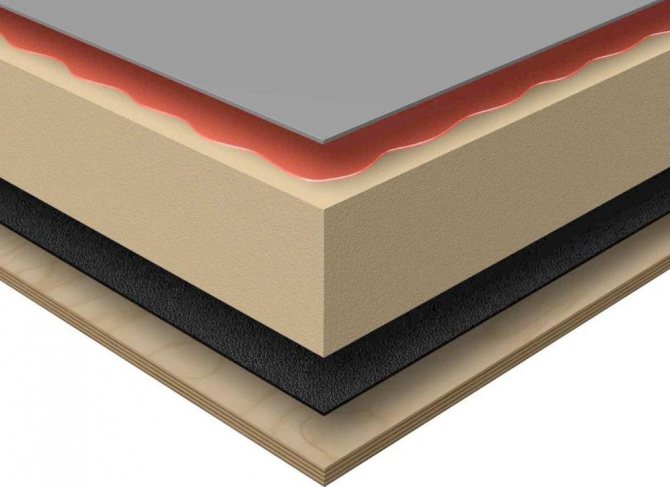

Features of flat roof insulation

In this case, the emphasis is on the use of bulk heat insulators and liquid waterproofing. As for the first, it is not expanded clay with sawdust that should be used, but special lightweight materials like expanded polystyrene crumbs, penoizol or foam glass. But the main feature lies in the structural solution - the creation of a special hatch under the roof covering in the form of a niche 15-20 cm thick. This space is completely filled up with an insulator. Outside, the flat, warm roof structure is covered with molten bitumen using a gas burner. A completely sealed roof deck is formed, which will provide hydro and vapor barrier.

Necessary materials for work

For work on the insulation of a pitched roof, you will need:

- screws and nails;

- wooden slats;

- vapor barrier membrane;

- impregnation for wood;

- waterproofing;

- finishing material.

For work with a flat roof you need:

- vapor barrier;

- waterproofing;

- drainage layer material;

- cement;

- sand.

The last three points are optional if the further operation of the roof is not envisaged.

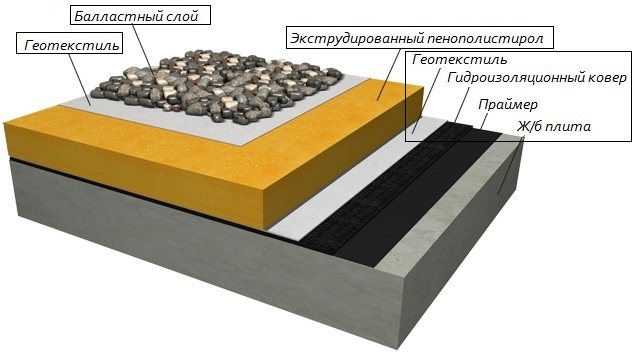

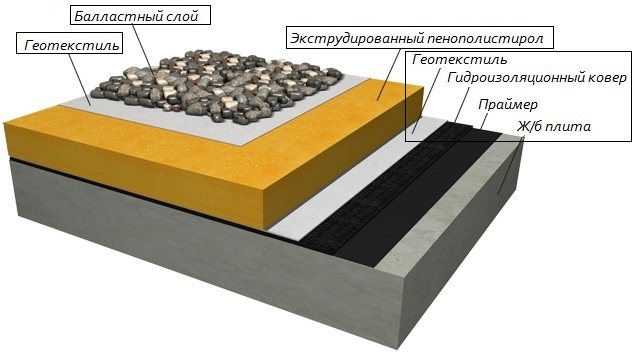

How and what to insulate a flat roof

Thermal insulation of a flat roof follows a slightly different scheme. The beginning of work is the definition of the purpose of the premises. The alleged use of the attic as a gym or some other place for entertainment suggests that the roof must be really strong in order to withstand serious loads.

- To form a slight slope of the roof, a cement screed is made on a reinforced concrete slab;

- Then, as in the case of a pitched roof, a waterproofing layer is laid;

- Upon completion of these works, everything is covered from above with a layer of heat-insulating material (foam plastic, stone wool, extruded polystyrene foam, etc.), on top of which a layer of fiberglass or geotextile is laid.

- And the final stage is backfilling of pebbles or a layer of gravel and the subsequent laying of floor or paving slabs.

Flat roof insulation scheme

If there is no living space under the roof, then the vapor barrier layer and insulation are placed in the attic, and the waterproofing layer is placed under the roofing material. And in the case of complete non-use of the attic flat roof, insulation is carried out either from the inside or from the outside.

Insulation materials

Modern manufacturers offer a wide range of materials for roof insulation. The most popular are:

- Mineral wool (fiberglass, stone slabs);

- Extruded polystyrene foam;

- Polyurethane foam.

The material to dwell on determines the characteristics of the roof. For example, pitched roofs are preferable to insulate with fiberglass.

Fiberglass

This material has excellent heat-insulating and sound-insulating properties. Also, fiberglass is durable, the term of use reaches fifty years, it is fire resistant and vapor permeable. And, of course, the price, the purchase of such material is quite an inexpensive pleasure.

Mineral wool

Depending on the original type of material (stone or glass), mineral wool is divided into two types:

Stone wool - the fibrous structure of the material formed by melting fine particles of rock, as well as various slags and mixtures obtained in industrial metallurgy, make the product truly unique.

The material is not afraid of high temperatures, and is also sufficiently resistant to aggressive chemicals.

Glass wool - a heat-insulating material with air fibers, which are especially durable. The product is obtained by melting ordinary glass. Like stone wool, the insulation is highly resistant to chemical products and does not burn.

The thermal conductivity of glass wool is 0.05 W / m ° C at 25 ° C. During operation, glass wool practically does not shrink, and its fibrous structure, even after a long period of time, remains the same elastic and elastic.

Mineral wool has excellent characteristics in the following indicators:

- Low thermal conductivity;

- Excellent sound insulation;

- Fire resistance, which is very important for the roof material;

- High environmental friendliness and durability.

Styrofoam and penoplex

Both heaters have a fairly low specific gravity, so their use does not make the roof heavier, and also does not provide for the additional use of material that insulates against steam, since neither foam nor foam does not absorb moisture.

Polyurethane foam

One of the modern materials is polyurethane foam.

It does not need to be glued or nailed to the surface, it is applied by spraying onto it. This material has excellent adhesion to surfaces and the result is a durable, seamless construction that is neither cold nor moisture permeable.

Ceiling insulation in a house with a cold roof

When the materials are selected, you can go directly to the process of laying the material. The peculiarity of this process depends on the roof structure and the future use of the attic.

If the use of the attic as a living space is not provided, then the insulating material is laid on the floor of the attic between the logs, and not between the roof rafters. A membrane is laid on top to improve vapor permeability, then it can be covered with any floor covering.

To exclude the formation of the appearance of "cold bridges", the insulation should adhere to the logs as tightly as possible. To do this, when cutting insulation, its size must be done on 1-2 cm... wider than the distance between the lags.

Insulation of the attic from the inside

If a decision is made to equip the attic for a living space, you should insulate the roof with your own hands using a different technology:

- Initially, a waterproofing layer is laid to protect the insulating material from getting wet. To do this, the waterproofing membrane is laid on top of the lathing and fixed with counter-lattice bars;

- Then the insulation itself is laid between the rafters. In order to avoid the formation of gaps, during installation, you should adhere to the same technology as when insulating the ceiling - the insulation should be wider by 1-2 cm.

- As a vapor-permeable layer, a vapor barrier film is attached over the insulation, at the joints, it is laid with an overlap;

- The film is fixed on top with bars, which will serve as the basis for the finishing.

Insulated attic floor