Waterproofing of pipelines is a necessary measure that is performed to protect the pipeline from moisture. Today, there are communications that are different in material and purpose, and in order to increase their operational life, it is necessary to organize a suitable waterproofer. The choice of a waterproofing composite depends on many factors: pipe material, area of use, environmental characteristics, etc.

Waterproofing of pipes and pipeline joints is a mandatory measure to protect networks from moisture

Types of waterproofing materials for pipes

To organize waterproofing of various communications, many options for waterproofing are used. Let's consider the most popular ones:

- polyvinyl chloride (PVC) tape;

- heat shrink tape;

- rubber cloth;

- gluing waterproofing Izol;

- polyurethane foam (PPU);

- heat-shrinkable couplings.

All of the above materials are distinguished by high technical characteristics, the main of which is water resistance. DWaterproofing of various pipes is necessary in order to protect the pipeline from the harmful effects of corrosion, as well as to extend the operational life of the system as a whole.

Polyvinyl chloride (PVC) tape

Polyvinyl chloride (PVC) tape is very popular when organizing waterproofing of various communications. It has excellent characteristics and is mainly used to protect the outer surface of pipes from the harmful effects of corrosion.

Note! The most popular tape is made of polyvinyl chloride for the protection of gas and oil pipelines, which are trunk lines.

Most pipes can be waterproofed with PVC tape

In addition, nowadays, polyvinyl chloride tape is used in the repair of heat pipes, namely, during the replacement of an old waterproofer with communications transporting hot water or gas. In some cases, PVC tape is used for waterproofing utility lines.

One side of the PVC tape is supplied at the production stage with a special adhesive composition, which makes it possible to carry out its installation as conveniently as possible. Before using this tape, it is recommended to carefully check it for cracks and other defects.

Such waterproofing is stored, transported and sold in special rolls that are wound on spools. To protect against moisture, such coils are wrapped in polyethylene.

Chimney and adjoining roof waterproofing

Insulation of the chimney from moisture is necessary if it is made of galvanized steel, which is easy to corrode, or if it is insulated with basalt wool, in order to prevent condensation from forming in it under the influence of temperature differences.

In the second case, the pipe is wrapped by analogy with a water supply or heating pipe (a more attractive outwardly foil material is usually used as a winding).

If it is necessary to insulate a non-insulated galvanized pipe, traditional winding and coating materials will not work here, since they do not withstand the high temperatures to which the chimney is exposed.

There are special heat-resistant paints specifically for such cases. Using a roller or a brush, the surface of the pipe is covered with 2-3 layers of heat-resistant paint and make sure that the paint does not peel off over time.

The scheme of waterproofing the passage of a brick chimney

Heat shrinkable tape

Such a tape is used when it is necessary to protect the welded joint. The place of the weld joint is the most vulnerable to destructive corrosive effects, therefore, the use of heat-shrinkable waterproofing tape is a necessity. However, in some cases it is used to protect the surface of the entire communication, but such cases are extremely rare.

Heat shrinkable tape is used to protect welded joints

It is important to remember that it is strictly forbidden to use such a tape for installation on a pipeline if the operating temperature exceeds 60 ° C. Heat-shrinkable tape provides reliable protection of welded joints and consists of two layers:

- hot melt layer;

- layer, which is a polyethylene film (PE film is the base).

In combination with this tape, you can also use a special fixing agent - a primer. In this case, such waterproofing is allowed to be used even for pipes that have a coating consisting of three layers.

Let's consider the main advantages of using a heat-shrinkable waterproofing tape:

- high elasticity, allowing you to mount such a tape on a pipe with virtually no restrictions;

- the material of the tape is highly fire-resistant;

- Heat-shrinkable tape does not allow moisture to pass through.

Before installing such a tape on a pipe, be sure to warm up the pipe to a temperature of 80–100 ° C. To date, there are quite a few varieties of such a tape and you can purchase it without much difficulty.

This tape has little resistance to UV rays, so it must be stored in a dark place. Otherwise, it will lose its properties and be useless. For waterproofing one welded joint of the pipeline, an amount of tape equal to 3.5 indicators of the pipe section is required.

Preheated pipe is wrapped with polyethylene tape

Heat shrinkable materials

Heat shrinkable tape

This tape is used to protect pipe joints from moisture, which are obtained as a result of welding. In some cases, it is used to repair pipes made of polyethylene. It is undesirable to use this material to protect pipelines from moisture, which have a high surface temperature.

Heat-shrinkable tape is used to protect pipe joints from moisture.

The heat-shrinkable tape consists of two layers: a base material in the form of a polyethylene film and a hot-melt sublayer. Its purpose is to increase the adhesion between the material and the pipe.

Advantages of heat-shrinkable tape:

- environmental friendliness;

- resistance to high temperatures;

- moisture resistance;

- the material is not flammable.

However, the material has a low resistance to sunlight, therefore, during storage, the tape should be removed in a dark place; it should not be kept outdoors.

Heat-shrinkable polyethylene couplings

These couplings are made of radiation-crosslinked polyethylene. Today, such an element is one of the most effective ways to protect pipe joints through which hot water flows. Therefore, when laying such pipelines, as a rule, polyethylene couplings are used.

Advantages of polyethylene heat-shrinkable sleeves:

- high level of reliability;

- excellent tightness of joints;

- easy and simple installation;

- resistance to high temperatures;

- resistance to various influences of aggressive environmental media;

- long service life.

Which option is better to choose depends on the pipe material and operating conditions.But waterproofing pipes significantly increases the service life of structures and networks, and also reduces the risk of breakages and leaks.

Rubber cloth

Waterproofing pipes in the ground provides protection from moisture and groundwater for steel pipes and other underground materials. Such insulation is usually carried out by means of a special rubber sheet.

Such a sheet provides reliable protection of the pipeline structure mounted underground from destructive corrosive effects, and also effectively insulates the joints between pipes.

Typically, rubber sheets are used to waterproof oil pipelines. In addition to the main function - isolation from groundwater, the rubber sheet is used to protect gas and oil pipelines, brick and reinforced concrete pipelines that transport wastewater.

Note! For the waterproofing of utility lines, such an insulator is practically not used. This is due to the fact that its transportation is impossible without special equipment.

Consider the main advantages of this waterproofer:

- the main advantage of this waterproofer is resistance to temperature extremes;

- the rubber sheet is resistant to corrosion, as well as to aggressive chemical compounds;

- it is resistant to electric fields in the soil;

- has a high strength factor;

- has high elasticity;

- and also has a long service life.

Rubber sheet is the simplest but most reliable material for protecting pipes from moisture

Roof chimney insulation

The chimney in a private house comes out through a hole in the roof. It requires careful protection. Let's figure out how the roof pipe is waterproofed. The gaps are sealed with a waterproof sealant, but the installation of a drainage system and special elements: "apron" and "tie" is still required.

The sealing of the structure is carried out in several stages. First you need to prime the pipe and treat it with bitumen-based mastic. You need to connect a diffuse membrane to it. Now you can proceed to making a wooden box. It is installed between the pipe and the roof (for more details: "How and how to seal the gap between the pipe and the roof - different options for different materials"). In this case, the gap should be at least 15 cm. All free niches are filled with non-combustible material, for example, mineral wool.

Insulation waterproofing Isol

The glued waterproofing material Izol is resistant to very high temperature indicators. In addition, this material is waterproof and has a high strength factor.

Such material adheres perfectly to the outer wall of the metal pipe and thereby provides high sealing performance. Due to its thermal stability, Izol is widely used as a waterproofing agent for steel pipes transporting hot water and steam.

However, it should be noted that piping waterproofing is weakly resistant to aggressive chemicals, which consist of organic connectors and solvents.... This material is classified into several main types, depending on the components used in its production.

It is stored, transported and sold waterproofing coating in special rolls. In addition to waterproofing metal communications, this material is widely used for waterproofing bridges and other metal structures.

Consider the main advantages of Izol glued waterproofing:

- good adhesion to metal material and concrete products;

- resistance to high temperatures (up to 150 ° C);

- high strength characteristics;

- high waterproofing performance;

- long service life (up to 50 years).

A shell made of polyurethane foam can serve as both moisture protection and thermal insulation

Features of waterproofing underground pipelines

Currently, pipelines, as an integral part of any engineering communications, are widely used in various fields: sewer and ventilation systems, water supply systems, heating, transportation of natural resources, etc.

Various materials are used for their manufacture, depending on the field of operation. Waterproofing of pipelines is necessary in order to extend the life of the pipes and the building or structure in which they are installed.

For a long time, ordinary tow was used to protect culverts from moisture and from leaks. Thanks to modern technologies, the highest quality and most user-friendly materials have been developed.

Waterproofing pipelines in the ground

Excavation work on the construction of foundations during the construction of water supply and sewerage pipelines must be carried out in accordance with the requirements. When constructing new pipelines, expanding and reconstructing existing water supply and sewerage facilities in residential and industrial buildings, the requirements for organizing construction production, safety precautions in construction and other approved rules must be observed.

Sewerage systems for cold and hot water supply, heating, as well as ventilation and air conditioning systems are subject to mandatory treatment with mastic against moisture in the ground. High-quality waterproofing and insulation of sewer pipes significantly prolongs the operation of the system, prevents the development of pathogenic bacteria, protects the walls and ceilings of the building from condensation and smudges.

Materials used for waterproofing pipes in the ground:

PVC tape

Today, PVC tape is used to protect the outer surface of metal pipes from rust and mildew. PVC tape is used for waterproofing pipes in the construction of a pipeline for gas and oil. Also, this material is used to glue pipe sections in the ground when repairing leaks in heating mains. The use of tape is permissible for the installation of threaded connections and joints. It can also be used for shallow installation of joints of household culverts.

The insulating tape is easy to adhere by applying glue to one side. Before use, it must be checked for integrity: any, even minor cracks or bubbles, significantly reduce the waterproofing performance. The insulating tape is easily glued by applying glue to one side.

The material is delivered in rolls, packed in polyethylene, which protects it from external damage.

Rubber sheet

Initially, the material was used to isolate underground utilities. Today, rubber sheets are also used to protect metal pipes located in basements and in the ground, in sewer and water supply systems. Also, the canvas insulates the joints in the pipelines through which oil and gas are distilled.

The material is durable, has a long service life, is resistant to alkalis, oils, and alcohols. The rubber sheet is easy to install due to its high elasticity, the material retains its waterproofing characteristics at high temperatures. It does not emit toxic substances into the atmosphere and is safe for humans.

Isol

The material of the glued waterproofing insulation is high strength, it is successfully used for waterproofing the heating system. It is often used to seal metal steel pipes, with which it adheres easily.

It is resistant to high temperatures (up to 150 ° C), therefore it is effectively used in the heating system, but it is unstable to active substances, which contain solvents and organic compounds.

Isol is highly elastic, so it lends itself well to stretching. The roll packaging in which it is sold are convenient to use.

Heat shrinkable tape

Heat-shrinkable tape is used for the insulation of welded joints of metal pipes and for waterproofing plastic pipes. The material consists of two layers: a polyethylene film and a hot melt layer. It is not recommended to use this tape on pipes with high operating temperatures.

It is not recommended to use the tape on pipes with a high temperature. Heat-shrinkable tape is not used in the design of entering water into a house with a heating element. The material should not be left in direct sunlight; it should be stored in darkened rooms.

Polymer self-adhesive tape

Such a waterproofing tape is called a PTFE sealing material. It is used to protect against thread leakage in sewer systems. During installation, the tape is wound over the threaded joint with an overlap. Polymer tape withstands high temperatures and retains its texture for a long time, is easy to use.

Heat-shrinkable polyethylene sleeves

Polyethylene couplings are currently considered the most effective in the field of waterproofing. They are used to protect joints in a pipeline that provides hot water. Couplings are used when laying culverts, both in the ground and above it.

The material is easy to install, has high strength properties: it is resistant to temperature extremes and various aggressive liquids.

Shell made of polyurethane foam (PPU)

Such a waterproofer is very popular due to its ease of installation. The polyurethane foam shell protects the pipe from corrosive effects, as well as from unwanted heat loss. Therefore, such a material can be considered not only a waterproofing agent, but also a heat insulator.

Note! It should be noted that even pipes made of modern polymeric materials need protection. This is due to the fact that condensate forms and accumulates on the surface of plastic pipes during operation, which leads to the development of fungus and mold in the main communications.

Thermo - and waterproofing shell made of polyurethane foam excludes the possibility of condensation on the surface of metal and plastic pipes. Such an insulator is distinguished by its efficiency and reliability, and no special construction knowledge and skills are required for its installation.

How to insulate a water pipe in the ground with your own hands

When choosing how to insulate a water pipe on a site, take into account the material of its manufacture, the outer diameter, the cost of the insulation and the complexity of installation work.

Fig. 11 Calculation of the thickness of the pipe heat insulator

Insulation installation

Usually, for water supply for individual water supply, low-pressure polyethylene pipes (HDPE) with a diameter of 1 inch are used, the installation of an insulation shell is performed in the following way:

- A shell of glass wool, mineral wool or foam, foamed polyethylene is installed, fixing it with adhesive tape. When installing mineral or glass wool, it is necessary to monitor the tightness of the joints - otherwise water will get into the joint and the wool will saturate it, while the insulating properties of the insulation will significantly decrease.

- After installation, a soft heat insulator can be protected from being squeezed by soil with a more durable material, usually roofing material is used, wrapping the shell with it several times and fixing it with tape. The advantage of its use is hydrophobicity, which protects the insulation from moisture saturation.

- The insulated pipeline is lowered into the channel and covered with a light free-flowing compound to reduce the pressure, expanded clay is usually used.

It should be borne in mind that the installation of plastic segments should be carried out by bonding to each other with a slight shift of 20 cm, like an overlapping joint.

Figure 12 Insulation of a plastic water pipe in the ground with a foam shell

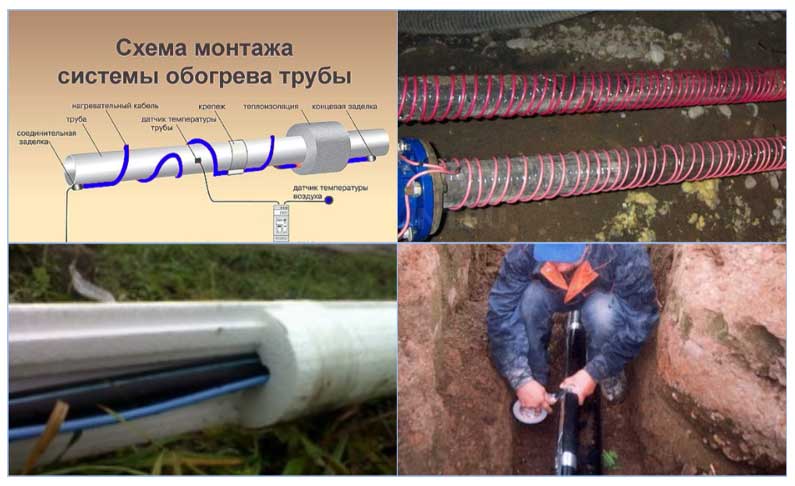

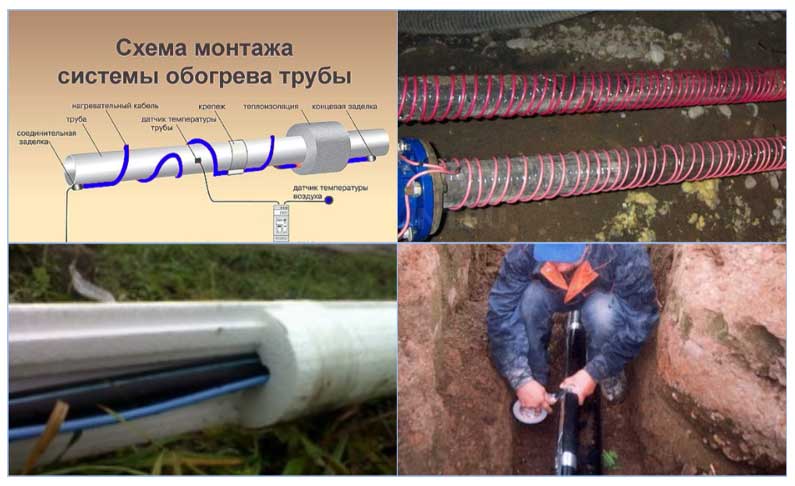

Cabling

The installation of an electrical cable is more expensive, but the depth of the pipeline is minimal. The heating wire can be located inside or outside the pipeline, water pipes are commercially available with an installed electric cable or with a cable duct for its installation. Most often, cable installation is used on the surface, while the depth of the pipeline does not exceed 50 cm.Work on the installation of a cable heater consists of the following stages:

- The pipeline at the location of the cable (in a spiral or in a straight line) is pasted over with foil-clad adhesive tape.

- An electrical cable is laid on the glued tape and fixed with the same adhesive tape.

- A shell of basalt insulation is installed on top of the resulting structure, which is connected with adhesive tape. When installing the heating cable along the line, it is practical to use foam insulation with special grooves.

- To control the operation of the system, it is advisable to install temperature sensors along the water supply line.

Fig. 13 How to insulate a water pipe underground with an electric cable

When deciding how best to insulate a water pipe in the ground with their own hands, many prefer a foam shell - it is easy to install, has the best physical parameters and has a low cost. The electric cable is more practical to use when the water pipes and the borehole head are shallow - it can be used to simultaneously heat the water in the mains and the well.

Heat shrinkable sleeves

First of all, it is worth noting that heat-shrinkable waterproofing couplings are put on the pipe before the start of welding, and after that they are "shrinked" in place of the pipe weld.

Consider the positive aspects of using such a clutch:

- high tightness rates;

- efficiency and reliability;

- resistance to aggressive chemicals;

- ease of installation;

- long operational life.

Heat-shrinkable couplings are used to insulate the joints of pipes of heating and hot water systems.

The choice of the most suitable waterproofing material depends on the specific conditions, therefore, for each case, it is necessary to select the most suitable waterproofing material. For the insulation of welded seams in communications that transport hot water, the most suitable option is a waterproofing heat-shrinkable sleeve. Such a sleeve is usually made of polyethylene.