Recently, a new floor covering called vinyl flooring is rapidly gaining popularity - vinyl tiles. Customers have already been able to appreciate all the positive characteristics of this relatively new flooring. In particular, it seems attractive that it can be used without restrictions, on any surfaces. In this regard, many people have a question: is it possible to lay a warm floor under vinyl tiles? And if so, how can this be done?

We will try to comprehensively comprehend the issue.

You can stack! But why?

This question is actually asked very often, as many users want to combine the excellent qualities of vinyl flooring with an increase in the level of living comfort. Comfort is always associated with warmth underfoot. Manufacturers of various underfloor heating systems are constantly talking about this. There is even a popular expression that is often used as a belief by the sellers of these products: "the head should be cold, and the feet should be warm."

But let's figure out what kind of warmth is actually comfortable for a person, and then we will already draw conclusions about how to lay vinyl on top of a warm floor.

In fact, a comfortable temperature for a person can be called a temperature that is significantly lower than his own body temperature. Otherwise, the person begins to experience discomfort. And this primarily concerns the temperature of the surface under the feet. After all, we are genetically accustomed to feeling the coolness of the floor under our feet, and this is understandable, familiar, comfortable.

When the earth begins to “burn” underfoot, a person's usual sensations go astray. Those who have purchased a system of underfloor heating for sure will confirm these words, because everything should be in moderation. In moderation, with a general comfortable temperature in the room, there will be warmth, which is given by an ordinary wooden floor, moreover, unpainted (painted colder).

So, returning to the topic of conversation, we can say that the thermal conductivity of our vinyl floor is equal to the thermal conductivity of wood. What does this mean? Only that the use of warm floors for this type of coverage is simply not required. Although it is possible if desired.

This coating itself is warm, comfortable and therefore does not need any external heating. Well, if only it is not laid on the concrete floor, which is arranged directly on the cold ground of the lower floor.

Why is it like that?

A reasonable question may arise: why is it so warm, is it a vinyl covering?

In fact, vinyl tiles are somewhat reminiscent of different finishing materials. For example, it is similar to linoleum without a base - in terms of strength and ability to withstand mechanical stress. Vinyl is similar to laminate in the way it is cut and laid. Moreover, it is the same to the touch as wood. And this is really so - vinyl has absorbed the best characteristics of the previous coatings to date, including:

- the strength of linoleum and its ability to withstand mechanical and other influences;

- ease of installation, inherent in products from laminated boards and tiles;

- external attractiveness, which is provided by new technologies, which make it possible to make an almost unlimited choice of colors and textures of the new coating.

Those who have floor tiles, laminate or linoleum in their apartment, when laying vinyl tiles, note its incomparably greater warmth than all other coatings.And this despite the fact that its thickness is only about 5-6 mm! It's all about the composition.

Vinyl tiles consist of several layers of different thermal conductivity:

- vinyl backing - a layer from below, which helps the tile better adhere to the base and increases sound insulation;

- medium dense vinyl layer;

- decorative vinyl layer on which the pattern is printed;

- polyurethane protective film that preserves the decorative layer and gives additional wear resistance to the finishing material.

All layers are interconnected by polyvinyl chloride polymer compound, which is harmless and only improves the performance of the coating.

What is this cover

The basis of this relatively new PVC material on the domestic market is quartz sand, from which 60 to 80% of the product is formed. Quartz vinyl tiles for underfloor heating boasts the highest strength and durability, is not afraid of moisture, fire and is practically not erased. Outwardly, it can look like any modern coating, from laminate to granite or marble. The product is multi-layer and consists of the following components:

- Transparent polyurethane that protects the surface from deformation and scratches.

- Decorative film that gives texture to the material.

- The main layer of quartz vinyl, which provides proper strength and stability.

- Fiberglass reinforcement.

- The vinyl layer is responsible for the balance.

Where should you lay your vinyl underfloor?

And yet we are all human - different. Someone wants it to be hot underfoot, and someone has no other source of heat except heating by means of a warm floor (and this also happens). Finally, there are places in an apartment or house where the floor should really be warmer than the traditional one. For example, in rooms such as a bathroom, a loggia or a nursery where a small child grows up.

In such cases, it makes sense to consider how to install underfloor heating under vinyl laminate or vinyl resin tiles.

What is the best underfloor heating for vinyl?

In general, virtually any underfloor heating system is suitable for installation under vinyl flooring. When heated, vinyl floors do not emit harmful substances, they do not melt at temperatures up to 80 degrees, although the recommended temperature for heating vinyl floors is considered to be up to 40 degrees Celsius.

Predominantly, vinyl tiles for underfloor heating are laid on the water floor, cable-electric and underfloor heating. We will describe the application of each type of underfloor heating system separately.

How to install vinyl floor tiles is the video below.

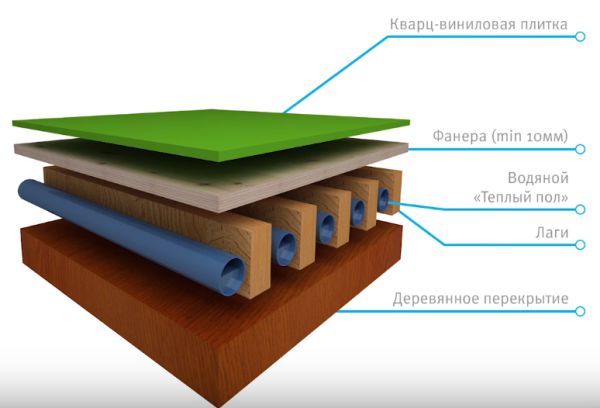

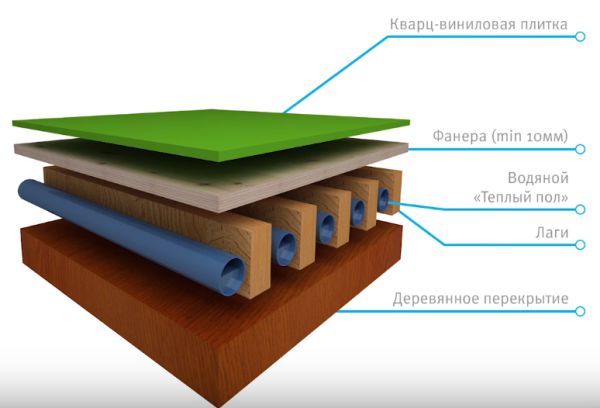

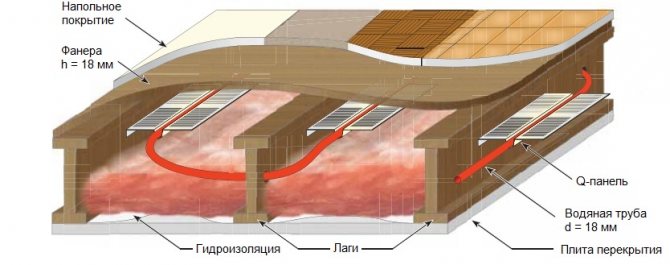

Option 1: Vinyl over water floor on wood base

It is worth making a reservation right away that it is impossible to lay the underfloor heating system on a wooden base using an electric circuit! This is not recommended from the point of view of firefighters and their requirements due to the risk of fires!

Thus, if the base is wooden planks or other wood flooring, then choose a water floor, followed by a vinyl tile or vinyl laminate.

Installation is carried out as follows:

- A water circuit is laid on a wooden base, between which wooden logs are laid.

- A sheet of plywood or OSB is laid on top of the inter-tube logs of the heated floor, which is fixed with self-tapping screws for strength.

- Self-tapping screws are recessed in a sheet of plywood, the insertion points are putty.

- On top of the plywood, flooring is laid in the form of a roll covering, tiles or in vinyl lamellas. If a vinyl covering with locks and an adhesive base is used, then it is not necessary to sand and repair the irregularities caused by self-tapping screws.

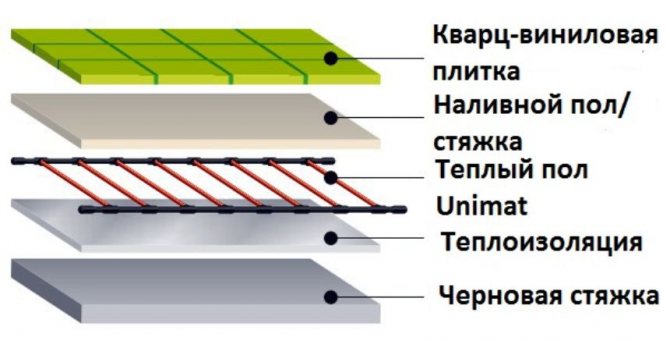

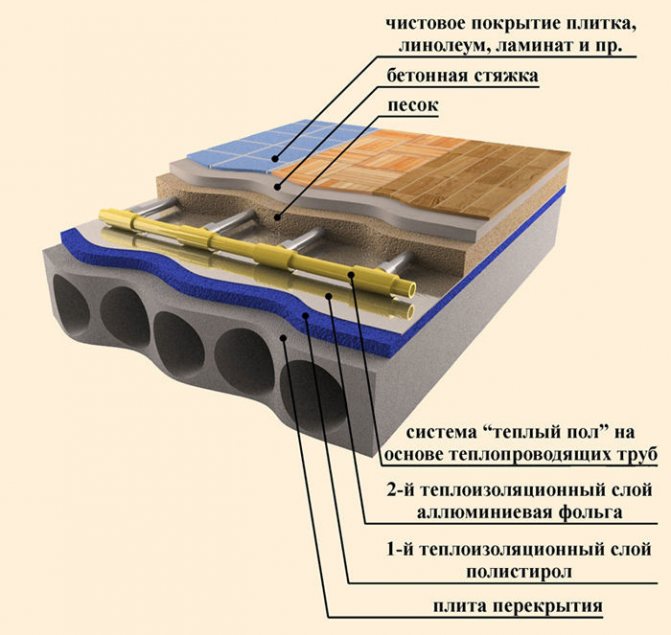

Option 2: Vinyl on a concrete screed with water-heated floors

This method is used in most cases when it is necessary to lay a system of heated floors with vinyl covering over concrete, which is most often found in our apartments.

In this case, the styling is done in this way:

- A layer of waterproofing material (roofing material or a simple polyethylene film) is laid on top of the concrete floor.

- A water floor system is being installed.

- The system is secured by laying a cement concrete screed.

- The final leveling coating is poured. It makes the floor smooth and even.

- The last layer is vinyl covering.

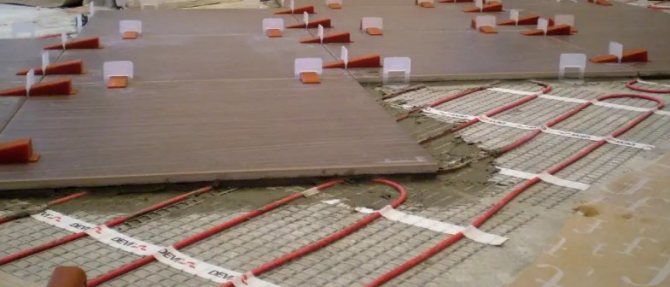

Option 3: Vinyl Decking over Electric Floor and Concrete

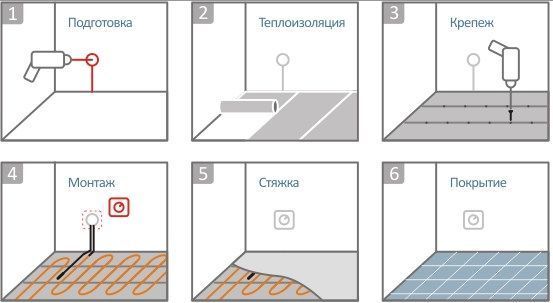

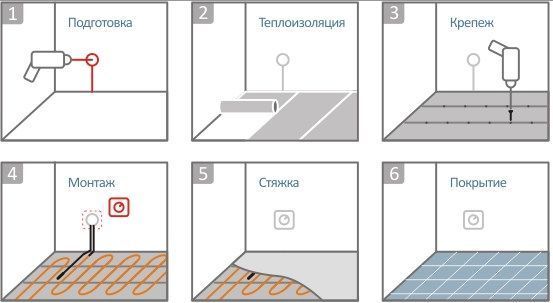

In the same case, if you have to insulate a concrete floor, you can also use a system of electric floors with heating and subsequent laying of a vinyl covering. This is done like this:

- On top of the leveled concrete, a floor system with an electrical circuit is installed.

- From above, the system is fixed with a layer of polymer-cement screed.

- Once the screed is completely dry, the flooring is ready for vinyl or vinyl roll installation. It is convenient to lay on such a floor both adhesive vinyl tiles and material with a lock joint.

Option 4: Vinyl flooring on top of concrete and film floor heating

This is the easiest way to make very warm floors with a warm floor system and vinyl flooring. This is done in this way:

- Lay the underfloor heating film system on the prepared (leveled, cleaned) concrete base.

- You can immediately lay a vinyl layer on top of the warm floor. It is important to take into account the fact that only vinyl covering with snap joints can be used for laying on a film warm floor!

Tile

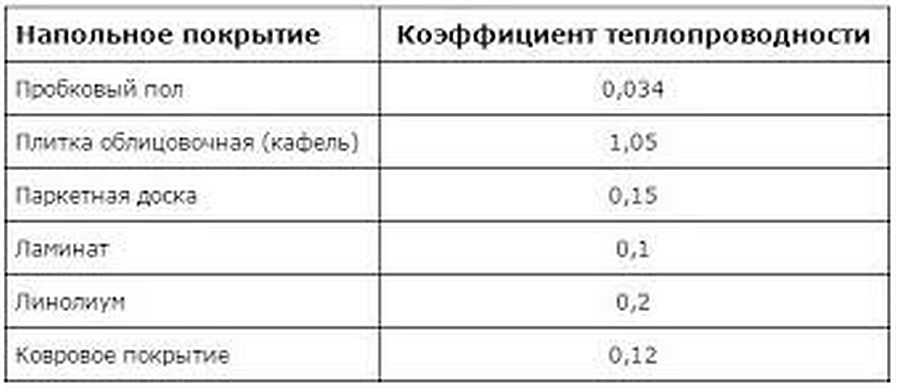

Ceramic floor heating tiles are ideal for the heating system in question. It has a high coefficient of thermal conductivity, and also tolerates numerous heating-cooling cycles well.

Advantages:

- Wear resistance. Practice has shown that even a cheap ceramic coating can last at least 20 years. The surface of the tile perfectly withstands impacts from hard objects, contact with household chemicals and other substances;

The structure of the warm water floor coverings - A large assortment. On the modern market, tiles are represented by the following types: ceramic tiles, porcelain stoneware, clinker tiles, cotto and others. The properties of ceramics allow you to create real works of art from a design point of view - ceramic flooring can have various patterns and ornaments;

- Strength. Studies have shown that ceramic tiles are capable of withstanding a load of hundreds of kilograms (provided that they have passed all the hardening and processing procedures);

- Ease of maintenance. The ceramic coating is easy to clean. In addition, the tile is not afraid of water and does not absorb moisture at all (a very important parameter for a water floor);

- Low flammability. The ceramics undergo several stages of processing in very high temperature ovens. Therefore, the usual combustion temperature (300-500 degrees) is not enough for the hardened clay to enter into a chemical reaction;

Disadvantages:

Stages of installation of a warm water floor under the tiles

- Complicated installation procedure. Even experienced finishers often make mistakes when laying. For example, the slightest unevenness in the floor (a hump or a frozen stone in the screed) leads to a decrease in the quality of the masonry;

- Low thermal insulation. Ceramic flooring transmits well, but does not hold heat well, therefore manufacturers of a water floor do not recommend walking around the house barefoot at a time when the heating system is operating at its maximum capacity.

A few general tips

When installing underfloor heating with subsequent coating of the product, some recommendations must be followed.

For example, do not stack vinyl on top of foam coated materials.

The heating temperature of warm floors covered with a vinyl layer on top should not exceed 40 degrees Celsius!

Where heated floors are laid, there should not be any carpets or furniture without legs, excluding the free passage of heated air.

The last statement once again makes you think about whether, in principle, warm floors are needed where there is a coating that in itself is much warmer than the warmest wood? Not to mention other coatings known today.

This floor itself is a warm floor. It creates a comfortable tactile sensation without the need for additional heating. At the same time, both a carpet and any furniture can be placed on this floor without fear of ruining the heating system. And if there is no point in laying additional insulation, then why look for different options and at the same time overpay?

Vinyl flooring is suitable for laying on top of any underfloor heating system. In each version, it is able to withstand any thermal influences and loads.

Laying schemes for PVC flooring

The first version of the scheme may include:

- wooden base;

- the contour of pipes laid between wooden logs;

- plywood / chipboard layer;

- PVC tiles.

Second option:

- cement-sand base;

- waterproofing layer;

- water floor contour;

- additional screed layer;

- self-leveling mixture for correcting differences;

- topcoat.

Third option:

- concrete base;

- heat / moisture insulating layers;

- electric heating cable (single-core / twin-core / self-regulating);

- cement-based screed for leveling the surface;

- PVC tiles.

Fourth option:

- cement-based screed;

- plywood sheets;

- moisture / heat insulation layers;

- film infrared floor;

- topcoat (in this case, tiles);

Each option is unique in its own way, as it is mounted based on personal preferences and skills, and is also installed in houses of different types.