Belt heaters are another type of heating devices, the principle of which is based on the emission of infrared waves that heat not the transit medium, but the objects they reach - waves, "resting" on the surface of the object, cause its molecules to vibrate, as a result of which the object heats up.

They have been used relatively recently, so they have not yet received widespread distribution, but due to their high technical characteristics, they are a promising direction in solving the problem of heating in everyday life and at work.

Let's take a closer look at what tape heaters are, their structure, characteristics and functionality.

What is a tape heater (ENGL)

The problem of technological heating of equipment, tanks, pipelines and premises has existed for a long time, especially in the conditions of northern latitudes. To solve this problem, it was necessary to develop an electric flexible heating element (ELH) - a safe device that can be laid on the surface of heated equipment, repeating its profile. The first step in solving the problem was the creation of electric heating cables with a conductor made of a material of a given resistance, which, passing a current through them, convert electrical energy into thermal energy.

Cable heaters are still used in everyday life and in industry, but a more perfect device for heating is the next step in solving the heating problem - ENGL, a heating flexible tape element consisting of several cables arranged in a tape. In fact, ENGL is an improved version of the cable heater,

Specifications

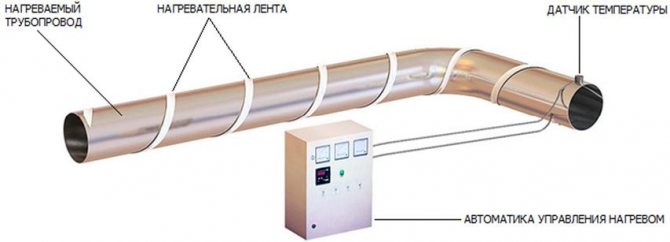

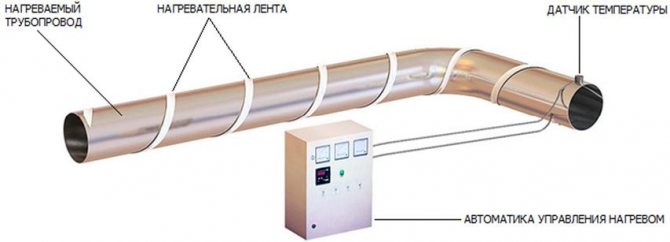

The system of automatic electric heating of fuel oil provides optimal temperature conditions for transportation and combustion of fuel oil supplied to the boiler burners. The NSP heaters used in this system have the most optimal thermophysical parameters for heating viscous and solidifying oil products and are significantly superior in technical, economic and operational parameters to electric heaters based on nichrome.

The electric heating system includes:

- Heaters NSP

- Flexible tape electric heaters LUNG

- Temperature control and regulation cabinet

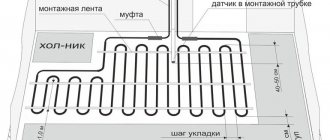

Fiberglass heaters NSP are mounted on the bottom of the tank in the fuel oil extraction zone. LUNG electric tape heaters are wound on a fuel oil pipeline and then thermally insulated. Thus, the maximum degree of economic efficiency of electric heating is ensured. A temperature regulator sensor DT1 is installed in the tank in the fuel oil take-off zone.

When the boiler room is started, the fuel oil is heated in the extraction zone from the tank to a temperature of 60 ° C. Then the fuel oil from the tank is fed into a preheated fuel oil pipeline, where the temperature of the fuel oil, as it is transported to the burners, is brought to 90 ... 120 ° C. Digital temperature regulators built into the control cabinet automatically maintain the temperature of fuel oil in the tank and at the inlet to the boiler burner at the set value and allow its operational visual control.

Flexible materials: Flexible neon LED, wholesale and retail LED flexible neon

The device and components of the tape heater

ENGL is a woven glass-fiber tape (base), in the middle of which several heating threads made of an alloy with high resistivity (nichrome - nickel with chromium) are located parallel to each other. Outside, the tape is covered with a waterproof shell made of silicone rubber, which is also used for crimping the ends of the ENGL. The tape heater is connected to the network through an electric wire coming out of the end crimping, which is connected in a tape with heating threads.

According to the type of mains voltage consumed, heating tapes are produced for 12, 220 and 380 V.

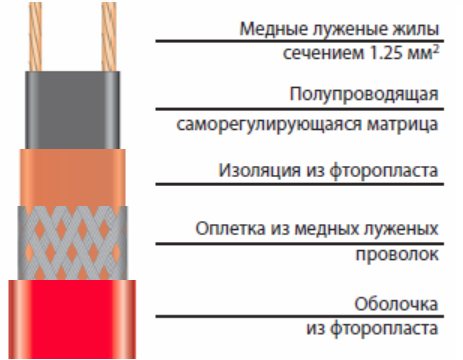

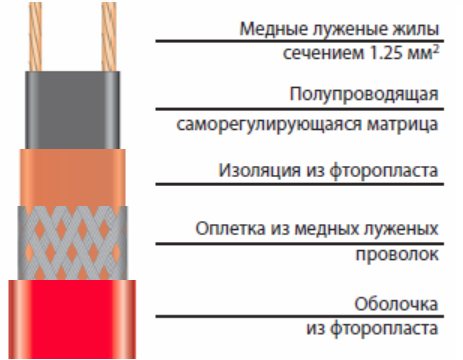

The main element of the tape heater, which determines its characteristics, is the heating cable, from which the rows are made up inside the tape. To get a better idea of the characteristics of ENGL, consider the types of cables that are used for heating.

Heating cables

According to the principle of operation, heating cables are divided into:

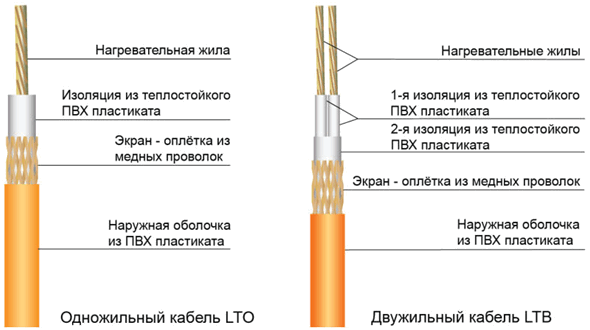

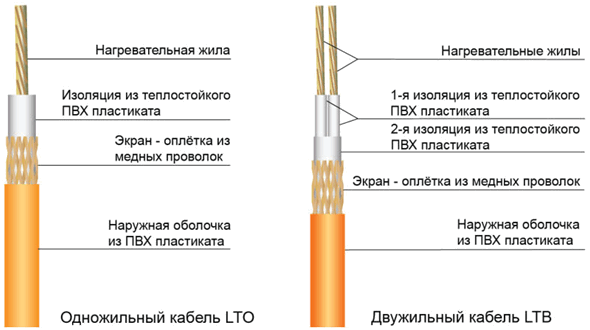

- resistive - with a fixed power and a heating core as a heat source, placed in a 3-layer shell (electrical insulation, shielding braid and UV protection);

- self-regulating - two parallel conductors (phase and zero) at a distance of 1 cm with a heat source located between them - a matrix that heats up when current passes through it from the phase wire to zero.

A single-core cable has only one heating core, so both ends must be connected to the network (the turns of such a cable must be positioned so that the far end returns to the starting point, and both cable contacts are next to each other);

A two-core cable consists of a heating and a conductive core, the currents in which flow in different directions - the negative factors of the magnetic fields of the wires compensate each other (a two-core cable is connected to the network from one end, a special sleeve is installed at the other end);

Advantages of tapes for heating pipes

Despite the significant cost of these materials, the economic effect of their use is noticeable even at the stage of pipeline installation.

The fact is that the heating tape allows you to reduce the depth of the laying of communications.

This reduces the cost of earthworks, allows you to complete the installation in a shorter time.

In addition, there are a number of other advantages that are provided by the use of such modern materials:

- The installation of the tape allows you to reduce the loss of thermal energy in heating and hot water supply systems.

- The proposed systems are distinguished by a significant margin of safety, they are multi-layer structures, including protective shells.

- Existing tapes are capable of operating in a continuous and periodic mode, depending on the task at hand.

- You can install the system for pipelines of different diameters,

- It is also possible to heat cisterns and use the roof de-icing device as elements.

The tape heater for pipes is calculated on a number of indicators. Of course, all this data is available from sales representatives, who carry out the selection in each individual case, but you also need to know the main indicators of the selection.

First of all, it is necessary to clarify the level of soil freezing in your region and the estimated depth of pipe laying. The temperature conditions of the pipeline operation depend on this.

Then determine the mode in which the tape pipe heater will operate. Why is it actually supposed to be installed - to protect pipes from freezing or to maintain the temperature in the specified parameters.

Then determine the length of the heated section. Select the heater model and installation method.

Based on these data, the system power and the required conductor length will be calculated.

Existing tape heaters

What products are presented by manufacturers, what are their pros and cons.

The most inexpensive is a tape resistive heater for pipes, which is a stranded wire fixed on a fiberglass base. But this model has a significant drawback - it is impossible to change the length of the tape, it is a fixed value.

Self-regulating heating tape

Self-adjusting belts are more economical in energy consumption. In addition, you can trim the desired length of the element. Despite the fact that its cost is somewhat higher, the installation of a heating tape of this type is more preferable. The basis of the heater is a pair of wires that can change their resistance depending on the temperature.

Relatively recently, the so-called infrared film, created on the basis of a composite material with the inclusion of copper conductors, appeared on the market. Today it is considered one of the most advanced materials in this direction.

Whichever type of heating tape you choose, remember that for it to work efficiently, the entire system must be insulated and isolated from moisture, otherwise, you will heat the ground, not the pipeline.

In addition, when winding the tape, do not allow the intersection of its turns, this can lead to overheating of the segments.

Characteristics

To systematize and simplify the selection of the desired device from a variety of types of tape heaters, their following characteristics are used:

- symbol;

- connection type

- heater type;

- resistance (Ohm);

- active part length (m);

- width x thickness or diameter (mm);

- length of low-temperature wires (m);

- minimum bending radius (mm);

- weight (kg);

- rated voltage (V);

- heat power (W / m);

- power consumption (W);

- surface temperature (oС).

These characteristics are used when calculating heating systems required to ensure the process or operating temperature of pipelines, equipment and premises.

Flexible carbon heating tape LUNG

Flexible carbon heating tape (LUNG) is designed for heating pipelines, technological equipment with flat surfaces and complex geometric shapes, as well as for installation in electric heating products as a heating element.

Scope of application of the tape LUNG

- Heating of pipelines for pumping bitumen.

- Heating up of fuel oil pipelines and regulation of the temperature of fuel oil in front of boiler burners in boiler houses and CHPPs. "Soft" heating and maintaining the temperature of various chemical materials in product pipelines. LUNG tape is wound on pipelines with a specified calculated pitch of winding; it is recommended to lay a non-combustible heat-insulating coating on top of it.

- Heating of surfaces, for example, construction formwork, drying chambers. LUNG tape is glued to flat surfaces using heat-resistant silicone glue.

- Creation of flexible heating panels of various sizes by gluing LUNG tapes on metal sheets. With such mobile heating sections it is possible to heat tanks, including railway tanks.

- Integration into rigid casings to obtain convective space heaters operating in a mild temperature regime without burning out oxygen in the air.

- Use in air heaters, air ducts for heating the air flow with minimal aerodynamic resistance and non-inertia heating.

LUNG belt operating conditions

- All surfaces on which the LUNG tape is mounted must be cleaned of burrs and sharp edges in order to avoid mechanical damage to the tape.

- Do not place flammable materials and products near the tape.

- During operation, it is not allowed to use tapes without a thermostat if heating to a temperature exceeding 250 ° C is possible.

- It is allowed to cover one side of the LUNG tape with a non-combustible heat-insulating material.

- It is allowed to bend the LUNG tape with a radius of at least 5mm.

- To obtain the best results in electrical and fire safety, it is recommended to use an RCD as a protective element.

Flexible materials: Flexible LED neon LED NEON FLEX in Moscow

LUNG tape design

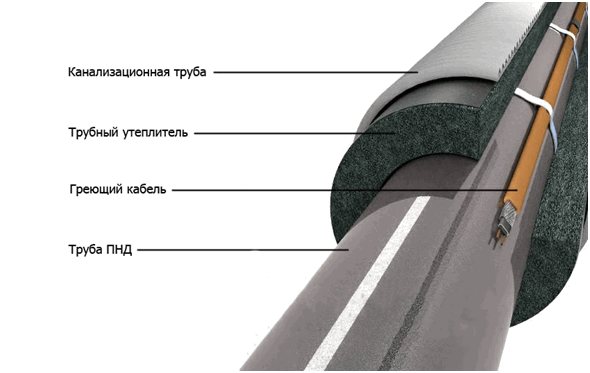

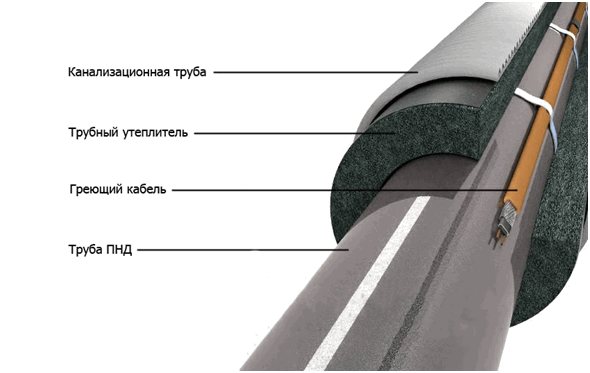

The LUNG tape contains a heating element made of fibrous carbon material, an electrical insulating cover made of glass fabric, duplicated with a layer of silicone material. Low-temperature leads connected to the heating element are made of copper wire in heat-resistant insulation and are used to connect the supply voltage to the tape. The heating element and end fittings are sealed for environmental protection.

LUNG tape is produced according to TU 3443-001-10829030-07. LUNG tape is protected by a patent of the Russian Federation.

It is possible to manufacture LUNG shorter than 5 meters. In this case, the connection to the power supply can be done in two ways. The first method is to connect LUNGs in series with each other up to a length of at least 5 meters. The second way is to connect each LUNG shorter than 5 meters to the power supply through the LATR, with a voltage supplied to the LUNG, giving the consumed current no more than 3-3.5A.

The main advantages of the LUNG tape

- Large heating surface.

- Elasticity and flexibility.

- Small thickness and light weight.

- Low thermal inertia.

- Wide range of power density (up to 250 W / m tape length).

- Supply voltage from 0 to 220V (technical parameters of LUNG heating tapes for individual use are agreed upon with the customer).

- Ease of design and installation on equipment.

- Possibility of tape mounting at temperatures up to –60 ° C.

Household band heaters

In the conditions of frosty winters, communications (water supply, sewerage) of private houses, country houses, rural housing have always needed protection. For this purpose, the highways and units located in basements, basements and attics were insulated with heat-insulating materials, and pipes buried in the ground were laid below the freezing mark. With the advent of tape heaters, the solution to this problem has been greatly simplified - pipes, shut-off valves and units began to be protected from defrosting by means of a cable or electrical tape heating device.

In this case, the method of placing the tape or cable allows you to vary with the degree of heating and material consumption. If the goal is to protect the water supply system from defrosting, then the tape can be run linearly along the pipe. If you plan to get water at room temperature at the outlet, then you can insulate the pipe by placing the heating strip with a snake, or equip the water supply system over the linear arrangement of the tape with a layer of heat-insulating material.

More accurate results can be achieved by using a thermostat with the band heater.

The sewerage system of private buildings also needs protection from frost, but excessive heating of the highway is useless here. Therefore, the sewer pipes are equipped with tape heaters located linearly on the system, and a layer of thermal insulation with a protective casing is mounted on top of the sewer.

The use of tape and cable heaters for the installation of icing systems on the roofs of private houses is gaining popularity in order to prevent the dangerous formation of ice in gutters and icicles.

Important! It should be remembered that the use of resistive heaters for the installation of the icing system is impractical, since they are sensitive to the overlap of the cable or tape, when one turn lies on the other, and the accumulation of foliage on them - in these places the system quickly burns out.

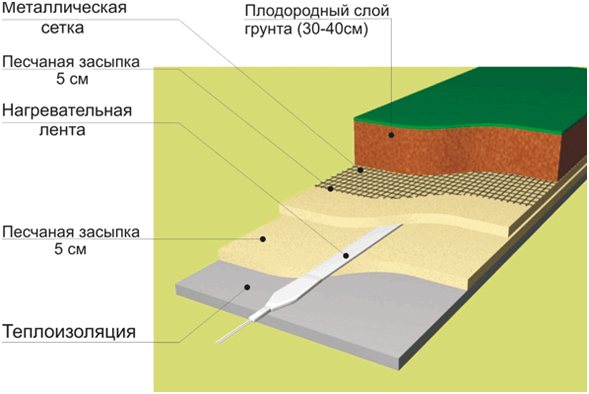

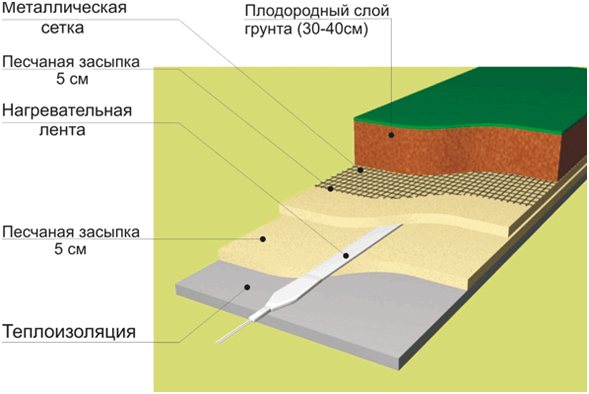

Belt heaters are also used in greenhouses, since creating the required temperature and air humidity in them is not enough for growing thermophilic crops - soil heating is necessary. In this case, the heating system is arranged on a specially prepared basement - a heat-insulating layer, on top of which sand filling is performed and leveled horizontally. A layer of sand is repeated on top of the laid heating tape, then the base is covered with a reinforcing steel mesh and a layer of fertile soil. In this case, laying a resistive tape is also impractical - a self-regulating one is required.

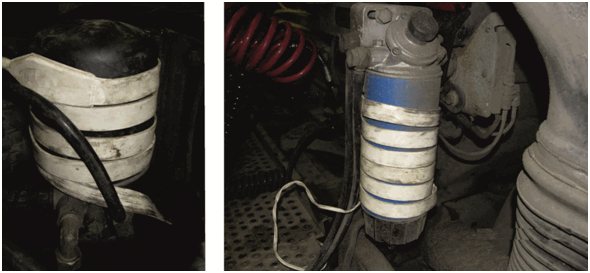

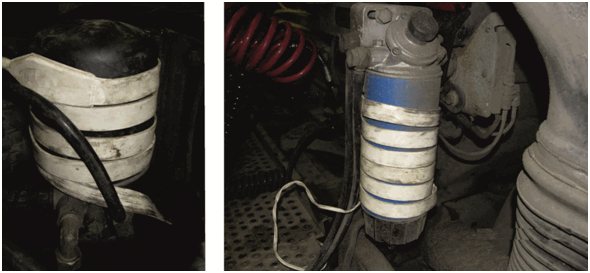

Belt heaters have found their application in automotive engineering, since the operation of vehicles in the winter is much more difficult due to thickening of engine oil and diesel fuel.

Important! Carrying out heating of units and highways of the car should be carried out only with tape heaters designed for an on-board network of 12 V and, according to the manufacturer's instructions for use, intended specifically for a given type of engine (gasoline or diesel) and a certain unit.

The operating instructions for the car strip heater also say whether the independent installation of this device on the car is allowed, or whether it should be done in a specialized car service.

Taking into account the fulfillment of these requirements, the band heater can be heated:

- salon;

- crankcase;

- for diesel engine: fuel filter;

- fuel line;

- fuel tank outside at the location of the pump;

- diesel canister;

- water separation sedimentation tanks;

- rechargeable battery.

The use of tape heaters in industry is no less widespread; they are used to heat tanks with non-combustible liquids, process and main pipelines, pipeline and pumping equipment, valves, etc. The list of technical means that require technological or preheating during operation is very large.

Installation of industrial devices is carried out by specialized organizations on the basis of design data, calculated taking into account all available factors.

ENGL heating tapes. Russia.

Electric heating of pipelines

Electric heating systems offered by our company are able to heat pipes much more efficiently than similar systems. They have a fairly wide range of uses (applicable for pipelines of a wide variety of profiles: from water pipelines to oil and fuel oil pipelines and impulse lines).

We offer two heating options:

1) Application of tape heating devices ENGL, this equipment significantly increases the heat transfer area from the electric heater to the heating surface, resulting in increased efficiency.

Often you have to deal with the fact that pipeline heating

necessary in the fields of the petrochemical and oil-extracting industry, where communications pass through explosive areas. For this, special heating tapes are used.

ENGL1Ex and ENGKEX-1, in the design of which explosion protection is implemented.

Often, industrial pipelines fail due to the formation of congestion, narrowing of the flow area with a high degree of viscosity of the liquids to be transported.In accordance with the calculations and applied technology, the pipeline heating system ensures constant maintenance of the set temperature level. The heating system used in pipelines pumping water protects against the risk of structural failure due to freezing.

Thus, the main task of our systems is to maintain the temperature of the product transported through the pipes.

This makes it possible:

- • maintain the kinematic viscosity of the fluid transported through the pipe, avoiding the formation of plugs;

- • increase the speed of pumping liquid;

- • restart the operation of the pipeline, completely or partially filled with the product, after stopping;

- • ensure that viscous products are drained from the tank within a short period of time.

In addition to working with liquids, these systems can also be used on gas pipelines. In this case, by heating the pipe, we prevent the formation of condensation when cooling the transported gas.

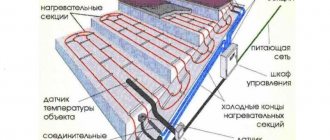

Cable heating system design

- Heating subsystem: heaters, resistive and self-regulating heating cables.

- Power subsystem: boxes with light indication, junction boxes, connecting tapes, terminations.

- Control subsystem: regulators, controllers, intrinsic safety barriers.

- Fastening subsystem: clamps, tapes, brackets, thermal insulation bushings.

The choice of heating cable for heating is determined by:

- • the nature of the product to be transported;

- • the ambient temperature in the region;

- • data on the initial / final temperature parameters of the liquid or gas;

- • type of heat engineering problem (heating, preventing icing, maintaining temperature);

- • aggressiveness of the environment, etc.

To calculate heat losses during heating of pipelines and the capacity of electrical heating systems. it is important to consider the thickness and type of insulation, which minimizes heat loss. When choosing the power, type and design of the cable and other accessories, take into account the data on the pipeline according to the questionnaire.

Criteria for selecting pipe heating systems

1. Heat engineering task:

- • anti-icing system is necessary to prevent freezing of the pumped liquid and prevent the formation of ice; maintenance temperature in anti-icing systems is + 3 ... + 5 ° С;

- • the system of stable maintenance of the thermal regime prevents the product from cooling down in the event of a decrease in the ambient temperature. In this case, it is assumed that it is necessary to calculate the heating of the pipeline and establish a process temperature that allows pumping products of the required viscosity, preventing condensation or stratification of mixtures;

- • warming up the product.

2. Pipeline length:

- • up to 100 m - any types of heating self-regulating wires for pipes, heating resistive wires (there is usually no need for a distribution network to heat the pipeline);

- • up to 300 m - any types self-regulating heating wires, heating resistive wires (there is a need for a distribution network, but its price is much lower than the cost of the heating system).

3. Working temperature:

- • +60 - + 80 ° С - almost all types of cables are applicable, the required power range up to 80 W / m is easily achieved;

- • +100 - + 200 ° С - use of heating tapes ENGL-1;

- • +220 - + 400 ° С - resistive cables are used ENGLU-400... Typical applications are heating units for storage and processing of fuel oil and bitumen, installations for the production of heavy oil products. A distinction should be made between the highest temperature at which the heating wire can be located and the temperature that can be maintained by the cable. The latter is usually lower than the first by 10–20 degrees, and often more.

We carry out installation of the supplied equipment on a turnkey basis!

Advantages and disadvantages

There are many positive characteristics of tape heaters, we will list the main ones:

- profitability;

- ease of installation;

- radiation wavelength in a harmless range;

- the ability to select devices with a safe surface temperature.

However, there are also disadvantages:

- sensitivity of resistive devices to external influences (overlap, intersection);

- the need to use thermostats with resistive tapes;

- high price of more advanced self-adjusting belts.