Everyone knows that various technologies and materials can be used for the installation of pipelines: steel and its types, metal-plastic, plastic.

Anyone who has ever faced the issue of installing pipes knows that copper pipes are very reliable and practical - they do not corrode, their use excludes the release of toxic and harmful substances and compounds, they are striking in their plasticity and elasticity, and can withstand heavy loads. Threaded fittings for copper pipes are the best connection method, although others are practiced, such as welding or compression.

Threaded fittings are used when there is a need for frequent assembly and disassembly of the pipeline, focal turns, the need for branches, rasstroy, corners, joints of pipes of the same and different diameters. They differ from the rest by the presence of an internal and external thread, which guarantees the quality of the connection. Since threaded fittings are subject to constant inspection, they are used in places where access is not difficult.

They are also indispensable for the repair or reconstruction of the water supply system. The thread of the fitting is often cylindrical, the same as on the pipe to be connected. Their main advantage is the possibility of repeated use.

Threaded fittings

Below we will look at the types of fittings for copper pipes.

According to the material of manufacture, threaded products are divided into:

- uncoated products zinc-plated (zinc-plated) chrome-plated (chrome-plated) nickel-plated (nickel-plated)

In principle, it is understood that the coating enhances the properties of copper and provides additional protection and strength to the connection, therefore it is more reliable and practical.

By design, threaded fittings are divided into the following types:

- tees; elbows; plugs; couplings; nipples; bends; crosses and others.

In addition to copper, they are made from brass, stainless steel, cast iron, bronze and other metals, compounds, materials, including plastic and metal-plastic.

Types of threaded fittings

Features of the connection of copper pipes

When installing using crimp fittings, use brass or bronze products with a special ferrule, which is located inside the fitting. The connection is made using a wrench. A little effort - and even for someone who has never installed a pipeline, everything will come out without problems and the first time.

A significant disadvantage of the crimp connection method is a low degree of reliability - such a connection is categorically inapplicable in the presence of increased pressure in the pipes. Prevention, expressed in tightening the nuts, carried out regularly, will help extend the life of such a pipeline. It often happens that during preventive tightening, deformation of the fittings occurs, do not despair - just replace the broken product.

Threaded copper fittings are used where crimping and other options cannot be used - it is impossible to solder pipes or you need to combine pipes made of different types of metal.

So, if you decide to resort to soldering, then it is worth considering - maybe it is better to use threaded fittings for copper pipes. You will not worry about corrosion and deformation due to temperature fluctuations, the presence of substances passing through the pipes.

Installation types

Two types of copper pipeline installation are actively used:

- brazing threaded connection (using ferrules)

The second type is much simpler and less expensive, you do not need additional equipment - just tighten the fitting with a wrench. No fire hazard and surprises.

You will achieve a strong connection without resorting to any hard work! If possible, try to use homogeneous metals (copper or copper alloys), this will help increase the life of the pipeline without additional expenses for repair work.

What is useful for making a connection using threaded fittings?

Nothing supernatural:

- a hacksaw for metal (or a special cutter), with which you will cut the pipe into pieces of the size you need. Tip: the cutting blade should be changed before work; wrench; pliers; file; calibrator; sandpaper.

Please note that for piping installation, in addition to pipes and fittings, you will need sealing tape.

DIY copper pipe installation - Pipes and plumbing

- Features of the installation of a copper heating system

- Features of the use of copper pipes in heating systems

- Installation of heating from copper pipes

Copper currently represents a high-quality and modern technology in the plumbing industry.

If, in the process of designing a heating system, it is wise to choose the material, then it would be most correct to opt for copper pipes. Copper is better than other materials for the needs of construction, with its help you can quickly and easily solve any problems. It is durable, strong and plastic - it is thanks to these qualities that the material has gained such popularity.

No other material can impress with so many quality characteristics. If we consider the possibility of using copper for the manufacture of heating pipes, then the first and most important property of the material is its thermal stability.

During operation, copper pipes do not have such side effects as expansion or deterioration in quality: the products retain their hardness and shape. An equally important quality is the high resistance of copper to pressure and corrosion.

Copper pipes are the most reliable, they can serve you for many years without needing repair or replacement.

Features of the installation of a copper heating system

Installation of copper pipes is carried out in 2 ways: by means of a threaded connection using a ferrule or by soldering.

The first method is so simple in its execution that it is suitable even for a craftsman without experience in working with copper products. In this case, you will not need to use any specific tool: copper products are easy to mount using ordinary wrenches that tighten the connections. When choosing a fitting, you need to pay attention to the diameter of the copper pipes.

To install a high-quality, reliable and durable heating structure, you will need the following tools and materials:

Single-wire heating circuit.

- hacksaw for metal or pipe cutter;

- manual calibrator;

- burner;

- spanners;

- pliers;

- file;

- grinding fine sandpaper;

- pipe expander;

- press tongs;

- press fittings;

- directly fittings;

- fittings for copper systems;

- solder and flux for copper systems;

- fum tape sealing threaded connections.

Using the above materials, you can install a heating system using copper fixtures easily, efficiently and quickly enough.

Features of the use of copper pipes in heating systems

Copper structures for heating are characterized, as already mentioned, by comparative ease of installation. A wide range of connecting fittings allows you to install heating of any complexity.

For heating, you can use thin-walled pipes made of this material, however, usually the wall thickness of such circular reinforcement is about 1 mm with an outer diameter of 3-3.6 mm. If old copper structures are replaced, they can be reused or sold.

Even in the case of the sale of products for scrap, you can get back up to 30% of the money spent.

Among the disadvantages of copper pipes for heating, their relatively high cost can be noted. Although in terms of price, structures made of this material can successfully compete with some metal-plastic ones.

If the cost of copper itself is slightly higher than the cost of metal-plastic heating pipes, then all the necessary fittings are much cheaper.

In addition, soldered joints are much more reliable than metal-plastic collet and pressed joints.

If you decide to install such heating structures, then it is best to buy pipes with a diameter of 3.05 cm (1.2 inches). This size is the most optimal for heating.

High quality characteristics and thin walls allow even an inexperienced craftsman to install copper heating, it is enough just to be attentive to the work and strictly follow all the rules.

Experts carry out the installation of structures made of this material by the method of hard and soft soldering, which makes it possible to carry out the process much more reliably and faster than when using threaded connections and welding.

Copper products have many positive characteristics.

They protect the heating system from the ingress of air into it, are able to withstand pressures up to 30 atmospheres, the service life of these products is over 60 years, in contrast, for example, to polymer products for heating rooms.

What is important when organizing a heating structure in a private country house, the pipes can be mounted independently using a press tool and press fittings.

Installation of heating from copper pipes

The installation of such products can be done in various ways, depending on the types of fittings used. Fittings can be divided into detachable and one-piece, as well as the connections of the copper pipes themselves.

Detachable connections are used when installing products for connecting with devices and fittings, as well as with elements made of other materials.

Pluggable connections should be easily disassembled and reassembled without damaging the surface.

https://www.youtube.com/watch?v=s2-0hGlxXgw

Permanent joints can be obtained by several methods: brazing, welding with a soldering iron, crimping, soft soldering.

Copper products for heating with a diameter of over 110 mm and a wall thickness of more than 1.6 mm can be joined by welding. Soldering with soft solder (low-temperature soldering up to 440 ° C) is performed using special fluxes that can improve the quality of soldering and increase adhesion.

Before soldering, the surface of the material must be cleaned. Such soldering is used in cold and hot water supply lines and in heating structures with a temperature not exceeding 115 ° C.

Using low-temperature capillary brazing, it is possible to connect any systems made of this material with a diameter of 7 to 110 mm.

Since this material tends to lose hardness at high temperatures, for soldering it is necessary that the solder has the lowest melting point. For this reason, it is recommended to use the low-temperature brazing method to install such heating.

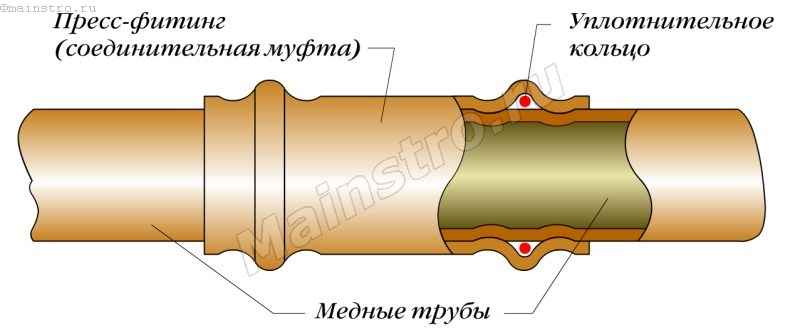

Crimping can be carried out with small and large diameters. For this type of connection, a special press and special fittings are used.

Using copper products for a heating structure means using the most durable and acceptable option.A feature that has already been noted is the relatively high cost of this material, but it is quite justified, since copper is an almost ideal high performance material.

Copper products for heating systems must be marked, this confirms that they are manufactured according to standards and processed with phosphorus, which increases their resistance to various influences.

Do-it-yourself installation of copper heating pipes Installation of copper heating pipes can be done by hand, even if you do not have the appropriate skills and experience. This is very good stuff.

Source: 1poteply.ru

[content-egg module = GdeSlon template = compare]

Repair work in the house related to the plumbing system requires a special approach to the choice of materials. Indeed, not only the durability and reliability of the service life depends on this, but also the quality of drinking water. Copper pipes and fittings for plumbing are a perfectly acceptable option, despite their considerable cost. This is what this article will be about.

Copper pipes and fittings for plumbing - a long-term, quality-justified investment

Installation

During installation, the nut is joined with the fitting, after which the thread is tightened - first by hand, then with a wrench. If joining with pipes made of other materials cannot be avoided, fum tape will come to the rescue, which is screwed onto the threaded part under the fitting.

If you do not want to speed up corrosive processes in the joint, do not use a transition from copper to galvanized or unalloyed steel. Electrochemical processes occurring between these metals can reduce the life of the pipeline.

How to choose?

In order to properly mount the system, it is necessary to take into account the features of the threaded fittings. You should focus on the purpose of the pipes, if you use high-quality materials, pay attention to all the rules - you are guaranteed a high-quality connection for many years. Find out what the sizes and purpose of fittings are, use it in the design.

Choice of fittings

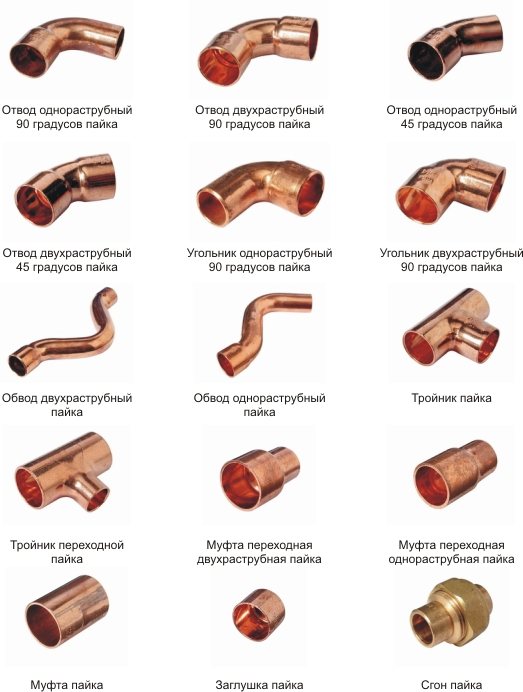

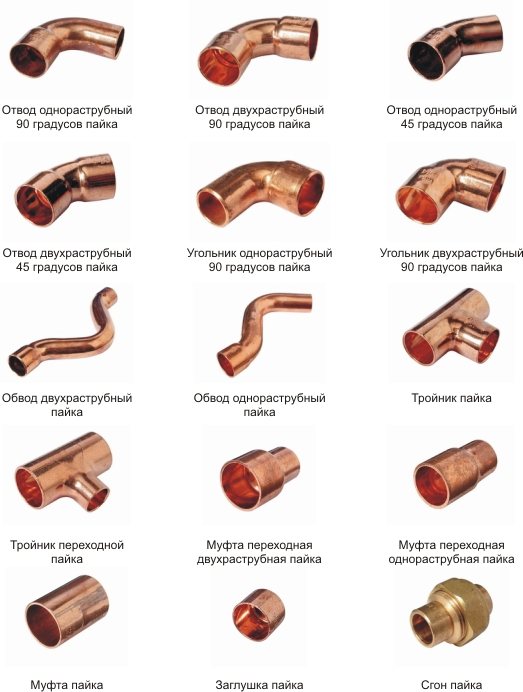

If you need to rotate the structure, the corners will come in handy, if you have planned branching, be sure to purchase tees, crosses, collectors. If you just need to connect two pieces of pipe (of a given or different diameters), stock up on couplings, and, of course, do not forget to buy plugs.

Where to apply?

Copper pipes with threaded fittings are highly competitive, despite the fact that many other types of connections and materials for the manufacture of pipelines have appeared in the world. And all thanks to the almost magical properties of copper - disinfection of water when broadcasting through pipes, the pipe itself does not oxidize, does not rust, products from it are very reliable, but at the same time plastic, characterized by resistance to temperature extremes and fluctuations from high to low.

Where is the area of application of copper pipes?

Believe me, everywhere! These lightweight and durable pipes take place in the design and laying of air ducts, and the crimp type of copper fittings is actively used in communication networks. Wherever you will not find a copper pipe - in heating systems and appliances, in air conditioners, in gas appliances and pipelines, in the water system - copper is always present. Some enthusiasts of experiments use copper pipes as an element of decor or interior - they take any shape and can be connected to any other pipe (and not only), are interesting for their unique color and brilliance.

How to mount?

Some recommendations for installation were given above, however, if you are not sure that you can do the job efficiently, it is better not to take it.

You can ask any familiar craftsman from the people or call a team or one professional.It's up to you to decide. But you shouldn't retreat from your decision to make a copper system.

An extensive selection of types and directions of connections, tightness and reliability, environmental friendliness and aesthetics are not all the advantages of a copper pipeline. Do not forget that you can solder and weld these pipes, connect using threads and flanges, crimps and compression technologies. Copper fittings help you assemble the system the way you need it, rather than adapting to the "material", and it will be leakproof and practical, and the time you spend on installation will be much less than if you take advantage of other options and possibilities.

Successful construction work!

If your piping design requires multiple disassembly and reassembly, threaded copper pipe fittings are best suited for installation. Their difference from others consists in the presence of a thread on the outside or inside, with the help of which the connection takes place. Threaded fittings are quite practical, but they lag behind in terms of reliability, and, as a result, they need periodic monitoring of the condition of the connections.

In this regard, in most cases, their use is advisable in easily accessible places of the pipeline. Another direction for the use of threaded fittings is the repair or reconstruction of the water supply system. Threaded fittings are quite practical, but they lag behind in terms of reliability, and, as a result, they need periodic monitoring of the condition of the connections. pipelines These are collapsible parts that are used to repeatedly connect system elements. Their design provides for the presence of external or internal threads.

Typically, this thread is cylindrical. Threads are provided both on the fittings themselves and directly on the pipes. Their advantage is reusability.

Threaded products are suitable not only for connecting elements, but also for installation with plumbing or pipeline fittings. The above-mentioned fittings can be classified as: uncoated; zinc-plated (zinc-plated); chrome-plated (chrome-plated); nickel-plated (nickel-plated) Naturally, plated fittings provide more reliable anti-corrosion protection. Threaded fitting belongs to one of the main types pipe connections. The range of threaded elements is huge. These are products that are different in type and design: elbows; tees; bends; nipples; couplings; plugs; fittings and so on. The material from which threaded fittings are made is also diverse: cast iron; brass; stainless steel; bronze; and, finally, copper. This is just about copper fittings and the further story will go. Copper pipes.

Connection features Brass and bronze fittings are suitable for crimping copper pipes. The tightness of the connection is ensured by the presence of a special compression ring inside the fitting. To perform the crimp, you need a wrench and a little effort when turning the nut.

No additional devices are required. Even if there is no experience in installing copper pipes, it will be easy to cope with such work. The disadvantage of such a connection is insufficient reliability. There are a number of restrictions on the pressure inside the pipes when connecting with the above method.

To maintain tightness, do not forget about prevention and timely tightening of the nuts. If, with frequent tightening of the nuts, deformation of the fitting occurs, it is necessary to replace the failed connection element. The connection using threaded fittings is used mainly where there is no possibility of soldering copper pipes or it is necessary to combine pipes made of different materials.then the method using threaded fittings is ideal for you. Reliability, ease of installation and anti-corrosion properties of copper pipes will stop your choice on the option of copper.

Another plus is high resistance to temperature fluctuations. There are two main types of installation. This is mounting by soldering and by means of threaded connections using ferrules. After reading the name of the above method, one may doubt the ease of installation.

But this is not the case. Simplicity and accessibility are the motto of this method. You don't need any special tools, just wrenches are enough.

And even with such an installation, there is no need to comply with fire safety techniques. When installing copper products, whenever possible, use homogeneous materials (copper and its alloys). This will increase the service life of the structure. You will need: a special cutter or a hacksaw for metal (with their help you will saw pipes into pieces of the required size, when using a hacksaw, do not forget to replace its blade with a new one); a calibrator; wrenches; a file (with its help you will clean the burrs at the cutting points); pliers; to remove the oxide film you will need a sandpaper. These are tools, and the following materials are needed: copper pipes directly (with a threaded connection, a stock of a couple of meters will not hurt); fittings (tees, adapters, etc. .) depending on the plumbing scheme; special fum tape for sealing. And now about the order of work. First, you need to saw off the desired section of the pipe (check with the diagram). If you are using pipes with insulation, then do not forget to remove the protective layer at the site of the future connection. Make a cut and remove the insulation. Using a file, remove burrs at the cut. Prepare the fitting: first put on the nut and then the ferrule. Butt the nut with the fitting and tighten the threaded joint.

Tighten the nut slowly, first by hand, and then with a wrench. If, when installing copper pipes, it is necessary to connect to a steel pipe, then it is appropriate to use fum tape. It is screwed onto the thread, then the fitting is screwed on. and the tight connection is ready. When installing copper products, whenever possible, use homogeneous materials (copper and its alloys).

This will increase the life of the structure. Useful tips for installing copper pipes When installing copper products, whenever possible, use homogeneous materials (copper and its alloys). This will increase the life of the structure. If this advice does not work, then you need to adhere to the following rule: do not allow galvanized unalloyed steel to be connected to copper (with such a connection, you will get faster corrosion of steel elements due to electrochemical processes). pipes.https: //experttrub.ru/youtu.be/YyD0_qTuj4Y "width =" 640 "height =" 425 "style =" max-width: 100% "> The choice of fitting depends on the purpose of the pipeline. A professional approach to the connection, high-quality materials will increase the service life of the structure. The size of the fitting for copper products is easy to choose, since there is a standard and nomenclature.

Products manufactured by different companies are interchangeable. The size is determined in accordance with the inner diameter, wall thickness, socket depth and gap width. Types of fittings depending on the purpose By purpose, threaded fittings for copper pipes are classified as follows: various angles (90 or 45 degrees). Their purpose is to rotate the product to the desired degree; collectors or tees, allowing you to make a branch from the main structure; crosses.

Provide the ability to carry out independent branches while maintaining the main direction; couplings. Designed to connect straight sections with the same diameter or different.Also suitable for joining elements made of different materials.

plugs, caps - overlap the end of the copper system; fittings discharge a flexible rubber tube, etc. Fields of application of copper pipes and fittings The competitiveness of copper pipes and fittings made of copper remains quite high nowadays, even in the presence of other high-quality materials. All this is due to the positive qualities of copper. Copper does not allow microbes and bacteria to get into the water, does not oxidize and is not subject to rust, the products are quite plastic and reliable, resistant to both high and low temperatures. ”640 ″ height =” 425 ″ style = ”max-width: 100%”> When using copper pipes, install duct networks.

Copper crimp fittings are successfully used in the creation of engineering communication networks. Gas supply, heating, air conditioning systems, plumbing - none of these industries can do without the use of copper products. Not only because of the high quality, but also as an original element of the interior in the modern or high-tech style. Designers are also attracted by the ease of installation, copper pipes are easier to cut and various bends than others.

Many inhabitants associate the durability and reliability of the pipeline precisely with the use of copper pipes in household communications. For a long time, this metal has been used in plumbing, sewerage and heating circuits in order to prove itself exclusively from the best side.

The presence of special couplings and fittings facilitate the connection of copper pipes, which allows you to carry out or change them yourself. Depending on whether external or internal fastening, either a split or one-piece method of mounting the circuit is used.

Do-it-yourself copper pipe installation: how to make a plumbing from copper pipes?

How to do the installation of copper pipes with your own hands: what tools and fittings are needed for installing a copper pipe. What is the difference between installing copper pipes for cold and hot water? How to solder copper pipes? Do-it-yourself installation of copper pipes, or How to make a plumbing from copper pipes?

- Copper Piping Tools Copper Piping Fittings What is the difference between installing copper pipes for hot and cold water pipes? Collet connection of copper pipes How to solder copper pipes? Examples of finished copper pipes

Let's see now DIY copper pipe installation, but, obviously, the installation is not for itself, but on the example of how a water supply system is made from copper pipes.

Copper Pipe Mounting Tools

The first thing that needs to be determined, having dared to install copper pipes with your own hands, is whether to mount the water supply using soldering or with the introduction of threaded connections. Brazed installation is more economical, but threaded installation is easier.

Accordingly, a different tool is needed.

For threaded connections, only pliers and wrenches are required.

To make the installation of copper pipes by soldering, you need a gas burner or electric tongs or a hair dryer, sandpaper for cleaning the joints, flux for soldering.

Cut copper pipes using a hand-held pipe cutter:

- or with a hacksaw for metal.

After cutting, burrs form on the pipe, which means that there must be a ratfil under the hand to remove them. With ratfil, they also remove the chamfer at the ends to be joined.

Bending of copper pipes is done with a pipe bender:

Pictured is a manual pipe bender for copper pipes; there is also a hydraulic one.

Fittings for installing copper pipes

For the installation of copper pipes, different fittings are used, not only straight, but also various shaped: bends, elbows with a turn of 45, 90 degrees, tees and transition couplings with similar and different diameters (for connecting pipes of 1 or different diameters), etc. ...This photo shows fittings for brazing copper pipes:

And in this photo - threaded fittings for copper pipes:

Fittings for threaded connections are made of brass, and for soldering they are made of copper, which can be seen even by the color of the parts (copper is reddish).

Connecting parts can have both internal and external threads, obviously, you should choose based on your own project, and from the assortment that is available in stores.

What is the difference between installing copper pipes for hot and cold water pipes?

Plumbing from copper pipes for hot and cool water is made according to the same method. But the details for this or that temperature differ in appearance: copper pipes with PVC film are used for hot water.

When installing copper pipes of a hot water supply system, the insulating layer in the place of the upcoming connection, of course, is removed earlier.

Collet connection for copper pipes

Collet connection of copper pipes is made using threaded fittings, and this more affordable do-it-yourself copper pipe installation.

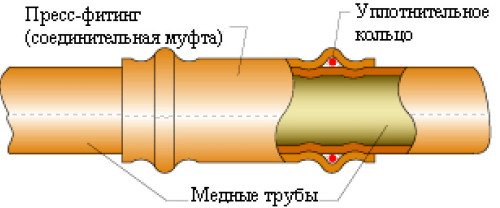

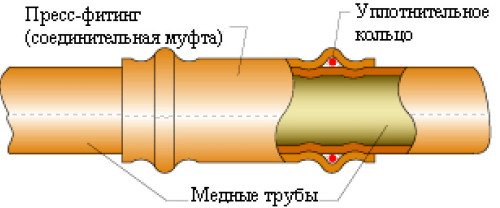

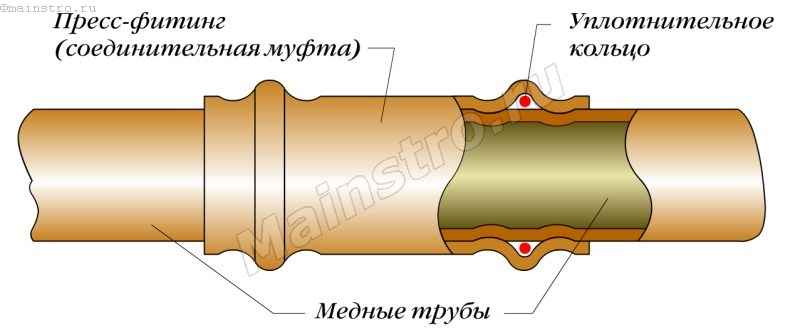

The collet connection of copper pipes with a fitting is very similar to the same connection of metal-plastic pipes: first, a union nut is put on the pipe, a compression ring and then docked with a suitable fitting and the nut is tightened.

As the union nut is tightened, a ferrule made of soft metal seals the joint by crimping around the pipe. If it becomes necessary to disassemble the ferrule connection, the ring must be replaced and not reused.

How to solder copper pipes?

When installing copper pipes with your own hands by soldering, you need to keep in mind the safety measures, since there is an open burner fire, and in the soldering area the temperature of the parts is more than 250 degrees.

Soldering copper pipes is easy: first you need to sand the pipe and fitting ends to be joined with sandpaper:

After that, they are applied flux for brazing copper pipes:

Then the prepared end of the pipe is inserted into the opening of the fitting, the junction is heated with a gas burner:

Or with a construction hairdryer:

Or with electric pliers:

When the parts are quite heated, a solder wire is brought to the contact point and the joint is filled with solder (see photo above).

The photo below shows the flux for brazing copper pipes (left) and solder:

Flux is a special paste that degreases, cleans the surface, prevents it from oxidizing during soldering.

Examples of finished copper pipes

In the following photos, there are several examples in which the water supply from copper pipes is already ready:

And here is a copper pipe in the underfloor heating system (although not completely on the topic of the section):

DIY copper pipe installation relatively not complicated, but not everyone can afford a copper pipe plumbing - the cost of copper pipes is very high.

In addition, with low water quality, pipes are oxidized, get a green color, and copper oxides that get into (drinking) water, to put it mildly, do not bring health benefits.

So, of course, it's up to you to decide whether to use copper pipes in the water supply system of your own home.

DIY copper pipe installation, copper pipe plumbing

This entry was posted in Water supply. Bookmark the permalink.

Source: https://stroy-industriya23.ru/montazh-mednyx-trub-svoimi-rukami-kak-sdelat-vodoprovod-iz-mednyx-trub.html

Push-in fittings, their types and applications

The modern market offers a wide range of auxiliary parts for connecting copper pipes without soldering (threaded method, for example) or by high or low temperature welding. Copper is a very easy and malleable metal, so even a beginner can handle it with the tools.

Push-in fittings for copper pipes are the easiest way to install line elements, because they are based on a clamping ring that is put on the tube and a nut that fixes the clamping point. This method of connection is quite simple and does not require special tools.

Most often, similar fittings for copper pipes are used:

- When conducting a line through which hot or cold water, gas or oil circulates. In pipelines in which the chemical medium does not exceed a heating of 175 ° C. The pressure in such systems should not exceed 16 atmospheres.

This type of installation is considered very reliable and tight, and the collet connecting fittings for copper pipes presented on the market today are available with an inner diameter of 8 mm to 100 mm. If pipes of a larger diameter are to be installed, then another method of joining them should be chosen.

There are the following types of collet fittings:

- Couplings for copper pipes, as a rule, are made of copper or the alloys in which it is included. Its function is to join contour elements of the same metal and the same diameter. Copper adapters for copper pipes are used to connect pipes of different diameters. They can also combine products from different materials, but it is better to choose brass counterparts. The branch connector for copper pipes is an angle that allows you to join the network elements at an angle from 45 ° to 120 °. When separation of the flow is required, a collet cross or tee is used .When connecting a flexible hose to a pipeline element, a union is used.

Push-in fittings are the most commonly found parts in domestic and industrial piping. This is due to their following advantages:

- They are affordable. Simple enough to use. Quite a wide range offers models for lines of any length and complexity. To work with them you do not need special equipment and a beginner can handle them. Push-in fittings provide a reliable tight connection. They are durable, like pipes. made of copper, but if necessary, they can be reused or as a temporary docking.

Since the clamping point weakens over time from loads and requires tightening, such a connection is used exclusively when external fastening of copper pipes to a wall, for example, is carried out. Access to the docking point is an important factor for such a pipeline.

Installation steps:

- Pipes are cut into lengths according to the diagram and cleaned. If necessary, calibration is carried out to obtain an even hole. A nut is put on the end of the tube, and then a collet. The end of the fitting with rubber bands is inserted into the tube. The clamping nut is screwed by hand onto the thread of the fitting and gently into it. the collet is tightened. The nut should be tightened with a wrench, but allowing for pinching.

Pulling the collet, you need to make sure that there is no skewing, otherwise all the work will have to be done again. When tightening the nut with a wrench, it is important not to overdo it, otherwise the copper will crack, and this piece of pipe will have to be cut off.

Solder

To perform reliable soldering, you need to purchase solder. It comes in two types - hard and soft.

- Brazing alloy is produced in the form of long rods. This solder can be used for brazing pipes for hot water, gas supply, air conditioning, or for a line operating at high pressure. The soldering temperature of such solder reaches 900 degrees. The most common types of hard solder are considered to be copper-phosphorus self-fluxing alloy Cu94 P6 and alloy Cu92 P6 Ag2 with the addition of silver from phosphorus and copper.

Important: such a solid solder contains a 6% addition of phosphorus, which reduces the soldering temperature to 750 degrees.

- Soft solder is produced in the form of a thin wire with a diameter of 2-3 mm. Such solder is used when soldering a water supply system with your own hands in everyday life.

- There is also a special paste called flux. Issued in banks. It must be used for high-quality cleaning of pipe joints, removing oxide from the seam after soldering and improving the melting characteristics of the solder.In this case, the flux can be used both for soldering at high temperatures (over 450 degrees) and for soldering at low temperatures (up to 450 degrees).

Important: the flux contributes to better adhesion of the solder to the copper.

In addition to all the tools, solder and flux, it is also necessary to prepare fittings if there is a need to make turns and bends in the water main. All fittings have a regulated diameter and comply with GOST. The cost of fittings and adapters is quite affordable.

Compression fittings

It is the crimp ring for copper pipes that ensures the reliability of joining the individual elements of the pipeline. Above was described how to use a push-in fitting with such a ring on normal pipe ends. When a flare connector for copper pipes is required, compression fittings are also used.

Pipe flaring can be done by yourself if you have special equipment. To widen the end to the desired size, it is better to use a flare tool, with which you can make the necessary calculations and calibrate.

Compression fittings for flared copper pipes consist of a sleeve and a clamping nut and are just as easy to use:

- A coupling is put on the prepared and cleaned end of the tube. The end of the other pipe is inserted into the expanding machine or expander and rotated until it forms an edge at an angle of 45 °. The second end of the coupling is inserted into the finished rolling and tightened with a nut.

Compression fittings for copper pipes are used exclusively in outdoor piping and are part of the service system. If they were used in annealed (soft) products, then a visual examination is enough for preventive checks, while in unannealed ones, tightening the clamping nuts will be required.

The connection of copper pipes with crimp fittings is most often used when carrying out repairs to a circuit or as temporary parts when wiring a new line. They are reliable, durable, but require periodic testing of the quality of the seal.

Threaded fittings

Threaded connection of copper pipes is the most common, since they can be easily replaced or reused on occasion. Fittings of this type can have both external and internal cylindrical threads.

The pipeline is far from the only place where such parts are used, and they are often part of the connections of plumbing elements. By configuration, threaded fittings for copper pipes are divided into:

- elbows; nipples; couplings; plugs; bends.

For the connection of copper elements, fittings should be selected from brass, copper or alloys with its content.

If you are going to use a threaded fitting on a soft copper pipe, it is recommended to "secure" the joint with a support sleeve, which will allow you to tighten the nut tightly without deforming the metal.

Elements for copper pipes

Copper fittings, with the help of which the connection of copper pipes is made, are presented on the modern market in a wide variety of sizes and their designs. The most famous types of such connectors are:

- threaded fittings for copper pipes;

- self-locking connecting elements;

- compression or crimp fittings;

- so-called press fittings;

- capillary type connecting fittings.

Of all the above types of connecting elements, in our time, press fittings for copper pipes are least often used, which is explained by the following reasons: their installation requires the use of complex and expensive equipment: special presses. The design of press fittings was originally developed in order to connect plastic and metal-plastic pipes with their help, so their use for the installation of copper products is not always advisable.

In order for the pipeline, during the arrangement of which copper parts are used, to serve as long as possible and be highly reliable, it is advisable to use elements made of homogeneous materials during its installation. Connecting copper pipes with fittings made from other raw materials should be done only in rare exceptions.

If it is not possible to avoid the use of fittings made of dissimilar materials during the installation of pipelines, then such a process must be performed, adhering to the following simple rules:

- copper pipes in communications, for the creation of which elements from different materials are used, are always installed after products from ferrous metals: in the direction of fluid movement;

- copper parts of pipelines cannot be connected to galvanized fittings and, non-observance of this requirement will lead to the fact that electrochemical reactions will act in such systems, which will significantly accelerate the process of corrosion of steel parts;

- copper elements of pipe structures are allowed to be connected with parts made of acid-resistant steels, but if there is such an opportunity, it is better to replace such parts with fittings made of polyvinyl chloride.

Press fittings

The one-piece connection is considered the most reliable, and it is precisely this connection that is used when the pipes are to be "hidden" in the floor or wall. One of the elements of such a system are press fittings for copper pipes.

At the heart of these parts are special polymer seals, and to assemble the pipeline you will need:

- Cut and strip the pipe to the required length. Calibrate the hole. Insert the pipe ends into the press fitting. Squeeze the joint with a copper pipe clamping pliers.

This method of connection does not require heating of parts and is considered one of the fastest. If the amount of work to be done is small, then you can purchase a manual press for copper pipes, for which, apart from little physical effort, nothing is required. It provides the required tightness by compressing the connecting fitting against the seal ring.

The electro-hydraulic copper pipe press is used by professionals when laying long lines with numerous connections. More expensive equipment has replaceable couplings, thanks to which it is possible to connect pipes of different diameters from any manufacturer.

To carry out repair or installation work on your own, you can rent a press for copper pipes, which is more profitable than spending money on a tool that may not be needed the next time soon.

Fittings types

All connecting fittings are divided into several types according to their functions:

- Straight - for direct connection of two pipes of the same diameter. These fittings are called couplings, and the body is usually in the shape of a cylinder.

- Transitional - for direct connection of two pipes of different diameters. Adapters, or reducers, have a complex shape: two short cylinders of different sizes are connected by a truncated cone.

- Corner, or swivel, - for connecting identical pipes at an angle. Such fittings are called bends or corners, the body bending angle is from 15 to 90 degrees.

- Splitter - for combining two or more streams or dividing one stream into several. Tee bodies have three branch pipes, the diameters of which may vary. Cross bodies are made up of four or more spigots connected at right angles.

- Sealing - to cover free pipes. These shaped pieces, called plugs, are a cap or plug.

Many, in my opinion, mistakenly believe that copper pipes are quite expensive when installing a water supply system or heating a house, and some, and that the age of copper for these purposes is a thing of the past.In this post, we will try to prove to you that this is not so, precisely because copper is a fairly convenient material for the installation of any structures, and if you take its durability into account, it is indispensable in many cases and it is she who will be chosen by a zealous owner for his own home.

If we compare copper with other materials from which water supply and other communication pipes are made (for example, with plastic or), then its advantages are obvious. First of all, it is an unusually long service life: copper pipes and fittings often last as long as the building itself.

Copper is very plastic, which increases the safety of the water supply system and retains its properties in a wide temperature range (from -200 to +250 ° C), which makes the pipes resistant to freezing when filled with water.

Copper pipes are resistant to ultraviolet radiation (unlike plastic ones), have a low roughness coefficient, which allows them to be used in similar conditions

Copper piping is practically unaffected by various types of viruses and bacteria, it is not afraid of oils, fats and various harmful substances. Even chlorine, which is inevitable for our water pipelines, is not capable of destroying a copper pipe, but, on the contrary, due to the formation of an oxide layer on its inner walls, chlorine helps to extend the life of the pipe.

Pipes

Round copper water pipes are produced both in coils (25 and 50 m long) and in sections (rods of various lengths). The most commonly used pipes have diameters from 8 to 28 mm with a wall thickness of 1 mm. It is worth emphasizing that copper pipes, due to their thin walls, are much lighter than steel ones. They can be insulated.

Installation of copper pipes does not cause any particular difficulties, mainly due to the fact that they are well cut and bend. Copper pipes can be connected in two ways: split and one-piece. The second includes soldering, welding, and pressure testing.

Various fittings are used to connect pipes, connect to fittings, to an existing water supply system.

Fitting

There are many varieties of connection and transition fittings. Some examples are shown in Photos 1-12. So, for soldering, not only ordinary and transitional couplings are used, but also various elbows, tees, crosses, contours, rolls and plugs. There are fittings with the transition of a soldered connection to a threaded one, for example, "American" with a cone seal (15 × 1/2 "). Threaded press fittings often use a ferrule, which, when the union nut is tightened, compresses the pipe, thereby sealing the connection.

Soldering

It is believed that soldering is the most reliable way of joining any pipes, and copper pipes are no exception. It can be produced by high temperature or low temperature connection. The latter includes fittings for copper pipes for soldering.

Many consumers prefer to deal with parts into which the manufacturer has inserted solder during the manufacturing stage. As a rule, it is placed in a specially made cavity in the socket and most often there are fittings with low-melting solder, for which the temperature of a blowtorch or a building hair dryer is enough to heat it.

The connection technology is very simple:

- The ends of the pieces of copper pipes are cleaned. They are inserted into the fitting (you can use an American for soldering copper pipes). Heat the part with a blowtorch or a hairdryer so that the solder melts and spreads, soldering the pipes with it. Do not move or move the joint until the joint has completely cooled.

This simplest method of brazing copper pipes, although it is known to the domestic consumer and is gradually gaining his sympathy, is still most popular in Europe and Asia.Some of the crafters prefer to see how much they are using solder by using hard grades and using high temperature equipment.

The main types of copper pipe connections and tools for this are shown in the table below.

Method soedineniyaDetaliInstrumenty sostykovkiVid soedineniyaNizkotemperaturnaya capillary spaykaMyagky solder fitingiGorelkanerazemnyyVysokotemperaturnaya capillary spaykaNalichie braze fittings (or without them) AtsetilenovayagorelkanerazemnyyKapillyarnaya fitting paykaFitingi with an inner solder (soft) Building dryer, gorelkanerazemnyyPressovaniePress - fitingiPress - kleschinerazemnyyKompressionnoe soedinenieObzhimnye fitingiGaechny klyuchnerazemnyySamofiksiruyuschie detaliSpetsialnye locking sleeve and fitingiGaechny klyuchrazemnyyFlantsevaya sostykovkaRastrubnye flantsyGorelka and nut split wrench

As a rule, for independent work, consumers choose special fittings, which, with a small investment of time and money, provide a high-quality connection of copper pipes. Any of the listed types are suitable for joining a pipeline made of this material. The choice depends on the experience of the master, the complexity of the circuit and the external or internal installation method.

Preparing for soldering - what you need to know about this process?

At the moment, copper can be soldered in two main ways, which differ from each other in the heating temperature. The high-temperature method provides for an increase in temperature to 900 degrees Celsius, this method has proven itself perfectly in pipelines where the pressure on the walls is maximum. Soldering copper pipes using the high temperature method will require special materials, including hard-melt flux and brazing material. Ordinary solder will not work here, since only the solid analogue reaches the required melting point.

The low-temperature soldering method is much simpler, since the metal heats up only to 500 degrees, although 380 degrees Celsius is usually quite enough. At home, this method is usually used to weld various copper elements. For work, we need a standard flux that melts at the specified temperatures, as well as a rod or wire with a diameter of up to 3 mm. If we talk about solder, then it should be soft - a 97 percent alloy of tin with metals, for example, antimony, silver or selenium, is perfect.

In order for the soldered parts to be firmly and firmly fastened together, it is required to select the appropriate flux. Flux is a special substance that resembles a paste in its consistency, containing zinc chloride in its composition. This substance is applied in a sufficiently thick layer to the surface of the pipe or any other copper part. The functions of the flux are quite diverse, among the most important are the following:

- Allows the solder to spread evenly over the soldering point;

- A kind of indicator that makes it possible to determine the right moment to bring the solder and start the process of soldering copper;

- Significantly improves the adhesion of copper and solder;

- Almost completely removes oxygen, which prevents oxidation of metal products.

Soldering is a rather dangerous process, since very high temperatures have to be dealt with, even with low-temperature soldering. Therefore, you need to be very careful, while observing all safety rules. All the nuances of the work should be taken into account, because the red-hot metal is just as dangerous to human health as the burner itself. In addition, copper is an excellent conductor of heat, which contributes to heating a huge area of the pipe, and not just the directly soldered section.

If it is necessary to weld copper elements that are not built into the piping system, it is necessary to prepare for this process in advance. For such cases, special non-combustible supports are provided, on which the copper elements can remain for the time required for their complete cooling.