Types of sprayed polyurethane foam and application technologies

Polyurethane foam is obtained by mixing two components - diisocyanate and polyol. Both components are individually toxic, therefore work is carried out with respirators. Mixing two toxic substances form a safe polymer - polyurethane - absolutely neutral, which does not react with any substances. After hardening, polyurethane foam is absolutely harmless and is often used in the food industry.

When two components are mixed, active gas formation occurs - mainly carbon dioxide is released. It turns out to be enclosed in the thinnest polyurethane shell, which gives high performance in terms of thermal insulation (carbon dioxide does not conduct heat well).

The two components are mixed in a special high pressure gun. To obtain ideal foam, the components must be heated to 45 ° C (there are heated supply hoses, and there are special heaters). Under pressure, in the form of very fine dust, the components are mixed in a gun and sprayed onto the surface, where they foaming and then hardening. This is the essence of polyurethane foam insulation.

To achieve the stated material properties, diisocyanate and polyol must be fed in equal proportions. Even a slight increase in one or the other component negatively affects the characteristics of the material. Worse, if there is more diisocyanate - such foam quickly "sits down", then collapses, loses its heat-insulating characteristics. If you overdo it with polyol, the picture is a little better - the foam becomes brittle, but it fulfills its tasks, although it has a thermal conductivity higher than that stated. This is precisely one of the disadvantages of polyurethane foam insulation - the end result depends very much on the qualifications of the workers and the class of equipment used.

It is possible to mix the components in the given proportions almost perfectly precisely using high-pressure installations. Therefore, when choosing a company, you need to pay attention to the equipment that is at their disposal - with low-pressure installations, most likely, you will get an inhomogeneous spraying with poor thermal insulation characteristics.

But different equipment is not everything. There are also different types of polyurethane foam by cell type and density:

In terms of prices, the cheapest is lightweight open-cell polyurethane foam. But if you add the need for a hydro and steam insulation device, then in general the price of insulation will not be so low. At the same time, it is still unrealistic to achieve ideal insulation, and it may well turn out that this type of PU foam insulation will be cold. So that you can navigate in prices, we give approximate prices for different types of PU foam (material + work):

Closed-cell polyurethane foam, per cubic meter, is much more expensive, but it does not require any additional layers, except for finishing. It is not afraid of water or steam, it fulfills its tasks for a long time (more than 25 years). The exact price of insulation with foamed polyurethane foam depends on its density and thickness of the layer, the size of the sprayed surface. It is counted individually.

Dignity

The main requirement for a material intended for thermal insulation is the coefficient of thermal conductivity. Figuratively speaking, the lower the coefficient, the less heat will pass through the material and escape into the atmosphere. Here is a table that clearly shows that polyurethane foam has no equal in thermal insulation:

| Material | Coefficient of thermal conductivity |

| Polyurethane foam | 0,019 — 0,03 |

| Expanded polystyrene | 0,03 — 0,037 |

| Mineral wool | 0, 04 — 0,05 |

| Foam concrete | 0,056 — 0,098 |

However, PPU has other advantages as well. Namely:

Wall insulation scheme with polyurethane foam.

- low thermal conductivity and very high thermal insulation properties;

- providing sound, hydro and vapor barrier;

- application by simple spraying;

- perfect adhesion, that is, the ability to reliably adhere to any surface, with the exception of Teflon and silicone;

- the ability to expand, filling all the cracks and holes, down to the smallest;

- the ability to isolate the most inaccessible places, structural joints and grooves;

- lack of seams;

- no leaks and cold bridges;

- protection of sensitive materials from bacteria and fungi;

- high resistance to open flame due to the addition of fire retardants, substances that provide fire resistance;

- speed and ease of use;

- long service life - 20-25 years.

Advantages and disadvantages

Let's start with the merits:

As you can see, there is a decent list of advantages that contribute to the fact that thermal insulation with polyurethane foam is gradually becoming more and more popular. But there are also disadvantages:

The main limiting factor in the spread of PU foam insulation is the high price. Although, when compared with the cost of insulation with extruded polystyrene foam, the prices do not seem so high, and this despite the fact that the sprayed thermal insulation fits many times faster in time, gives the best result. In general, if you are planning to insulate your home, this technology is well worth researching.

Duties

After the worker gets a job in the specialty of "steam engine operator", an employment contract is concluded with him, in which job duties are described in detail. These are pre-agreed points that tell you what the employee has to do during work. He must strictly comply with them, otherwise the employer may fire him. The job description of the PPU driver must be strictly observed. This section includes:

- Preliminary preparation of PPU for work.

- Carrying out the process of dewaxing oil flow lines, prefabricated units, wells and other objects with steam in accordance with the norms of the technological process.

- Connection of units with technological field installations and wells.

- Conducting a line for heating hot oil with steam, or dewaxing.

- Regulation of the operating parameters of the engine boiler, oil heater, instrumentation and any other PPU units.

- Installation and dismantling of any instrumentation on the working unit.

- Conducting planned and unscheduled repairs.

- Making records of the work done in a special log book.

In some cases, if such a need arises, the PPU driver can be involved as a driver. This item must be additionally spelled out in the official duties.

Application conditions and surface preparation

Even with good adhesion, which is characteristic of polyurethane foam insulation, surface preparation will not be superfluous. First of all, you need to remove everything that crumbles - and first of all the old paint. Oily stains are also subject to mandatory removal and neutralization. They shouldn't be.

Anything that should not be covered with foam should be covered with plastic tape attached to it. It must be fixed carefully, without gaps - it is difficult to tear off the foam.

When insulating a roof with polyurethane foam, there are two ways to apply thermal insulation. The first is to make a permanent solid crate, onto which foam is poured. Second, a temporary frame is made, consisting of two parallel planes.

If the outer walls of the building are insulated with polyurethane foam, it is assumed that there is a finishing finish. And after cleaning the surface, you need to make sure that it can be strengthened on something - it will not work on foam.To do this, most often, wooden or metal strips are stuffed onto the walls, to which the external finish is then attached. This completes the preparation. But the application of polyurethane foam is possible only on a completely dry surface, at temperatures above + 10 ° C. There are no other conditions.

PPU production by pouring

The production of polyurethane foam by pouring means mixing the components of polyurethane foam and feeding it into a prepared mold or cavity without the participation of air pressure. The production of polyurethane foam by pouring allows the production of polyurethane foam insulating shells for pipelines, polyurethane foam insulation panels. All PP molded products are made by injection molding. The production of polyurethane foam by pouring it into a prepared mold makes it possible to produce a variety of interior and exterior decor elements. Block soft polyurethane foam for office and home furniture is also produced by injection molding. To reduce the cost of building a house, they use polyurethane foam pouring into the inter-wall space. For example, 2 cm of polyurethane foam is equivalent to 50 cm of brick in terms of its thermal insulation properties. Such a house will be warm, but it will come out much cheaper. The production of PPU using the injection molding method implies special processing of the mold due to the strong adhesion of the PPU. Various types of oily, silicone and wax lubricants are used as anti-adhesive lubricants.

Spraying process

If you have entered into an agreement with a company, a minibus will arrive at the appointed time. It has equipment for spraying. The high-pressure washer requires a voltage of 380 V. If you have only 220 V, the generator is usually started and produces the required voltage. A low-pressure apparatus can operate from a 220 V network, but, as mentioned below, the quality of thermal insulation will be much worse.

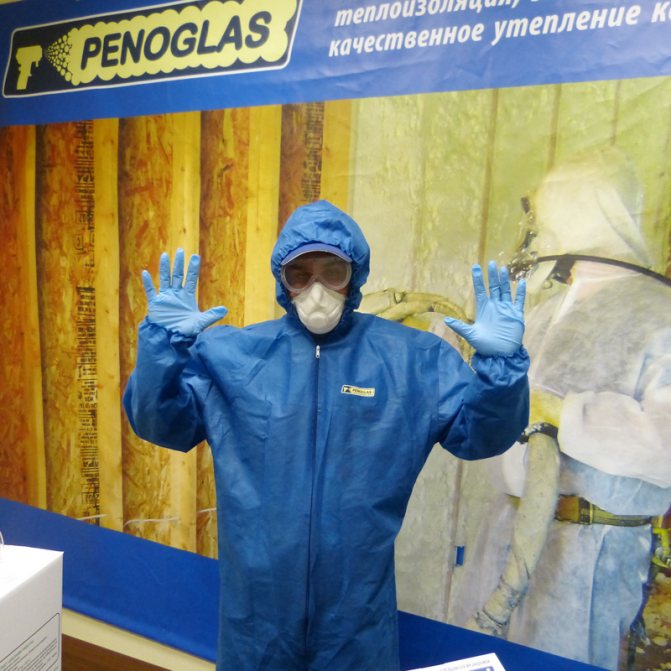

Usually, only the hoses are pulled into or around the house, through which the components for the formation of foam are fed into the gun. It's comfortable. Workers who spray thermal insulation are dressed in protective suits, respirators, gloves and goggles. A respirator is necessary, since before hardening, the components of the foam are toxic, and everything else is to protect the skin from the ingress of polyurethane foam, which then cannot be peeled off.

The foam is applied from the bottom up, in small portions. Pour everything, without gaps, trying to prevent the formation of shells. As the foam expands, make sure that the layer thickness is not less than the required one. After the foam hardens, the excess can be cut off, and nothing can make up for the deficiency.

Process basics

Many people believe that it will be cheaper to insulate the house with polyurethane foam with their own hands. But in practice, everything turns out to be not so simple, because you need to possess not only theoretical knowledge, but also practical skills. In addition, specialized equipment and materials are required. Before starting work, you must correctly configure the equipment.

When a person understands the operation of the system, but he does not have his own equipment, you can rent it, but it is quite expensive. In this case, it makes sense to invite a specialist with equipment who will quickly perform thermal insulation procedures, saving the owners from many problems.

If a person decides to independently carry out the warming process, then he needs to take into account some features. Among them:

- PPU thermal insulation can be carried out both in a finished house and at the stages of its construction. Spraying of the substance is carried out over the entire surface or on its individual parts. Cavities are filled with polyurethane foam as needed.

- During the work on insulation, the region of residence should be taken into account.The thickness of the substance layer directly depends on the specific climatic conditions.

Spray insulation parameters

It should be said right away that, as for any other insulation, it is preferable to insulate the walls of buildings from the outside. If, then the outer wall will freeze through. How many defrost / freeze cycles it can withstand depends on the material, but rarely will such a house last more than 10 years.

When insulating with polyurethane foam outside, a finishing external finish is required - the surface has a very unattractive appearance. But there are no problems with the freezing of the walls, the building will serve for a long time.

There are no problems with the roof at all. Roofing materials are designed for repeated freezing, so that insulation with polyurethane foam of the roof can be done from the inside, by spraying it directly onto the “wrong side” of the roofing material or on the lathing.

Outside to insulate the house or sorted out from the inside. Now a little about the layer thickness. Insulation with polyurethane foam is usually done in large thickness. This is not due to the fact that small is not enough. Usually, just according to the thermal technical characteristics, a thickness of insulation of 2-3 cm is required, but they do it at least 5 cm.This is so that under any conditions the dew point is in the thickness of the thermal insulation, and not in the material of the wall. Since polyurethane foam is non-hygroscopic, it cannot get wet, condensation simply does not occur, and excess moisture is naturally excreted due to the vapor permeability of the material.

Reducing heat loss in any structure is one of the most pressing challenges facing engineers and builders. Despite the emergence of various types of new materials, characterized by extremely low thermal conductivity, the role of an additional layer of thermal insulation, which must be equipped without fail, remains dominant.

The growth of individual construction has also led to the expansion of the range of relevant products. But each of the heaters has its own characteristics, on the basis of which practically none of them can be considered a means "for all occasions." Much depends on the operating conditions, the place of installation and some other factors.

But still, there is a tool that can be considered close to universal - polyurethane foam. This is a type of foam that uses the foaming effect of the mixture. When solidified, a rather dense sealing layer is formed. This material has found wide application in industry.

But we'll look at it in terms of home and family use. After all, it is not only a good insulation, but is also able to provide high-quality steam and sound insulation. In addition, it is a reliable protection of metals from corrosive processes. According to the statements of individual specialists, it now takes the 1st place among polymeric materials in terms of its properties.

Where can I apply

- Thermal insulation of walls, basement, basement.

- Loggias, door and window openings.

- Ancillary structures. Outbuildings, baths, sheds, garages (including gates).

- For insulation of ventilation gaps in frame structures.

- Sealing joints, cracks, cracks.

By the way, processing small areas is much more costly than large ones. The cost of spraying polyurethane foam by a specialized company can range from 14,000 rubles / m2.

If we are talking only about sealing seams or joints, then it is advisable to purchase a can with the so-called polyurethane foam, and to it. But if it is necessary to process entire surfaces, then this method is clearly not suitable.

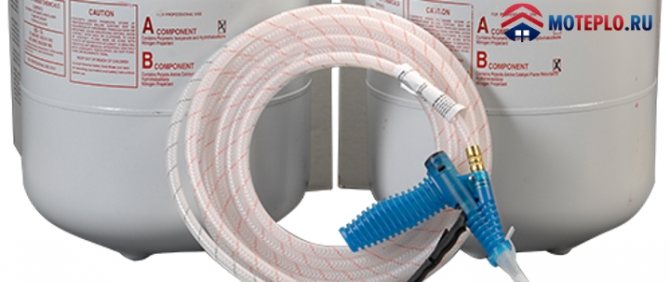

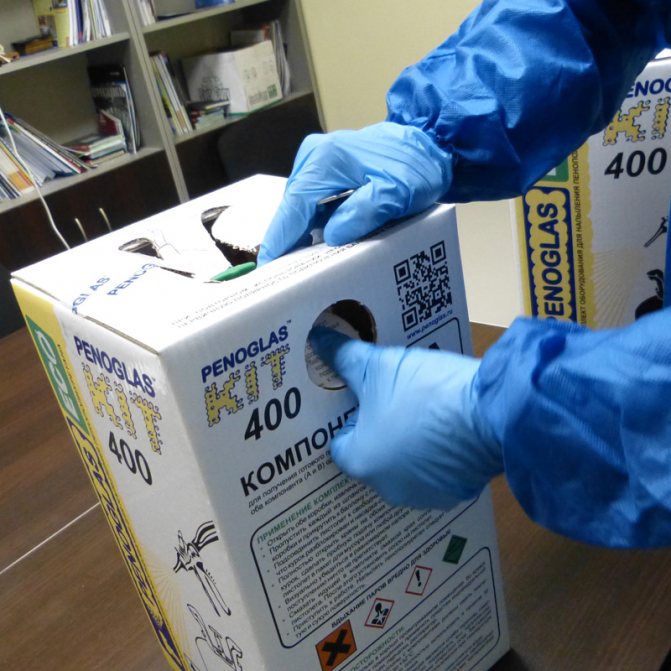

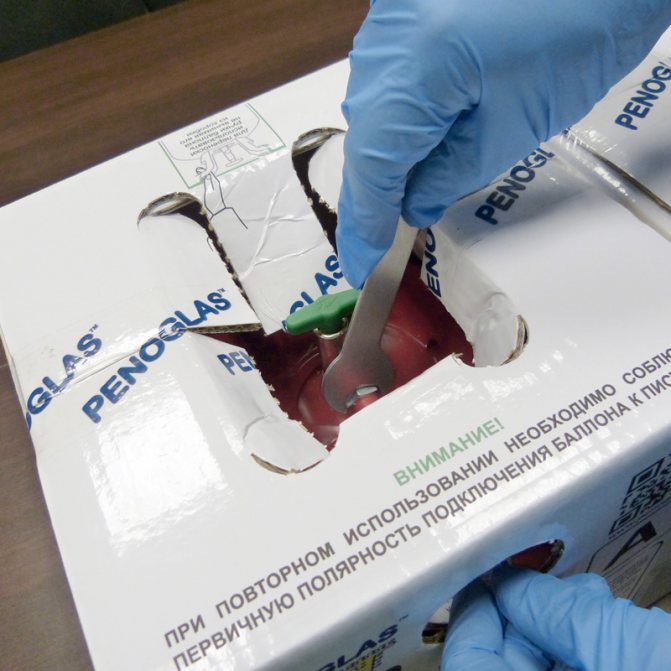

There are disposable installations on sale with which you can do all the work yourself. And although after use the equipment is thrown into a landfill, from an economic point of view, its acquisition is much more profitable.

This insulation technique is much more economical, since the resulting layer is much thinner than when using traditional materials - mineral wool, slabs - without compromising quality. At the same time, any part of the surface can be processed, regardless of the complexity of its configuration and the possibility of access to it. And if you take into account the absence of seams, adhesion of the composition to any base, then the advantages are obvious.

As an example, the device FOAMKIT (not considered an advertisement!). If you focus on the thickness of the coating layer 2.5 mm, it is able to process an area from 18 to 94 m2 (depending on the model). The weight allows one person to carry it, and no professional skills are required to bring the unit into working condition. The kit includes a spray gun. The possibility of work breaks is provided. It is clear that after this the gun must be cleaned. In order not to waste time on this, it comes with replaceable nozzles (8 pcs.), Which are easy to replace.

The price, respectively, is from 19,650 to 41,000 rubles.

A few notes

- Often polyurethane foam is confused with penoizol. These are completely different materials, and each has its own specific application.

- When spraying polyurethane on the facade or roof, the vapor barrier does not need to be equipped.

- You should work at a positive temperature - from 50 and above. However, the dew point of the surface to be treated must also be taken into account. Its temperature must exceed this value by at least 30.

- The base must be clean. Do not apply the composition to dirt or dust.

The main condition for the quality of work is correct calculations (required thermal characteristics, vapor permeability, etc.), as well as adherence to technology. Therefore, it is better to purchase ready-made formulations, and not make them yourself.

Insulation of residential buildings

and industrial or commercial buildings, experts recommend equipping only outside. However, installation of insulation on an external wall is not always possible.

Reasons

there may be several - from the ban of the city authorities to the technical difficulties arising during the installation process itself.

In such cases, the option is allowed internal insulation

subject to the selection of the correct material for insulation.

Among the few cons of polyurethane foam

most often mentioned is the high cost of the material required to perform the thermal insulation work of the equipment and the services of the relevant specialists.

but with detailed analysis

each of these disadvantages turns out to be only a small problem that can be solved without much effort. So, the risk of destruction of the coating under the influence of ultraviolet radiation is eliminated by cladding using lining or drywall.

Acquisition costs

polyurethane foam and equipment for spraying pay off thanks to a decrease in the amount invested in paying bills and buying medicines, as well as the absence of the need to change the insulation two or three years after installation.

The thermal insulation layer obtained thanks to the sprayed polyurethane foam will last at least five decades

, and its properties (high strength, moisture resistance, non-toxicity, environmental friendliness), structure and shape remain the same as immediately after installation.

As additional plus

it is worth mentioning the significant savings in space consumed when using other types of insulation. As for the costs of the services of specialists, then they can also be eliminated if you carry out the insulation yourself.

For even more savings

, do not purchase large-volume cylinders. An intentional or forced break in work exceeding 1 month leads to the need to purchase a new installation for spraying. A device that has been in use becomes unusable.

Types of polyurethane foam and scope

- Open-celled (elastic), with a density of 10-20 kg / m³;

- Closed-cell (rigid), with a density of 20-30 kg / m³ and higher, up to 80 kg / m³.

Polyurethane foam will perfectly protect the room from heat loss, as well as cope with its waterproofing.

In elastic PU foam, up to 90% of the cells are open. The low density gives it a certain stretch ability. In rigid polyurethane foam, up to 98% of the cells are closed. This and its high density make it an extremely durable insulating material.

Different types are used in different areas. When it comes to spraying on a material that can change its size - for example, metal structures that contract and expand with temperature changes - then elastic polyurethane foam is used. It is indispensable for waterproofing, for protecting the connection between the wall and the roof, for spraying on wooden and metal surfaces in contact with cold air outside the building.

Closed-cell (rigid) polyurethane foam is used for internal insulation and outdoor work. It is usually sprayed onto concrete, cement and brick surfaces. Closed-cell polyurethane foam is also used when you want to give the frame of the structure additional rigidity. Its high strength makes it possible to significantly strengthen unstable elements. Both types of PPU have many advantages, but very few disadvantages.

useful links

How do I choose an installation?

Component consumption calculator

Polyurethane foam spraying video

Photo gallery

Where to start your polyurethane foam spraying business

1. Buy equipment.

For spraying, you can purchase any installation of the "Master" or "Profi" series. If there is a desire to apply PPU filling in addition to spraying, then in this case, you will need to install a 9-Universal. But filling works are rare enough.

You will also need a compressor with the specified parameters for operation.

If possible, it is better to purchase a compressor “with a reserve”, since, in fact, there is never a lot of air.

It is advisable to purchase overalls and protective equipment, but you can get by with one protective mask or gas mask.

Installation and compressor costs - from 80,000 to 120,000 rubles.

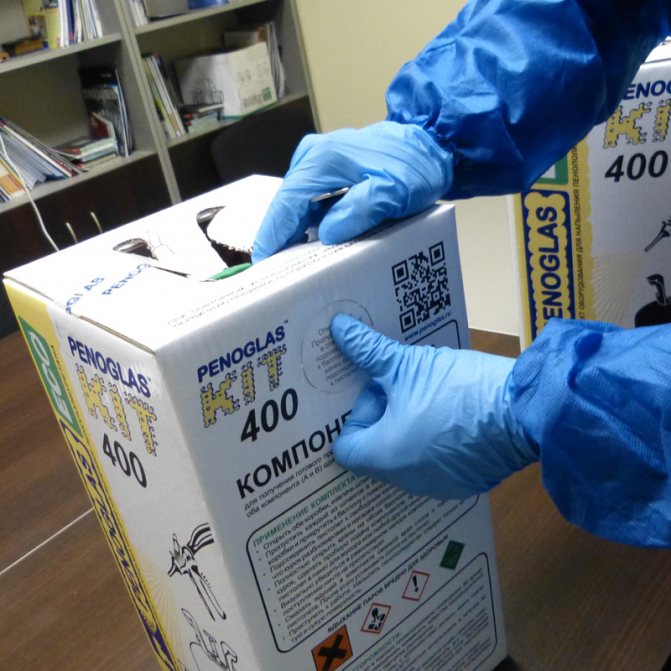

2. Buy components.

We offer to purchase a trial minimum batch of components in the amount of 100 kg, 50 kg each A and B. This is a system of rigid closed-cell polyurethane foam with a density of 35-45 kg / cu. m.

3. Spray polyurethane foam.

Find a spot for spraying.

The best option is some kind of real estate. Summer cottage, house, sauna, garage, attic, wall, ceiling - it doesn't matter. The main thing is that the ability to spray PPU will appear, and now it will be possible to safely take orders.

Be sure to take a photo of the sprayed object. Prepare samples of polyurethane foam in the form of cut cubes. Customers need demonstration and visibility.

4. Declare yourself.

Post advertisements on the Internet on special sites, message boards, various Internet publications and contact specialists to create your own business card site.

When carrying out construction and insulation work with polyurethane foam or any other material, the issue of saving often becomes an obstacle to quality.

Almost all work in construction can be done independently, with solid experience and qualifications. The question of whether it is worth hiring experienced specialists or doing everything yourself has been very relevant lately. After the appearance on the market of disposable kits for spraying with polyurethane foam, many decided to abandon the services of construction companies and take everything into their own hands.

Layout of a sandwich panel made of polyurethane foam.

Today, polyurethane foam is one of the most advanced materials for thermal insulation. This material is used in almost all industries, from mechanical engineering to filling children's toys.

Despite its chemical origin, polyurethane foam is one of the most environmentally friendly and safe insulation materials used in construction. When creating its constituent elements, they do not use formaldehyde, asbestos, which is harmful to the lungs, or freon. In the process of spraying on a certain surface, polyurethane foam becomes a stable and inert substance, which after many years does not release anything into the air, that is, it does not harm the environment and the general ecology of the planet.

Choose an installation for spraying PPU

The principle of operation of the PPU spraying equipment is as follows:

- pick up components from barrels;

- warm them up to the temperature recommended by TU;

- dose in the required ratio of polyol and isocyanate;

- supply components under pressure to pressure hoses;

- inject "A" and "B" into the mixing chamber of the sprayer;

- remove the polyurethane foam composition from the sprayer by spraying it onto the enclosing structure.

If you do not go into details, then according to the above algorithm, all installations work. But, as you know, The devil is in the detail. Let's talk about these details.

Let's start with how important it is to mix both ingredients completely and well. Then the reaction is 100% and the PUF is obtained with the declared characteristics and will serve for a long time.

If there is an imbalance (as the "sprayers" say) in the weight or volume ratio (regulated by the manufacturer in the technical specifications) of the components, then there is no need to talk about the quality of the foam.

If component A (polyol, according to Russian terminology) is more than it should be, then, for example, hard closed-cell polyurethane foam turns out to be soft, short-lived and may have the smell of unreacted catalysts, the material loses volume, it has poor (high) thermal conductivity and increased moisture absorption.

In the case of an excess of component B (isocyanate in Russian terminology), the foam turns out to be denser and more fragile, with a well-perceptible isocyanate odor. In terms of thermal conductivity and moisture absorption, the foam also does not meet the standard values.

For mixing and spraying of PU foam components, low and high pressure equipment is used in conjunction with a set of auxiliary means: generators, compressors, compressed air dryers, liquid heaters, drum pumps, etc.

Polyurethane foam spraying: basic process requirements

Polyurethane foam is a one-of-a-kind insulation that adheres to almost all building surfaces, be it wood, foam concrete, glass, and so on. Exceptions are possible only with surfaces made of fluoroplastic and polyethylene. In this case, the entire area in contact with polyurethane foam must be carefully prepared for spraying with this material.

Connection diagram of the components of the installation for spraying polyurethane foam.

Basic requirements for a surface to be insulated:

- The surface to be treated must be thoroughly cleaned. It must be dry and free of any signs of moisture. Defects larger than 6 mm must be eliminated. The temperature during work must be between 12 and 16 degrees Celsius.

Only if all the requirements for surface preparation are met, it is possible to achieve the required level of adhesion, which is the basis of the technological process when spraying with polyurethane foam.

Due to strong adhesion, as well as the method of spraying, polyurethane foam, in comparison with various heaters, has the necessary advantages and qualities, therefore it is widely used for warming rooms with high levels of humidity.

Possessing impressive characteristics, the material effectively protects the room from the penetration of low temperatures in winter, moisture and other atmospheric phenomena.

When carrying out construction and insulation work with polyurethane foam or any other material, the issue of saving often becomes an obstacle to quality. Almost all work in construction can be done independently, with solid experience and qualifications. The question of whether it is worth hiring experienced specialists or doing everything yourself has been very relevant lately. After the appearance on the market of disposable kits for spraying with polyurethane foam, many decided to abandon the services of construction companies and take everything into their own hands.

Today, polyurethane foam is one of the most advanced materials for thermal insulation. This material is used in almost all industries, from mechanical engineering to filling children's toys.

Despite its chemical origin, polyurethane foam is one of the most environmentally friendly and safe insulation materials used in construction. When creating its constituent elements, they do not use formaldehyde, asbestos, which is harmful to the lungs, or freon. In the process of spraying on a certain surface, polyurethane foam becomes a stable and inert substance, which after many years does not release anything into the air, that is, it does not harm the environment and the general ecology of the planet.

Low pressure polyurethane foam spraying equipment

The operating pressure of the low pressure unit for spraying PPU is 1 ... 1.2 MPa or 9.87 ... 11.84 Atm.

Compressed air is required to mix the components in the spray gun and to clean the mixer.

The equipment is not power-consuming, most of the popular models are for 220V, the power consumption is 0.75 ... 0.9 kW. It also requires 3 to 5kW for the compressor. When you connect additional options that optimize the operation of the equipment, energy consumption increases. In particular:

- barrel pumps for pumping components into the installation;

- dehumidification of air;

- air heating;

- heating of components, from milk cans or other containers with shades or thermal belts to flow heaters.

In the event that the above listed add. options, until the mixing of the components in the gun, the process chronology is identical to the high pressure setting (see below).

In fairness, we note that manufacturers and adherents of high-pressure equipment will deny such an identity. They dispute the very fact that the pumps of a low-pressure installation are capable of constantly, smoothly and evenly supplying liquid to the sprayer, strictly maintaining the ratio.

In our opinion, they are capable, if a pair of pumps was initially tested at the stand and correctly selected at the factory, if the pumps are in working order, not worn out. It is important that the assembly is carried out precisely at the plant, and not in the artisanal conditions of a garage cooperative. It is important that the equipment is accepted by the quality control department, even if not as demanding as the military acceptance.

It matters what raw material is used and at what temperature. The length of the hoses and the lift of the components matter. Nevertheless, our experience says that, yes, there are limitations, but if you know them, then there are no problems with the supply of components to the atomizer at the low pressure unit.

The working pressure of the components in the atomizer is approximately 2 times less than the pressure in the supply hoses, ie, on average, about 0.5 ... 0.7 MPa. This is about 20 times less than in the mixing chamber of high-pressure installations.

The components in the chamber are broken up and mixed by a jet of compressed air entering the atomizer from the compressor. Then, by means of the same air, the mixed components are delivered from the mixing chamber through the nozzle and spray nozzle of the gun to the insulated surface. There, the final polymerization (foaming) and the transformation of the two liquids into the final product take place, i.e. in PPU.

Also, the presence of compressed air at the outlet of the sprayer leads to the formation of PUF-suspension.In other words, some of the material does not appear on the surface. As a result, work on a low-pressure unit is dirtier than on a high-pressure unit. For low-pressure equipment, an irrecoverable loss (rebound, drift, undershoot) of 5% should be considered.

All low-pressure PPU spraying units are manufactured in Russia. In the West, only high pressure equipment is used. The price range for the minimum (basic) set is from 120,000 rubles. up to 250,000 rubles.

Here we take into account only really working, serially produced models at factories. If we take into account and "garage samopaly", then the starting price will be about 35 ... 40 thousand rubles.

In skillful hands, if the components are correctly selected, if the raw materials are heated, the air is dried and heated, the supply of compressed air is adjusted, then on a low-pressure unit, the quality of PU foam is difficult to distinguish from foam obtained at high pressure. At the same time, of course, the process of spraying at low pressure itself is much more complicated, longer and more labor-intensive.

Polyurethane foam spraying: basic process requirements

Polyurethane foam is a one-of-a-kind insulation that adheres to almost all building surfaces, be it wood, foam concrete, glass, and so on. Exceptions are possible only with surfaces made of fluoroplastic and polyethylene. In this case, the entire area in contact with polyurethane foam must be carefully prepared for spraying with this material.

Basic requirements for a surface to be insulated:

- The surface to be treated must be thoroughly cleaned.

- It should be dry and free of any signs of moisture.

- Defects larger than 6 mm must be eliminated.

- The temperature during work should be between 12 and 16 degrees Celsius.

Only if all the requirements for surface preparation are met, it is possible to achieve the required level of adhesion, which is the basis of the technological process when spraying with polyurethane foam.

Due to strong adhesion, as well as the method of spraying, polyurethane foam, in comparison with various heaters, has the necessary advantages and qualities, therefore it is widely used for warming rooms with high levels of humidity.

Possessing impressive characteristics, the material effectively protects the room from the penetration of low temperatures in winter, moisture and other atmospheric phenomena.

Back to the table of contents

Working conditions and wages

When applying for a job according to the professional standard, the PPU driver must discuss with the management his mode of activity. Typically, the process should be carried out in such a way that the smooth operation of the steam installation is ensured for 10-12 hours. Few people will be able to continuously perform their duties in such a long period of time, therefore, by agreement, a 7-8-hour work shift is established with several breaks, which are 0.5 hours. It is often offered to work on a rotational basis.

Payment for the PPU driver is made according to a special tariff scale, in which there is a division by category. The higher this figure is in the diploma of training or advanced training, the higher the remuneration will be. If it becomes necessary to go on a business trip, then the work is paid there by additional agreement. The average salary of a mobile steam plant driver is 45,000-50,000 rubles. In many ways, it depends on the region and field of activity.

Scope and advantages of insulation

The main advantages of polyurethane foam:

- high thermal insulation;

- lack of susceptibility to the harmful effects of the environment;

- long service life;

- environmental friendliness;

- allows for spraying in hard-to-reach areas of the room;

- high strength and reliability;

- has no seams, joints, cracks;

- fire resistance and fire safety.

A very widespread use in the field of insulation of premises and buildings with polyurethane foam leads to the leadership of the material in modern construction.

Today it is one of the best insulation methods, which involves obtaining the desired coating without additional loads on the main structure.

When using polyurethane foam, the correct calculation of vapor permeability should be carried out in order to avoid heat losses and excessive consumption of energy resources for heating.

It is important to achieve a movement of the dew point inside the material, as a result of which heating costs will be significantly reduced. In addition will result in significant sound insulation.

Ceiling insulation is important, since polyurethane foam has a low coefficient of thermal conductivity, which will prevent significant heat loss.

Back to the table of contents

Material characteristics

Thermal insulation by PPU spraying is in demand not only in industrial premises, but also in residential buildings. The substance is often used for thermal insulation of house ceilings, partitions, walls and floors. It should be noted that the material has sound insulation properties, and also protects the room from freezing and moisture ingress.

Positive traits

Polyurethane foam has a number of advantages, due to which it is considered one of the highest quality thermal insulation materials. The main ones are:

- The ability to firmly adhere to any surface - wood, metal and concrete.

- Low thermal conductivity contributes to the preservation of accumulated heat during internal insulation. If the coating is carried out outside, the substance prevents the penetration of cold air masses.

- The material carefully fills the gaps, contributing to sound insulation. When processing the roof from the inside, the material drowns out the noise of rain, which is very important for rooms located in the attic.

- Prevents the appearance of corrosion on metal structures, protects materials from negative environmental influences.

- Complex structures can be processed that cannot be insulated with conventional materials.

- The substance is classified as non-flammable. This property is due to the presence of polyol substance A in the composition. Combustion is possible at 450-500 ° C.

- The low weight of polyurethane foam allows it to be applied to any surface without fear of weighting the floors. After hardening, the thermal insulation material will give the structure additional rigidity.

- After processing with polyurethane foam, a seamless surface is obtained. This cannot be achieved using other insulation materials.

- The substance is easy to apply, quickly expands and hardens. The thermal insulation procedure will take 1-2 days.

- Due to the moisture resistance of PU foam, when using it, there is no need for additional fastening of the vapor barrier coating.

- Resistant to mold, decay, insects and rodents.

- Renowned manufacturers give a material guarantee for up to 50 years. However, with the right exterior finish, the insulation will last much longer.

Negative sides

It is impossible not to mention the cons of the material. All the disadvantages that may arise are due to independent work on thermal insulation and further operation of the insulation. Some of them:

- The main disadvantage of this type of thermal insulation is its high cost: renting or purchasing special equipment for applying the substance is expensive.

- During work, you need to wear a special protective suit, as well as a respirator. The latter is needed to protect the respiratory tract from harmful vapors released by the substance. It is imperative to protect all areas of the skin, eyes and mucous membranes.

- If a person does not have experience in working with polyurethane foam, the thermal insulation process can be extended, moreover, without quality assurance.

- The material is non-combustible, but when it comes into contact with fire, it smokes a lot, emitting many substances harmful to humans.

- If sprayed polyurethane foam is applied outside the building, it must be covered with finishing materials. The absence of the latter is fraught with rapid destruction of the substance under the influence of ultraviolet radiation.

Where and when to start insulation work?

According to the technology of spraying with polyurethane foam, work should take place in good weather or in a warm room. It is forbidden to make insulation in conditions of high humidity, during rain or snow. At a surface temperature below normal, the work should be performed in two stages: first, the first layer is applied, and after it has solidified, the second layer of the recommended thickness.

Warming must be started from hard-to-reach areas: chimney pipes, pipelines, ventilation hatches. Considering the layer thickness of about 15 mm, for more reliable insulation, it is necessary to pass the surface with polyurethane foam at least three times.

List of required tools for spraying polyurethane foam:

- apparatus for spraying with polyurethane foam;

- protective overalls with a special coating;

- protective glasses;

- rubber boots;

- protective mask.