Price overview

You can buy a heating heating cable in any electrical store; sales are carried out in all cities of Russia and Ukraine, and the price (price) is presented in open sources. We suggest that you familiarize yourself with it (review per meter):

| Town | Cost, rubles | Town | Cost, rubles |

| Moscow | 450 | Kiev | 430 |

| Minsk | 430 | Rostov-on-Don | 400 |

| Voronezh | 420 | Volgograd | 400 |

| Almaty | 430 | Izhevsk | 420 |

| Donetsk | 430 | Ekaterinburg | 430 |

| Krasnodar | 420 | Kazan | 420 |

| Nizhny Novgorod | 420 | Novosibirsk | 430 |

| Ufa | 400 | Samara | 420 |

| Saratov | 400 | St. Petersburg | 450 |

| Omsk | 430 | Odessa | 430 |

We recommend choosing heating cables made in Italy, Korea or Russia (BSX, BT, BTV, Deviflex, DPH, DSIG, FSLE, GWS, HTP, Lavita, Pipe, SRL, TXLP). But be sure to check the quality certificate, not only personal safety, but also heating capacity depends on the correctness of the data.

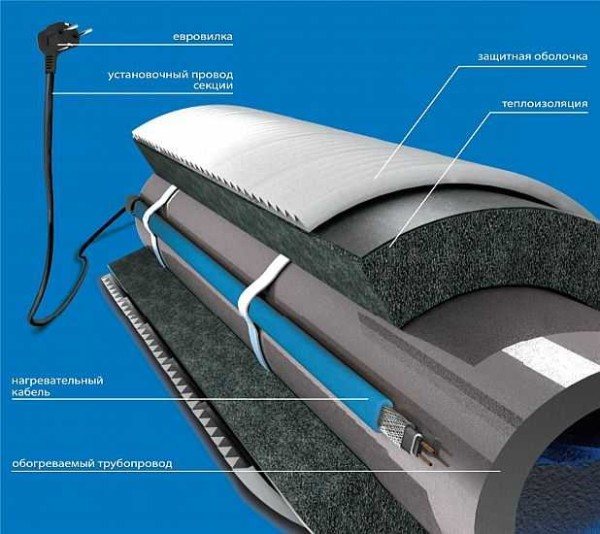

Pipe installation

Heating cable for water supply

Directly during the laying of the pipeline, it is preferable for it to install the cable through the pipe. There are two ways to do this at once - around the highway or along it. Let's get acquainted with the features of each of them in more detail.

Option number 1. Along the highway

It is quite obvious that the cable is easiest to install along the pipes in one line. In this case, the conductor must be fixed exactly under the pipe, due to which the heating element will be reliably protected from above from all kinds of mechanical damage. In addition, the liquid, as you know, freezes from below, and therefore such an arrangement of the cable will allow you to quickly cope with the freezing of the line (if this happens).

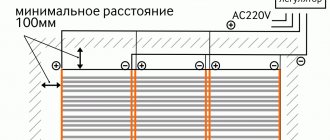

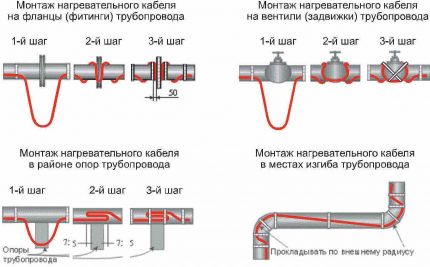

But if you intend to lay several lines along one pipeline at once, then do it in strict accordance with the diagrams below.

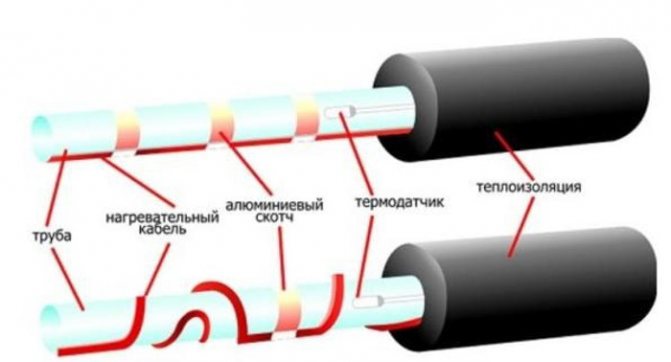

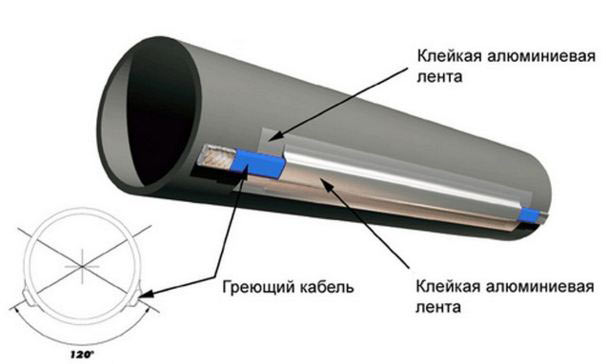

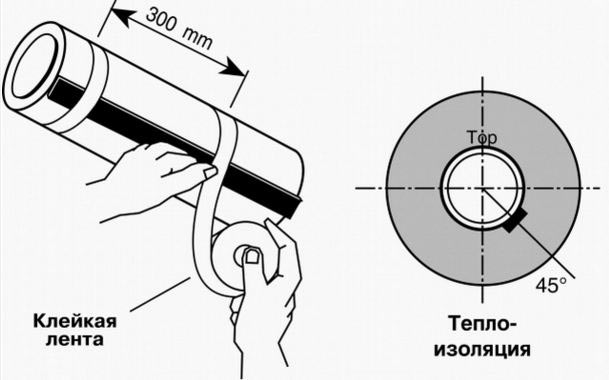

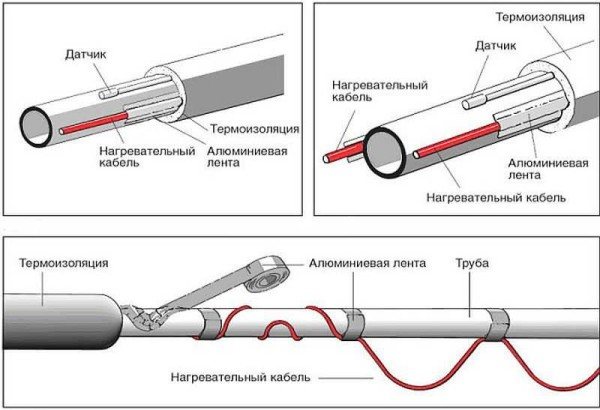

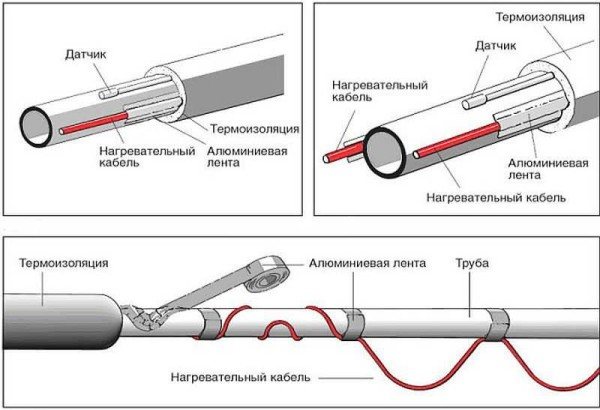

If we talk about how to fix the heating cable for the water supply, then we recommend using aluminum tape for this - it will not only securely fix the product, but also significantly increase its heat transfer. Alternatively, you can use adhesive tape for fixing, wrapping it around the water pipe as shown in the image below.

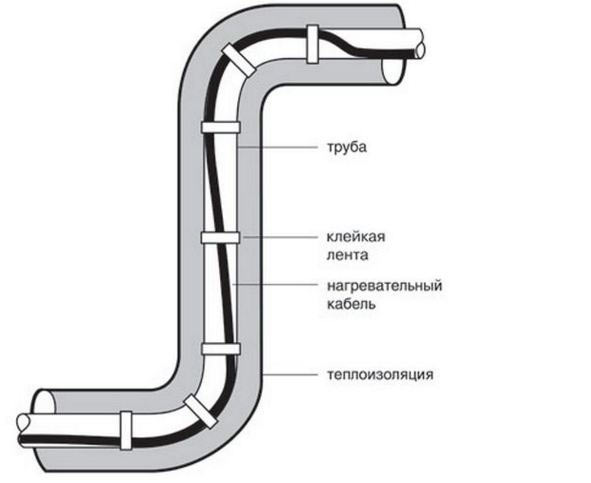

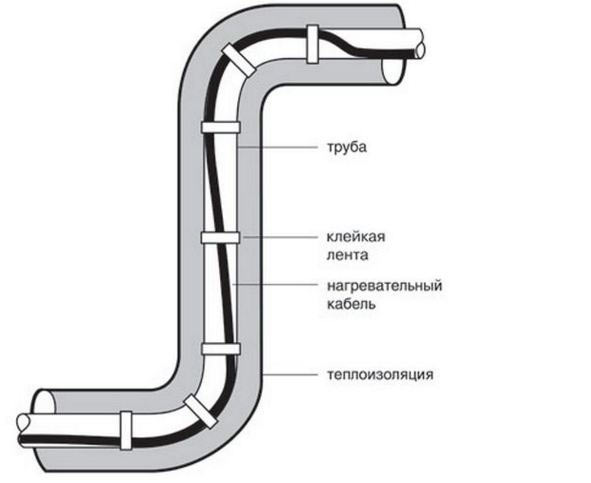

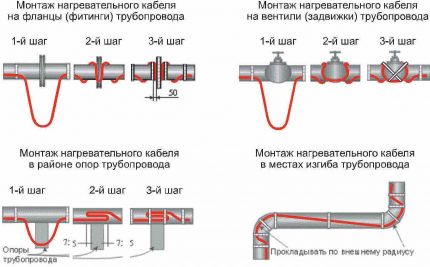

Particular attention must be paid to the installation of the cable in the corner sections of the trunk! To ensure that the bend of the product is not too large, try to place it along the outer radius of the line. A more detailed view of this mounting option is shown in the diagram below.

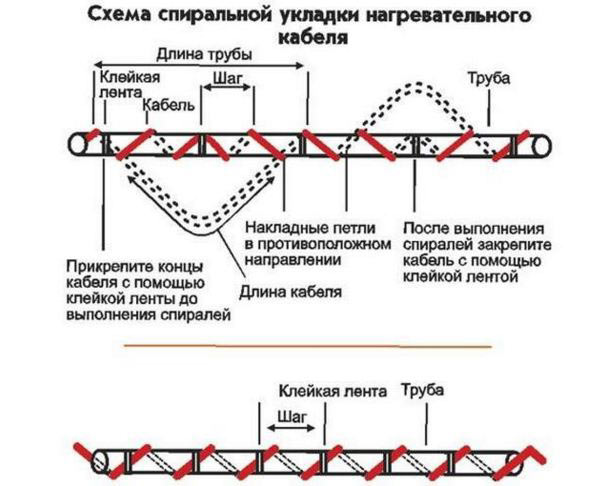

Option number 2. In a spiral

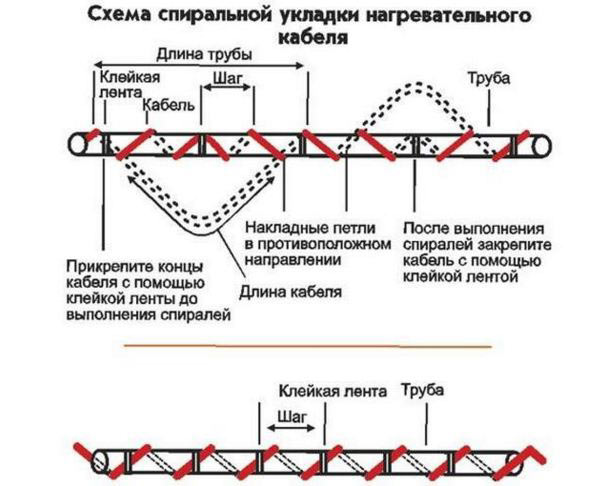

If the temperature in your area is low enough during the cold season, it is advisable to completely wrap the heating cable around the water supply. Thanks to this, the heating efficiency will noticeably increase, since the pitch of the coil will be approximately 5 centimeters (if you want, you can take a larger step). Characteristically, the length of the cable with such a winding scheme will be approximately 1.7 times greater than that of the pipeline.

If you have to lay the product in a spiral in a hard-to-reach place, follow the diagram below.

In this case, the cable must first be wrapped with an allowance, and then the loops must be wrapped in the opposite direction. As a result, there are fewer steps to be taken when comparing the procedure with step-by-step winding of the pipeline.

Option number 3. How to wrap individual elements

Individual elements of this kind (and these include various taps, supports, flanges, etc.) must be wrapped with a large amount of heating cable, since the heat dissipation in such nodes is much greater.You can find all the necessary installation schemes in the image below.

In addition, we recommend that you familiarize yourself with the thematic video material below, illustrating the laying of a cable through a pipeline.

Note! Separately, it is worth talking about the installation of the temperature sensor. For uninterrupted heating of the line and to avoid overheating of the cable, the temperature sensor should be located at the coldest point of the line at the greatest distance from the line itself.

In addition, the place where the sensor will be located must be glued in advance with aluminum tape. We advise you to familiarize yourself with the basic options for the location of such a sensor.

Installation methods

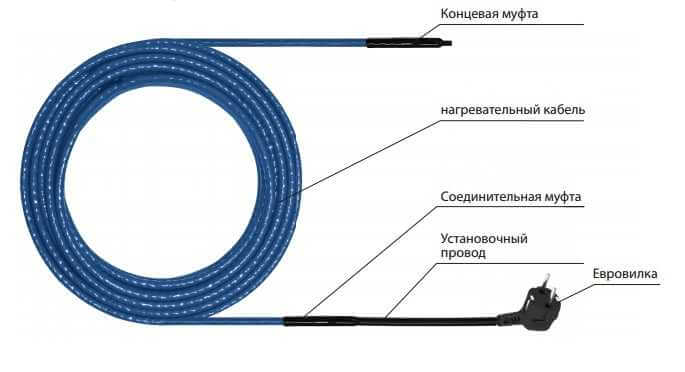

The heating cable for the water supply is laid outside or inside the pipe. For each method, there are special types of wires - some for outdoor installation only, others for indoor installation. The installation method is necessarily prescribed in the technical specifications.

Inside the pipe

To install a heating element inside a water pipe, it must meet several requirements:

- the shell should not emit harmful substances;

- the degree of electrical protection must be at least IP68;

- hermetically sealed end coupling.

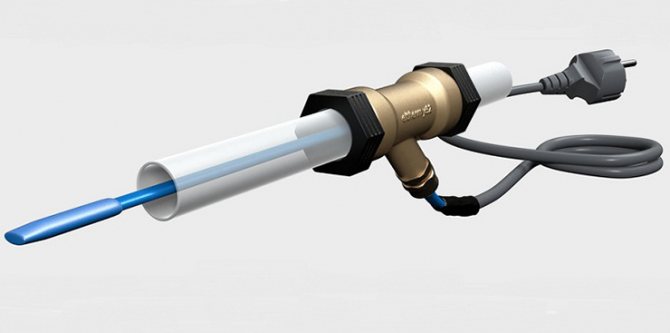

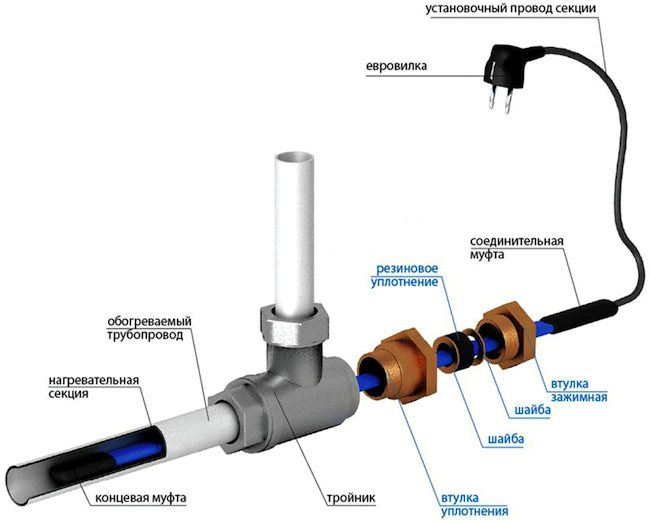

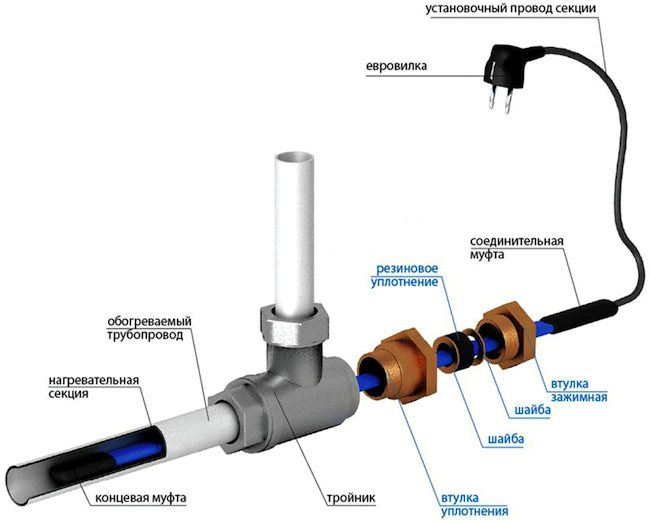

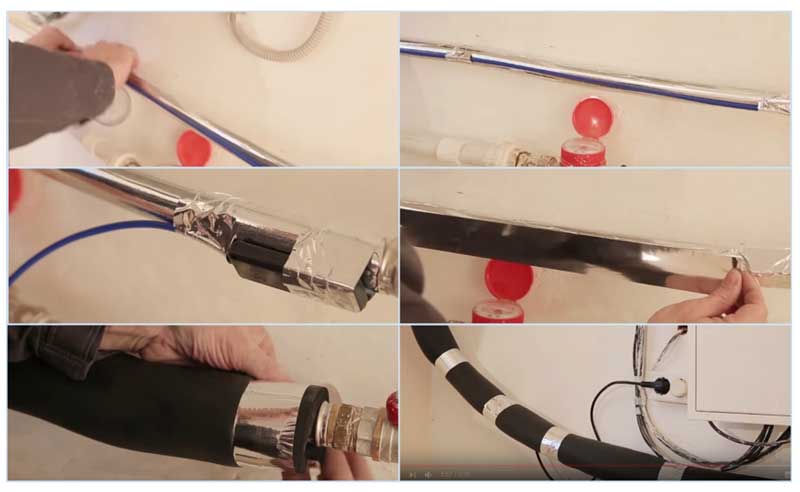

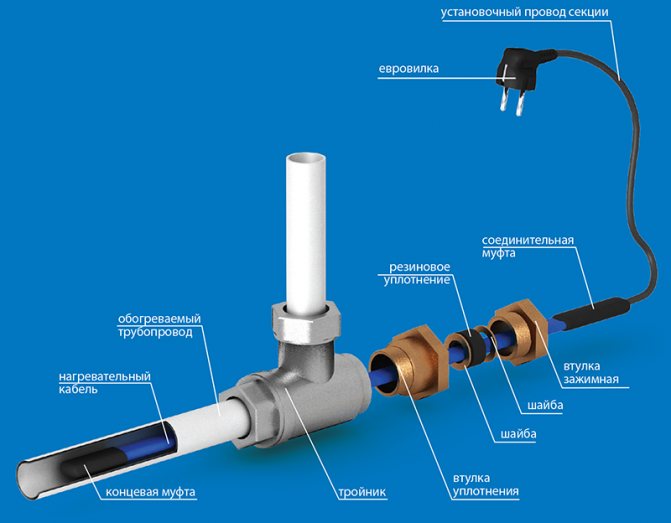

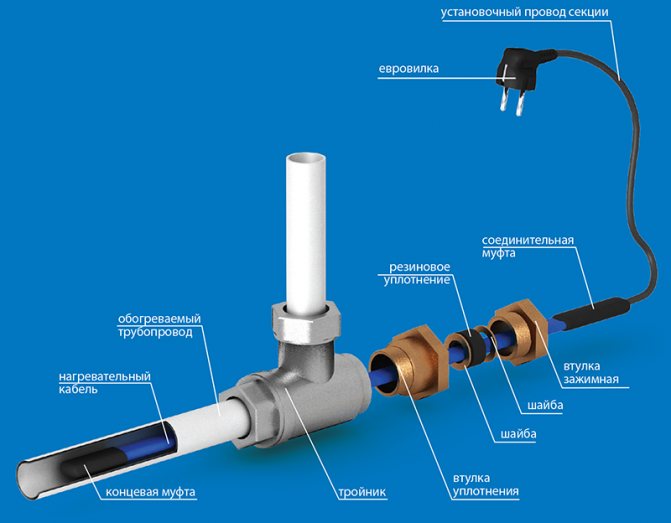

In order to be able to tuck the wire inside, a tee is placed at the end of the pipeline, into one of the branches of which a wire is inserted through the gland (included in the kit).

An example of installing a heating cable inside a pipe through a gland

Please note that the joint - the transition between the heating cable and the electrical cable - must be outside the pipe and gland. It is not intended for wet environments.

The tee for installing the heating cable inside the pipe can have different angles of outlet - 180 °, 90 °, 120 °. With this installation method, the wire is not fixed in any way. It is simply tucked inside.

Types of tees for installing a heating cable inside a water supply system

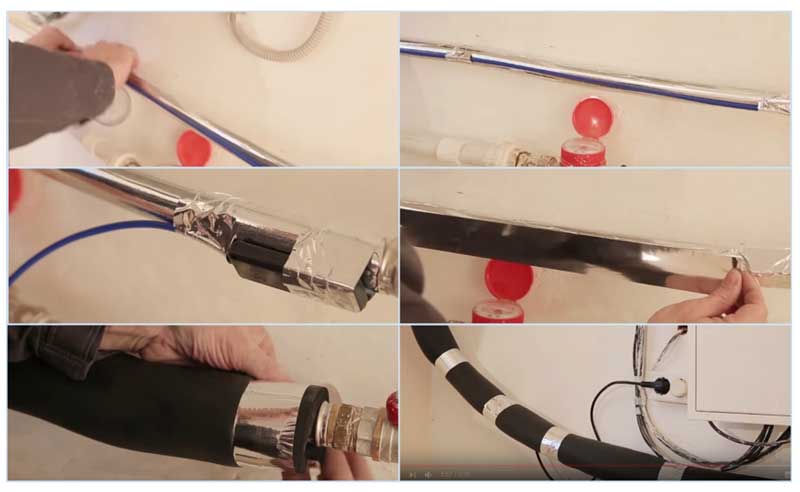

Outdoor installation

It is necessary to fix the heating cable for the water supply on the outer surface of the pipe so that it fits tightly over the entire area. Before installation on metal pipes, they are cleaned of dust, dirt, rust, traces of welding, etc. There should be no elements left on the surface that could damage the conductor. A reason is laid on clean metal, fixed every 30 cm (more often it is possible, less often it is not) with the help of metallized adhesive tape or plastic clamps.

If one or two threads stretch along, then they are mounted from below - in the coldest zone, stacked parallel, at some distance from each other. When laying three or more wires, they are located so that most of them are at the bottom, but the distance between the heating cables is maintained (this is especially important for resistive modifications).

Methods for fixing the heating cable to the pipe

There is a second installation method - a spiral. It is necessary to lay the wire carefully - they do not like sharp or repeated bends. There are two ways. The first is to unwind the sleeve by gradually winding the released cable onto the pipe. The second is to fix it with sagging (bottom picture in the photo), which then wind up and secure with metallized adhesive tape.

If a plastic water pipe will be heated, then metallized tape is first glued under the wire. It improves thermal conductivity, increasing heating efficiency. Another nuance of installing a heating cable on a water supply system: tees, valves and other similar devices require more heat. Make a few loops on each fitting when laying. Just keep an eye on the minimum bend radius.

Fittings, taps need to be warmed up better

How to insulate

It is unambiguously undesirable to use mineral wool of any origin to insulate a heated pipeline. She is afraid of getting wet - in a wet state, it loses its thermal insulation properties. Having frozen wet, after the temperature rises, it simply crumbles into dust. It is very difficult to ensure the absence of moisture around the pipeline, so it is better not to take this insulation.

Insulation materials that shrink under the influence of gravity are not very good. Shrinking, they also lose their thermal insulation properties. If your pipeline is laid in a specially built sewage system, nothing can put pressure on it, you can also use foam rubber. But if you just bury the pipe, you need rigid insulation. There is another option - on top of a crumpled insulation (for example, expanded polyethylene with closed cells), put on a rigid pipe, for example, a plastic sewer pipe.

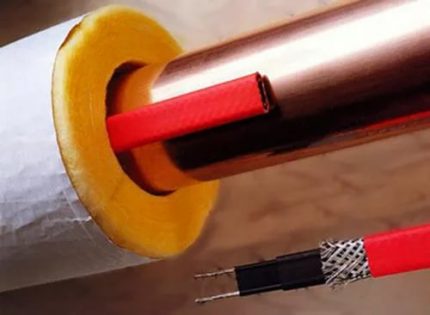

An example of insulating a water pipe with a heating cable

Another material is expanded polystyrene, molded in the form of fragments of pipes of different diameters. This type of insulation is often called a shell. It has good thermal insulation characteristics, it is not afraid of water, it can endure some loads (it depends on the density).

What power is required for a heating cable for a water supply

The required power depends on the region in which you live, on how the pipeline is laid, on the diameter of the pipes, whether it is insulated or not, and even on how you lay the heating - inside the pipe or on top of it. In principle, each manufacturer has tables that determine the cable consumption per meter of pipe. These tables are compiled for each power, so it makes no sense to lay out some of them here.

From experience, we can say that with average insulation of the pipeline (expanded polystyrene shell 30 mm thick) in Central Russia, a power of 10 W / m is sufficient to heat one meter of pipe from the inside, and at least 17 W / m must be taken outside. The farther north you live, the more power (or thicker insulation stand) you need.

Types of heating cables

How to connect a heating cable to the network

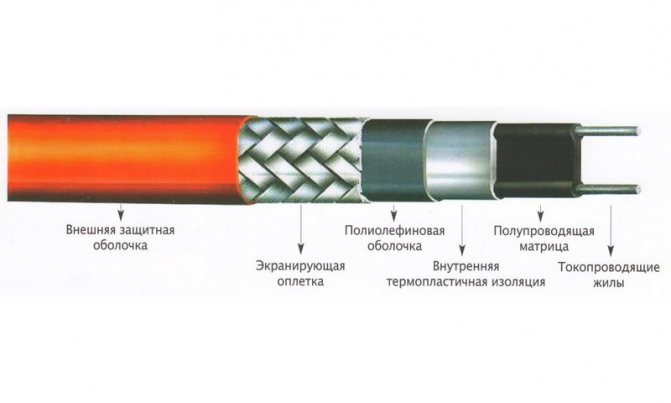

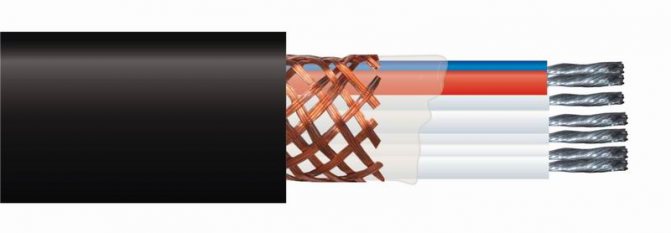

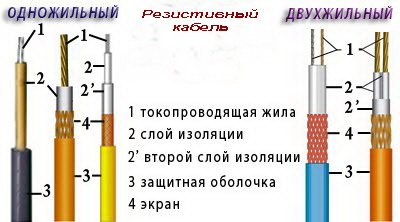

Tubular heating cables are resistive and self-regulating. The first type of products is single-core and two-core, located in a pipe and divided into:

- Linear.

Products also consist of one or more spiral strands of a metal conductor, emit thermal energy passing through the conductors of electric current.

- Zonal.

The self-regulating cable is similar in principle to the resistive type. It is located inside or outside the pipes. A distinctive feature of the product is its ability to independently reduce the power of thermal energy. It also lacks an insulating coating. It can be installed on any pipe system, including small areas. Self-regulation of heat generation in different sections of the cable structure eliminates combustion or overheating of the installation.

IMPORTANT! Resistive cables cannot be cut; it is advisable to purchase them ready-made (in size). Self-regulating products can be cut to the size required.

Resistive cable connection

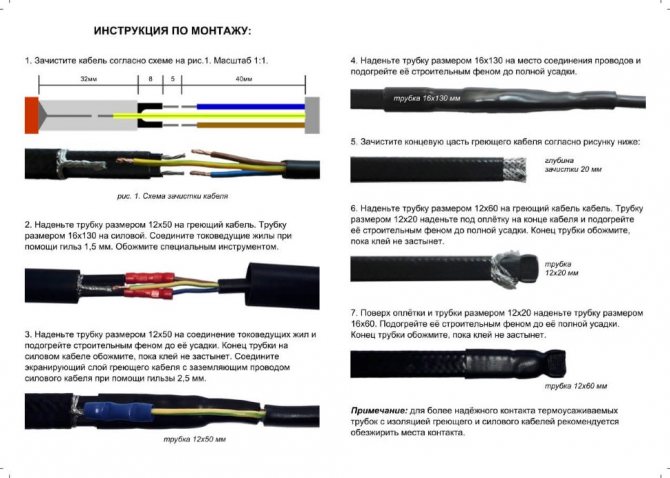

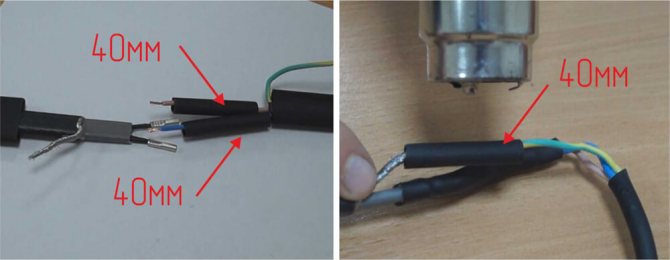

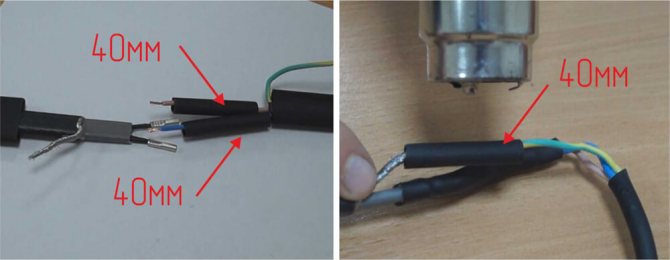

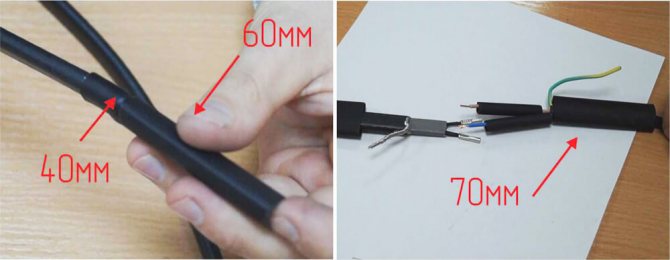

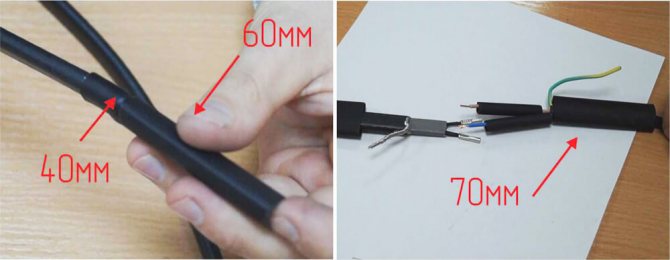

Let's consider how to connect the heating cable to the power cable, which is supplemented with a ground wire.

- The first layer of insulation is removed according to the already known scheme. A protective screen is located under it, which must be carefully cut along, bend and twisted into a separate core.

- It is necessary to clean the heating veins, after which sleeves are put on the three resulting wires, which must be squeezed at the base.

- A heat shrink tube is mounted on each wire.

- Two pieces of thermal insulating tubes of large diameter and different lengths are put on the power cable, similarly to the method described above. After that, the outer insulation is removed from it, and the ends of each of the three cores are separately released.

- The stripped wires are inserted into the sleeves. The ground wire (usually yellow-green insulation) is connected to the core into which the braid was twisted. The other end of each sleeve is crimped with a crimper.

- The tubes, previously put on each core, are shifted and processed with a hairdryer. After that, the same operation must be done with the tubes that are put on the main wire. Smaller at first, then larger.

Now it is clear whether it is possible to connect the heating cable to each other and how to do it.

It is worth remembering that if you do not have the appropriate skills and abilities, then performing the described procedure yourself is unsafe, it is better to turn to professionals who are guaranteed to do the job at the highest level.

How to connect the product to the network

Heating cable for plastic pipes and its installation

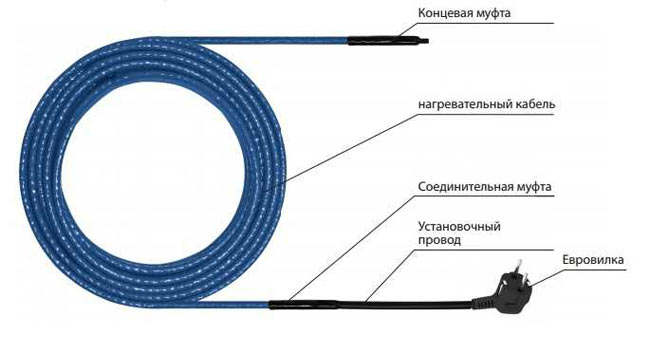

In view of the fact that now you are only studying the use of a heating cable, we have to get acquainted with another important point of work - the insulation of the end of the product. For this purpose, a special heat-shrinkable tube is used that can reliably protect the conductors from the harmful effects of moisture. In addition, for the device to work, its heating part must be connected to the "cold" part, as it is called. You will learn about all stages of this procedure from the videos below.

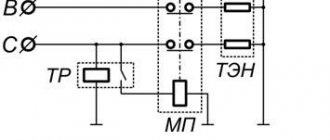

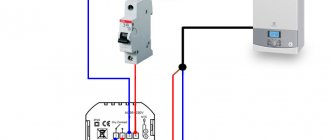

To make the heating of the pipeline as safe and economical as possible, it is recommended to additionally install a thermostat and an RCD. Thanks to the first device, you will be able to regulate the heating temperature by means of a temperature sensor, and thanks to the second, you can protect the heating line from electric current leaks. At the same time, it should be remembered, when connecting the sensor to the thermostat, that the correct functioning of most of the models is possible only with a total length of the pipeline no more than fifty meters (at the moment it is recommended to clarify it at the time of purchase).

Shrink kit composition

DSG 6/2 Heat-shrinkable tube, Ø 6 mm, length 120 mm

The tube is divided into three parts, 40mm each, to connect the heating cable heating cores with the power cable cores, as well as the braid with the ground core inside the sleeve.

DSG 16/4 Heat-shrinkable tube, Ø 16 mm, length 150 mm

An external heat-shrink tubing in the joint sleeve, seals all connections between the heating cable and the supply wire.

DSG 12/3 Heat-shrinkable tube, Ø 12 mm, length 170 mm

It is divided into three parts: 70mm - closes the connection of two current-carrying conductors of the heating cable with two current-carrying conductors of the supply wire.

Self-regulating cable

It is used to protect the water supply system from freezing and to maintain the temperature in the hot water system. It can also be used to thaw snow or ice in gutters during storm sewer construction.

How does it work

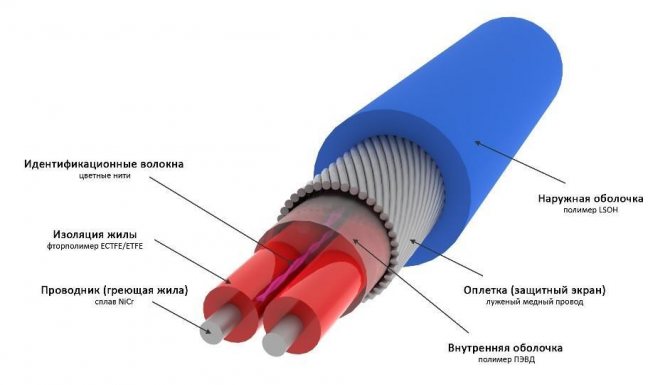

There are two copper conductors in the cable, between which there is a carbon dust polymer resistor.

When a voltage of 220 volts is connected, the current passing through this resistor heats it to a certain temperature.

When heated, coal dust expands and its resistance increases. As a result, the load current decreases and the heating power decreases.

The constantly repeating heating-cooling cycle creates a self-regulating effect.

The total load varies along its entire length, depending on the ambient temperature for each section of the cable. That is, if the temperature of the medium increases, then the released power decreases, and vice versa.

Thus, self-regulation prevents overheating of warmer areas. It can be lengthened or shortened anywhere along the route, since the voltage is applied to it in parallel. This capability simplifies on-site cable design and installation.

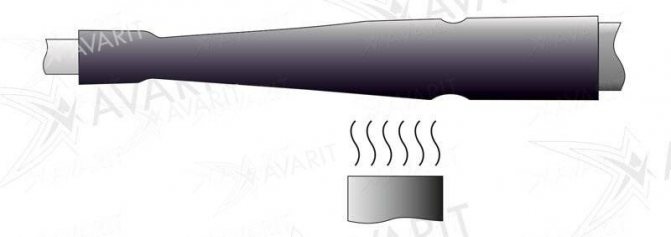

During installation, do not exceed the maximum power for different temperatures during cable operation. It can be bent with a radius of at least 25 mm and only along the flat side.

The use of a heating cable for any water supply that runs down the street is necessary. But there are many problems associated with this, one of which is fragility. Therefore, very often, when laying pipes in the ground shallowly, they use a gasket inside the pipes.

Very often a cable of this type performs its functions in a very narrow range, and therefore you have to turn it on / off manually.

If you do not connect temperature sensors, then you can do with manual switching on and off of the heating system. And the energy savings with this method of heating control will still be tangible.

The only problem is knowing when to plug in the cable. To do this, there is the simplest way - you need to measure the temperature of the pipe and water in the water supply system or in the well during the onset of cold weather. If both indicators are approximately equal, then the pipe does not need to be heated.

When to turn on the heating is up to you, but it is advisable to do this if there is a large difference in the measurement results, based on the outside temperature.

How to choose a heating cable for household piping

TV cable: which is better

In everyday life, the installation of a heating cable is carried out on water pipes, firefighters, sewer and drainage metal, metal-plastic, plastic pipelines, meters. Resistor systems require constant human monitoring and are therefore rarely used.

Criteria for choosing a self-regulating heating cable for a pipeline:

- purpose (industrial or household);

- indoor or outdoor;

- complete or cut;

- power;

- presence / absence of shielding.

For domestic use, you should not buy a product designed to work at high temperatures or in an aggressive environment. This means that there is no need to pay extra for a high protection class and a particularly durable shell.

The self-regulating plumbing heating cable can be installed inside or outside. The choice depends on the situation. For a previously installed pipeline, a product is purchased for inward installation. On pipes with a small diameter, the wire can only be mounted externally.

Internal installation

Mounting the heating cable inside has the following advantages:

- reducing the risk of mechanical damage;

- energy savings due to water heating, not pipes;

- more attractive appearance of the pipeline.

Important! There is also a drawback - a food casing is required. These cables are produced in Europe and are expensive.

Outdoor installation

Outside, the cable can be laid along the pipe (one or more wires in parallel) or in a spiral. The method is selected depending on the heat release and pipe diameter. When buying, you need to study the power table in the instructions for use.

There are 2 types of self-regulating heating systems for external heating: complete and cut-off. There is almost no difference in cost. Cut products require additional accessories and tools. It is enough to install the kit on a pipe and connect it to the network using a cord and plug.

If you plan to install the heating cable yourself, the complete product is more convenient. Recently, Samreg cables from Korea, which have an affordable cost, have become quite popular. The length of the kit is 1-30 m, the product is sold for a cut in coils of various sizes, so you can create a system for a pipeline of any length.

The power of the heating cable depends on the installation location and pipe diameter. For domestic use, 16-24 W / m is sufficient for outdoor installation and 13 W / m for indoor. Additional power reserve is required in regions where winter temperatures are below -30 ° C.

Important! For drainage and sewerage systems, you can buy a cable without grounding (protective shield).For the water supply system, the heating cable must be grounded.

Heating device application

A special water pipe protector aims to maintain the same temperature in the pipeline.

As a result, the water supply system does not fail for a long time, because it is protected from the formation of drops on the surface of all structures.

The device that does not allow this problem to appear has been used for a long time, and it has already been appreciated from the positive side.

The heating cable, which is installed inside the pipeline, is very similar to a standard cable, but a special device is connected to it to control the heating of the water.

Such a device can be connected to the water supply system when the outside air temperature drops to -5 degrees Celsius.

It will get even colder later, which means that the self-regulating cable will protect the pipes from the appearance of ice plugs.

If the installation of the water supply heating device came at a time when the temperature dropped to -6 - -10 degrees, then the normalization of the water supply system will not occur immediately.

It will take time for the frozen pipes to warm up and thaw out. Only then will the connected heating cable start heating the water, preventing it from freezing.

The device for heating the water supply system is produced in 3 varieties. They are distinguished from each other by the heat release scheme.

Depending on it, the devices that protect the pipes from freezing are resistive, self-regulating and with mineral insulation.

Resistive heating cable can be zone or line type. In the latter, heat is generated as a result of the conduction of charged particles through the heating conductor.

Additionally, it is divided into a single-core and two-core device. Moreover, some of the veins inside it are made in a spiral or linear form.

A self-regulating cable for heating a pipe is similar in its internal organization to a resistive device. It is also created on the basis of two conductors that conduct an electric current through themselves.

But a self-regulating cable is different from any other in that its design is not insulated and controls the heat generation along the entire length of the pipe.

If the temperature outside the water supply system rises, the resistance of the polymer increases, resulting in less heat being generated.

Thanks to this function, the self-regulating cable protects the pipes from overheating, which can ruin their plastic coating.

Another advantage of such a protector is that it can be cut into separate pieces of 20 cm or a maximum of 1 meter.

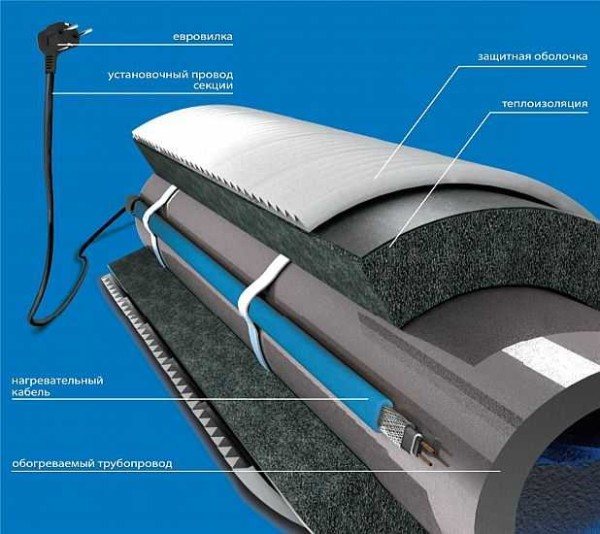

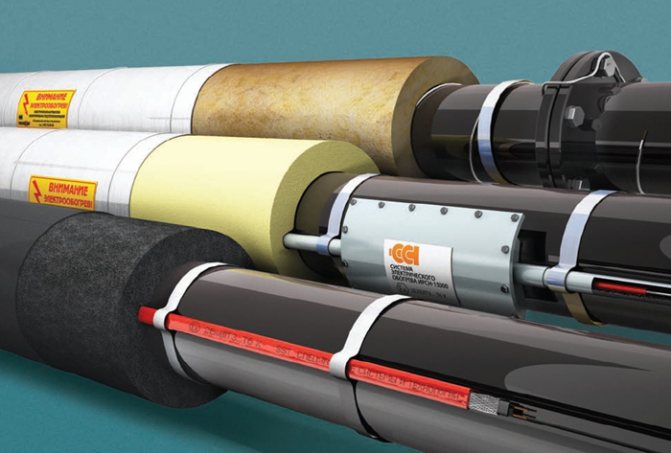

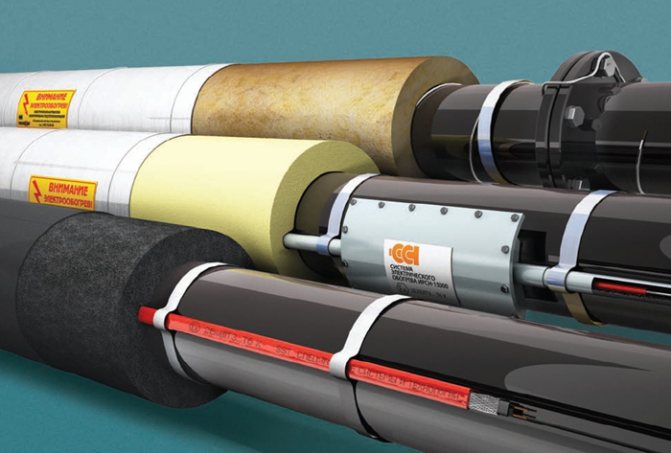

Thermal insulation of heating cables

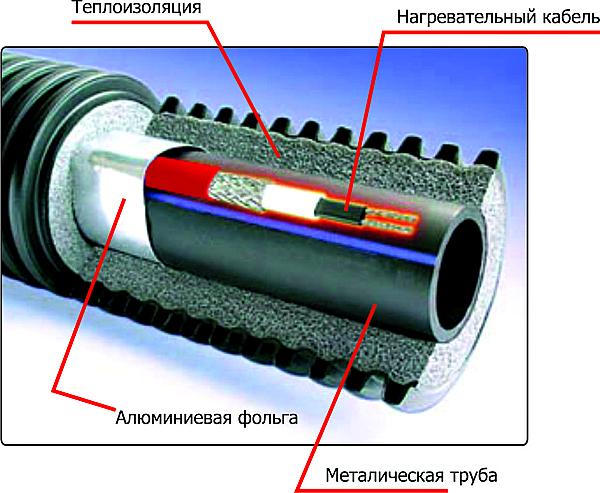

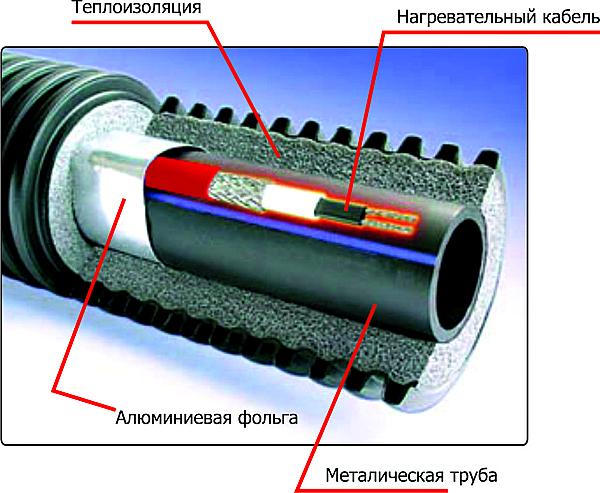

Regardless of the type of cable required. Thermal insulation is installed over the heating system and the water pipe. If the water supply system, together with the heating cable, is not placed in a sealed "cocoon", heating will go in all directions, that is, mostly into the air.

The thickness of the insulating layer is chosen depending on external factors. Suppose that for installation in the ground, a 20-30 mm layer is sufficient, while for above-ground execution, an insulation of at least 50 mm in thickness is required

Expanded polystyrene or foamed polyethylene are used as reliable and effective insulation materials. They are moisture resistant and provide some protective cushioning for the pipe, but they also need protection.

For this reason, a pipe-in-pipe design is often used, when water pipes located in the ground or in the air, together with a heater, are placed inside another pipe of a larger diameter.

Heating cable: DIY external installation

With the external arrangement of such heating, the cable is fixed on the surface of the pipe.Moreover, its length can be equal to the length of the pipe, as well as exceed it. It depends on the installation method, that is, on the method by which the heating cable, the installation of which was done by hand, is attached to the pipes:

- Linear method. The length of the cable is equal to the size of the pipe. The number of threads of the heating element is selected depending on the required power.

- Spiral method. The cable is longer than the pipe. It is laid around the canal in a spiral. This is the most costly method of attaching a thermal insulation device.

External installation of heating cables is the easiest and fastest way to set up a pipe heating system. Sometimes it is more effective than the external one. Often times the cable laid inside the pipe will defrost the ice much faster than the cable wound outside. But it performs its functions in any case.

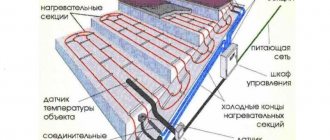

Where are heating systems used?

The scope of application of heating cables for pipes (and not only) is quite large. They are installed in places where controlled heating of adjacent (surrounding) surfaces or materials is required.

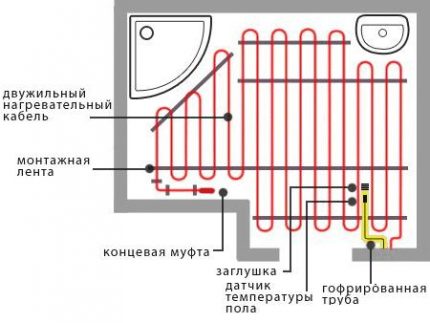

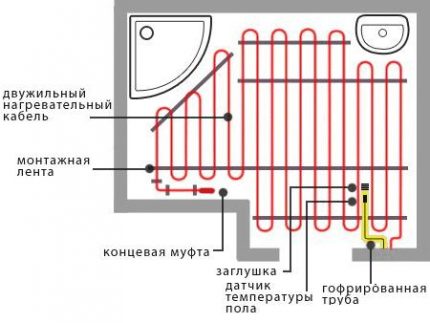

Some types of cable are specially designed for the equipment of "warm floor" systems. They are laid under ceramic tiles, boards, laminate, carpet, and sometimes they are poured with concrete screed.

The last option is the least effective, since the screed "steals" heat, and only part of it passes through the topcoat.

The layout of the heating cable in the bathroom according to the "warm floor" system. The wire is placed with a "snake" over the entire area of the room so that the two ends are in opposite corners

Heating of cables is common in plumbing and sewerage systems. Communications buried in the ground or passing above the ground in the northern regions of Russia are at risk of complete freezing for six months - from October to April.

If the pipeline is laid above the level of soil freezing and is not sufficiently insulated, it will quickly lose its performance. Therefore, we recommend that you learn more about the types of heating cables for heating water supply systems.

The heating cable fixed to the pipe will help to replace the heat-insulating "cocoon". There are different mounting methods, the most common being linear and spiral. The second covers a large area of the pipe

If the pipes are already buried in trenches and dismantling is impossible or undesirable, the cable is installed inside the water (sewer) pipe through a tee cut in the most convenient place.

The next application of self-regulating cable is and gutters.

The wires are fixed in a special way at the edges of the roof, in trays and gutters, in downpipes. They prevent the formation of ice that destroys drainage systems

Under the influence of high temperature, snow and ice gradually turn into water, which flows down through trays and pipes. Roofs become safe for people and vehicles in the yard.

The practical use of heating cables for those who do not like foggy glasses and mirrors is to mount the samreg on the back of the mirror, after which condensation will no longer bother.

In manufacturing and during construction work, heating is often needed to aid in the “maturation” of concrete slurries.

In order for the characteristics of the finished material to meet the standards, it is necessary to create a special temperature regime. For this purpose, self-regulating cables are evenly placed in the place where the solution will be poured, and fittings are used to fix them. After hardening, they remain inside the structure.

A similar situation is with liquids, for maintaining a certain temperature of which samregs are also used. Instead of heating a tank with a technical liquid in the traditional way, a cable is lowered into it, as a result, the characteristics of chemical or food solutions do not change for some time.

Heating systems have not bypassed the agricultural industry either. The cable is placed directly into the ground, under the upper nutrient layer, which protects the roots of crops from freezing.

The main types of heating cables for water supply systems

These seemingly ordinary cables, through which pipes are heated, are also distinguished by their insulating structure mentioned above, which differs depending on what kind of heating cable is in question. First of all, we note that at the present time, such cables can be used not only for heating water pipes with the onset of cold weather, but also in order to heat drainage systems, melt snow and ice, which tend to accumulate in gutters. This prevents their destruction.

Modern industry, as we managed to find out, produces two varieties of this cable at once. Despite the fact that their function is practically the same, the heat release scheme and device are different for them, which means that they should be treated in a special way during installation.

But, which is characteristic, all resistive cables are also divided into:

- linear and zonal options;

- two- and single-core.

Design and methods of application

The principle of the cable is to reproduce heat by converting it from electricity. The cable takes electricity and transfers it to the pipe, thereby preventing the liquid inside from freezing. Pipe frost protection is divided into several types, which are designed to heat not only water and sewer pipes, but also for drains and tanks. They have different technical characteristics and are used outside of pipes and underground. Design features of the cable:

- A cable consists of one or more cores that are inside it. They are made from alloys with high resistance to electric current. The volume of specific heat generation depends on this indicator. The higher the resistance, the larger it is.

- The inner core is protected by a polymer sheath and an aluminum shield. Sometimes it is braided with copper wire.

- All internal parts are covered with an outer shell. It is made of durable PVC material, which is waterproof and does not deteriorate when exposed to ultraviolet rays.

The composition of the cable may vary depending on the manufacturer.

Pipe heating application

Thermostatic cable is used to heat pipes with a diameter of more than 40 mm.

Features of the installation of the heating system inside the pipeline

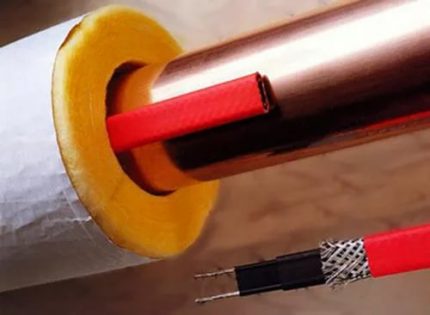

The heating cable is placed inside the pipe if external installation is not possible. It is pushed inside the pipe and connected to the electrical network using a special heat-shrink sleeve.

Heating cable laying inside the pipe

It is highly desirable that this work be carried out by a qualified electrician, since work on the installation of electrical equipment inside the water supply system is characterized by increased danger in the event of installation errors.

The heating system does not require additional service and maintenance.

How to fix it over the pipe?

There are two main ways to secure the cable. Parallel (linear) and circular.

With parallel (linear) installation, it is fixed over the pipe. The length of the cable in this case is equal to the length of the heated section.

Parallel installation of the heating cable outside the pipe

The possibility of self-regulation of the cable allows the use of an overlap when heating external locking structures is required. Cranes, valves, meters, tie-ins.

It is necessary to ensure its tight fit to the heated surface. To do this, it is imperative to clean the pipe surface.

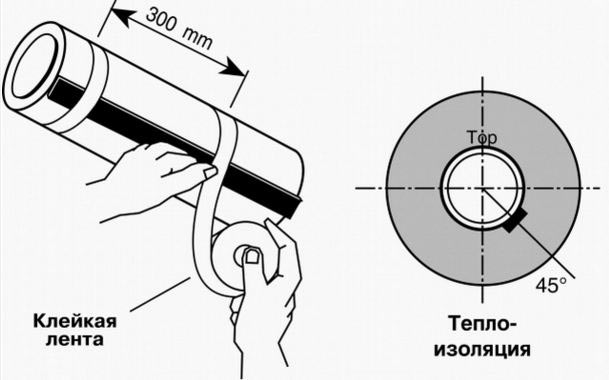

With circular fastening, the cable wraps around the pipe with a turn pitch as per specification.

After completing the work, you should wrap the resulting system with aluminum tape for fixing and shielding. In order to reduce heat loss, it is recommended to add thermal insulation.

During installation, it is strictly forbidden to use plastic tape instead of aluminum.

Installation features

The cable should be laid in a favorable thermal zone.

At temperatures below -5 degrees, installation is prohibited. This limitation is due to the structure of the polymer within it.

If laid in low temperatures, it can be damaged.

How to lay the wire if it loses its flexibility at 0 degrees?

Having carefully unwound the bay, it is connected to the network for about a minute. The cable will regain flexibility. After that, you can carry out the installation.

It is highly discouraged to connect an uncoiled wire to the network.

Installation diagrams

The decision on how to properly lay the cable in the pipeline is based on its purpose, heater power, and location. When laying, use a spiral, linear or internal installation.

Linear mounting

The main type of connection between the heater and the pipeline, in which the wire is placed on the surface and fixed with adhesive tape.

Linear mounting

The installation process is as follows:

- A strip of aluminum foil is glued along the entire length of the pipeline to increase heat transfer to polymer pipes.

- The cable is wound with transverse tape segments with a pitch of 300 mm.

- An aluminum tape is glued on top along the entire length, ensuring its tight contact with the surface of the heat conductor.

- Additionally secured with nylon ties.

- Upon completion of the work, put on a heat insulator, fix it with ties or glue.

Spiral mounting

This type of installation allows you to increase the heating power along the entire length or in certain sections of the pipes.

Spiral winding

Winding on an underground plastic pipeline is carried out in the following order:

- Wrap the pipe along its entire length with foil tape.

- The cable is spirally wound and secured with adhesive tape along its entire length. If necessary, you can additionally fix it with plastic ties with a step of 300 mm.

- They put on the insulation upstairs, connecting its segments with a spike in a groove.

- From above, the entire structure is fixed with tape.

It will be interesting to you. Features of wire ПУГНП

Internal installation

Internal laying in pipelines is an economical and effective way to prevent frost penetration. For installation, use only a self-regulating cable that does not have a temperature sensor that interferes with the flow of liquid in the pipes; it is lowered inside without fixing in a free position. The cable can only be placed in pipelines with a diameter of 1 ”and above in short sections in the direction of flow.

Installing the wire inside the pipe

For entry into the pipeline, fittings with sealed gaskets are used through which the wire is passed.

The use of a heating cable is the most effective method of anti-icing, because any other thermal insulation will not heat the pipeline, but will only increase its freezing time.

Roof heating cable

Careful installation of the heating cable will keep the gutters and pipes open, but they will not freeze when the temperature drops. This is often necessary when using a metal roof without filling or insulation foil.

Electric sets of a heating cable for a gutter and protection of a gutter system are available in a wide range of lengths, usually cables such as tcoe (armored flexible wire for underfloor heating), brands and types of engl, fsm, engkeh (for heating the roof of hazardous industrial premises) and others.

Photo - Roof cable

Connection diagram: step by step instructions on how to connect a heating tape or armored cable:

- For a typical installation, leave about 2-4 meters of cable unused, ideally hanging from the roof;

- Be sure to ground all metal gutters and pipes;

- It is much more convenient to control the cable connection if you use a special switch to it, it can be connected in the same way as an RCD;

- Make sure the switch and other cable joints are well insulated and sealed;

- Installation is carried out "snake" - it is not too economical, but quite effective.