Expanded polystyrene is a versatile material that is used for heat and sound insulation of buildings under shock and noise loads. When carrying out repair work related to thermal insulation or redevelopment, it is necessary to cut out large sheets of insulation. In this regard, the question arises of how to cut the foam so that the line turns out to be even.

Consider equipment that is used for cutting foam at home. These include:

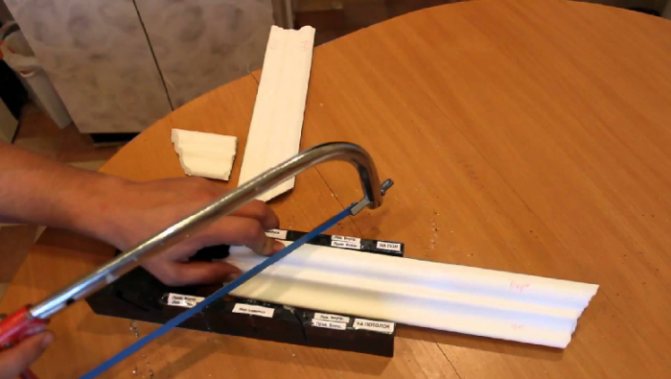

- hacksaw for metal;

- saw on wood with fine teeth;

- Bulgarian;

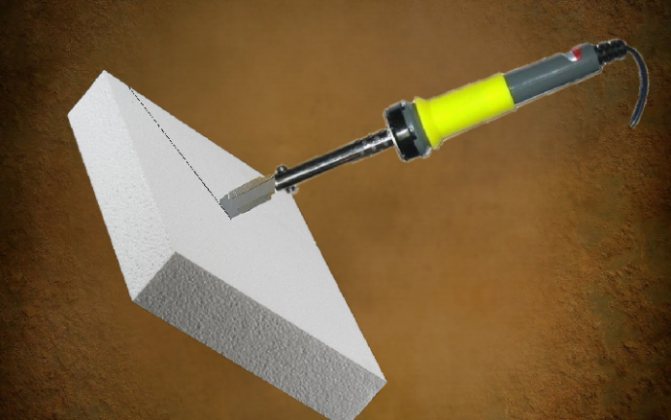

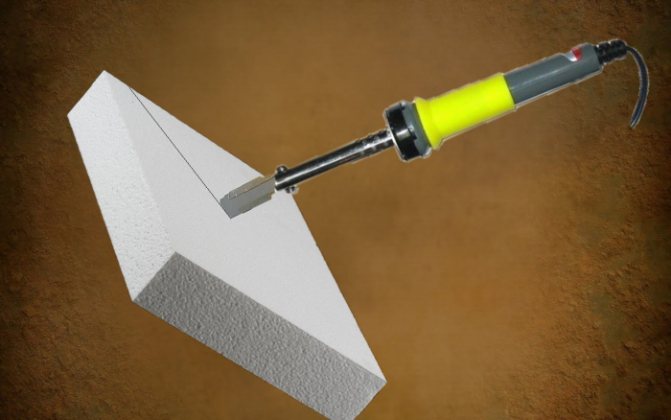

- soldering iron;

- nichrome wire.

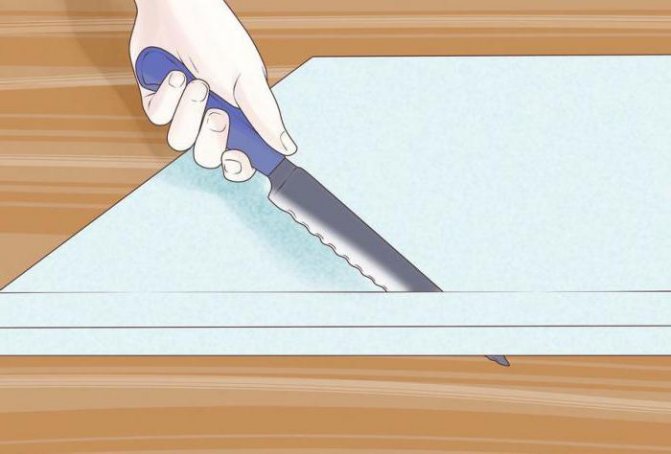

Before you start cutting, you need to mark the workpiece with a simple sharpened pencil. If a hacksaw or jigsaw is used as a cutting tool for Styrofoam, do not make quick movements. This is due to the good thermal insulation properties of the material, when when friction occurs, heat is not removed and it heats up, which complicates the process. Use a soldering iron if you need to quickly cut the workpiece. To do this, flatten its end with a hammer and fix a special part, for the manufacture of which you need to take the metal cap of the fountain pen and the blade. After warming up the device, start cutting the sheets.

Use a grinder to cut only very thin foam. It is unlikely that it will be possible to achieve a high quality cut, the result will be the same as when working with a jigsaw. In addition, with this method of processing the material, there will be a lot of debris and noise.

Choosing the right knife

To cut the foam, you can use an ordinary knife, which should be sharpened well and preheated. The stationery option is suitable for cutting soft material, it has a sufficiently flexible blade and it is not recommended to use it for processing slabs of significant thickness, since it is difficult to obtain an even vertical cut. The advantages will be a small amount of waste, availability and low cost of the tool. Remember that the thinner the sheet, the smoother the cut will be, the optimal thickness should be no more than 5 cm.

The most optimal way to cut

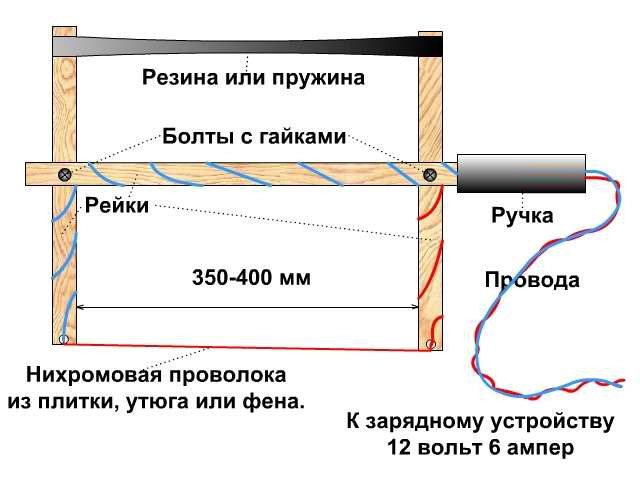

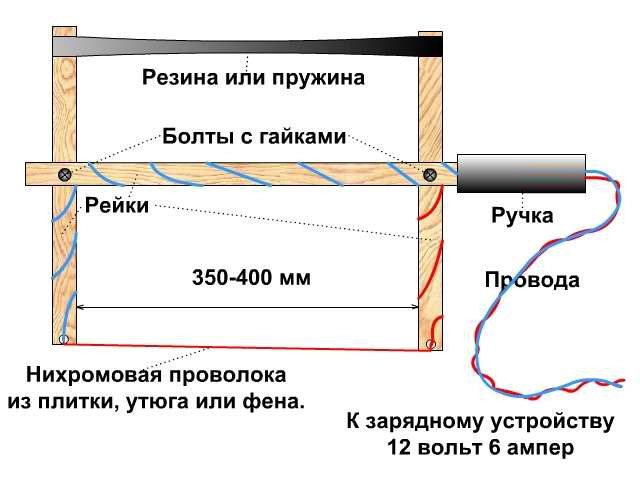

This method can be used if you have an elementary understanding of electrical engineering, for the manufacture of the device you will need to prepare:

- wire;

- transformer;

- spring.

The table is placed at an angle (20-60˚), and a wire is pulled across, one end of which is fixed rigidly, and a spring is used to secure the other. The wires of the transformer connected to the electrical network are connected to them. The current is supplied, the workpiece is placed on the table. The sheets are cut by sliding under their own weight.

You can pass current from the power transformer of the old TV. Another option is to include a variable resistance (rheostat) in the electrical circuit. The strength of the current must be controlled so that there is no strong heating, which will result in the melting of the foam and the appearance of sag lines along the edges.

The attractive side of this method is the ability to cut fragments both in a straight line and along kinks and convolutions, which makes the process universal. It is important to remember that the wire should not be very hot. It will be enough if it just turns slightly red, otherwise the cut will turn out to be too wide. A strong spring should be selected, this will make it possible to adjust the length.

The widespread availability of massive, full-size foam boards has automatically led to a boom in the use of a relatively strong, soft, and at the same time easy-to-work material in the home. In fact, it became possible to manufacture a huge number of all kinds of useful things from a thick foam sheet, you just need to find a way how and how to cut the foam in order to prevent deformation, fracture or crumbling of the material.

Why is it difficult to cut styrofoam

The widespread use of foam material was largely restrained by a porous structure resembling a compressed layer of the smallest polystyrene cells filled with a gas-forming agent.

If you have ever cut foam sheets, then you probably paid attention to the following feature:

- The denser and heavier the material, the easier it is to cut it with sharpened tools. The thinner the cutting edge, the easier and faster it is to cut even the hardest carbamide foam;

- Lightweight foam grades are easiest to cut with power tools. The higher the cutting edge speed, the cleaner the cut surface. In industrial conditions, thin foam boards are cut with a thin water jet, with practically no waste;

- When trying to cut a slab with a sharp blade with several movements, a situation arises when each new cut increases the amount of foam sawdust and dust almost twice.

Advice! Craftsmen prefer to cut non-thick foam plates using the boot method. To do this, a sharp-cut wide blade with great effort makes a cut with a knife "towards itself", without changing the angle of inclination and depth of cut.

Most modelers and craftsmen who professionally work with foam will argue that cutting foam boards is not difficult at all, especially since the density and strength of the material is relatively low. And they will be right. Cutting foam at home is not difficult, you just need to select the exact mode and equipment for cutting the foam.

The number of options for the practical application and use of foam for those who know how to work with their own hands has long exceeded a hundred. Dozens of different models, injection molds, toys, moldings, decorative elements, insulation, parts of acoustic systems and even refrigerators are made from foam material. The main problem that accompanies any attempts to process the material mechanically is the selection of the mode, how and how to cut the foam so that it does not crumble, as a result, cutting is always accompanied by the formation of a large amount of waste.

If the tip of the cutting tool is not sharpened enough or moves at a low speed, when trying to cut the smallest gas-filled balls, the cutting edge does not cut them, but slides over the polystyrene foam, crushes and pulls out the foam from the compressed mass. It is possible to cut a foam sheet in this way, but a huge amount of waste is generated.

How to cut styrofoam so as not to crumble

When working with foam, almost every one of us has at least once faced such a problem as cutting a sheet of foam at home into certain parts. The most common option is fracture, but this method will not allow you to achieve an even edge and accurate dimensions.

In addition, when breaking, a huge amount of debris remains in the form of balls of material, which are practically uncontrollable, since they quickly stick to all objects around us. Therefore, in this article we will consider the options and methods of the best way to cut the foam so that it does not crumble, without excess debris and exact dimensions.

Properties and characteristics of foam

Expanded polystyrene (polystyrene) is a white heat and sound insulating material, which consists of 98% of air, enclosed in a huge number of microscopic thin-walled cells of slightly foamed polystyrene. As a rule, this material is biologically safe; products and various packaging of food products are made from it.

The widespread use of foam is characterized by the following properties:

- Very low sound and thermal conductivity;

- Practically non-hygroscopic (resistant to moisture);

- Quite light in weight and in work;

- Resistant to aging;

- Does not rot (mold, mildew, etc.);

- Not subject to the effects of various microorganisms;

- Not absorbed by many animals.

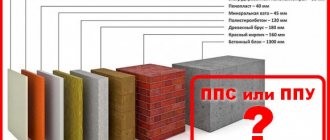

Polyfoam is an effective insulating universal material, as it has been used for more than 30 years for insulation of the balcony floor, thermal insulation of ceilings, roofs, walls of buildings, both from the outside and from the inside, for high-quality sound insulation of noise rooms. It is also quite often used in industry for thermal insulation, for example, refrigerators, various packaging, refrigerators, freezers, and even for the transportation of furniture and equipment.

How to cut styrofoam so as not to crumble

In construction, for floor insulation, gluing foam to concrete walls or ceilings, in most cases, you have to cut huge sheets of insulation material. Therefore, the first question arises: how and how to cut the foam at home? This is a big problem because the foam crumbles a lot and breaks very quickly. Cutting polystyrene with your own hands can be carried out by several methods, consider their variety.

Technology, how to properly cut a sheet of foam

For home conditions, you can offer several proven methods:

- With the help of a sharpened shoe or construction knife;

- A hacksaw for metal with an improved hacksaw blade;

- Powerful soldering iron with a razor blade attached to the tip;

- Thermal cutter or hot nichrome spiral;

- With a jigsaw or grinder.

Important! Any attempt to cut the foam sheet with hot blades, wires or a high-speed tool must be worked under an exhaust hood or outdoors, since a large amount of volatile toxic substances is released when the foam melts.

If you want to cut the foam with a jigsaw or grinder, you should definitely use a respirator and goggles. Foam dust during cutting is highly electrified and adheres with incredible force to the skin of the hands, face, gets into the eyes and lungs.

Mechanical cutting scheme for polystyrene foam

The easiest way is to cut a slab that is not thick, up to 50 mm, using an ordinary, even table knife. To do this, the foam plate is placed on the edge of the working table and a cut is made. The cutting edge of the knife should be as close to the reference plane as possible. Before cutting, the blade must be sharpened and refined with a polishing wheel.

The cut-off part of the sheet must be supported so as not to break off the material under load. To cut with maximum quality, the knife is moved with little effort in one direction - "away from you", the reverse motion of the blade is performed "idle". If you have to cut a sheet laid out on the table top with a boot knife, then the direction of application of the force changes to the opposite - "towards yourself".

It is strongly not recommended to cut thin-sheet foam material in weight or in a vertical position.

It is much easier to cut the foam with a hacksaw for metal. For dense grades, the hacksaw blade can be left unchanged; for highly porous foam sheets, the side surfaces of the blade are ground on a sharpener to remove the gap of the teeth. The hacksaw can cut in almost any position without restriction.

The most productive tool for cutting sheets is an angle machine or grinder. Depending on the diameter of the cutting wheel, the grinder can cut foam plastic with a thickness of up to 50 mm on the fly. In this case, the quality of the cut will be much higher than in the case of using a knife or saw. The disadvantage of this method is the large amount of dust and shavings. If you reduce the cutting speed of the foam to a minimum, the material will start to burn and melt, which is not always allowed by cutting conditions.

It is enough just to cut the foam sheet with a jigsaw. In terms of productivity and cut quality, the jigsaw is inferior to the grinder, but it has an invaluable advantage - it can be used to make curly cuts that are difficult to obtain by another method of mechanical cutting.

Thermal methods for cutting foam

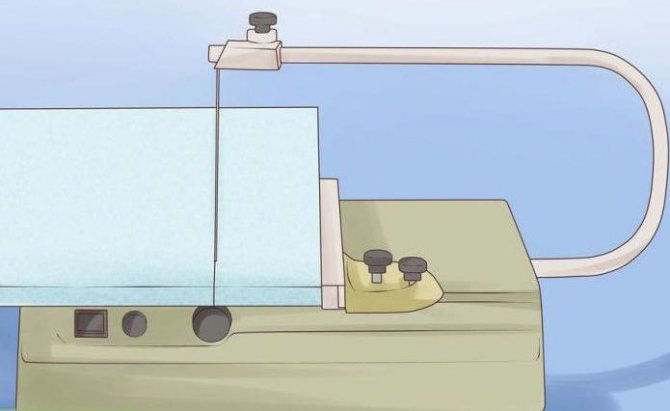

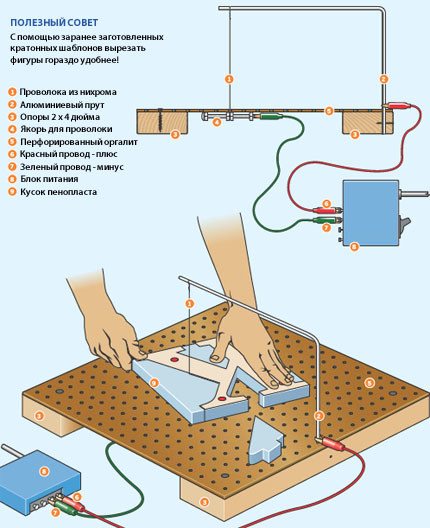

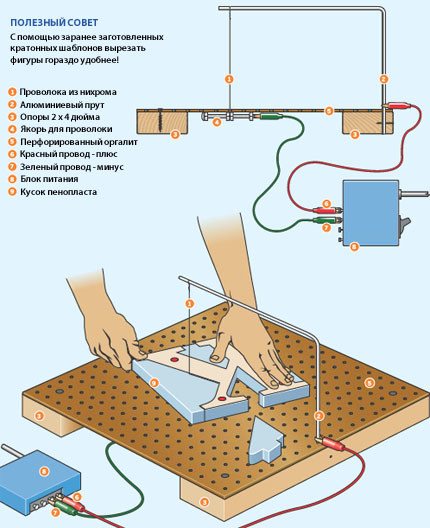

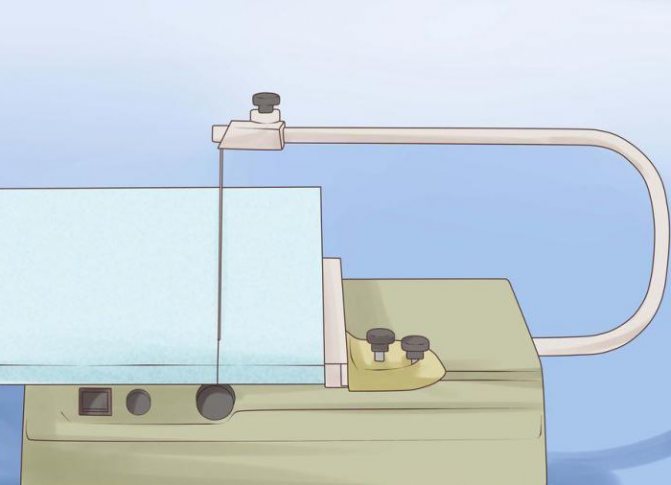

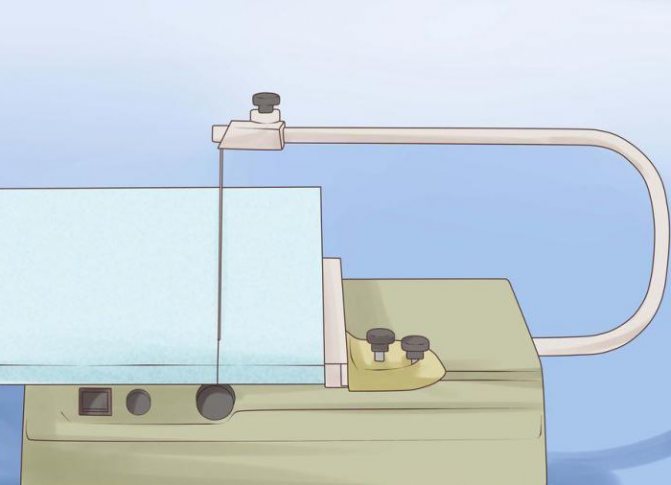

The second most common method of cutting foam is a thermal cutter. In fact, this is a nichrome thread, laid on the frame in the form of a frame. When an electric current passes through a nichrome wire, the metal surface heats up and melts the foam. There are several design options for the torch. The simplest one looks like a nichrome string stretched over ceramic insulators installed at the ends of a wooden or metal frame.

With such a tool, you can cut not only foam sheets, but also wooden slats, plastic pipes, any material with a melting or decomposition temperature of up to 270 ° C.

If you need to cut slabs with a long cut, then it will be more convenient to use a machine in the form of a vertically stretched thread on a PCB support.

To control the heating of the nichrome string, a LATR or rheostat is used. Excessive surface temperatures can melt and even ignite the foam. A remarkable property of this cutting method is the complete absence of dust and chips, in addition, the cutting surface is melted, as if coated with alkyd varnish.

If only small pieces of the foam block need to be cut during the processing of the foam, for example, when making a sculpture or model, it is best to use a nozzle for a powerful electric soldering iron.

Separately, the most interesting way to cut foam plastic with a laser should be mentioned. Perhaps it will seem fantastic, even at home laser cutting of foam is possible, photo. A conventional LED laser with a power of 2-5 watts allows you to cut a sheet of foam in a completely arbitrary path.

While such a tool is capable of cutting paper and polystyrene within 10-15 minutes, it will be very difficult to achieve large volumes of cutting on it.

Polyfoam is a versatile building material that has many advantages over other analogues.

In addition, this material is used for decorating and making volumetric structures that serve as decoration for holidays and events. Often letters and inscriptions are cut out of polystyrene.

The use of foam is widespread due to the low cost. At the same time, it retains heat well and completely insulates the room from the penetration of sounds. Therefore, this material is used for finishing the facades of houses - it is easy to paint and fix.

How and how to cut the foam slabs?

Sheet polystyrene is an insulation made of expanded polystyrene. In another way, it is also called polystyrene foam. It is one of the most popular materials for thermal insulation of houses, as it has a low cost and easy installation. But during the installation of the slabs, it is often necessary to cut them. It is imperative to make the cut of the foam sheet straight, as large gaps can impair thermal performance.

Overview of methods

You can cut polystyrene foam at home in many ways:

- with a knife;

- hacksaw;

- jigsaw;

- grinder;

- electric knife;

- machine for cutting expanded polystyrene with wire.

1. A sharp knife is good for slabs up to 5 cm thick. The blade must be thin and not flexible, otherwise the cut will be crooked. So that when cutting the foam with your own hands there is even less waste, it is better to heat the knife. It should be borne in mind that the blade will have to be sharpened approximately every 2 m, as otherwise the work will take longer and there will be more debris.

2. You can also cut with a jigsaw and a grinder at home, and plates with a greater thickness. The main thing is that there is enough height of the blade or disc. The jigsaw must be moved smoothly, otherwise the styrofoam balls will begin to peel off from each other. It should be borne in mind that during sawing in such ways, the foam crumbles strongly.

3. A hacksaw for metal or wood is well suited for cutting expanded polystyrene plates up to 10 cm thick. The smaller the teeth, the better the cut will be. In addition, this method of sawing is fast and does not require much effort. It is necessary to act smoothly and evenly, without sudden movements.

4. To prevent the foam from crumbling and the cut is smooth, you can use a wire with a cross section of 0.5 mm and stretch it between the two handles. Sawing begins along the markings and at the same speed. The constant friction will heat the wire and melt the foam. With this method of cutting, the edges of the board are smooth and even, and the amount of waste is minimal. The only drawback is that this kind of work will require two people.

5. If you plan to cut a large number of foam plates, then it is better to purchase a soldering iron nozzle or a special electric knife. Thanks to the sharp blade and high temperature, the slabs are cut quickly and smoothly. In addition, with their help, curly cuts are made. But it should be borne in mind that the length of the blades for many tools is no more than 5 cm. Also, when working with hot tools, you should be careful not to get molten foam on your clothes or skin. It will not be possible to remove it from the skin instantly, which means that there will be a severe burn.

6. Another good device that comes out to cut the foam slabs is a special machine. Buy it or do it yourself. Cutting is fast, quiet and effortless, and you can cut material of any thickness (depending on the capabilities of the machine). The amount of waste is minimal, and the cut is absolutely even and smooth. Another advantage of this method, thanks to the hot nichrome wire, the cut cells are melted back. As a result, the thermal insulation characteristics of the foam are not deteriorated.

Tips and tricks and how to make a simple machine with your own hands

Before cutting the styrofoam, it is necessary to mark with a sharpened pencil. If possible, then you need to cut the slab in the direction away from you. When cutting foam plastic by heating (a machine with a wire, an electric knife), dangerous black smoke is emitted, which causes significant harm to humans. Therefore, it should only be cut in such a way in a well-ventilated area or outdoors.

In order to make a simple machine, you need a surface with an inclination (20-60 °). A nichrome wire is stretched across it with the desired cutting height. One end is firmly fixed, and the other is connected to the spring. Then the wires are connected from the power supply. The current strength must be controlled so that the wire does not overheat too much, therefore a rheostat is additionally connected. The temperature should not exceed + 100 ° С. After everything is ready and the thread is heated, the foam is cut.To do this, you just need to put the plate, and it will begin to roll itself (if the surface is smooth enough) or it is evenly pulled through the wire. If you do this too slowly, the cut will be wide, since a lot of the foam will have time to melt during this time. If it is fast, then there is a risk of breaking the thread.

Ready-made polystyrene foam cutting machines have more options. With their help, 3D shapes are made. Depending on the configuration, they can have from one to six strings. They are controlled either by an operator manually or through a computer program. Some are compact, making them easy to transport, which is extremely important for builders. The cost of machines for cutting polystyrene foam starts at 40,000 rubles. There are also models with a laser - such devices make the highest quality cuts. Laser cutting machines are used to cut shapes for shop windows, exhibitions or any other important event.

Before choosing the best way to cut polystyrene foam, you should decide how much material needs to be processed. If the cutting will be carried out only once, then you can do with a sharp knife or hacksaw. In another case, it is better to buy an electric knife or make a machine with a wire yourself or purchase a ready-made one.

Cutting tools

Foam boards have impressive dimensions. Since this material is used not only for insulating the walls of a dwelling, but also for packaging during cargo transportation, finishing small parts, it often has to be cut.

This must be done carefully, because the foam is very fragile and can break in the wrong places.

To do this, you should select the tools with which the separation can be done efficiently:

- If the sheet is no more than 5 millimeters thick, then a wallpaper or clerical knife can be used for cutting. This process is laborious and time-consuming, but it has a wonderful result - the edges are as smooth and even as possible.

- To cut expanded polystyrene, you can use a metal hacksaw with fine teeth or a grinder with a thin disc. Cutting involves beveled corners and edges, so these tools are used as a last resort.

- An electric jigsaw is used for sheets. But in the process of work, difficulties may arise with processing the edges of the product sheet.

- It is rational to cut a large amount of foam with a hot wire. The cutting of building material is carried out quickly and efficiently.

Note:

any of the above tools must be sharp, as this can severely deform the edges of the product.

Foam Cutting Machine

Expanded polystyrene is a good insulation, an excellent raw material for various decorative elements, which you can make yourself. For decorative cutting of foam, you need a specialized machine. There are many options for such equipment, it all depends on the intended design of the product.

The material can be cut with tungsten filament. It should be noted that this filament is hot, but its temperature can be adjusted.... In addition to polystyrene, other materials can be cut with such a thread. This is especially true in the manufacture of various components for stucco molding.

The required stencil is applied to the expanded polystyrene plate, and an object is created with the help of a tungsten thread. This procedure is not difficult, it does not take much time.

Also for the equipment, you can use a construction blade, a cutter. The device of the machines may differ, but the principle of operation remains the same - the use of a tungsten filament, which is connected to the mains. With the help of such a device, you can independently make decorative elements from foam plastic of any configuration.

To perform cutting, it is recommended to purchase the following tool:

- Tungsten filament.

- String.

- Thermal cutter.

If you assemble the cutting machine correctly, then there will be no difficulties in the process of work. The main thing is to use a quality tool, to show maximum diligence and attentiveness. And to perform such work, you will not need to contact experienced craftsmen.

Which tools are better

Among all the above cutting tools, there are only a few that are suitable for a high-quality procedure.

Moreover, if the slicing is done at home.

Each tool is used in accordance with a specific technology:

- You can cut the material efficiently and evenly using nichrome wire. For this, a device is assembled, consisting of a string through which an electric current passes. The simplest transformer is used to generate electric current. The device can be made portable. All you need to do is use a charger.

- Figured cutting is provided using a special machine that can be purchased at a hardware store, or you can do it yourself. is a device consisting of a table, a metal frame and a blade. The device can be used in manual mode.

Worth considering

: for high-quality cutting of foam, electrical devices are mainly used, therefore it is important to observe safety rules in the process of their use, to monitor the health of the wiring and the integrity of the wires.

Workplace preparation

In order for the cutting process to be carried out in accordance with all the rules, it is important to properly organize the workplace.

To do this, you should adhere to several basic rules:

- The surface must be free of unnecessary objects and must be flat. For convenience, you can use an inclined surface in the form of a table for drawings. But it is suitable for curly cutting. Often tables are equipped with fasteners so that the sheet does not slip.

- The workplace should be well lit, that is, be near a window or have all-round artificial lighting, which is located on the left hand.

- Instruments must be prepared in advance. Do not forget about the tools for marking: a ruler and a pencil. Protective clothing also comes in handy. These are gloves, goggles and an apron.

- To cut shapes, you need to make rigid cardboard templates. This will speed up the process as much as possible. And all the details will be the same in size and shape to each other.

- Scraps should be removed from the surface immediately so that debris does not interfere with the cut. Even small particles should be removed; they can be swept away with a stiff brush.

If all points are followed, then the risk of damage to the material will decrease, and this will save finances that will be spent on replacement.

Cutting technology

The cutting technology is different for each tool, so it is worth considering them separately for each case.

The main features are represented by the following steps:

- It is easiest to cut the foam with a clerical knife. For this, the sheet is fixed on a flat surface. The blade of the knife is at an angle of 45 ° to the surface of the sheet. Do not press hard on the handle, as this can affect the quality of the cut.

- A carver who uses a machine with a nichrome string in his work does not make efforts. Due to the high temperature of the cutting part, the edges are processed and become smooth. In the places of the cut, the foam will definitely not crumble.

- The installation, which is a machine for cutting foam sheets and blocks, is most effective for large volumes of work. The material does not crumble or break, and the cuts are neat.

The choice of the device depends on the quality of the building material and on the number of sheets.

The further use of the parts is also a determining factor.

If they are stained or trimmed, then you don't have to worry about the quality of the cuts.

Styrofoam can be separated without problems at home using a huge number of tools. The main thing is to choose one according to the needs of the cutter, as well as adhere to the technological aspects of the process.

Watch a video in which the master tells how to make a machine for cutting foam with your own hands in 5 minutes:

Polyfoam is used by builders for a variety of purposes. This material exhibits high thermal insulation qualities, therefore, building facades, floors and other objects are insulated with it. Also, various decorative elements are made from this material.

The foam is easy to process and easy to cut. But at the same time, the material can crumble strongly. Destruction of an array is a negative phenomenon. Therefore, it is necessary to properly handle this material, you need to find out before starting work. At the same time, it will be possible to create not only plates for insulation from an array of polystyrene, but also decorative products. Their appearance will be neat and the material will not deteriorate.

How to cut polystyrene at home, so as not to crumble; tool overview

Sheet polystyrene is an insulation made of expanded polystyrene. In another way, it is also called polystyrene foam. It is one of the most popular materials for thermal insulation of houses, as it has a low cost and easy installation. But during the installation of the slabs, it is often necessary to cut them. It is imperative to make the cut of the foam sheet straight, as large gaps can impair thermal performance.

You can cut polystyrene foam at home in many ways:

- with a knife;

- hacksaw;

- jigsaw;

- grinder;

- electric knife;

- machine for cutting expanded polystyrene with wire.

1. A sharp knife is good for slabs up to 5 cm thick. The blade must be thin and not flexible, otherwise the cut will be crooked. So that when cutting the foam with your own hands there is even less waste, it is better to heat the knife. It should be borne in mind that the blade will have to be sharpened approximately every 2 m, as otherwise the work will take longer and there will be more debris.

2. You can also cut with a jigsaw and a grinder at home, and plates with a greater thickness. The main thing is that there is enough height of the blade or disc. The jigsaw must be moved smoothly, otherwise the styrofoam balls will begin to peel off from each other. It should be borne in mind that during sawing in such ways, the foam crumbles strongly.

3. A hacksaw for metal or wood is well suited for cutting expanded polystyrene plates up to 10 cm thick. The smaller the teeth, the better the cut will be. In addition, this method of sawing is fast and does not require much effort. It is necessary to act smoothly and evenly, without sudden movements.

4. To prevent the foam from crumbling and the cut is smooth, you can use a wire with a cross section of 0.5 mm and stretch it between the two handles. Sawing begins along the markings and at the same speed. The constant friction will heat the wire and melt the foam. With this method of cutting, the edges of the board are smooth and even, and the amount of waste is minimal. The only drawback is that this kind of work will require two people.

5. If you plan to cut a large number of foam plates, then it is better to purchase a soldering iron nozzle or a special electric knife. Thanks to the sharp blade and high temperature, the slabs are cut quickly and smoothly.

Features of foam

Styrofoam is a lightweight material in all respects. The polymer is miscible with air and foam filling components. Its structure is similar to glued balls. It is this feature that explains why we cut the foam, rather than break it. Otherwise, the cut is uneven.

In some types of material, the balls of the structure are held more tightly, do not crumble. But quite often the foam crumbles, and sometimes very strongly. Such destruction of the material is dangerous for the sheet. The brittleness of the foam leads to a change in shape, a decrease in properties and functional qualities.

If it is required to adjust the dimensions of the array, this operation is carried out using a special tool. In this case, the sheet will not collapse.

Types of tools

Studying the question of how to properly cut polystyrene at home, you need to pay attention to the types of tools. They are divided into mechanical and thermal. For self-cutting of the array, with a small amount of work, the first group of tools is preferred.

For home processing of foam, novice craftsmen are advised to choose a mechanical tool. Professional installers and designers prefer thermal cutting. In this case, it will be possible to create a high accuracy of the edge, create objects of any complexity.

A thermal cutter is quite expensive. Novice craftsmen who make repairs at home rarely purchase such equipment. But for large volumes of work, it is simply irreplaceable. Actions with a thermal cutter are performed quickly and efficiently.

How and how to cut polystyrene

In order to cut a certain shape of insulation, any device for cutting foam can be used:

- knife;

- hacksaw for wood or metal;

- soldering iron;

- angle grinder called "grinder";

- thin metal wire such as a string;

- thermal cutter;

- foam cutting machine;

- jigsaw with a heated file.

If a hacksaw is chosen for wood, then its teeth should be as small as possible. All tools that do not heat up to a certain temperature do not guarantee that the foam will not crumble. Such tools are used for small amounts of work, but when it is necessary to insulate all the enclosing structures of the house, it is better to use an apparatus for cutting foam, the action of which is based on heating the cutting element.

Tool production method

Considering the question of how to properly cut the foam so that the sheet does not crumble, you should take a closer look at the method of making the tool. It can be factory-made or home-made.

Professional builders are required to purchase special certified equipment. Whether it is a mechanical or thermal tool, for such purposes it is necessary to perform work with factory-made equipment. The fact is that when creating such devices, the developers provided it with all the necessary qualities, safety and comfort as much as possible. This is very important when doing a lot of work.

But, making repairs with your own hands, it is unprofitable to purchase special equipment. In this case, you can create it yourself. It will be a more primitive device, but it will be able to cope with the tasks assigned to it.

How to properly cut styrofoam with a knife so that it does not crumble

When plates of polymer material are used in the process of insulating walls, floors, roofs with their own hands, thermal cutters are not always justified. The designs, as a rule, have strictly geometric shapes, and it is quite possible to cut the material with a simple knife, the main thing is that the blade is thin, and its length exceeds the thickness of the insulation sheet. A good tool for such work is a clerical knife if you have to cut thin polystyrene foam.

Choose a long blade to cut foam with a knife

The fact is that the blade of such a tool is very thin and when cutting a sheet, a large thickness of a perfectly even cut is unlikely to be achieved, convolutions may form on the cut, which will not allow making a tight abutment of individual parts of the insulation. And this will lead to the formation of cold bridges.

Mechanical cutting

First of all, you should consider the main mechanical devices with which you can cut the foam. How to cut the material depends on the skills of the master and the amount of work. These tools include a knife, grinder, saw and jigsaw. For self-cutting slabs in the process of arranging a layer of insulation, it is better to use a knife. Its blade should be of medium hardness. Such a tool allows you to cut slabs up to 8 cm thick fairly efficiently and quickly.

A jigsaw, grinder or saw are used only for special work. Professional builders use such equipment. In this case, the tool differs in a number of parameters from conventional angle grinders, jigsaws or saws.

If a thick blade and high RPMs are used, the foam can easily deteriorate. Therefore, at home, a knife with replaceable blades is used for cutting.

Thermal cutter

Thermal equipment allows to achieve high cutting accuracy. It is purchased by professional craftsmen and designers. When carrying out a large amount of work at home, this type of equipment should also be considered. In this case, we cut the foam

The device is powered by the system or battery. Through the elements of this technique, electricity is supplied to the nichrome thread. At the same time, the metal heats up quickly and strongly. This allows you to qualitatively cut off excess foam, cut it in any direction.

The most accurate material processing is obtained using a thermal cutter. It should be noted that the foam does not respond well to heat, but in this case the cut is very fast. Therefore, its quality is high.

Homemade cutter

You can create a thermal cutter yourself. To do this, you need to collect a set of necessary parts. First of all, you need a small transformer. You can take this part, for example, from an old TV.

In this case, you will also need to cut the foam with a nichrome string. It is pulled between two long screws. They need to be fixed to a wooden plank. This material is known to be non-conductive. Therefore, electricity from the transformer will only go to the screws and the string.

After connecting all the elements, the voltage must be corrected. It depends on the thickness. Too much hot wire will not allow to cut the material properly.

Easy way to cut

The presented approaches make it easy to cut the foam. How to cut such material, folk craftsmen give advice. They came up with another way. It will be quite effective, especially when cutting large foam sheets.

This requires a thin and strong string. Its ends are tied to wooden handles. If the sheet is large, you must do the work with an assistant. In this case, 2 people become on both sides of the array. Each one takes a wooden handle with a tied string. Further, along the markings drawn in advance, they move the thread. It heats up from friction.

The material is easily and quickly cut. If the sheet is small, you can perform this procedure yourself.

There are a few tips from professional installers for handling styrofoam. It will be easy to choose what to cut it. Experts say that each of the presented methods is suitable for cutting. It all depends on the skills of the master and the amount of work he does.

Before starting cutting, the material must be marked with a simple pencil. With the mechanical and thermal methods, the foam can get hot.In this case, it releases harmful substances into the environment. Therefore, the work is carried out in the open air.

In this case, special equipment is used. Otherwise, the material will stick to the blade when heated. The grinder or jigsaw works at low speeds. This allows the heat to be removed from the cutting zone.

Styrofoam is widely used as insulation for walls, floors or ceilings. The main thing when using it is the correct cutting of the material. It is important not to crush the expanded polystyrene and make the most accurate and smooth cut. For these purposes, there are various tools and methods that can be applied at home.

Professional recommendations

There are a few tips from professional installers for handling styrofoam. It will be easy to choose what to cut it. Experts say that each of the presented methods is suitable for cutting. It all depends on the skills of the master and the amount of work he does.

Before starting cutting, the material must be marked with a simple pencil. With the mechanical and thermal methods, the foam can get hot. In this case, it releases harmful substances into the environment. Therefore, the work is carried out in the open air.

In this case, special equipment is used. Otherwise, the material will stick to the blade when heated. The grinder or jigsaw works at low speeds. This allows the heat to be removed from the cutting zone.

By following these recommendations, you can quickly and efficiently cut the foam for any application.

Varieties of tools for cutting foam at home

Styrofoam cutting tools come in a variety of shapes. The type of cut determines the efficiency of the tool. There are 2 main types of devices.

Types of cutters:

- Mechanical;

- Thermal.

A mechanical tool is used to perform a small amount of work. Cutting under mechanical stress is easy. But at the same time, the cut may be of poor quality.

The thermal tool belongs to professional equipment. It is widely used by construction specialists.

The thermal cutter is used for different types of Styrofoam. With its help, you can quickly and efficiently perform a cut. The basis of a thermal tool is a glowing thread or wire.

By the type of assembly, tools are classified into branded and homemade. The first option is represented by cutters made in production. Professional equipment includes both knives and thermal cutters.

Thermal cutting with a knife

For this method, you need to think about heating the tool. Open flames or heating equipment can be used. The knife itself must be well sharpened. You need to stock up on a guide straight bar for cutting. It is best to do the work outdoors. This will prevent the accumulation of harmful odors that negatively affect health.

The cutting line is marked, a guide bar is applied, a cut is made with a heated knife. This method allows you to do it quickly and efficiently.

Ways to cut styrofoam at home with your own hands

Soft material up to 4 cm thick can be cut with a regular knife at home. In this case, the blade needs constant sharpening. Otherwise, the cut will come out uneven and crumble.

During operation, there will be a rather unpleasant cutting sound. It is advised to carry out the process with headphones or earplugs.

For a smoother and smoother cut, it is advised to heat the blade before cutting. You can also take a grinder or a jigsaw for cutting at home. But the edges will be uneven, too much noise from work and waste. Thicker foam (8-10 cm) is cut with a hacksaw. This is a fast and efficient way. The work should be carried out with a tool with small teeth. This will make the cut smooth.

The advantages of using a hacksaw:

- The effectiveness of the method - less effort is made than when working with a knife;

- Not traumatic;

- Thick foam can be cut.

Steel wire is often used for cutting. You will need to attach the handles on both sides of the wire. And then, according to the planned marking, cutting is performed. During operation, the wire heats up and begins to melt the material. The edges are smooth and there is no debris. But there must be two people to perform the action.

How to cut styrofoam. Step-by-step instruction

- The first step is to find a sufficiently thin and sharp object that will be used to form the incision.

- If there is no special tool, then it is quite possible to use a credit card, a table knife, or any object with thin edges.

- Along the notch line, the foam can be easily broken. This is most conveniently done at the edge of the table. You can only press lightly.

- If there are convex pieces left, then they can be cleaned with a knife.

Professional foam cutter by yourself

If the volume of work is larger and at the same time curly processing is required, then you should pay attention to professional equipment. Experts use a soldering iron with a knife attachment. The incandescent blade helps create any cut.

During work, safety precautions should be observed so that hot oil does not get on the body or clothing.

At home, you can use homemade equipment with nichrome thread. The method has already shown its effectiveness and convenience. At the same time, there is little waste. The edges are sealed, and the material does not lose its properties.

Required materials to create a homemade tool:

- Wire;

- Long spoke;

- Transformer;

- Reastat;

- Necessary electrical wires.

The knitting needle is fixed on the table and the thread is pulled between its ends. Then connect the serial connection of the elements. When the current is applied, the thread should only slightly redden. Too hot thread will cause an uneven and wide cut. If a large amount of work is planned, then it is better to purchase a special tool in the store. It heats up quickly and guarantees quality work. But it has a high cost.

Styrofoam cutting has some peculiarities at home. So in preparation, you need to make accurate markings with a sharp pencil. When performing work, you should cut the material from yourself to the side. Cutting should be done in a well-ventilated area or outdoors. When heated, the foam begins to release toxic substances.

Efficiently cutting foam with a string at home

There are many ways to cut polystyrene. But it is important not only to get the job done, but also to make an even smooth edge so that the material does not crumble. The best tool is wire cutting. You can make such a device with your own hands at home.

The manufacturing process requires care, no special skills are needed. Curly cutting is popular, so a thermal cutter is required for work. The cutting tool is a nichrome thread attached to the handle. But some cases do not require a special cutting device.

Necessary tools for work:

- Metal ruler;

- Pencil;

- Stationery knife.

To begin with, using a pencil, a marking of the future cut is made. Further to the line, you need to attach a ruler and use a clerical knife. There is no need to try to get the knife to cut off the plate completely. Then turn the slab over and complete the cut. Then manually complete the incision.

How to make a homemade foam cutting machine: steps

A machine with nichrome thread is considered the best option for cutting at home. It is quite simple to make it. It is enough to stock up on the necessary tools.

Materials and tools for work:

- An old table or structure made of wooden blocks and plywood;

- Spiral;

- Spring;

- Rheostat;

- Low power transformer;

- Wires;

- Two bolts with nuts.

On both sides of the table in the center, you need to retreat 20 cm and drill holes. Then bolts are inserted into the holes and nuts are tightened. Other materials can also play the role of racks, it all depends on the availability of materials at hand. Then a nichrome thread is pulled on one rack at a height of 10 cm from the surface. We fasten the spiral to the second and only then connect the thread.

This fastening of the thread is due to the fact that when heated, the material begins to expand and sags. This reduces the cut quality.

Then the wires are brought to the racks. It is advised to connect from below so that they do not interfere with work. Then the wiring is connected to the transformer.

The choice of a transformer is due to many factors. This is influenced by the length, thickness and composition of the nichrome thread. In some cases, a rheostat is used for power supply. This solution is considered safer, since unregulated power can be supplied through the transformer.

The transformer is fixed under the worktop. On this, the homemade device is considered complete. The device is connected to the mains and you can start working.