Now it has become very fashionable to have a pool on your suburban area. Why not? Why not equip a full-fledged place for taking water procedures? Moreover, if you do it yourself or with the assistance of some outside help. But remember: the waterproofing of the pool must be done on time. Otherwise, this "newfangled thing" will not please you for long. Do not delay with this process: waterproof the pool before using it.

Types of waterproofing

If the pool is located inside the structure, then only internal waterproofing is performed, which protects the surface of the font from the negative effects of water penetrating through (possibly) poor-quality materials or cracks. And, if the pool is outside, then in addition to the inside, it is necessary to perform external waterproofing, which protects the bowl of the concrete pool from groundwater and all aggressive elements contained in them.

That is, the purpose of waterproofing is to make the concrete waterproof. The strength and durability of the concrete pool as a whole depends on how well and correctly it is performed.

Important! If during the operation of the pool cracks of more than 4 mm appear, then it is unlikely that any waterproofing of the pool will solve this problem. In this case, you will have to take more "drastic" measures.

Classification of materials for waterproofing

By application

All used waterproofing materials are divided into two main groups:

- bituminous;

- polymer.

Insulating bitumen is a material obtained by blowing hot air through tar. For your information: tar is obtained by heating the last fraction formed during oil refining in vacuum to a very high temperature (exceeding 400 degrees). The main feature of insulating bitumen (a resinous substance) is that it does not dissolve in water. After applying it to the surface, it forms a durable and waterproof coating that does not corrode.

Practice shows that the use of such waterproofing can significantly increase the service life of the pool and guarantee its long-term operation even in conditions of constant contact with groundwater. Roll and coating materials (mastics) are made from bitumen.

Polymer waterproofing compounds include polyurethane-based compounds. After this material is applied to the surface, it interacts with air and transforms into a polymer film that protects against moisture. Polymer waterproofing is a universal coating and has a number of advantages:

- good elasticity;

- durability (service life is more than 15 years);

- has excellent adhesion to materials such as ceramic tiles, concrete, glass and brick;

- resistant to temperature extremes;

- easy to apply (due to the fact that the composition is a liquid or semi-liquid substance).

Polymer insulation can be coated or sprayed. On the construction market, it is presented in the form of mastics and sealants. With the help of mastic it is possible to cover rather uneven and hard-to-reach surfaces with a protective layer. A sealant is a more viscous "representative" of polymer waterproofing, which can be easily applied to a surface of any geometric shape (for example, it can be used to isolate joints and seams). Liquid rubber also belongs to the category of polymer waterproofing.

By application method

According to the method of application, materials are divided into:

- coating;

- sprayed;

- roll.

Lubricants (penetrating impregnations, bitumen and polymer mastics) are used to create a seamless monolithic layer. Most often, one- or two-component cement-polymer waterproofing is made, using which you can carefully seal pores and small cracks formed in concrete. Lubricants, which have a relatively low cost, are able to provide high-quality protection of the font with minimal labor costs: after all, you can apply several layers of mastic with a brush or spatula on your own.

Roll materials (roofing material, film membrane, PVC film) are used to equip the protection of the pool both from the outside and from the inside. True, using such materials, you will not be able to avoid the presence of seams in the insulation.

Advice! We lay the roll materials in two layers in order to overlap the seams.

Swimming pool film

- PVC film "Alkorplan 2000" dark blue, width 1.65 m or 2.05 m

- PVC film "Alkorplan 2000" ribbed blue 20 x 1.65 m

- PVC film "Alkorplan 3000" "Persia Blue Mosaic" 25 х 1.65 m

- PVC film "Alkorplan 3000" "Mosaic mosaic (blurred)" 25 x 1.65 m

- PVC film "Alkorplan 3000" "Byzance mosaic (not blurred)" 25 x 1.65 m

- PVC film "Alkorplan 3000" "Marble marble" 25 x 1.65 m

- PVC film "Alkorplan 3000" "Carrara marble" 25 x 1.65 m

- Alkorplan PVC track marking black, 25 х 0.25 m

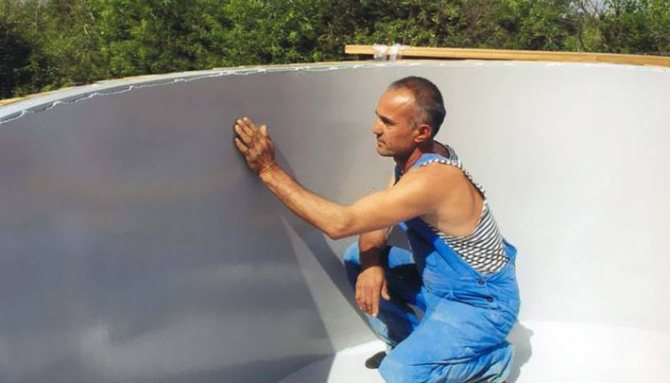

Swimming pool film - this is another way to tile your pool, but before you come to any choice, you should decide not only on its shape, location, but also on the view. Cladding materials should not only have an aesthetic function, but do not forget about their practical value. And one of these options is pool film, which is quite popular.

Pool films are inferior to mosaic or tile finishes, but still in demand. And there are good reasons for this.

The film is considered a new facing material and solves two functional tasks at once: covering the bowl and waterproofing the reservoir. In the latter case, the size, shape and type of the pool is unimportant. Innovative technologies make it possible to glue the film on a wide variety of surfaces. It can be: concrete, plastic, tiles, iron. It can withstand a variety of products that are aimed at maintaining the pool and the effects of microorganisms that can start in the water.

The film has a fairly wide range of colors and a variety of patterns, which will make your pool very beautiful. At the same time, the film in a very quick time will ensure tightness, even if there are cracks in the bowl.

The upper word has a slightly roughened surface for anti-skid properties.

To lay the film, you do not need to have special knowledge. Here you may just need to familiarize yourself with the instructions and follow what is written there. Film is an inexpensive material, so it is a good way to both save money and decorate the pool. A small price will allow almost everyone to purchase a material that can become a decoration and provide waterproofing.

But among the pluses, there are certain drawbacks. This material is not durable. Average service life is 6 years. It gets dirty quite easily, can fade and lose its shape. If the waterproofing is broken, then bubbles may appear on the inner wall. And if there is a skiper, then the difference between the color of the film under water and above the surface will be visible.

On our website you can see a wide range of film coatings.

External waterproofing technology

Before proceeding with the arrangement of the protection of the bowl of the font from the inside, the external waterproofing of the pool is made:

- if the groundwater level is higher than the bottom plate, then we construct a drainage system around the font;

- we carry out a concrete screed for the base of the pool;

- lay out the prepared roll material on the ground (according to previously performed measurements);

- we connect the seams by welding;

- we carry out the laying of external waterproofing, performing it with a large margin at the edges, so that later it can be brought onto the walls of the pool and connected to the inner insulating layer of the bowl.

Important! Instead of roll material, penetrating compounds can be used as external waterproofing, for example, mastics, with which we fill the smallest pores and cracks.

Features of the waterproofing process

What do you need to consider?

Pool waterproofing is an obligatory stage of work, without which the pool will not be a pool, but simply a concrete pit in the ground. Moisture-protective coatings, which are usually made multi-layer, allow you to solve a number of tasks:

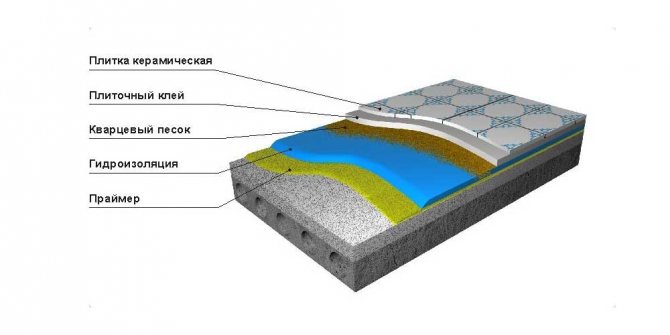

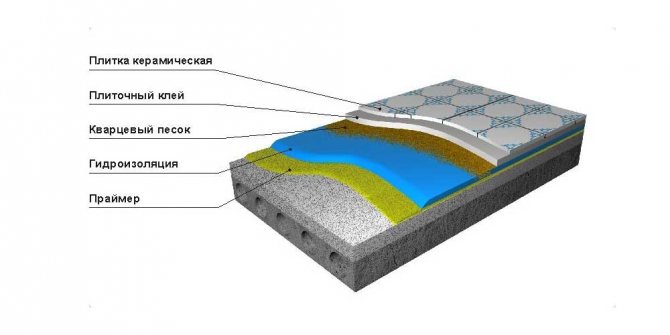

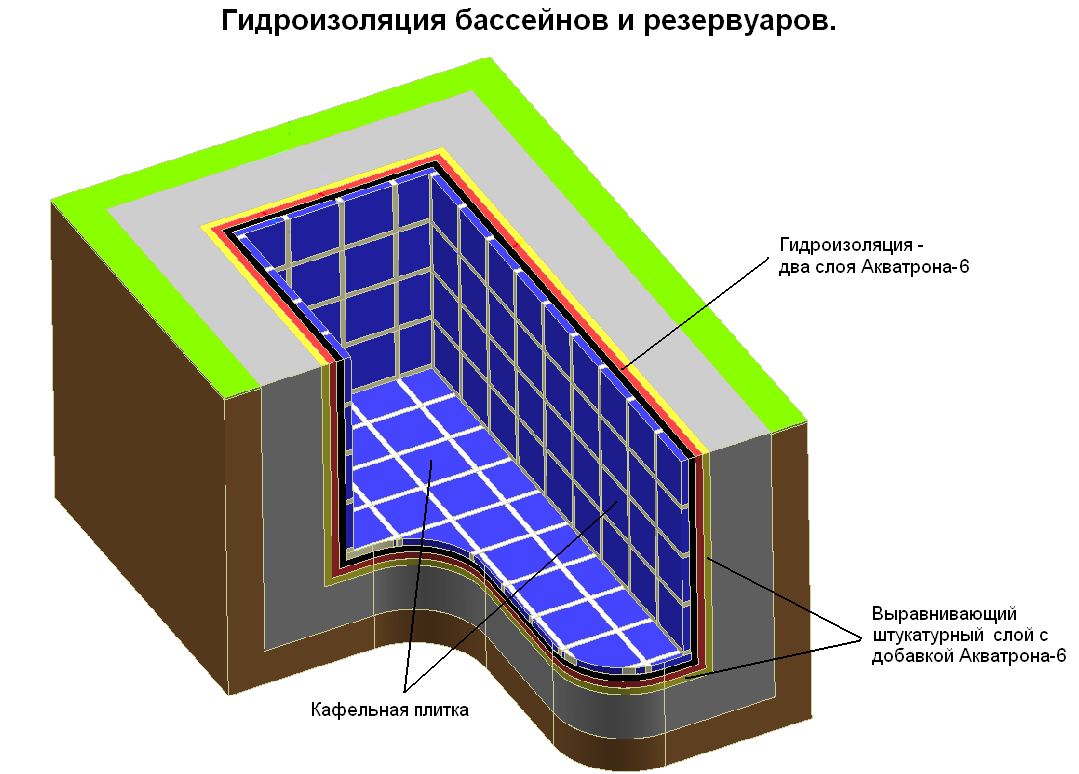

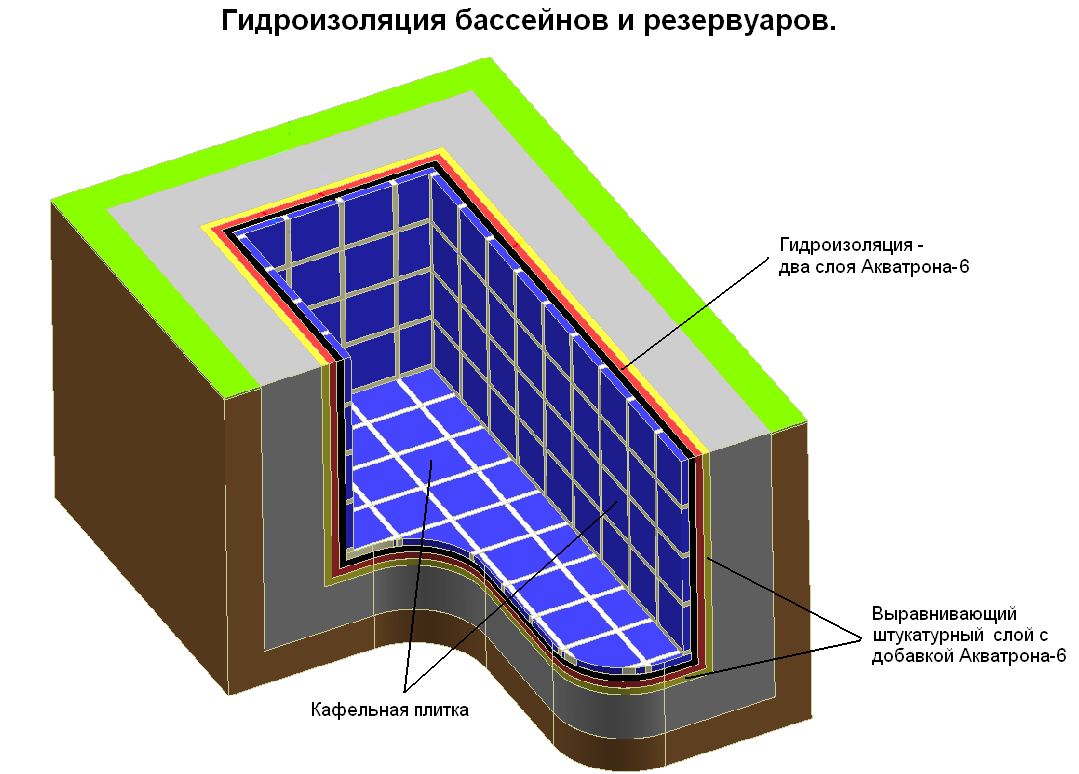

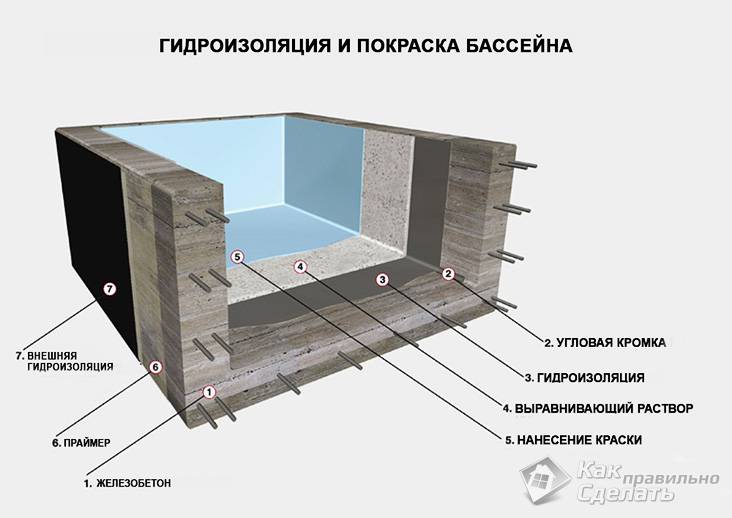

Typical flooring arrangement with tiled cladding

- Keeping water inside. A pool is a reservoir with a large (or very large) volume of water, so the pressure on the walls of the structure from the inside will be very significant. Consequently, pressurized water will look for the slightest gap to escape. And if the used waterproofing for the pool is not reliable enough, the water will find this gap!

- Protection of the concrete base. High-quality concrete, which is used for hydraulic structures, must tolerate long-term contact with a humid environment well. Nevertheless, waterproofing materials act as a barrier, which significantly increases the life of the concrete and the leveling layer.

The concrete base requires protection - otherwise, sooner or later, the bowl will begin to collapse

I would like to draw your attention to the fact that even the most effective waterproofing of swimming pools will not help if the concrete walls are made in violation of the technology. The same applies to low-grade concrete: sooner or later, the tank will begin to collapse.

- Finishing protection. If you plan to use ceramic tiles for the interior decoration of the bowl, you should make sure that the base for gluing is protected from water. Yes, the tile itself has almost absolute resistance to moisture, but if you do not waterproof the walls of the pool, then the adhesion to the adhesive will be broken. As a result, the cladding will begin to fall off.

If there are gaps, then water will penetrate to the base and the finish will fall off

- External protection. External waterproofing is required primarily for those parts of the structure that are located below ground level. On the one hand, it protects the concrete from infiltration of groundwater with dissolved layers. On the other hand, it will act as an additional protection against leakage, preventing the soil from getting wet around the perimeter.

Outside, the reservoir also requires protection from contact with groundwater

In general, pool waterproofing is clearly not a stage that can be neglected. The quality of this work directly depends on how reliable and durable the water bowl will turn out to be. And to ensure this quality, we need to use the right materials.

Materials used

Treatment of the tank to prevent leakage / infiltration and to protect the concrete from moisture can be done with different formulations. The range of such funds is very wide today - there are plenty to choose from.

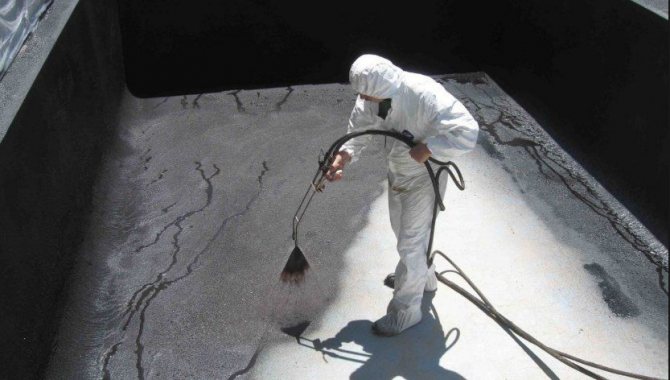

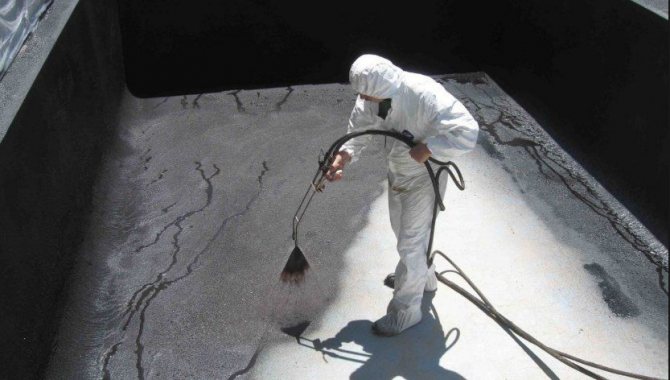

Penetrating formulations are usually applied with a spray gun - so the consumption is less and the protection is more effective

Keep in mind that some materials can also be used as decorative finishes. Others allow concrete to be waterproofed, but require cladding.

Main material groups:

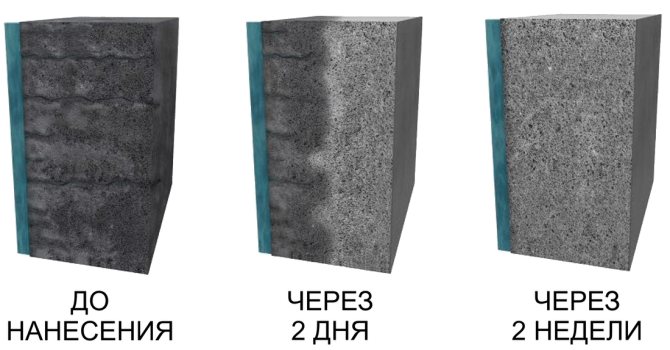

- Penetrating agents for concrete. The product ("Penetron" and its analogues) is applied to the concrete surface and, penetrating into microcracks, clogs them.By and large, penetrating waterproofing is used as a preventive and auxiliary one. It is quite effective, but to protect the concrete base, it is still advisable to enhance its effect with another waterproof one made of another material.

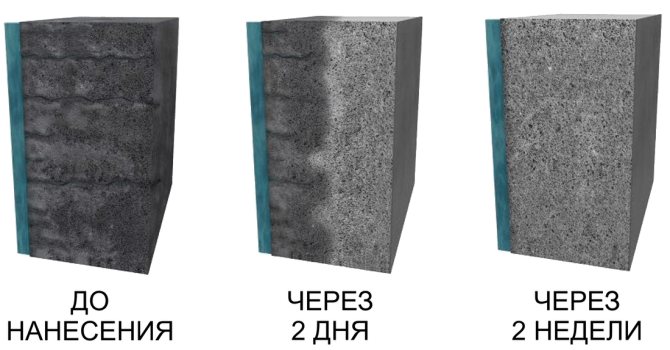

Diagram illustrating the effectiveness of concrete penetrators

Penetrating compounds have one drawback - they are mostly liquid. As a result, such means are not suitable for all works - for example, sealing joints and cracks will be very difficult. There are exceptions ("Penekrite" and analogues), but it is rather difficult to find them, and they cost a lot.

- Polymer-cement coatings... The basis of the material is cement with the addition of sand, polymer additives are responsible for moisture protection. The finishing of the concrete bowl is carried out in the same way as with ordinary cement plaster - along the grid, using spatulas and floats. The key disadvantage is low elasticity: without protection, the layer of material can crack at temperature drops.

Concrete surfaces for finishing can be impregnated with liquid glass - this increases the resistance of the cement at times

- Silicate materials. Liquid glass for waterproofing a pool is used in two ways. In the first case, sodium and potassium silicates are added to the composition of the cement used to level the walls of the tank from the inside. In the second, the composition in liquid form is applied to the concrete surface, penetrating into the pores and preventing moisture seepage.

- Mastics. They are used for both exterior and interior decoration; after partial polymerization, they form an airtight coating that is impervious to vagi. Outside, a simple and fairly cheap bituminous mastic is usually applied to protect the pool bowl. For internal processing, more expensive formulations are used - PeneSplitSeal and PenePurFoam (injection resins), Polybit Polyflex, Idrosilex Pronto, etc.

Bitumen-based mastics are mainly used for roughing

The lack of mastics for internal processing is the complexity of the subsequent tiling of the pool bowl. That is, theoretically it is quite possible to do this, but in practice the main difficulty lies in the fragile adhesion of polymerized mastics with adhesives.

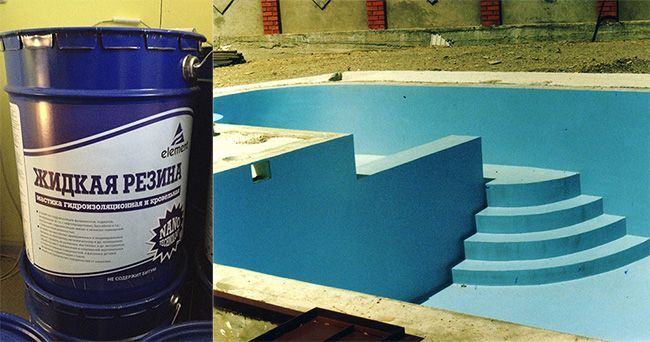

On a large scale of work, liquid rubber is applied mechanically

- Liquid rubber for the pool. It is not used so often, since it is almost impossible to fix the cladding on it with a sufficient margin of safety. On the other hand, waterproofing with liquid rubber ensures complete tightness, and the material itself has an enviable resistance not only to water, but also to most of the components used for cleaning and disinfecting swimming pools. It is applied either by hand (paint formulations) or by cold spraying (two-component polymerizing emulsions).

For self-painting, liquid rubber pigments are applied with brushes and rollers

Using a plastic film for lining the bowl is a difficult but effective option

- Films and membranes. They are presented on the market in an extensive assortment, differing not only in thickness, but also in structure (and, therefore, in performance indicators). The film is usually simply placed in a bowl on an adhesive layer, while the membrane is formed from moisture-proof impregnation and reinforcing fabric. The advantages of materials are their elasticity: due to their elasticity, they can bridge cracks up to 3 mm, while maintaining water resistance.

When using a PVC membrane or film, it is very important to ensure the tightness of the joints - for example, by welding, as in this photo

A significant disadvantage of membranes is their high price. Plain coatings cost from 800 rubles per square meter (with a thickness of 1.5 mm), materials with a pattern or markings - from 1200-1600 rubles / m2 and more.

Most of the materials listed here will be used in the professional manufacture of swimming pools.This is explained by the fact that the required quality of the coating can be ensured only with mechanized application using special equipment.

If you plan to carry out all the work on your own, then the combination of the following materials will be optimal:

- moisture-proof additives in concrete;

- penetrating impregnation for concrete base;

- external coating waterproofing using bituminous mastic;

- interior finishing with liquid rubber paint.

- or internal leveling with a moisture-resistant impregnated mortar and subsequent tiling.

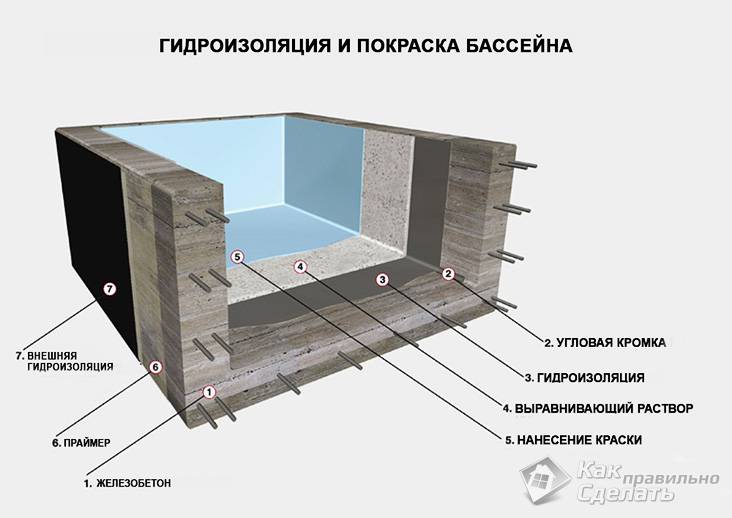

Typical pool finishing scheme for independent construction

Naturally, other complex waterproofing schemes also have a right to exist.

Internal waterproofing technology

Internal waterproofing of the pool is an important step in the construction of the entire facility. The technology for applying all kinds of coating materials is quite simple:

- after pouring the bowl (by the way, in order to increase the waterproofing properties of concrete, we add plasticizers and special additives to it), we leave it for final drying;

- small cracks and other defects are sealed with resin or sealant;

- we equip the screed of the base of the font with the help of a self-leveling solution;

- we make plastering works;

- we clean the surface of the bowl to make it rough (this is necessary for better adhesion of the protective coating to the concrete);

- we remove dust and debris; degrease the surface;

- we prime the inner surface of the pool bowl with a special compound;

- let the primer dry (the drying time is indicated on the package);

- we prepare the coating composition according to the instructions;

- we apply waterproofing in two or three layers, profusely brushing over the seams, small cracks, gaps and junctions of the surfaces of the pool surface with a brush (each subsequent layer is applied only after the previous one has dried);

- after the waterproofing layer has completely dried, we check the pool for leaks;

- we carry out facing work.

On a note! Remember: "the cheapskate pays twice," so you better buy expensive coating materials (they are more effective), and in combination with a fiberglass mesh, they become more durable and elastic.

Swimming pool waterproofing technology from the inside

Waterproofing application scheme

Let's consider all the work in stages. Thanks to these instructions, you can do your own waterproofing from the inside.

Plaster the bowl

So, you should:

- Clean the concrete base from all debris and dust.

- Sew up all cracks and seams and treat them with special joint sealing agents. All joints must be glued with sealing tapes.

- Level the entire surface by plastering the bowl. At the same time, treat the walls with special compounds for pools that are resistant to moisture, and at the bottom of the bowl, make a screed from a self-leveling cement mixture.

Primer

Prime the dried surface with a primer. It can be applied with a brush or roller. After 3-4 hours the surface will be ready and the next layers can be applied.- Now dilute the dry mixture of penetrating waterproofing with water to get a thin consistency like sour cream. Better to use the instructions. It is the ratio indicated by the manufacturers that is optimal.

- Using a wide brush, apply the solution to the base that you have already prepared in advance. Especially carefully treat the places of entry of communications, the seams between the walls and the bottom of the pool, as well as the seams formed during concreting, and the places where there were cracks.

- It is worth noting that when treating the pool with waterproofing compounds, you need to apply them in a complex manner: first of all, a penetrating solution, after which a coating.As soon as you apply the penetrating solution, the entire surface should be treated with hydrochloric acid 4–5%, and then rinsed with water. After half an hour has passed, treat the surface again with a solution of 4–5% soda ash. And only after all the procedures can the coating mastic be applied.

- Once the entire pool surface has been covered with waterproofing material, warn everyone not to step on it. You cannot walk on them, moreover, for 3 days the temperature should not fall below 0 ° C. That is why such work should be carried out in the summer.

- In order to avoid cracking and peeling of the material, the entire surface needs to be moistened within 3 days. Those places that are under water pressure must be moistened for at least 10 days. For humidification, a water spray is well suited, and the concrete surface of the pool itself must be covered with plastic wrap for this time.

- Finally, after completing all work, the pool bowl should be checked for leaks. Water is collected in the pool and kept there for 10 days. If no leak is found, all the water is drained, the bottom is cleaned of debris and allowed to dry.

- At the end, facing work is carried out. The pool bowl is lined with tiles or mosaics.

Most popular waterproofing materials

Liquid rubber

Liquid rubber is a bitumen-polymer mastic that has good waterproofing properties and combines the advantages of coating materials and roll materials. It is applied in several layers: as a result, we get a pleasant to the touch, dense and durable seamless coating.

Liquid rubber is a versatile material in the sense that it can act both as a topcoat, that is, without further decoration (just buy a colored material), and as a base for tiles or mosaics.

Liquid glass

An aqueous alkaline solution of sodium or potassium silicates is nothing more than water glass, which is also known in the trade as silicate glue. Liquid glass in combination with a cement-sand mortar creates a durable waterproofing coating. The advantages of silicate glue include the fact that it is relatively inexpensive, and the disadvantages that this material quickly hardens after mixing (within 5 minutes) and is short-lived.

Evaluation criteria for waterproofing material

By application

Insulating bitumen is a material obtained by blowing hot air through tar. For your information: tar is obtained by heating the last fraction formed during oil refining in vacuum to a very high temperature (exceeding 400 degrees). The main feature of insulating bitumen (a resinous substance) is that it does not dissolve in water. After applying it to the surface, it forms a durable and waterproof coating that does not corrode.

Practice shows that the use of such waterproofing can significantly increase the service life of the pool and guarantee its long-term operation even in conditions of constant contact with groundwater. Roll and coating materials (mastics) are made from bitumen.

https://www.youtube.com/watch?v=h2-VIzMKLlA

Polymer waterproofing compounds include polyurethane-based compounds. After this material is applied to the surface, it interacts with air and transforms into a polymer film that protects against moisture. Polymer waterproofing is a universal coating and has a number of advantages:

- good elasticity;

- durability (service life is more than 15 years);

- has excellent adhesion to materials such as ceramic tiles, concrete, glass and brick;

- resistant to temperature extremes;

- easy to apply (due to the fact that the composition is a liquid or semi-liquid substance).

Polymer insulation can be coated or sprayed.On the construction market, it is presented in the form of mastics and sealants. With the help of mastic it is possible to cover rather uneven and hard-to-reach surfaces with a protective layer. A sealant is a more viscous "representative" of polymer waterproofing, which can be easily applied to a surface of any geometric shape (for example, it can be used to isolate joints and seams). Liquid rubber also belongs to the category of polymer waterproofing.

According to the method of application, materials are divided into:

- coating;

- sprayed;

- roll.

Lubricants (penetrating impregnations, bitumen and polymer mastics) are used to create a seamless monolithic layer. Most often, one- or two-component cement-polymer waterproofing is made, using which you can carefully seal pores and small cracks formed in concrete.

Roll materials (roofing material, film membrane, PVC film) are used to equip the protection of the pool both from the outside and from the inside. True, using such materials, you will not be able to avoid the presence of seams in the insulation.

Advice! We lay the roll materials in two layers in order to overlap the seams.

Pool waterproofing can be done with a variety of materials, but not all are equally effective. Requirements for waterproofing material:

- moisture resistance;

- resistance to deformation and other mechanical stress;

- immunity to temperature extremes;

- good adhesion to other materials;

- elasticity.

Liquid rubber

Liquid rubber is a bitumen-polymer mastic that has good waterproofing properties and combines the advantages of coating materials and roll materials. It is applied in several layers: as a result, we get a pleasant to the touch, dense and durable seamless coating.

Liquid rubber is a versatile material in the sense that it can act both as a topcoat, that is, without further decoration (just buy a colored material), and as a base for tiles or mosaics.

Liquid glass

An aqueous alkaline solution of sodium or potassium silicates is nothing more than water glass, which is also known in the trade as silicate glue. Liquid glass in combination with a cement-sand mortar creates a durable waterproofing coating. The advantages of silicate glue include the fact that it is relatively inexpensive, and the disadvantages that this material quickly hardens after mixing (within 5 minutes) and is short-lived.

Read next: What is adhesion

PVC foil

PVC film is the most popular material for waterproofing. For all its advantages, one should not forget about the disadvantages: expensive installation (since you cannot do without the participation of professionals) and the material is susceptible to mechanical stress.

So, the abundance of waterproofing materials will provide high-quality protection for your pool, and it will delight you for many years.

Liquid waterproofing for swimming pools

For waterproofing swimming pools, all the same materials are used as for ordinary concrete foundations. The working conditions of these two objects (pools and foundations) are approximately the same - both work in difficult and wet conditions. So, waterproofing foundations is to some extent similar to this topic.

→ The most accessible type of waterproofing is coating. These include liquid rubber and liquid glass. The so-called rubber paint for concrete is a solution of bitumen, polymers and other chemical additives. Supplied to the construction market in plastic containers of various sizes. Liquid glass is an ordinary cantor glue, which is successfully used as a waterproofing agent.

Penetrating waterproofing

→ The next type of pool waterproofing is the use of penetrating waterproofing.These are special solutions that are applied to the concrete surface with a brush, roller or spray gun. Due to the special composition, concrete is protected at the molecular level. Even the smallest pores of concrete cease to "pull" moisture from the soil or from the contents of the pool. It is used for internal and external surface treatment.

This method is considered to be very effective, but expensive. Penetrating waterproofing can significantly increase the frost resistance of concrete and significantly increase its water resistance. It is supplied in both liquid and dry powder form. Here are some materials that can be successfully applied to waterproof your reservoir: Penetron - deserves a special review, Mastersil 501, Lakhta, etc.

Penetrating waterproofing for swimming pools

→ The glued waterproofing is inherently clear from its name. The outside walls of the pool are pasted over with roll materials based on bitumen. A simple example is stekloizol, stekloelast and similar famous products.

Waterproofing for pools of this type is applied to the surface using a hot method using a gas torch or gasoline blowtorch. The whole process can be compared with the technology of the welded roof, only here you have to work with a vertical, and not with a horizontal surface, as on the roof.

Papered insulation resists frost well, is not afraid of sunlight and has excellent extensibility, which means, as a result, a kind of strength. A sure sign of good waterproofing is a solid, solid and monolithic layer. This is the surface that should be obtained when working.

→ Screen technologies can also be successfully used for waterproofing concrete pools. A kind of screen is created between the damp soil and concrete, which reliably protects the walls from moisture penetration. We apply this method only for external waterproofing. Bentonite mats are used as insulating materials. What it is, how they work and "what do they eat with", you can read in this article.

→ Membrane waterproofing materials and PVC films are successfully used in the issue discussed here. The quality of these membranes and films has been tested for decades, but their use requires the participation of qualified personnel. To create a homogeneous sealed layer, thermal bonding of the film has to be carried out. Accordingly, a lot will depend on the quality of the work done.

Read more: Choosing a press tongs for metal-plastic pipes

If you have a small pool, there is an option to invite a specialist from the relevant company to your home. After all measurements, the required dimensions. Then the ready-made "pool bag" is delivered directly to the client at home. All that remains is to carefully put this plastic bag into the concrete basin of the pool and check it for leaks.

This method of waterproofing, in addition to its main function, also plays a decorative role. The color shades of PVC films (for example, ALKORPLAN) are different, so there is a “tidbit” for any gourmet. Membranes and films perfectly perceive the load of water even on uneven surfaces, but they can be mechanically damaged by carelessness: cut, pierce, etc.

For this reason, large and serious pools are still waterproofed with mastics of coating waterproofing and penetrating technologies are used in the complex.

Pool plastering

→ In addition to all of the above, one cannot fail to mention the special water-repellent (hydrophobic) cement-based plasters. Manufacturers of these building materials add special additives and plasticizers to their products, while creating a reliable barrier to water.

Any body of water, whether it is on a personal plot or in a bathhouse, is always a kind of highlight. You always want him to look "one hundred percent". But this is a complex hydraulic structure, and therefore you should not think that if the waterproofing of the pool is done well, there will be no problems in terms of operation.

Quote from Wisdom: Conscience usually does not torment those who are to blame.