The need for thermal insulation of the pool

One of the ways to prolong the life of the pool is to insulate it. It is of two types: wall insulation and bottom insulation.

The pool is insulated for two reasons:

- The temperature difference between the pool bowl and the ground, the water will quickly cool down;

- The second reason follows from the first. Too high costs for electricity, which is spent on heating the water in the bowl.

It is necessary to insulate the pool with a material, the coefficient of thermal conductivity, which is quite high. Because the temperature of the ground is about 5 degrees Celsius, and the pool is 25 degrees. The drop is too great.

PPU

The most effective solution to the problem is the insulation of the pool with polyurethane foam (polyurethane foam). The process goes like this: two components, mixing, fall on the surface under pressure, and during the polymerization reaction they form a seamless layer of insulation, which, without fasteners, adheres to any surface.

Polyurethane has a long service life, is moisture resistant, dimensionally stable and has an extremely low thermal conductivity. Also, the foam is environmentally friendly, has a low flammability class, does not form fungus and mold, and does not decompose.

So you get a durable and reliable solution that will help maintain a stable thermal regime of the liquid in almost any container and minimize heat loss.

Pool types

Pools are of various types, from special sports and recreational pools to stationary and stationary ones installed in the country.

Stationary

Such a pool is not transferred over the site, a foundation pit is pulled out under it and the formwork for the pool bowl is poured. A place is being arranged for drainage and water intake. But there are times that there is no water on the site, which could constantly fill the bowl. In this case, resort to the following solution. At the request of the owner, a fire engine is brought in, which fills the pool with water. But what about water purification, you ask. That's how. A skimmer cleaning system is installed, which, with proper care and proper use of water in the pool throughout the year, the water can not be changed for several years.

Stationary pool

Mobile

This type of pool costs the owner less than a stationary one and does not require year-round maintenance. Only for the swimming season in summer. In addition, this type of pool can be moved by the owner to different parts of the suburban area. In turn, there are several subspecies of a mobile pool: inflatable and frame. The first is one of the simplest. But it is easy to pierce it with careless handling. The second type is more durable and durable. The water in it can not be changed all season if a good filter is installed. But unfortunately, you have to face the following problem: many insects in search of water find your pool and often drown there. The most unpleasant thing is that wasps can fly in on a hot afternoon, which will interfere with rest.

Waterproofing materials

The range of related products is impressive. Basically, we focus on such indicators of the feasibility of using products, such as the ability to do all the work with our own hands (and, preferably, without the use of special equipment) and the cost of the goods. Nevertheless, it is necessary to first point out a number of points related to the peculiarities of the operation of the pool. This will help with choosing the best waterproofing option.

In the water, no matter what preliminary preparation it has gone through, including chemical / cleaning, there are always impurities of various compounds, some of which are aggressive and can react with the waterproofing material. This is especially important for the interior decoration of the bowl, since, by definition, it is this part of the pool that will almost always have direct contact with the liquid.

The specificity of the functioning of this hydraulic structure is that the water must be renewed periodically. This is necessary, first of all, from the point of view of sanitation. This means that it will be regularly drained, followed by filling the bowl, which, because of this, will be subjected not only to static, but also to dynamic loads, and very significant. And they directly affect the integrity of the waterproofing. Based on this feature of the pool operation, it is advisable to use materials that, after installation, create a monolithic (seamless) protective layer.

Dynamic loads, as well as periodic fluctuations in water temperature, present another requirement for waterproofing - elasticity. Otherwise, cracks will appear in this layer - it's only a matter of time, but sooner or later leaks will surely appear.

Maintainability. Much depends on the size of the reservoir. If they are impressive, then when choosing a material, it is necessary to take into account whether it is possible to eliminate the defect of this protection using a "point" method. It is clear that the replacement of the entire layer (monolithic "canvas") in pools with large linear parameters is both complex and expensive.

Films

These materials include polyethylene roll products, which are universally used in the private sector. They are used both for waterproofing and for covering small areas to create a greenhouse effect. The price is practically the lowest among analogs.

For example, a 100 m canvas with a width of 3 m will cost from 2,050 rubles. Polyvinyl chloride film is more expensive by 600 - 700 rubles / roll.

But they have drawbacks. First, the slightest damage will require replacing part of the waterproofing layer. Secondly, when finishing the bowl, the stripes will have to be joined, that is, the formation of seam joints from the inside is inevitable.

Membrane-type waterproofing materials are of higher quality, but also expensive. Their plus is that they are available in various standard sizes, so it is not difficult to choose the dimensions of the canvas so as to cover the entire bowl with a single layer. But again, if damaged, the entire membrane will have to be replaced. "Spot" repair of such products (at least with your own hands) is usually ineffective, since the patch will not last long.

The approximate cost is from 250 rubles / m².

Mastic compounds

Such waterproofing belongs to the categories "coating" and "penetrating". An example is products under the brands "Penetron", "Xypex", although these are not the only products that are on sale. People without sufficient experience, and even "spurred" by advertising, are guided by the advantages of such materials and use them to decorate pools from the inside. Indeed, working with mastics is both simple and convenient.

But it is worth mentioning that these formulations are not recommended for the arrangement of basic protection against liquids. They should be used either in combination with other materials (for example, membrane), or for “spot” repairs.

Estimated price - from 135 rubles / kg.

Bitumen

This fairly common material, especially in the private sector, should not be used for waterproofing swimming pools. Suffice it to point out a number of significant shortcomings. Firstly, low adhesion, therefore, on the basis of the protective layer will not adhere firmly.Secondly, the chemical composition, which means that there is a possibility of releasing some harmful substances into the water. Thirdly, the fragility of such waterproofing.

That is why, despite the versatility of the use of bitumen in the field of construction and repair, it is not recommended to use it for finishing swimming pools from the inside.

Liquid rubber

This is probably one of the best options. You can read about all the advantages of such compositions (and there are quite a few of them) in the article on the characteristics of liquid rubber. Suffice it to point out that the layer is absolutely harmless from the point of view of ecology, seamless, and installation is not difficult. Moreover, there are several options - using a sprayer or coating (roller or brush). And the maintainability is excellent.

The cost of liquid rubber is from 53 rubles / liter.

Pastes

Belong to the category of lubricants. Unlike mastics, they are applied in a thicker layer. But they are relatively expensive. Plus, they are applied only after the reinforcement mesh has been laid.

The cost of pasta is from 265 rubles / kg.

There is also a number of materials that belong to waterproofing - bentonite mats, liquid glass and a number of others. Anyone interested in characteristics and prices will find the relevant information on our website. But from the point of view of "do it yourself", as well as due to a number of shortcomings, it is hardly worth using such products when decorating the pool bowl from the inside.

Thermal insulation materials for the pool

It is impossible to insulate the pool with any material you like. It will be money wasted. Because it may not fit and provide the required parameters. Let's figure out which material is best.

Thermal insulation membrane

The advantages of this material are:

- Mechanically strong and flexible;

- Meets all hygiene requirements;

- Very little water rinse;

- Easy to fit and cook by hand welding;

- Welding seams are very strong, have double thickening;

- Environmentally friendly;

- Ease of repair;

- Can be sent for recycling.

Foam concrete

This type of material waterproofs the pool well, as it has:

- low water permeability;

- resists high pressure;

- holds a blow in front of an aggressive aquatic environment;

- is one of the most budgetary waterproofers.

Foam concrete - material for pool insulation

Styrofoam

Polyfoam is one of the most affordable and inexpensive types of pool insulation, which will stop the transfer of heat from water to the ground. Its advantages are:

- availability;

- little weight;

- environmental friendliness;

- low price;

- high thermal insulation and waterproofing properties;

- does not progress corrosion.

In addition, this material is easy to install and does not require special installations and machines.

Technological features and advantages of sprayed PU foam

Polyurethane foam is most effective when insulating a house or pool. This is due to its cellular structure. In addition, the cells are filled with carbon dioxide. In addition, the heat transfer coefficient of this material is higher in comparison with other materials. On this point, PPU surpasses even air.

Other advantages of the material:

- spraying does not leave seams through which cold could break through;

- spraying can be done on structures of various shapes, of any configuration and complexity;

- simultaneous insulation and waterproofing is provided by PPU spraying;

- fireproof, as it dies out when ignited on its own.

How to insulate a sauna / pool?

Baths and saunas are insulated at the final stage of construction. They are insulated on both sides - from the inside and outside. For the insulation of the bath and the pool are used foam glass plates... They are attached to special adhesives and mechanical fasteners for foam glass, and on top they are covered with decorative and protective layers. It must be remembered that the insulation of a bath and a pool is a complex engineering task that must be solved by specialists with appropriate qualifications. You will save money, time and hassle if you contact our specialist engineers.

Our PINOSKLO company provides all the necessary services for thermal insulation with foam glass - from calculating the amount of insulation to installation. Contact us!

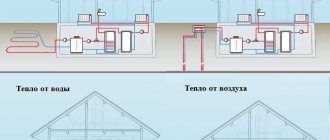

Insulation methods and materials

There are slight differences in the insulation of pools made of different materials. Let's take a closer look.

Plastic basin

The pool is insulated by spraying with polyurethane foam. You can do this yourself by purchasing a special device. Further, the bowl is placed in the ground or belongs to a specially designated room. This type of insulation helps to prevent the pool water from cooling down.

Concrete basin

Warming is carried out by the method of PPU spraying. Here it acts as both a heat insulator and a hydro and steam insulator. However, insulation must be carried out not only outside, but also inside. So that there is no early cooling of the water in the pool bowl. Inside the pool, polyurethane foam is sanded, reinforced, and then cement mortar is applied. Then everything is decorated with mosaics.

PPU spraying - a way to insulate the pool

Thermal insulation of the bowl and pipeline

It makes sense to insulate the bowl and the pipeline only in stationary pools. Mobile models simply do not need this. The simplest way to insulate the bowl is to use polystyrene foam. Insulation sheets are simply laid around the concrete during pouring.

As a rule, the bottom is not insulated. The average depth of the pool is sufficient to keep the water from freezing. Thermal insulation of the pool with foam will also save the structural material from moisture.

Ultimately, this will save the concrete from the freeze-thaw cycle when moisture gets in. Polyfoam performs an additional function of moisture protection. Sometimes, in addition to or instead of polystyrene, expanded clay backfill is used with a layer of 20-30 cm thick.

For thermal insulation of the pipeline, it is better to use foil and basalt mineral wool shells. The shell has already been formed for the size of the pipe, it remains only to insert the pipe into the insulation and glue the joint with foil tape.

It is impossible to immediately fill the insulation with earth, since the fallen lumps of dirt and stones can damage the insulating layer. Therefore, a sand pillow is always poured under the bottom of the insulation. Ideally, you need to fill the pipes with sand in the same way until the main part is hidden under its layer.

Pool insulation is an important part of the installation work. Thanks to which you can save money on electricity in the future, as well as the water in the pool bowl will always be at the same set temperature.