Circulation pump in a gas boiler

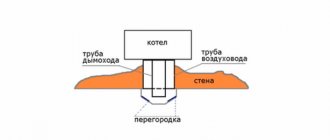

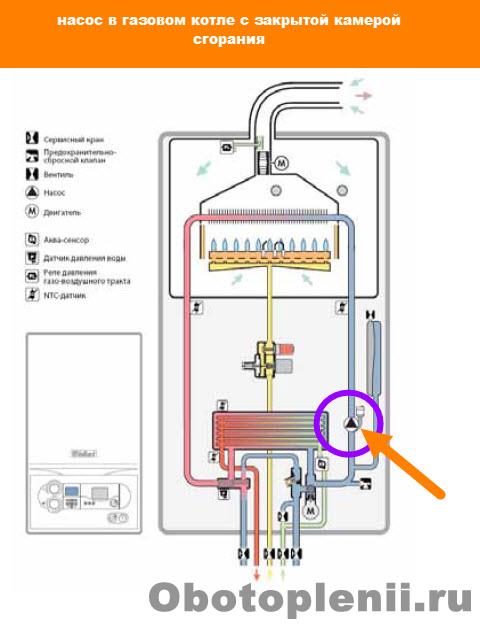

The circulation pump in the construction of a gas boiler accelerates the coolant through the heating system, due to which the coolant is cooled in the system more slowly and returns to the boiler in a "heated" form. Since heating in the boiler occurs to a certain temperature, the next heating cycle of the coolant will be shorter. Hence, lower gas consumption and fast water heating cycles (higher efficiency).

It is believed that the installation of circulation pumps is not required for hydraulic heating systems, however, it will not interfere at all in old heating systems with large diameter pipes.

When buying a gas boiler with a circulation pump in the design, you no longer need to install a separate circulation pump in the heating system.

The main reasons for the increase in pressure

Most often, the reason why the pressure in the heating circuit rises in a closed heating system is a breakdown of the equipment due to which the indicators either jump upwards or fall sharply downwards. But other than this, the reasons also include the following:

- A sharp increase in the pressure of the coolant due to a closed shut-off valve. An increase in pressure is observed in the system, after which the boiler is blocked and the system stops. To fix the problem, you need to check the fittings for leaks, open valves and taps to relieve pressure.

- The reason for the rise in pressure in the heating system may be a dirty dirt filter. Rust particles, debris, sand and slag accumulate on the surface of such a filter. As a result, the pressure in the area between the boiler and the filter increases greatly. To eliminate the cause, it is necessary to clean the filters regularly, at least 3-4 times a year. Also, a good solution would be to replace conventional mud collectors with magnetic or flush filters. They are more expensive, but much easier to maintain.

- The operating pressure of the system may rise due to a malfunction of the boiler automation. This is a factory defect, incorrect system settings, a breakdown of the control board. All these problems require boiler repair, which can only be carried out by a master.

- Leaks of the make-up valve are observed, that is, water will constantly penetrate into the general circuit, which causes a pressure surge. Repairs are usually fairly straightforward; all you need to do is replace the rubber gaskets. But if there is a defect, the crane or equipment should be completely replaced.

Why does the pressure drop in a double-circuit or conventional boiler? This situation most often occurs when the expansion tank breaks down or the air valve is missing. Repair or complete replacement of the tank may be required to fix the problem.

Features of pump repair for Daewoo DDP 7525 boilers

DDP 7525 pump of the DEU boiler

Damage to the circulation pump of the Daewoo gas boiler

Is a fairly common problem. Many clients often have to deal with it in practice. In particular, this applies to the DDP 7525 pump. In our article we will talk about:

- the reasons for the problem;

- ways of solving;

- technical features of the device.

Undoubtedly, the main technical advantage of the product of the Korean company is the presence of reverse rotation. This allows the pump to change direction depending on the boiler operating mode. So, first, when the heating mode is on, the pump circulates in one direction, then in the opposite direction when hot water is turned on.

This feature of the system also covers the main problem of such gas boilers: it is impossible to replace such a pump with any other.In addition, according to statistics, the failure of Korean devices occurs more often than European ones.

Breakdown of DDP 7525 pumps occurs due to:

- wear of the friction bearings and the shaft connected to them;

- the occurrence of a short circuit in the motor winding.

Let's dwell on these points and look at them in more detail.

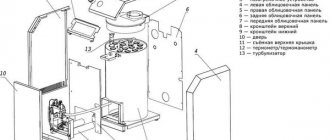

Pump rotor

The circulation pump consists of two friction bearings. Moreover, one is located directly in the engine cover, which protects the electrical part from water ingress. Therefore, it wears out faster. You can feel the difference by looking at the photos:

a serviceable part is shown on the left, in the opposite side - a failed one.

In our opinion, the main reason for this problem is the increased contamination of the coolant in the system. And there is an explanation for this: the fluid moved by the pump directly contacts the friction bearings. And in the water there are rust particles, due to which the surface is erased. Thus, the composition and quality of the coolant influences the bearing life.

Daewoo boiler pump winding

The second possible cause of a malfunction of the circulation pump is the occurrence of a short circuit in the mains. We suggest carefully examining the photos. On one, you can see traces of melting of the insulating coating in the places where the electrical wires and the motor coil are connected. On the other, we see the device in an absolutely good condition.

It is quite simple to determine that it was a short circuit that caused the breakdown. First of all, you need to remove the engine cover and carefully examine the condition inside. As practice shows, this is one of the weakest points of the Daewoo pump.

A possible cause of a short circuit is the ingress of liquid into the motor. In the modern version of the device, specially for such cases, the presence of holes is provided so that water can flow out.

There are also options when, due to increased bearing wear, the rotor play increases, and the impeller, fixed on the shaft, begins to exert a mechanical effect on the base. You can see the results of these processes for yourself.

Below you will take a closer look at the design features of the Daewoo pump and its disassembly scheme.

Unscrew four bolts with a hexagon in a circle.

We unscrew the plug to de-air the pump.

Immediately pay attention to the O-ring on the plug, if you have it like that on the left, then you will definitely have problems with the pump.

Next, pry off this cover with a screwdriver

We turn off the capacitor that opened there

We insert a flat screwdriver of a suitable size into the slot on the shaft and, turning the pump over to the top with it, knock out the rotor from the engine, not with a strong blow. (DO THIS VERY CAREFULLY, ENGINE SHAFT IS FRAGILE)

Here we will see the same rubber seal that often passes water into the motor.

And the last, with the help of some kind of insert, we knock out of the housing, either only the stator, or together with an external bearing.

That's all! If you have any comments or suggestions, write comments. : bye: New Daewoo boiler pumps always in stock.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | The cost |

| Service contract floor standing boiler (gas, diesel) up to 60 kW | with 1 planned visit | 14 000 ₽ |

| Service contract floor standing boiler (gas, diesel) from 60 to 170 kW | with 1 planned visit | 20 000 ₽ |

| Service contract floor standing boiler (gas, diesel) up to 60 kW | with 2 planned trips | 22 000 ₽ |

| Service contract floor standing boiler (gas, diesel) from 60 to 170 kW | with 2 planned trips | 30 000 ₽ |

| Service contract for a wall-mounted gas boiler | with 1 planned visit | 10 000 ₽ |

| Service contract for a wall-mounted gas boiler | with 2 planned trips | 15_000_₽ |

Boiler room maintenance cost

Boiler room repair, diagnostics and prevention

| Name of works | Volume | The cost |

| Departure and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| Departure and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5 500 ₽ |

| Burner cleaning (atmospheric) | power up to 60 kW | from 2 000 ₽ |

| Burner cleaning (blower) | power up to 60 kW | from 3,500 ₽ |

| Burner cleaning (atmospheric) | power from 60 to 170 kW | from 8 500 ₽ |

| Boiler combustion chamber cleaning | power up to 60 kW | from 4 000 ₽ |

| Boiler combustion chamber cleaning | power from 60 to 170 kW | from 6 000 ₽ |

| Checking and pumping up the pressure in the expansion tank | without dismantling works | from 2 500 ₽ |

| Checking and pumping up the pressure on the expansion tank | with dismantling and installation | 4 500 ₽ |

| Refueling the heating system with a pump | system volume up to 200 liters | 3 000 ₽ |

| Replacement of Taine, pump, heat exchanger, with coolant drain | for a unit | 3 000 ₽ |

| Converting a gas boiler to liquefied gas | for a unit | 3 000 ₽ |

| Burner adjustment | gas / diesel | 2 500 ₽ |

Boiler room maintenance cost

Request a call

Call around the clock, we work without holidays and weekends.

Contact page

The emergency service works around the clock in Moscow and the Moscow region. In the nearest area the departure is planned according to the schedule

8 (495) 744 -67 -74

Calculating the cost of heating

Heating system repair cost

Water supply installation cost

Engineering systems: heating water supply:

- Pump replacement Electric heating - Pump replacement Despite the popularity of gas heating, its electric prototype is gaining more and more fans. There are many reasons for the electric boiler to gain new admirers. These are, first of all, low ...

- Circulation pump malfunctions Owners of autonomous heating know that a circulation pump is needed for normal circulation of the coolant. Private houses are mainly located far from service centers or workshops, so it is worthwhile to master the repair of a circulation pump with your own hands. Regular maintenance The pump, like other equipment, needs ...

- Replacing the heating pump Replacing the heating pump from 2,500 rubles Departure of the engineer Paid additionally Dismantling the pump from 1,800 rubles Installation of a new pump from 2,500 rubles Commissioning the system commissioning Additional costs

- Replacing the pump in the boiler room ► Replacing the pump ◄ in the boiler room Replacing the pump in the suburban boiler room .......

- Replacing a wood-fired boiler Replacing a wood-fired boiler High-quality and efficient heating at home is the most important ……

- Electric heating - Replacing pipes The reliability and efficiency of hot water heating is ensured by boilers operating on various types of energy sources. Thus, electric heating uses the current that flows through the heating element and transfers its energy to the working fluid. Gas is the cheapest ……

- Replacing the coolant in the heating system Installation of heating a house at one of the last stages involves filling the heating system with a coolant, which is mainly used as ordinary tap water. It is the composition and condition of the coolant during the operation of heating equipment that largely determines the efficiency of the entire integrated heating system. Among the row ...

- Boiler replacement. Boiler room repair. Boiler room repair estimate. Replacing the hot water boiler. Replacement of heating system pumps. OJSC "ALFA-BANK" 107078, Moscow, Kalanchevskaya str., 27 BIK 044525593 Comp. No. 30101810200000000593 Beneficiary's bank INN 7733630084 KPP 773301001 Account. No. 40702810101100003335 "DESIGN PRESTIGE LLC" Recipient Account No. 1030 ...

- Installation of a heating point A heating point is the most important unit of an individual heating network. It is a whole complex of structures, devices and equipment located in a separate room (boiler house) and performing the following functions: - distribution of the heat carrier among heat consumption systems (heating, ventilation, hot and cold water supply); - ...

- Heating replacement The winter season constantly pleases children and alarms adults. Such feelings are exacerbated among the residents of the suburbs. Children will play with great pleasure in snowballs and sledding, parents will gladly take part in this. In addition to games for adults, add at this time ...

- Heating a house without a pump Having decided to build a private house, each owner must carefully consider and ……

- Repair or replacement of heating if necessary The most necessary, even vital of utilities is heating the house. This is especially true of the middle zone, where the cold season is half a year. The system determines how comfortable the residents will feel, how safe their living will be. And here it does not have much ...

- Replacing the boiler house of the house Heating maintenance - Replacing the boiler house of the house Unfortunately, there is no such equipment that can work forever. This means that everything has its own maximum service life. Timely maintenance of heating equipment, of course, can allow the boiler house to last longer and delay the need for ... ...

- Replacing the heating medium from RUB 18,000 Draining the heating system Blowing out the liquid residues with the compressor Filling with new heating medium Bleeding the air Commissioning the heating system Disposing of the old heating medium Call for details 8 495 744 67 74 Please note, it may be necessary ► flushing the heating system with chemical reagents Specialists ...

- Replacing heating pipes Replacing heating pipes is a rather urgent task today. There are several reasons for this. For example: · In some cases, the need for this procedure is caused by the desire to improve the efficiency of the heating system. After all, modern plastic or copper pipes are capable of ...

- Replacing the coolant in the heating of the summer cottage Creating a warm, safe atmosphere in a summer country house has its own characteristics. Often the owners come here for a short time, and when they leave, they turn off the appliances …….

- Heating system without a pump Having built a country house or summer cottage, each person thinks about how to heat his home as efficiently as possible. Today there are many types of heating, and sometimes it is very difficult to choose a specific heating option. We strongly recommend paying attention to the heating design ...

- Replacement of a heating boiler in private houses A specialized company replaces heating boilers and refurbishes boiler rooms in private houses and furnace enterprises in (New) Moscow and the Moscow Region. A package of necessary documents for a gas utility trust after changing gas equipment. Installation of heating equipment in a private house is made on a turnkey basis ...

- Replacing a heating system in a private house Replacing a heating system in a private house, as a rule, begins with the selection and calculation of the capacity of heating equipment, including the calculation of the required number of heating radiators. At the same time, we take into account both the priority types of fuel for a particular region and the heated area. It is from the implementation ...

- Replacing the heating system in Zaovrazhie The heating system is one of the most important components of any building. It must be carried out by experienced technicians and work flawlessly. However, over time, any engineering system begins to malfunction. The reason for this is the wear of parts, which leads to the exit from ...

Previous post Repair of the underfloor heating collector

The next entry Pump repair ◄ in the boiler room

Signs of a breakdown of the gas boiler pump

The main indicators of a malfunction of the coolant supply pump are failures in electrical power, short circuit (mechanical damage to the motor windings), a noticeable deterioration in the supply of heat in the system. All such problems during the cold period must be eliminated promptly.

The boiler pump is repaired by a master in the event of malfunctions associated with partial (complete) replacement of parts. In other situations, a complete replacement of the assembly with a new structural element is performed. The installers always have in stock branded spare parts for carrying out full maintenance of gas heating boilers of various brands.