For many people, the comfort in the house is associated with a warm floor. Since laminated parquet is a cold material, to increase the level of comfort, insulation is used under the laminate. Of course, parquet and laminate flooring have a number of advantages, but cold floors cause discomfort, so enough attention should be paid to floor insulation.

Implementation options

Heating an apartment or house with "warm floors" has a number of advantages in comparison with the traditional version, with the use of heating radiators. So, it remains only to decide which warm floor under the laminate is best suited for this coating.

For the device of the "warm floor" system three main technologies are applied:

- Using water heating;

- Using electric cable;

- Using electrical panels with infrared radiation.

But are they all suitable for use with laminate flooring? And in general, is it possible to lay underfloor heating under the laminate? In order to answer these questions, it is necessary to study the features of the listed systems in somewhat more detail.

Water

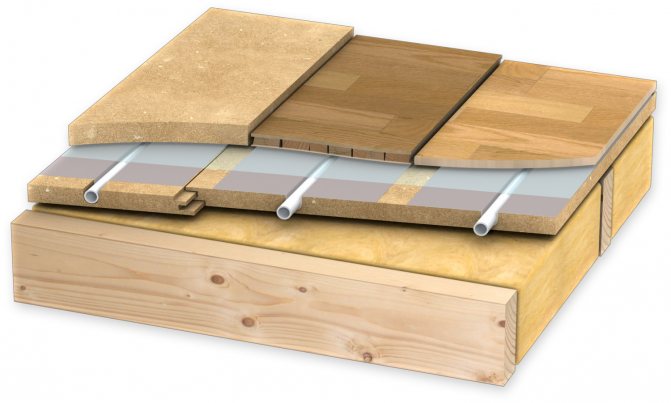

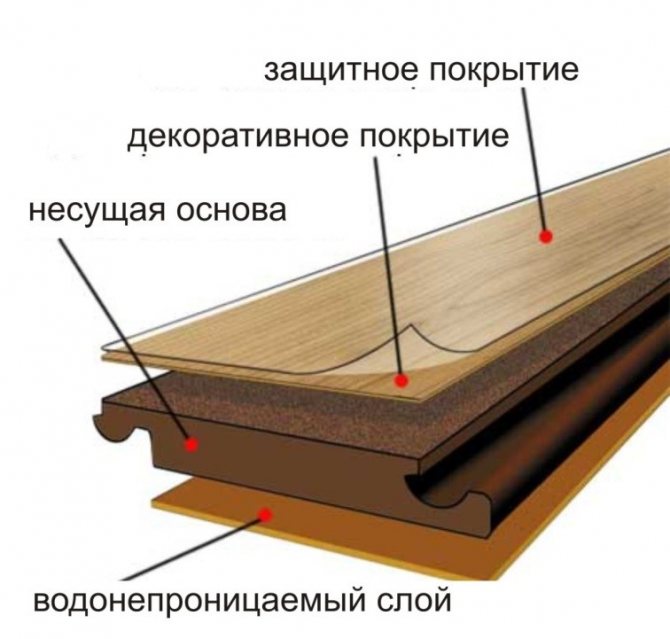

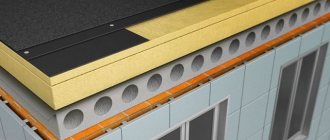

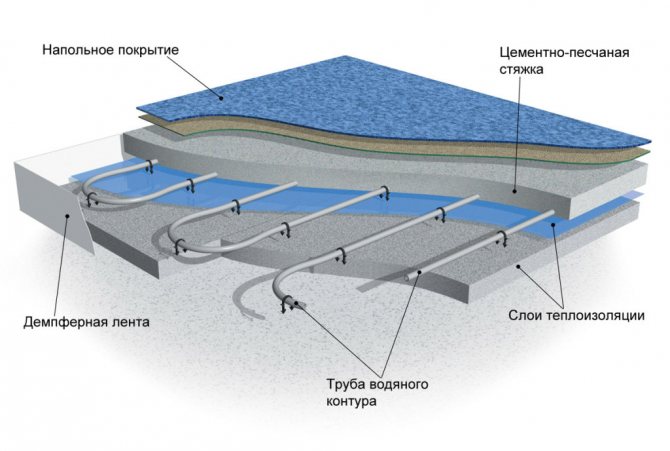

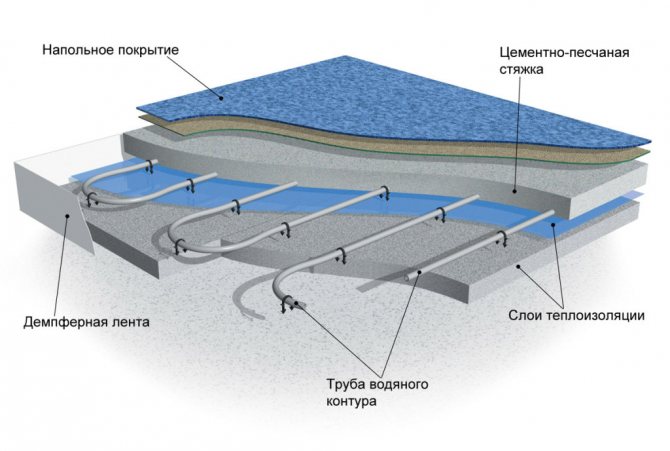

Functions on the basis of hot water moving through pipes hidden in the floor... Consists of several layers:

- Waterproofing, with the obligatory laying of a damper tape around the perimeter of the room.

- Then comes a layer of thermal insulation, which can be used as foam, expanded polystyrene and other insulating materials.

- Pipes with a small section are laid on it, poured with a concrete screed.

- The last layer of the structure is the topcoat, in this case the laminate.

The main disadvantage of this type of system is the laboriousness of installation. In addition, an underfloor heating water floor should not be installed under the laminate due to the existing risk of pipe burst under the coating.

Such a "nuisance" may well occur in the event of a pressure surge in the system. As a result, a beautiful, practical floor will be ruined. therefore water-type heating system is not suitable for use with laminate flooring.

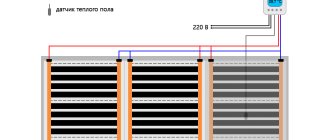

Electric cable based

When using this type of "warm floor" the room is heated using a two-wire electric cableconverting electrical energy into heat.

It is laid on a carefully leveled, cleaned surface covered with a layer of thermal insulation. Underfloor heating laminate is usually made of high quality and durable materials with high thermal conductivity.: extruded polystyrene foam, expanded polystyrene foam or cork.

From above, the cable is closed with a thin concrete screed made using a reinforcing mesh, on which the laminate is laid.

The main advantage of this type of system is simplicity and ease of manufacture.... Installation of a warm electric floor under the laminate can be done independently, without the involvement of specialists.

As for the shortcomings, the main one is the high operating costs associated with paying for consumed electricity. But such a system combines very well with laminate.

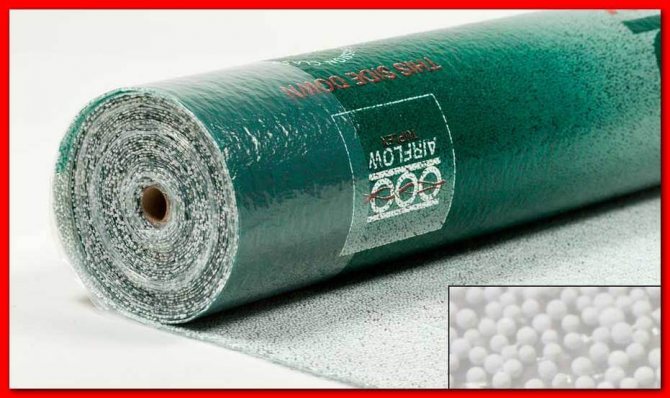

Infrared

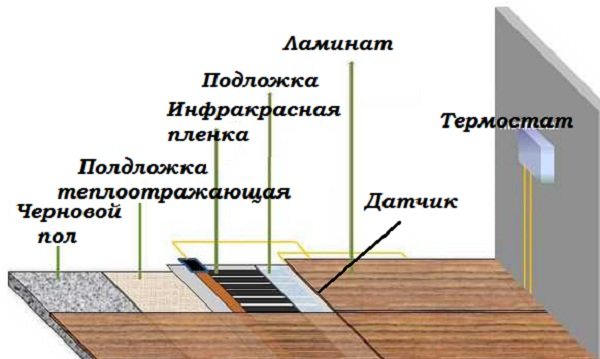

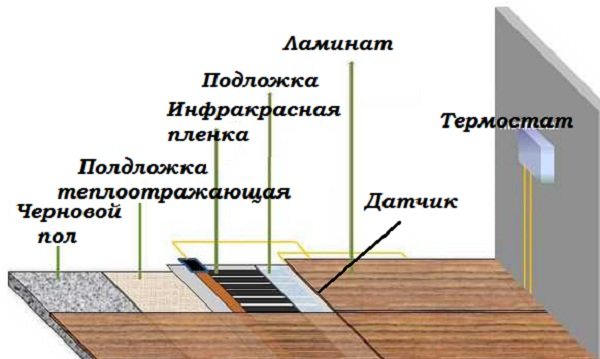

This underfloor heating system for laminate is the most modern and technologically advanced... At the heart of its design is an infrared-type film laid on a heat-reflecting material (penofol or penoizol) and covered with a polyethylene layer on top.

Infrared underfloor heating has a number of advantages compared to other heating options. These include:

- Durability and structural reliability;

- Convenience and ease of installation;

- Minimum terms of work;

- Saving space due to the absence of the need to fill the screed;

- Greater cost-effectiveness compared to cable-type floors.

But this system also has its obvious disadvantages. For example:

- High cost;

- Impossibility to use in rooms with high humidity;

- The presence of a perfectly flat, smooth base.

This type of underfloor heating works very well with laminate flooring.

Having decided to use water-based underfloor heating in conjunction with a laminate as a heating source, you need to pay attention to the following points:

- When connecting "warm floors" to a centralized heating system, it is better to use coverings of other types, since the laminate is very sensitive to waterlogging, which can occur when the pipe ruptures due to water hammer. That is, it can only be laid on water floors connected to autonomous heating systems, for example, in private houses.

- To achieve the best effect the base on which the pipes will be laid must be carefully insulated... Pipes should be fastened to a reinforcement mesh or special profiles equipped with clamps. In addition, for this purpose, you can use mats designed for laying a water-heated floor, which can simultaneously serve as a waterproofer, insulation and pipe fixing.

Thus, the energy from the coolant will not be wasted.

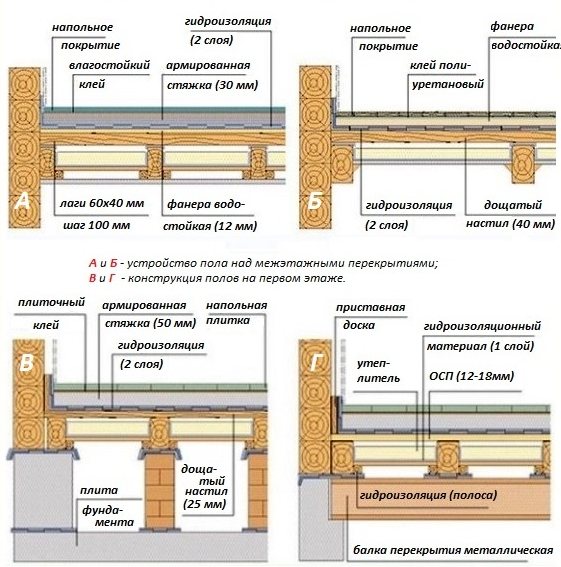

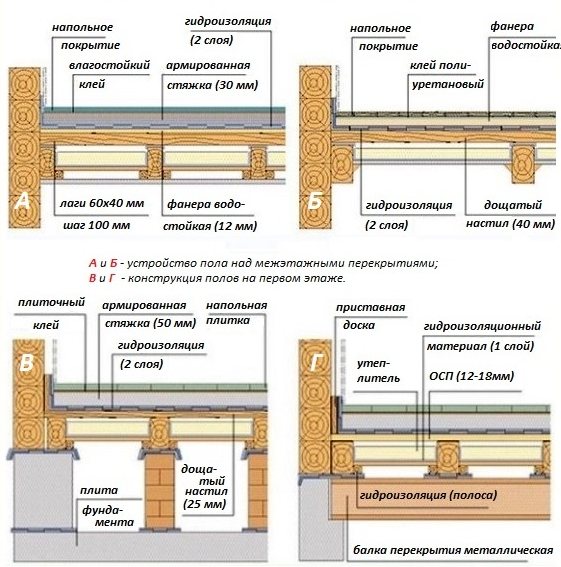

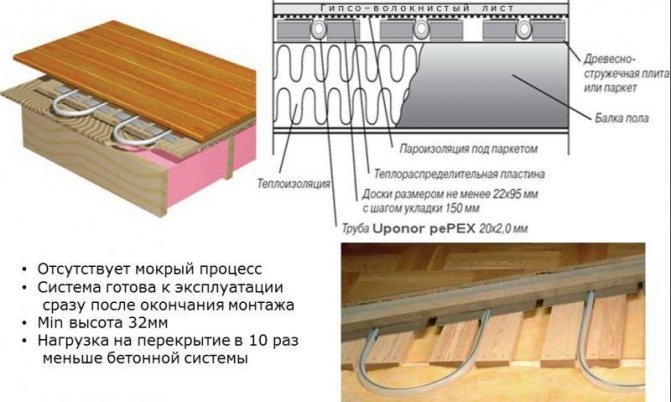

Installing warm floors in your home under the laminate with your own hands, you can use a different technology for the device of water-based systems, without using a screed.

This installation method can be used in rooms where a wooden board is used as a base..

In these cases, a flooring system is installed, which can be wooden or polystyrene. In another way, it is called "dry warm floor".

Underfloor heating parts with wood base

Many clients dream of installing a warm floor on a wooden base, is it possible? Of course yes! You just need to get away from the standard method and take into account all the specifics of the wooden coating. Technologies have reached the point that at the moment the wooden base is laid exclusively in two options - water and eclectic.

For further work, it is worthwhile to draw a line in the definition of the concept of "wooden floors". If we are talking about lived boards, then this base recommends removing and installing a heating system using a traditional concrete screed. The main reason for this manipulation is the following: the flooring will be flat, without the obvious bumps that were generated by excessive "economy".

If the client does not want to reduce the height of the ceilings, then the most correct solution is to install a dry floor with a wooden base. But we must not forget about the nuances that clients will encounter:

For the installation of a dry underfloor heating, lattice sections made of chipboard or OSB are required, in which slots for laying pipes are provided. Their width varies from 14 to 28 centimeters. The plates themselves are held together by clamps, which form the grating.

There is another option for installing water pipes on a wooden base - a rack system. For this, slats from chipboard, plywood are mounted, and pipe contours are formed between them. This system contributes to savings, since you do not need to buy ready-made modules.

Materials and equipment

Installing a warm floor under a laminate requires the use of a certain set of materials and equipment, which include:

- Waterproofing;

- Pipes with a diameter of 16-20 mm. They can be made of polyethylene, metal-plastic or copper;

- Damper tape;

- Plasticizer;

- Collector group;

- Insulation (expanded polystyrene);

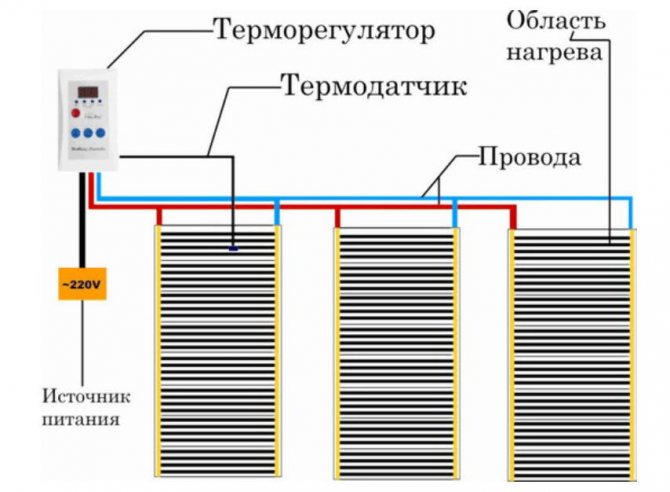

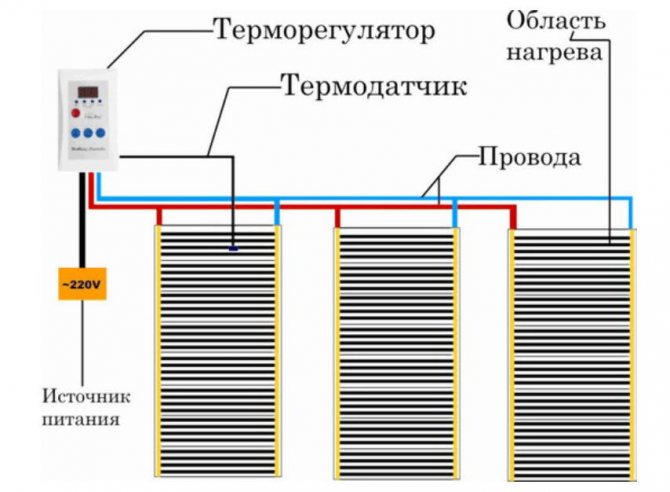

- Thermoregulators;

- Pump-mixing block;

- Fasteners.

For an electric floor you will need:

- Two-core cable.

- Foil polystyrene.

- Heat-reflecting material (isolon or infraflex).

- Fasteners, temperature regulator.

Before laying the warm floor under the laminate, it is necessary to carefully level the base on which it will be located using flooring or cement-sand screed.

Stages of installation of the structure of a water heat-insulated floor under a laminate

The following steps are mandatory and constituent parts of the installation of the system:

- Sub-floor preparation. It should not have bumps, pits, chips, as well as dust and other debris. Smooth the wood base with plaster or leveling compound. You can also use a sander.

- Drying the cleaned surface.

- Creation of waterproofing by laying out one sheet. The joints can be treated with waterproofing tape.

- Installation of heating elements (tubes), to the system of which the sensor is attached to measure the heat of water.

- Checking the functional activity of the structure.

- A concrete screed is applied to the surface of the pipes, which must be carefully leveled.

- A layer of waterproofing is placed on the screed.

- Laminate flooring.

- Installation of the flooring itself - laminate.

Considering that underfloor heating and laminate are incompatible things, we were able to combine these two opposites. The concrete screed, as well as subsequent layers in the form of waterproofing and gaskets in this system, will not allow the laminate to heat up much and, therefore, evaporate unhealthy compounds.

DIY installation

Before you put a warm floor under the laminate, you need to decide on the option of laying it... It can happen as follows:

- By lags. To do this, it is convenient to use special modules made of chipboard, which are factory equipped with grooves with special channels, thermal distribution plates made of metal and all the necessary fasteners. They only need to be assembled in accordance with the instructions. But such a kit is very expensive.

- On racks... To do this, use a planed board, moisture-resistant plywood or chipboard with a thickness of 21-28 mm. The distance between the slats is usually equal to their width, and the width corresponds to the distance between the pipes in the circuit.

Preparation of the base

When laying the "water underfloor heating" system on a wooden base, installation must be carried out after a set of preparatory works, which include:

- "Opening" the old coating and the base located under it... At the same time, old hydro- and heat-insulating materials are removed, and the base itself is cleaned of traces of dirt, mildew and mildew.

- Visual assessment of the general condition of the foundation. It needs to be inspected for various damage. At this stage, it is necessary to dismantle the sections of the beams that have become unusable, replacing them with new inserts. If strong distortions and blockages of the surface are found, it must be leveled using metal corners, special pads and other fixing elements.

- Treatment of a wooden base with antiseptic preparations... This will avoid further decay and destruction of this material.

The last stage in the preparation of the foundation is its cleaning from dust and debris... Detailed instructions for preparing a warm floor under a laminate can be found in the video presented on the Internet.

Frame fabrication

When laying a warm water floor on a supporting wooden structure with a spacing of beams up to 60 cm, work can be carried out directly on this base... For this, cranial bars are fixed at the bottom of the beams, acting as supports. Subfloor boards are stuffed on them.

It is possible to lay a subfloor without cranial bars.... In this case, the boards are fixed directly into the supporting beams from the basement or underground side. The space between the supporting lags is filled with a vapor barrier material, on which a 15-20 cm thick layer of thermal insulation made of mineral wool, expanded polystyrene or foam is laid.

The distance between the primary floor and the thermal insulation layer must be at least 8-10 cm. For additional ventilation, it is advisable to leave a small unprotected area in the "draft base" near the wall.

When making a frame for floors with a beam pitch of more than 60 cm, the cranial bars should be fastened at a higher height, since the subfloor in this case will be attached to chipboard or plywood nailed to the support beams.

After the insulation, it is necessary to attach a vapor barrier layer. You can find out in more detail how the warm floor is laid under the laminate in the video.

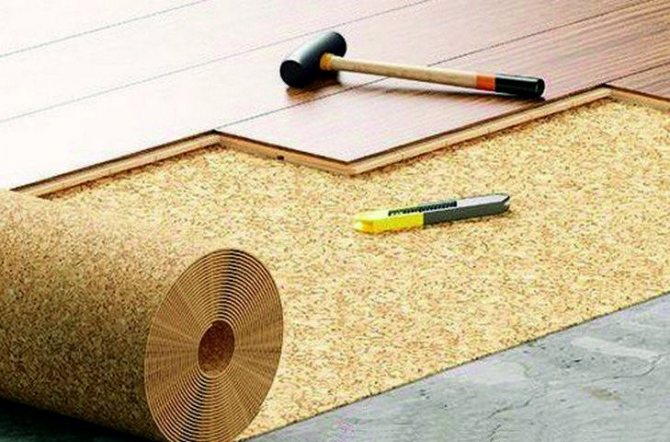

Pipe laying

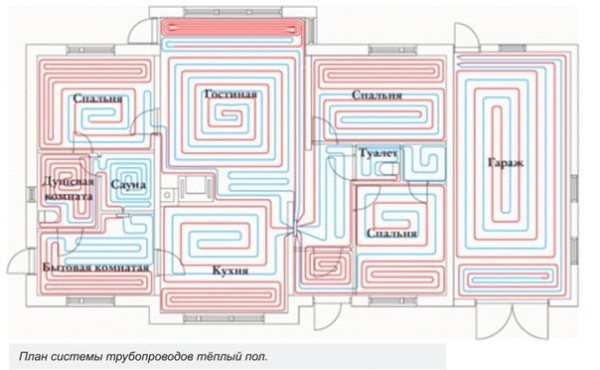

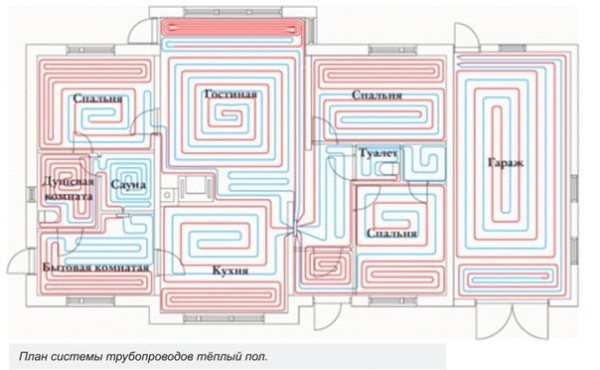

For the installation of water-based underfloor heating, pipes made of polypropylene and metal-plastic are used... Their layout can be done in two ways:

- in a spiral;

- snake.

The first method is more preferable, since in this case there is an alternation of "cold" and "warm" circuits.

At home, it is easier and more convenient to lay pipes "snake". They should be laid out in increments of no more than 30 cm. Near the walls, the step can be minimal: 10-15 cm. This will avoid heat loss at the junctions.

Connection

Connecting underfloor heating to the heating system can be carried out in various ways... The most common are:

- Mixing units;

- Collector system.

After that, the crimping procedure is performed, the main purpose of which is to identify leaks and malfunctions in the pipeline. This operation must be carried out before laying the floor covering!

For "safety net", it is better to carry out a test run in conjunction with specialists. Additional information on connecting underfloor heating under a laminate with your own hands can be found in the video.

Infrared floor heating pros and cons, find out all sides of this type of heating. Read what is the best electric underfloor heating, how to choose the right one and how to lay the covering.

Choose the right electric boiler for heating a private house, recommendations for choosing here.

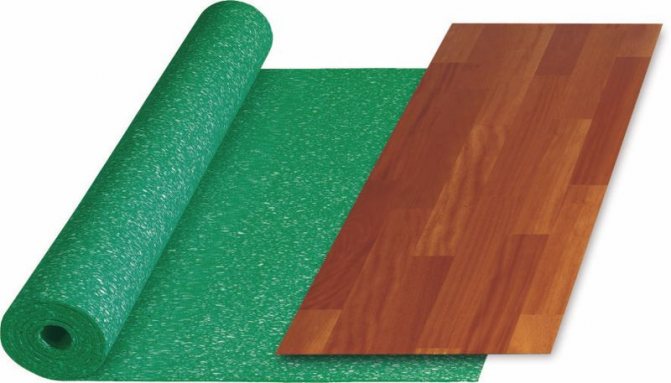

Substrate

After the technical part of the structure has been tested under increased pressure, a substrate is laid on top of the pipes, the function of which can be performed by the following materials:

- Bung;

- Foamed polyethylene foam;

- Foil polystyrene;

- Extruded polypropylene.

The listed materials have different costs. For example, the most expensive is the foil-clad polystyrene backing. But she also has the highest thermal insulation characteristics.

How to properly prepare the base

There are several ways to prepare wood flooring for underfloor heating. The best substitute for a concrete screed is considered to be the installation of chipboard from 16 to 22 mm thick. It will be able to withstand a significant load, stabilize the wooden base and will not crush the heating elements. Both electrical and water heating elements can be placed on it.

Decking device in a wooden base for underfloor heating

- The slab is laid on logs. It is better that the step size is no more than 60 cm, otherwise you will need to install additional beams.

- Before putting the slab, waterproofing and insulating material are laid, so that it is in the intervals between the logs.

- The next steps depend on the type of heating you have selected. If these are electrical heating elements in the form of a film or mats, then a soft foil substrate is needed that will reflect the heat into the room. Water and cable heating options will require fasteners or guides, between which heating elements will be located.

Installation of electric heating

What type of heating is best for a wooden base? Installation of the cable option will require efforts in the form of installing fasteners or elements between which the cable will be located. Such elements can be sawn grooves in planks, aluminum guides or wooden plates.

Step-by-step installation of electric underfloor heating

Therefore, an electric warm mat or infrared film can be considered the best option for a wooden base under a laminate. Why?

- The flat warm mat and infrared foil can withstand heavy loads and are designed for effortless installation.

Features of laying electric heating on a wooden floor - They can be installed under the laminate flooring without an additional board, provided the wood flooring is sufficiently level and strong. In this case, all the gaps between the boards are foamed, the boards are leveled in height, and all irregularities are eliminated. Foil insulation is laid on the waterproofing film, and mats or infrared film are placed on top.

- An infrared warm mat or film was created specifically for laminate flooring, this is the most gentle warm floor option for such a coating.

The disadvantages of electric heating are that it will require significant energy consumption. With any, even the most economical option, this is a tangible amount. The most economical models of electric mats, equipped with various technical innovations, are quite expensive. Therefore, we return to the cable version of electric heating, which, with all the costs and efforts, is more economical in the end.

Pros and cons of electric floor heating

Infrared heating

If there is a choice between electric mats and infrared film, do not hesitate which one to choose. The most convenient and profitable option of all available is film, for several reasons. It was really conceived by the creators as an option for additional heating for coatings such as laminate, linoleum, carpet.

Connecting infrared underfloor heating

Taking into account the latest advances in this area, Kaleo infrared floors are unique in their characteristics. They can withstand significant loads, are versatile, easy to install, capable of heating up to + 60 degrees. Kaleo produces several types of infrared films and mats: from budget to expensive options. They can effectively warm up the room even with a concrete screed.

Undoubted advantages:

Benefits of infrared film

- Heating elements are connected in parallel. If one panel fails, the others continue to work.

- Failed panels are easy to replace.

- This option can be used in a damp room.

- Installation of the film on an adhesive base is provided, which prevents the strips from shifting.

- Among the products manufactured by Kaleo, it is easy to choose a warm floor option that is suitable for the price.

What kind of insulation is recommended for such a film? The manufacturer offers it as a set, as it is made of polyester using special technologies.

Laying laminate

After the installation of the underfloor heating under the laminate is completed, you can proceed to the most important stage of finishing work - laying the topcoat... This requires:

- Prepare the floor, preheating it for 48-72 hours. Then the heating is turned off. At the time of installation of the coating, the surface temperature should be about 15 degrees.

- Bought the laminate is also adapted to future operating conditions... To do this, it is unpacked and laid out in the room where it will fit, for about a day.

- For laying on a "warm floor" it is necessary use a coating with the appropriate marking: E1 or E0, which meets the most stringent environmental safety requirements, and the inscriptions: "Underflоorheating" or "Warm Wasser".

The installation method can be any, depending on the architectural features of the room and your own preferences.

Cost of work and materials

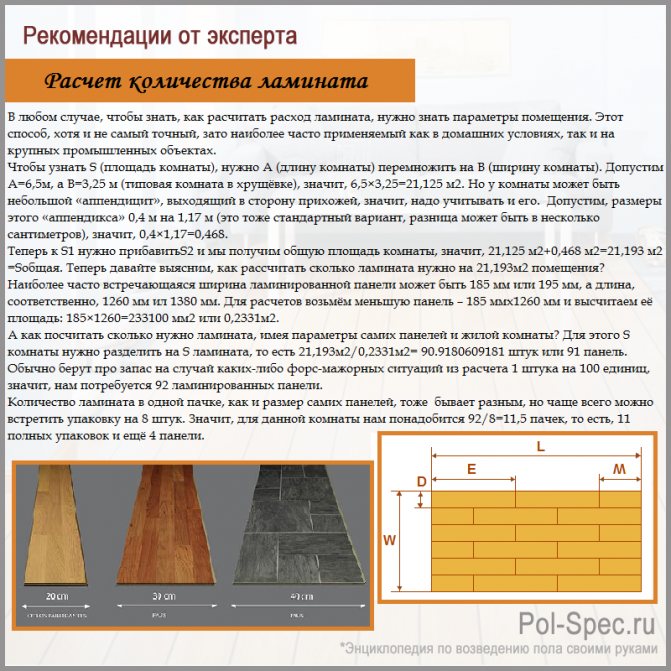

Another important point that excites those who want to install a warm floor under the laminate: prices for materials, installation and work on its device.

They depend on the complexity and area of installation, as well as on the manufacturer of this floor covering. For example, the average prices for the products of the most famous and popular brands will be as follows:

| Firm | Model | Class | Warranty period | Dimensions, mm | Price per sq.m, rub. |

| TARKETT, Russia | Woodstock Premium | 33 AC5 | 25 | 1292X194X8 | 630 |

| CLASSEN, Germany | Futuro harmony ml | 32 AC4 | 15 | 1286x194x8 | 555 |

| KRONOTEX, Germany | Dynamic | 32 AC4 | 20 | 1380x193x8 | 500 |

Please note, when purchasing a laminate under a warm floor, before choosing this or that model, you need to make sure that it is suitable for water heating systems!

Service cost will be:

- Installation of hot water floors: from $ 7 per square meter.

- Floor laying electric type: $ 5 to $ 7.

- Infrared device underfloor heating: $ 3-5.

- Laying laminate: $ 2-4 per square meter.

Do-it-yourself water meter installation: tips and tricks, step-by-step instructions and tips from the masters in our article. Read how to make a solid fuel boiler for long burning with your own hands at https://klimatlab.com/otoplenie/tverdtoplivo/tverdotoplivnyj-kotel-dlitelnogo-goreniya-svoimi-rukami.html