The principle of operation of electrode boilers

The principle by which the coolant spreads through the heating system depends on the type of equipment:

- If the system is of a closed type, the installation of a circulation pump is required, otherwise the movement of the coolant will not occur.

- With an open system, the coolant flows naturally.

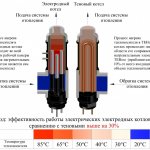

The job is to comply with the laws of physics. The liquid heats up because the water molecules break down into differently charged ions.

The coolant heats up due to the movement of ions between two opposite electrodes. Chaotic movement of positively, negatively charged particles is created, thermal energy is released. Energy is used to heat water, antifreeze.

Principle of operation

Electrodes - manufacturers of electric field with variable action.

The heating method eliminates the formation of scale on the walls of the heating equipment, prolongs the service life.

Types of boilers by the number of circuits

Single-circuit devices are heating units designed only for heating network water. Double-circuit devices also additionally provide hot water supply. They are a good option for installation in country houses. At the same time, two important tasks are being solved: high-quality operation of the heating system and the constant availability of hot water are guaranteed.

Single-circuit

Single-circuit boiler, a boiler is used for DHW

The power of such devices is quite enough for space heating. But such a unit cannot provide hot water on a regular basis. For these purposes, an additional DHW cylinder must be connected.

Double-circuit

If staying without hot water is impossible, you need to immediately purchase a double-circuit gas-electric boiler. Unlike a single-circuit one, its design contains an additional heat exchanger, which solves the problem of heating water. If the power allows, you can increase the number of taps. To minimize the loss of water temperature, they should be located close to each other (boiler and parsing points).

All the disadvantages of gas-electric units are determined by the technical characteristics and depend on the manufacturer. When choosing a heater, it is recommended to contact a specialist.

Coolant requirements

The electrode boiler is very sensitive to the composition of the coolant. Plain tap water will not work. It is necessary to purchase distilled water, add a little table salt. Proportion: 100 grams of salt per 100 liters of liquid.

Ready heat transfer fluids

For normal operation, the liquid must be brought to the desired density and conductivity. Salt varies in composition and results may vary.

When completing the preparation of the solution, be guided by the value of the current in the electronic boiler. In the instructions for the device you can find a detailed table of the required values. They are taken depending on the power, the volume of the filled coolant. Gradually adding salt, distilled water, you need to achieve the required performance.

Before filling the system with electrolysis solution, carry out mandatory cleaning from scale and salt deposits. If not, the problem can change the thermal conductivity of the liquid.

Pros, cons of equipment

Customer reviews of electrode boilers are very different. Benefits:

- The device is compact. The device can be transported without problems.

- The device is easy to connect.

Installed device

- Due to the small size of the device, it can be used as an additional, backup heat generator.

- To install the device, you do not need to draw up a project, contact the service for approval.

- If a coolant leak occurs, the device will work as before. After fixing the problem, you can restart the device in operation.

- Electrolysis boilers are comfortable with voltage drops.

- They do not emit harmful substances, do not create powerful electromagnetic fields.

Disadvantages:

- The use of steel, cast iron radiators in the heating system is unacceptable. For efficient work, you need devices made of bimetal, aluminum. The nuance makes the system more expensive.

- The use of tap water is not permitted. It is necessary to use distilled water mixed with table salt when making electrolysis liquid.

Ban on tap water

- The boiler can be installed in a closed circuit. Requires the purchase of a sealed expansion tank, an emergency pressure relief valve, an air vent.

- The heat carrier should not be heated above 85оС.

After analyzing the minuses of the apparatus, one can understand what are associated with the quality of the coolant, chemical properties.

Other characteristics of heat generators

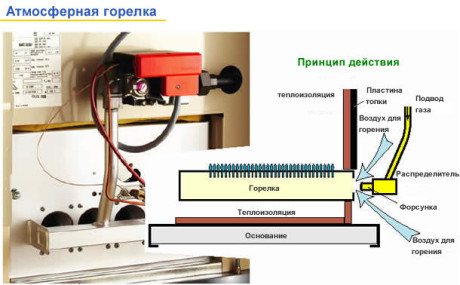

- Method for removing combustion products and supplying oxygen:

- Natural draft boilers. Open firebox, atmospheric burner, vertical chimney.

- Forced draft boilers. Closed firebox, pressurized burner, it is possible to use a horizontal coaxial chimney.

- Electrodependence. Some solid fuel devices do not require a 220 volt connection. They are not very functional, but in systems with natural circulation they provide complete autonomy. Units on other types of fuel, as well as pellet and pyrolysis boilers cannot work if there is no light in the house for some reason. Therefore it is necessary to use a backup generator or battery pack. But electric boilers in such cases will most likely not be able to revive - too much energy needs to be generated.

- The ability to automatically turn on. Gas boilers with piezoelectric ignition start themselves up if there were interruptions in gas or electricity. And, for example, a diesel heat generator will have to be started manually.

- Available operating modes of the burner. They are:

- Single stage (it is either on or off).

- Two-stage (there is a maximum mode, and there is a "light" mode at about 40% power).

- Modulated (performance is smoothly regulated, practically in the entire range). These are the most economical devices.

- Automation and safety. Perhaps the least regulation and control possibilities are provided by simple heat generators that burn solid fuels. Basically, modern boilers have a whole range of technological systems. One of the most popular functions is the programming of work according to the indications of a thermostat or timer. Gas heating devices can be protected against burner damping, heat exchanger overheating, gas or electricity supply interruption. Many heat generators help prevent the coolant from freezing, react to any violations of the chimney and a drop in water pressure.

Boiler with atmospheric burner

Modern boiler control panel

Consequences of electrolysis, direct current action

During the operation of the hydrolysis solution, water decomposes into hydrogen, oxygen, and leads to the formation of air pockets. Prevents fluid from circulating normally within the system.

Some users have found signs of corrosion on aluminum radiators - a consequence of electrochemical exposure.

If cast iron radiators are installed in the heating system, the quality of the coolant will change for the worse.Distilled water removes impurities from the pores of cast iron. The electrode boiler requires the installation of bimetallic structures.

The fluid in the system is under constant current, and grounding is required. The process is complex, not possible on all types of heating systems.

A clamp can be installed on a steel pipe, if the system consists of cast-iron radiators and plastic pipes - the process is almost impossible to solve.

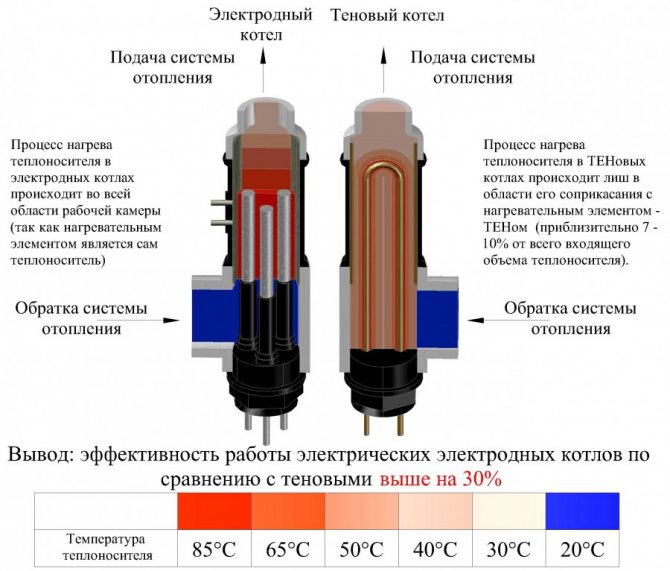

Outstanding efficiency myths

The advertising materials claim that the boiler equipment on the electrodes extracts thermal energy from the void. Indicators - 120-150% of the applied electrical power. But they completely do not pay attention to the laws of physics, heat engineering.

Myth - the conversion of electrical energy by an electrode boiler many times over. We focused on the promotion of heat technology, which operated from a heat pump with a positive COP coefficient.

Do not believe the statement that electrical energy is 100% converted into heat. Losses are inevitable.

How to choose the right boiler

Nowadays, you can buy a gas boiler for heating a private house in any construction supermarket. When choosing a German or Russian unit, it is necessary, first of all, to pay attention to its thermal power. Skilled sales consultants who need to inform the area of the premises intended for heating will help you choose a wall or floor unit.

How to calculate power

Accurate calculation of thermal systems involves taking into account dozens of parameters and is the prerogative of professionals. In order to choose a boiler yourself, you can use a simple formula that is suitable for standard private houses with a ceiling height of up to 3 meters. For this, the value is assumed that for heating 10 m2, 1 kW of the declared power is required.

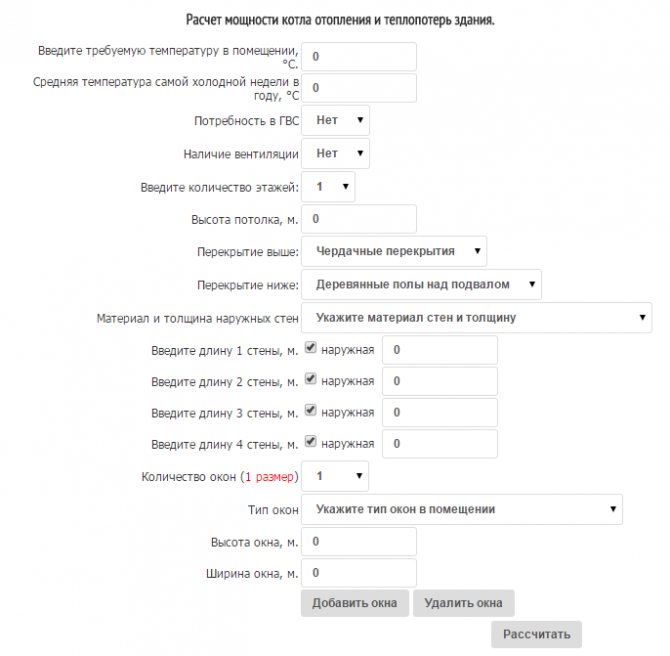

For a more accurate calculation, you can use online calculators, which are special utilities. By entering data on the number of windows, wall thickness and other parameters into the program, you can get the required power of the heating equipment yourself.

There is also a calculation option that takes into account the regional climate coefficient.

Feasibility of use

Used for heating small rooms. Electrode-type equipment has a slight inertia, heating occurs almost instantly, in a short time you can heat a small room.

With its compact size, it can be placed in any part of the heating system.

Electrode boilers are designed for closed-type systems where the displacement is minimized. The device can be used for heating floor heating, radiators at the same time. The process requires careful preparation of the coolant, complex electronic thermal control circuits.

Heating system maintenance on electrode equipment

Electrode boilers are a technical development for heating a summer residence of premises with a small area. A feature that distinguishes it from a device operating on a heating element is the impossibility of breakdown from a voltage drop.

During the operation of the device operating at the limit, a high temperature and pressure are formed inside the case, a circulation of low-quality coolant occurs, the device wears out very quickly. In such conditions, electrodes, insulators wear out, the tightness of the joints will become unusable.

In case of poor-quality heating of the coolant, leakage, urgent equipment repair is required. Before starting work, the device must be de-energized.

Cleaning the appliance

- To carry out maintenance, you need to dismantle the device. Unscrew the screw connection on the flange, pull out the electrode.

- Assess how worn out the electrodes are. Make sure insulators are intact. There are no cracks on the case.If the electrodes are worn out by more than 40%, equipment replacement is required.

- Clean the surface of the electrodes, holders.

- Clean the inside of the case.

- You can assemble the device in the reverse order.

- Degrease surfaces, apply sealant. You will need a high temperature substance.

Repair kit

Gas heat generator for air heating 120 kW

Gas heat generator with a capacity of 120 kW is designed for air heating of industrial and warehouse premises, construction sites, workshops, sports, exhibition and trading halls, agricultural facilities, hangars, greenhouses and other similar premises.

An industrial gas air heater is a heat unit with a recuperative-type heat exchanger, in which, with the simultaneous flow of heat exchanging media, heat from the combustion products to the heated air is transferred through the wall separating them. The heated air is distributed both directly and through special air ducts.

The industrial heat generator for air heating of the greenhouse provides the functionality of the structures in the cold season. When choosing a suitable heating system, the area of the heated room is taken into account. For heating farm industrial greenhouses, a special multi-circuit air heating system is used.

The supply of warm air under the ceiling ensures snow melting during heavy rainfall. The distribution of heat along the upper technological circuit allows you to regulate the temperature regime in the ridge part of the greenhouse, excluding the ingress of cold air into the plant growth zone. The heating on the lower side maintains the set thermal mode.

Advantages of an air gas heat generator:

- Fast heating of the room and the ability to adjust the temperature;

- No risk of drying out plants due to the supply of air to the upper part of the greenhouse;

- The supplied warm air is distributed evenly over the entire area of the greenhouse;

- High efficiency of thermal drives for greenhouses and other equipment.

- Air heating systems for greenhouses create optimal conditions for growing various crops.

- The ability to work on three types of fuel: main gas, imported liquefied gas, diesel fuel.

Heat generator cost:

1. Heat generator 120 kW with a diesel burner - 277 657 rubles.

2. Heat generator 120 kW with a gas burner + a set for liquefied gas - 330,241 rubles.

3. Heat generator 120 kW with a gas burner (mains gas) - 328,318 rubles.

4. Heat generator 120 kW with oil burner - 573 852 rubles.

5. Heat generator 120 kW with a 2-stage diesel burner - 303,565 rubles.

6. Heat generator 120 kW with a 2-stage gas burner (mains gas) - 364,099 rubles.

7. Heat generator 120 kW with a combined dual-fuel burner (main gas / diesel fuel) - 492 342 rubles.

Testimonials

“I retired, took up the dacha chores, it is cool in the spring and autumn periods. I wondered how to heat the dacha. I recently purchased an electrode boiler. My house is insulated, protected from wind blowing, I arranged the option. The boiler does not work all the time, everything is in order. "

Nadezhda, Stary Oskol.

“My wife and I bought a device specifically for our dacha. Guys, the boiler is working well. I have not tried it in large rooms. Can be installed in a room without bothering to allocate a separate room for a boiler room. I advise. "

Vladimir, Krasnodar.