Here you will find out:

- Is it necessary to insulate the well from the cold

- Well insulation materials

- Well operation modes and isolation methods

- We insulate the entrance water pipe

- Do-it-yourself casing insulation

- Options for additional protection during installation

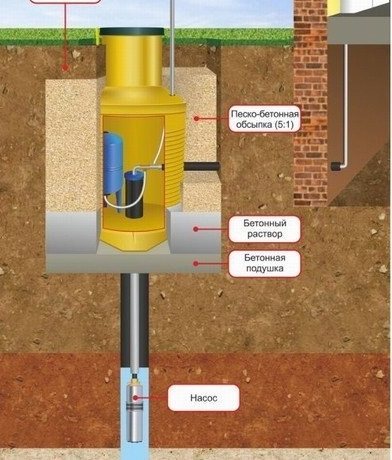

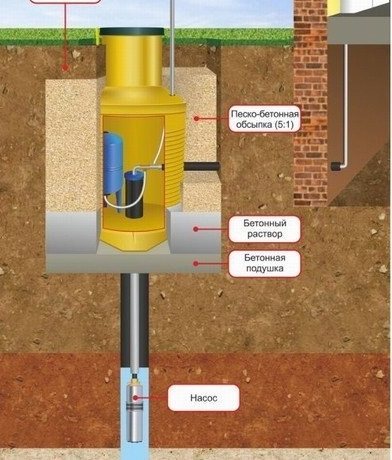

- Plastic caisson as the best way to insulate

Before insulating a well for the winter, it is necessary to think over all the subtleties. Choose the best thermal insulation materials, as well as available options for wells of different designs.

Is it necessary to insulate the well from the cold

Wells are insulated for the winter for the following reasons:

- If a well for sand or an artesian well has an upper casing in a caisson pit, then when water passes through the pipes from the head to the house in an open section of the caisson, it can freeze and, when expanded, damage the water supply system.

- If the water level in the well is high, its presence close to the surface can cause freezing and corresponding damage to the casing pipes, in which case it will become impossible to use the well.

- Any submersible electric pump has a check valve in the area of the outlet pipe, it is built into the pump model itself or installed separately by screwing it onto the upper pipe connection. Thus, it prevents the outflow of water into the well and it is always in the standpipe. A similar situation is observed with surface electric pumps, where a check valve is installed at the end of the supply hose. In severe frosts, water can freeze on the suction section of the HDPE pipe and its supply to the building with pumping equipment will stop due to the ice plug.

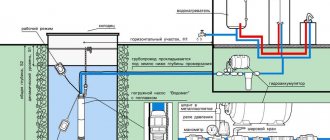

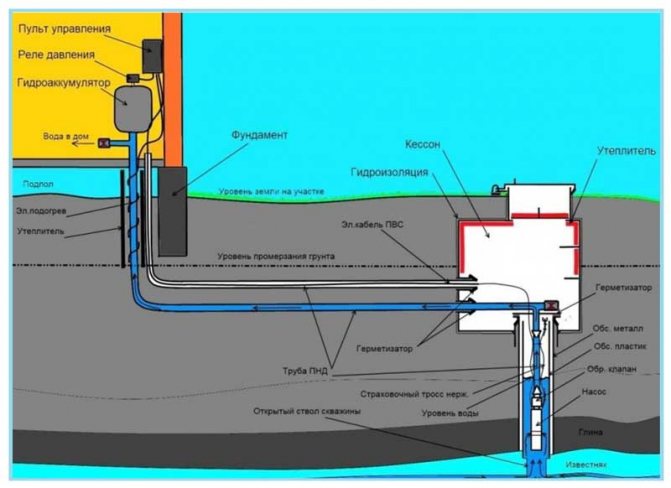

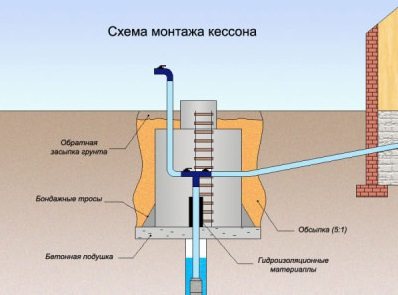

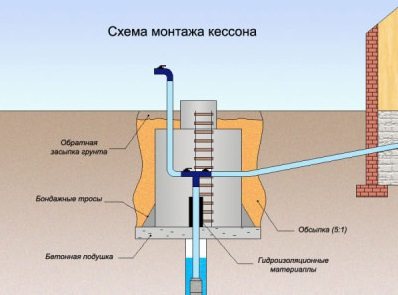

Diagram of the caisson design and well insulation

- In many caisson pits, surface pumps and equipment are installed - if the pump is shallow underground together with automatic equipment, they also need protection from the cold due to the constant presence of water in them when they are turned off.

- The need for insulation also arises in the absence of the owners for a long time, and if during operation the well is subjected to short-term conservation, the water frozen in the casing and pressure pipes will make it impossible for its further supply.

- Some types of wells do not have a caisson pit - the construction of the upper casing is located at or slightly above the ground surface. In this case, you need to think about the fact that the well needs to be insulated at its mouth to ensure uninterrupted water supply.

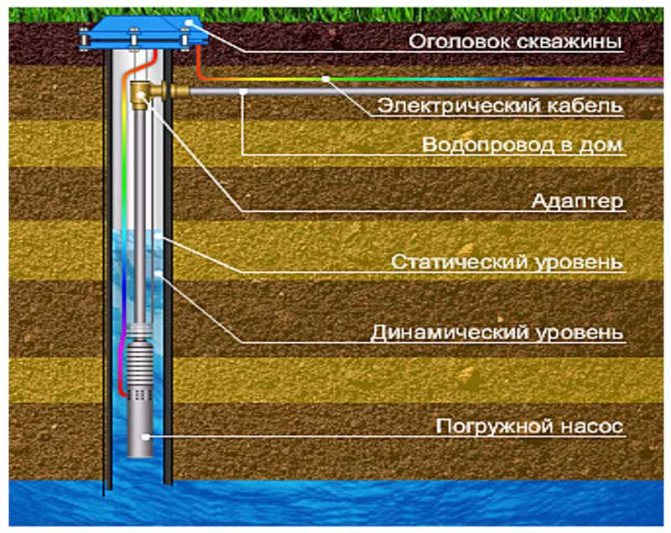

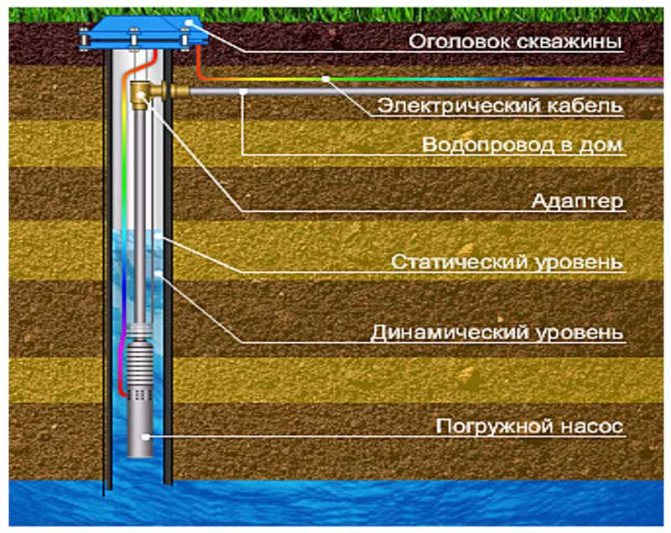

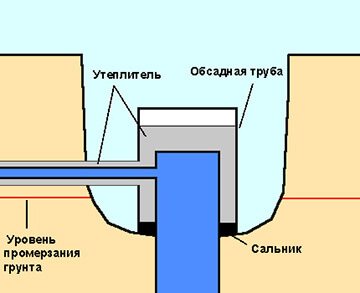

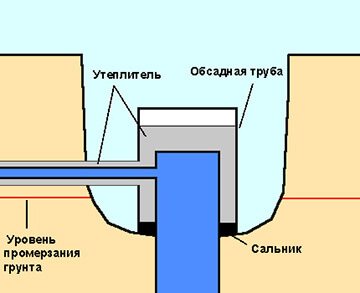

Connecting an electric pump via a borehole adapter

Freeze protection of the wellhead

It is recommended to insulate the well in winter (the season is of great importance for the design of the system) to isolate the pipeline from frozen soil layers. The system can consist of a casing and a head, a caisson (or without it). It is recommended to pay special attention here to the ambient temperature. This determines the need for additional insulation.

Basic principles of caisson insulation

A caisson is a special device for a water intake system. This is a tank, mounted in the ground, cylindrical or rectangular, made of metal or plastic. You can also create a structure by pouring concrete. It is mounted together with filters, accumulator and pump. The caisson for the well is insulated from the inside. Caissons are not used for rooms with good heating.

In winter, waterproofing is recommended to be carried out reliably and with high quality for its tightness.The material used as insulation must be resistant to winter frosts, rodents and insects. Usually gravel or ordinary sand is used. In some cases, a heating device is installed containing a sensor with the ability to indicate the temperature, or an ordinary incandescent lamp is used in conjunction with a heating cable.

One of the ways to insulate the caisson for the winter:

Head casing installation

In winter, the surface of the earth is very freezing, respectively, and the metal pipes located in it, drain installations, concrete rings. The influence of frosty air affects the material both inside the pressure pipe and on the outside. If the pump is located shallow, insulation methods are used.

To protect the head from ice, a casing is used. This is an excellent means of insulation up to 0.5 meters. Its diameter must be larger than the head to be able to lay glass wool or wool with mineral fibers.

It is not recommended to cover the gaps remaining after the procedure with spray agents. This damages the insulation layer.

Such an installation requires little money and time. It is better to put the casing pipe from metal or concreteso it will last longer. Plastic, on the other hand, can crack and crack from ground movement.

It is recommended to install all the material as tightly as possible to each other, it is impossible to leave slots and crevices (in winter, moisture will penetrate through them and freeze, subsequently the ice will ruin the structure and deformation will occur).

The ingress of moisture can be prevented during installation with a gland. The stuffing box is a rubber expanding filler (hemp stuffing box or cuff) that helps close the gap between the casing and auxiliary pipes of more than 100 millimeters. The stuffing box is made from rubber production waste, it can withstand temperature extremes, soil pressure, and is effective against rodents and insects. Rubber seals can be replaced with lead ones.

Well insulation materials

There are several methods and materials with which you can insulate a well with your own hands. The most important task is to prevent the well from freezing.

In order not to get trapped in the winter due to an idle well, it is better to think about its insulation from summer and spring.

The following materials are used as insulation:

- Sawdust;

- Dry leaves of trees;

- Straw;

- Peat;

- Hay.

Using each insulation material separately will not be effective. They are an additional material that prevents the well from freezing.

Use natural materials as additional insulation.

Natural materials are not 100% protected from moisture ingress. If they get wet, then their effectiveness decreases significantly. That is why it is necessary to consider these heaters from the point of view of additional ones. Mineral wool heaters and polystyrene foam should be used as the main heaters of the well as secondary insulation. Thermal insulation material is used when the well is characterized by a high level of groundwater. You can read the advice of summer residents about this. The operation of their wells in the winter was in full swing.

To insulate a well, different methods of insulation should be used. The most effective is the use of natural materials together with "artificial" ones in the form of mineral wool insulation and foam. This combination of materials will prevent the well from freezing in the cold winter.

Heat insulating materials

A competent solution to the problem of insulating water supply wells in regions with a cold climate depends on knowledge of the features of heat-insulating materials.In the southern regions and places of deep bedding of the water supply system, it is enough to fill the head of the well with sawdust or close it with straw.

Well insulation materials.

Many insulation materials are used in harsh climates. They are used in combination when there is a threat of pipeline freezing.

Penoplex is widely used, which contains the smallest air bubbles. It is distinguished by low thermal conductivity, rigidity, moisture resistance. It is suitable for thermal insulation of external and internal surfaces of coffered chambers, external and underground areas.

Penofol is a self-extinguishing polyethylene foam. This soft sheet material does not contain harmful additives and reflects heat well.

It is suitable for protecting the inner surface of underground chambers and pipelines without external stress.

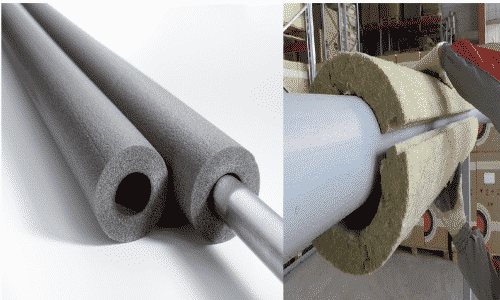

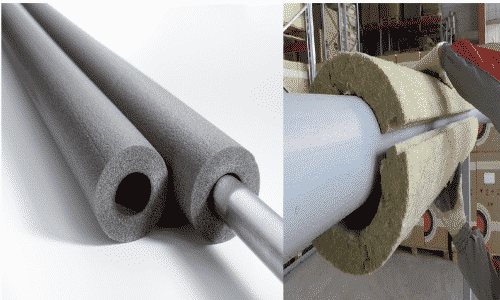

Mineral wool, glass wool (fleecy insulation) has high thermal insulation properties. For its laying, a box is made that covers the head of the wellhead.

Using a heating cable

The types of heating cables are resistive, having small dimensions, and self-regulating (SGK), which change the heating temperature of the sheath depending on the temperature of the water that surrounds them, the product.

Well insulation when using a heating cable.

In contrast to resistive SGCs, they have a higher efficiency if we take into account the characteristics of HDPE products, which are most often used for water intake from a well. They have low thermal conductivity, therefore, when installing SGK, you need to remember the consequences of their placement inside and outside the pipeline.

On its surface, the flying cable has a lower efficiency than inside. To increase the performance of the product installed outside, additional insulation (shell) should be used.

Thermostats of the corresponding length are sold with the cables, and in addition to the individual wire models, three-entry fittings are provided. They are needed in order to connect to a pipeline made of low pressure polyethylene.

How to insulate a well

When choosing an option, the initial data should be taken into account: where the pumping equipment is installed, whether the pit is equipped, how and with what the casing was protected during the construction phase of the hydraulic structure.

So, the first measure to reduce heat loss is the installation of a caisson for the well. This is the most common method of insulation, which partially protects the head of the well. However, in cold climates, auxiliary methods must be used.

Heat insulating materials

Such a measure to reduce heat loss is often taken along with other options: arranging a caisson, laying a heating cable. Particular attention is paid to the choice of materials for thermal insulation.

Installation of thermal insulation is accepted along with other options: arrangement of a caisson, laying a heating cable. Foamed polyethylene is used along with other types and only in cases when a significant load does not affect communications. Polyfoam and expanded polystyrene (penoplex) are distinguished by a closed cellular structure and low thermal conductivity, they resist moisture. Mineral wool coatings slightly absorb water, which leads to a loss of thermal insulation properties during operation. Polyurethane foam is the most suitable solution for the operation of pipes in any conditions.

Varieties that are characterized by moisture resistance should be considered, since the coating will constantly be in contact with moisture (with the appearance of condensation, precipitation, groundwater, etc.). Possible options:

- Styrofoam and expanded polystyrene (penoplex).These materials are distinguished by a closed cellular structure and low thermal conductivity, they resist moisture, but polystyrene foam is a preferable insulation, but it is more expensive than foam.

- Foamed polyethylene, including one of the varieties with a foil-coated Penofol: characterized by low thermal conductivity, not exposed to water, but characterized by small thickness and easily deformed. Therefore, it is often used along with other types and only in cases when a significant load does not affect communications.

- Polyurethane foam is the most suitable solution for the operation of pipes in any conditions. The main advantages: strength, low thermal insulation, resistance to moisture, long service life. But PPU is distinguished by its high price, the need to use special equipment.

- Mineral wool coatings (glass wool, basalt wool, etc.): slightly absorb water, which, during operation, leads to a loss of shape, and at the same time, properties. Due to its elasticity, it is possible to give the material any shape, it is convenient when insulating products with a circular cross-section, more often materials of this group are used for preserving a well.

Using a heating cable

The main task is to increase the temperature of the coolant and directly communications. Self-regulating and resistive cable types are used. The first of the options is more preferable, since it is functional, has a high efficiency, which is due to the ability to change the temperature regime of communications, depending on the operating conditions.

The heating cable does not allow the water supply system in a private house to freeze if it is inside or outside the communications. The first option is considered more effective, but requires careful insulation, since the cable will be constantly in the water. Externally positioning the wire will not provide the same result as locating it internally, but it is safe to do so. During installation, it is determined which cable routing scheme is more suitable for these conditions: straight (one-sided, two-sided), orbit.

Well operation modes and isolation methods

The choice of one or another method of insulation should depend, first of all, on how often the well will be used.

- If we are talking about permanent operation, then a constant pressure will be maintained in the pipes, and the water there, if theoretically, should not freeze. But the fact is that the liquid can move and not all the time, but only when water is used, so if there is a prolonged downtime (say, at night), then it may well freeze in the pipes, even under pressure. Moreover, the head can contain special technical devices (battery or pump), which are particularly sensitive to subzero temperatures. For this reason, it is necessary to insulate wells for operation, but in this case, one also cannot do without passive methods - we are talking about a caisson or a thermal insulation layer.

- And how to insulate a well if the pipeline is used seasonally (for example, only in summer), and in winter all pumping equipment is turned off? And the well itself is being preserved? No way, you should simply drain all the liquid from the system, pipes and taps, and then carefully preserve them.

- Finally, in the case of irregular operation, when water will be collected even in winter, but, for example, only on weekends, it is possible to equip an external electric heating next to the head and the supply pipe. This kind of equipment can be turned on when you arrive at the dacha, and after a certain time you can fully use the well.

How to insulate a well on the street with your own hands

Basic requirements for heat-insulating material: moisture resistance, stiffness, low thermal conductivity.The choice of insulation method depends on the initial conditions: the type of well, its size, the location of pumping equipment, the presence of a pit or caisson. The method of laying pipes is also taken into account: above the soil surface or under a layer of soil.

Insulation of the caisson or pit

Thermal insulation is carried out on the outside of the walls. First, they are protected with a waterproofing material (for example, mastic). Then a heater is installed (a shell or a structure of separate segments), it is fixed with wire. At the last stage, the seams are filled with polyurethane foam, the foundation pit is backfilled.

Thermal insulation is carried out on the outside of the walls.

Insulation of the casing and head

The box is being installed, preferably made of wood. Its dimensions can be substantial if the space around the head allows. Inside such a box is filled with any soft heat-insulating material: glass wool, mineral wool. Alternative: dry leaves, straw, etc.

How to insulate a pipe from a well to a house

Available methods:

- heating cable;

- rigid shell made of heat-insulating material;

- pipe in pipe: communications at the installation stage are laid in products of a larger diameter, as a result, the air gap performs the function of a heat insulator.

They often combine different methods.

We insulate the entrance water pipe

In addition to the mine itself, the pipeline entering the well and the house also needs thermal insulation. As a rule, in the country, the highway leading from the source to the house is laid shallow. This is due to the technically narrow scope of work. That is why you have to additionally insulate it.

Method one into another

Take a plastic or metal pipe with a diameter larger than the water supply. We will lay it on the base in a trench and bring it to the well, house and equipment. In fact, it will act as a sleeve or case.

It is not necessary to start a mine in the shaft, 10 centimeters inside is enough, and we will isolate it. To facilitate the process, 20-25 centimeters of sawdust is first poured into the trench, on which a pipe is placed. A soft insulation, glass wool, or penoflex is thrown from above. The structure can be covered with soil. We push the water pipe into the case, leading it into the house and the well.

An air cushion between the insulated sleeve and the water pipe will create an additional obstacle to the cold.

Important: for additional waterproofing, the case with insulation is wrapped with roofing material or polyethylene.

Thermal insulation using penoflex

Modern material, flexible and durable. It looks like cylinders from 3 to 6 meters long. They differ in thickness and density. There is a foam flex for each pipe diameter. In this case, you do not need to use a sleeve. The pipe is completely insulated before laying, gluing all joints with metallized tape. Insulation of highways underground, using Penoflex technology, is possible at a depth of 70 centimeters.

Descent of the filled area to a depth below the freezing level

Specialist consultations

The decision can be considered original, if not one significant "BUT". But first, let's figure out the essence of the approach. When operating a well with Kid's assistance in winter, one of the clients applies the following procedure. After the pump stops working, it first etches it to the top (2 meters). Thoroughly drains all the water from the hose. After that, the pump is lowered back. As a result, there is no water left in the hose at the freezing depth.

Of course, this approach can be considered the same solution. But its significant drawback is the constant manipulation of the pump. Such manipulations significantly increase the risk of the pump (especially the vibratory pump) jamming in the casing.

I do not want so

Expert in touch

Sources:

- Main photo "Trash patterns" source.

- Illustration for an antifreeze hydrant obtained from here

- An illustration of the drain valve is obtained here

- Check valve illustration here

- The source of the illustration for heating pipelines is here

Still have questions? Our experts are ready to advise by phone

Do-it-yourself casing insulation

During direct installation of the casing, it is impossible to isolate it properly. Therefore, the well is insulated for water after installation.

Thermal protection of the shaft along the inner wall of the pipe will lead to a mandatory narrowing of the bore diameter, therefore, the casing is insulated only from the outside.

First step. We dig in the source from all sides in a circle to a depth of up to three meters. It should be counted from the upper cut of the earthen embankment. We strengthen the walls of the ground with wooden boards or boards. You can also use metal sheets by twisting them around the trench.

Second step. Having compacted the base of the pit, we pour insulating material on the bottom. It can be anything, even old down jackets or quilted jackets. It is necessary to lay the insulation carefully, pressing it tightly against each other.

Step three. Gradually filling the entire hole with the casing, it is closed. The upper part of the shaft, which we have insulated, is in an aggressive environment. Therefore, it must be closed with a lid. It is made from a sheet of metal or a wooden shield, with a diameter larger than a dug hole. This is necessary so that the rainwater does not wet the insulation.

You can protect the upper part of the well by building a small box with a roof over it.

Foam shells can be used as insulating materials. This method is very simple and reliable. It is enough just to choose the required diameter and fix the halves on the pipe.

Thermal insulation of a well with a high groundwater level is more difficult. In addition to thermal insulation, waterproofing of the insulation itself or the choice of a material that is not afraid of water will be required.

We drain the water through the borehole adapter

This solution for freeing pipelines from water and protecting them from freezing is quite laborious. It involves disconnecting the adapter, lifting the pump together with the riser to a low height. After draining the water, the steps are carried out in the reverse order.

Read more about the arrangement of a water well with a borehole adapter here

This solution is usually used when preparing a well for winter. In case of emergency, it can also be used when using the well in the winter.

Equip with adapter

Specialist consultation

Specialist consultations

Further we will focus on solutions that can hardly be considered successful, but which are still encountered.

Options for additional protection during installation

When carrying out installation work, additional protection options are provided. In order to be able to mothball the pipeline, the pipeline network is made with a slope towards the source with the installation of a reverse-acting valve. When the pumping equipment is turned off, water from the pipes by gravity rolls back into the shaft, while it is important that there are no cavities where it could linger.

Sometimes the water supply pipe is placed inside a larger pipe. The air gap between them insulates the structure, the outer pipe can be introduced into the heated room, in this case, the efficiency of the system is significantly increased.

Attempts to prevent water from freezing by increasing the internal pressure in the pipeline are doomed to failure. Suffice it to recall from the school physics course that the temperature of its crystallization decreases by one degree with an increase in pressure of one hundred and thirty atmospheres, but such parameters are unattainable in domestic conditions.

Well insulation methods

The choice of a suitable method for insulating water supply wells depends on thermal insulation materials, the complexity and efficiency of the work, as well as the modes of use of hydraulic structures.

- Constant operation of the water supply system in a private house throughout the year ensures the maintenance of optimal internal pressure, which will prevent stagnation and freezing of water. During night periods, consumption can be significantly reduced or stopped, which will lead to temporary freezing of water. In this case, it will be necessary to insulate pipes and installed hydraulic devices (pump and accumulator) using a caisson.

- During seasonal operation of the system, it is recommended to turn off the pumping equipment and temporarily suspend the well for the winter. Before the first frost starts, water is removed from the pipeline, and the equipment is dismantled.

- During temporary operation of the well, when the water supply is carried out throughout the year, but with long interruptions, it is recommended to organize external heating of the head and the underwater pipe. Such devices are used to quickly warm up the water supply system at any time of the year.

For thermal insulation, classical and alternative methods are used, the choice of which depends on the design features and the location of the well.

Plastic caisson as the best way to insulate

If you place the head of the well and all the pipework below the level of freezing of the soil, then you will not have to worry about insulating them. At such a depth, even in the most severe frosts, water will not freeze in the well, since its temperature will be constantly above zero. To accomplish this task, it is necessary to dig a pit around the wellbore to a depth of 2-2.5 meters and install a caisson. For one hundred percent reliability, the walls of the caisson and the cover of its hatch are insulated with mineral wool or foam.

Well insulation using a plastic caisson installed in a dug pit around the casing to a depth of 2.5 meters

At extremely low temperatures in the caisson well, it is recommended to install an additional cover with insulation directly above the well in order to exclude the possibility of water freezing in the pipes. Installation of this element is carried out in advance, since it is undesirable to open the hatch in severe frosts.

How to build a caisson

Step one. A container (made of metal or plastic) of the required dimensions is being prepared, you can, as an option, use a barrel for two hundred liters. And if the installation of additional devices is not planned in the caisson, then such a capacity will be more than enough.

Step two. A pit breaks out around the head. It is important that the bottom of the dug pit is located somewhere 35-45 centimeters below the level of soil freezing (the calculation is made for a very cold winter). As for the diameter of the pit, it should protrude from the head about 50 centimeters on each side.

Step three. The bottom of the pit is covered with a "pillow" made of gravel and sand. The "pillow" layer should be approximately 100 millimeters.

Step four. A hole is made in the bottom of the barrel for the pipe, and in its lateral part - for the inlet of the pipeline.

Step five. The barrel is installed on the bottom of the pit, as if put on the head.

Step six. Inside this barrel, the head is connected to the pipeline. Actually, in such a large barrel, you can even equip a special surface pump or, as an option, equipment for distributing water.In addition, even a special drainage pipe can be cut into its bottom to drain accumulated condensate deep into the soil.

Step seven. A thermal insulation layer is laid around the barrel. It is important that for this a heater is used that is immune to the aggressive effects of the soil (for example, expanded polystyrene). In addition, the barrel can be wrapped on the sides with a layer of mineral wool, but in this case, waterproofing should be laid on top of it.

Step eight. The caisson is closed with a lid, to which a ventilation pipe is fixed. The top of the barrel must also be insulated with the same insulation.

Step nine. The pit is filled up. That's it, the miniature caisson can be used! A similar design is suitable for a small well.

Insulation of the caisson structure for the winter

To reliably insulate the well, you cannot do without special materials. The main parts of the caisson structure are located underground, therefore special requirements are imposed on the materials for their insulation. They should not lose their performance under soil pressure, wrinkle and deform.

We need excellent water-repellent properties, since when soil water penetrates inside the insulation, it will be destroyed during their crystallization. If the material of the heat insulator is of interest to rodents, they will pull it apart or gnaw through passages in it, thus destroying its insulating qualities.

It is possible to insulate the caisson for the winter both from the inside and from the outside. With the internal location of the insulation, the integrity of its layer is not affected by soil movement and other unfavorable external factors. The most commonly used foam or expanded polystyrene.

From the outside, it is necessary to insulate plastic products, since they become brittle at sharply negative temperatures. The heat-insulating layer must be protected from the effects of water, rodents and insects, otherwise it will not last long. At the same time, the cylindrical shape of the caisson requires the least consumption of insulation material, however, the rectangular shape facilitates its installation.

How to insulate a well for the winter with your own hands at the installation stage

The most effective method for reducing heat loss and preventing icing of the communication system, pumping equipment is protection at the stage of equipping a hydraulic structure. In this case, the most suitable techniques are used, and more often they are combined: they use plastic casing instead of metal, the pumping equipment is lowered to the bottom of the well / well, where it will be below the level of soil freezing.

Variants and methods of insulation of various wells

Measures taken:

- arrangement of the caisson, which is additionally insulated, this method can be used when installing deep and surface pumps;

- when the installation of submersible equipment is carried out, it is permissible to close the well head without a caisson with heat-insulating material;

- at the mouth of a hydraulic structure, a heating cable is lowered to a certain depth;

- along with the caisson, they equip an insulated box with a lid / hatch.

Installation of insulation

For thermal insulation of communications, it is recommended to consider special casings. It is a one-piece or prefabricated shell, characterized by rigidity, low thermal conductivity, and does not absorb water. For caissons and an insulated box, it is also permissible to construct a semblance of such a shell - a "shell". It is assembled from separate small-sized sheets of foam, reinforced with auxiliary materials, additionally protected with a film, cement mortar.

Well insulation with caisson

Mandatory steps: arrangement of ventilation and sealing of the entrance hatch.The structure of the caisson is protected from heat loss above the ground surface and in the soil layer (part of the structure is buried).

To do this, use different types of insulation, and additionally protect the structure with brick, concrete or wood. The choice of materials depends on the type of original structure of the protective structure.

Well insulation without caisson

In this case, communications pass above the soil surface from the well to the house. It is recommended to use cylindrical insulation (hard) or mineral wool material.

It is recommended to use cylindrical insulation (hard) or mineral wool material.

At the same time, a heating cable is run through the pressure pipeline. In this case, the equipment must be installed in an insulated building.

Insulation of an underground pipe system

It is not necessary to use waterproofing and heat-insulating materials in winter, since you can insulate a well on the street using layers of soil. Such layers do not freeze and do not put pressure on the water supply system. The complexity of installation work depends precisely on the depth of the line.

The type of eyeliner also matters: top, bottom. With top liner in winter, additional means will be required to retain heat. With a lower liner, the amount of insulation decreases, since there is a layer of soil.

It is recommended to use ordinary sand, since it is possible to insulate the caisson for the well with bulk materials. In winter, expanded clay, cotton wool with fiberglass, and polystyrene will be effective means.

The use of modern thermal insulation materials

For the winter, the head of the well and the pipes are insulated by various means.

Penoplex, expanded clay, mineral wool, polyurethane foam, expanded polystyrene with a special shell are used as thermal insulation and waterproofing.

Such products are divided into groups:

- to maintain the strength and reliability of the structure;

- for easy installation (basalt fiber);

- for easy cutting and installation;

- to ensure moisture resistance.

Sometimes difficulties arise when insulating hard-to-reach places. For this purpose, a waterproof paint with thermal properties is used (it can withstand temperature changes). Among its main functions is also the protection of metal from corrosion.

External well insulation using foam:

Using a heating cable

It is recommended to use a special heating cable during frosty periods. Its advantages are:

- low cost;

- ease of installation;

- sold with additional materials included;

- environmental friendliness;

- energy saving;

- has competitive heating properties;

- comply with electrical safety standards.

It is possible to purchase one of the types of heating cable installed inside the pipe or outside. A coupling and a tee are used as fasteners. Curved sections of the trunk can obstruct the installation of this cable. Its fastening consists in winding the system with aluminum foil.

It is recommended not to allow the heating cord to come into contact with the heat-insulating material (it is mandatory for the installation to preserve heat and save energy).

The process can be carried out in a linear or spiral fashion, with one or more cables. When the air temperature drops to 3-5 degrees Celsius, the heating system will automatically turn on.

Correct use of a heating cable for insulating pipes and wells for the winter:

Additional protection during the installation phase

At the installation stage, additional protection is carried out for all types of well use: seasonal, variable, permanent. An important criterion here is the installation of pipes (type) using one or another insulation. The parameters of the soil are taken into account to select the thickness of the heating material used.

Several techniques can be used in winter:

- The use of pipes of different diameters.In the process of constructing a well, pipes of a smaller diameter and larger are used. In this design, an air gap is created to help retain heat. The water supply system is heated under the soil layer.

- Forced circulation of water. This method is used when the water is constantly turned off. It consists in turning on the pump according to the schedule. The meaning of the method is that it is possible to obtain warm ground water in the well.

It is recommended to decide which of the methods will be the main and which will be additional. An additional method is often used to protect the well from sudden temperature changes. This guarantees the circulation of water under all external conditions. Also, excess pressure is used to prevent the entire system from freezing. But here there are huge risks of rupture of the water supply.

Passive insulation

The water in the well rises from a fairly large depth, where the temperature never drops below zero. Therefore, in some cases, it is enough just to save this heat so as not to resort to additional insulation.

In this case, a pit or a caisson is perfect, followed by the application of a good insulation above the level of soil freezing. But this option is good for a private house with year-round living. If you need to insulate a well in the country, this method will have to be abandoned.

Even with a good insulation, water, if it stands motionless for weeks, will cool down and as a result turn into ice, which can break the pipe. To prevent this from happening, the well must be used regularly, thus warming up the water supply system.