Types of pressed fuel briquettes

Heating units operating on pressed briquettes are easy to maintain and do not need equipment for storing fuel and its automatic supply. Briquettes can be used to replace other types of solid fuel without upgrading the boiler.

The use of briquettes obtained by the pressing method as fuel greatly simplifies the supply of fuel to the furnace, there is no dirt and dust, and too frequent removal of slag is not required.

The main types of such fuel:

- Wood fuel briquettes are obtained by pressing the crushed dry wood waste: chips, bark, sawdust. They have a cylindrical or rectangular shape, weight - 0.5-2.0 kg. Recently, a new technology for the production of this pressed fuel makes it possible to obtain short cylinders - washers that can be loaded into the boiler automatically.

- The raw material for the manufacture of coal briquettes is small coal, which is not suitable for combustion in the furnace due to the fact that it spills out through the grate. To obtain durable products in the form of a cube or cylinder, resin, protein, molasses, soda and other binding components are added to the coal fines.

- Fuel briquettes can be pressed from crop waste: flax, rape and grain straw, sunflower seed husks, chopped corn stalks.

Among solid fuel heating units that use, among other types of fuel, pressed briquettes, Dacon units are very popular with consumers.

The principle of operation of pellet boilers

In fact, this is a solid fuel unit in which pellets are used as fuel. These are granules made from wood waste (bark, sawdust, shavings), peat or straw. They are cylindrical in shape. High quality environmentally friendly fuel does not pollute the atmosphere and is harmless to humans.

Pellet boilers differ from conventional solid fuel units in that the fuel supply process can be fully automated. Thanks to this, the device can work with minimal human intervention.

Pellet heating boilers consist of a bunker for storing and supplying fuel, a burner and an automation system. Screws are installed to feed pellets into the pre-furnace. From there, the pellets are transported via an external screw to the burner nozzle. Here they are automatically ignited, completely burned out.

Important! The heat transfer of one kilogram of pellets is equivalent to the combustion of 0.5 liters of diesel fuel. This unit is equal to 5 kWh.

Compared to wood, pellets burn more efficiently and provide more heat energy. In this case, pellets cannot ignite spontaneously. Ash can only be removed once a week. The amount of carbon dioxide that the boiler emits into the atmosphere is much lower, which is important to protect against the greenhouse effect.

How much does peat weigh?

As mentioned above, peat of different maturity levels has a different degree of water saturation, and, accordingly, a different volumetric weight. This can also apply to the product being sold. The table shows the average theoretical data on the weight of peat, depending on the level of moisture.

Specific gravity and density of peat in 1m3. Volumetric weight of peat in the table

| Name | The physical state | Density (g / cm3) | Specific gravity (kg / m3) | Bulk (bulk) weight (t / m3) |

| Wet peat | (water-saturated substance) | 1–1,2 | 1000–1200 | 1–1,2 |

| Peat dry | solid | 0,2–0,4 | 200–400 | 0,2–0,4 |

| Moist peat | solid | 0,6–0,8 | 600–800 | 0,6–0,8 |

The bulk weight of peat also depends on the degree of decomposition and belonging to the group, so at the same moisture content of up to 85%, high-moor peats are heavier than low-lying peats, but if the moisture content is more than 85%, the weight of low-lying peat will be higher.

List of the best models of domestic pellet boilers

Despite the great popularity of pellets, the choice of equipment is not so wide:

- Valday 22M. Russia. This is a single-circuit pellet heating boiler. 22 kW is the maximum, 4 kW is the minimum. The equipment operates on pellets made of peat, wood, and can be heated with wood. The moisture content of raw materials is up to 35%. When laying firewood, additional grates are installed. Ash content 90%, built-in remote access control unit, overheating protection. Hopper loading up to 160 kg. Consumption 6.3 kg / h. The heat exchanger is steel; the unit operates on one load up to 26 hours. Price from 1960 $ (13800 rubles).

- Kupper PRO. Teplodar. Unit with one circuit and automatic burner. Power 4-22 kW. Heating with sawdust is acceptable, suitable for houses with an area of 20 m2 or more. There is a possibility of reconfiguring for gas supply, in the basic configuration there is a 6 kW heating element. The universal device also works on electricity - this is convenient for off-season periods. The automatic control panel minimizes user involvement. At the first start, it is necessary to set the operating modes, then the equipment maintains the specified parameters. Bunker with a volume of 120 kg, consumption up to 9 kg / h, operating period on one load up to 14 hours. Efficiency 95%. Price from $ 1,330 (94,000 rubles).

- Stropuva P20. The Lithuanian manufacturer offers pellet aggregates without auger for feeding raw materials and an auto-ignition system. To start the device, you need to turn on the gas burner, the energy carrier settles into the chamber under the influence of gravity. The power is 20 kW, the regularity of ash removal is 1 time in 4-5 weeks. Efficiency up to 90%, steel heat exchanger, price from $ 2,200 (160,000 rubles). The device has 4 built-in temperature sensors - this allows you to fine-tune the modes and control the operation of the burner. There is a forced blower fan - it is more convenient to change the intensity of heating the coolant. The relatively small volume of the bunker compartment (90 kg), and low fuel consumption within 4 kg / h are advantages. On one load, the device works up to 23 hours.

A wide range of Korean factories and Belarusian manufacturers are on sale. Prices vary depending on the automatic filling and the type of device - it all depends on the capabilities and needs of the user.

How to properly heat the boiler with wood briquettes

The economic efficiency of wood briquettes is observed only if the boiler is properly loaded and fired. There are simple rules to help increase the operating time from one bookmark and the amount of accumulated heat in the heating system:

- Initially, a small amount of wood or sawdust is ignited.

- After burning out, briquettes are placed in the firebox.

- If it is necessary to quickly warm up the room, the pressed boards are laid so that there is a sufficient gap between them. The briquettes will burn out faster, but will give off more heat. For long-term burning, the plates are laid with a minimum gap between them. This arrangement is one of the features of burning wood briquettes in pyrolysis boilers. To prevent the appearance of an open flame, it is required to lay the slabs with a minimum gap between them.

The pressed fuel contains a minimum amount of sulfur, a non-combustible residue, therefore, there is no negative impact on human health. If everything is done correctly, the bars burn with an even flame without sparks, crackling, etc.

Can briquettes be used for a wood-burning boiler

Fuel briquettes burn, emitting small amounts of sulfur and soot. Unlike firewood, the same temperature is maintained during the entire combustion period, which has a beneficial effect on the condition of the heat exchanger.

Briquettes are suitable for the following types of boilers:

- Classic units.

- Pyrolysis models.

- Boilers with automatic fuel supply, provided that a "washer" is used.

Almost all solid fuel equipment is capable of operating using wood briquettes. It is optimal to use those models, the technical documentation of which clearly indicates the possibility of using pressed fuel.

Rating of the best pellet boilers for home

Looking through the options for boilers, you should pay attention to equipment that has already proven itself from the best side:

- Stropuva P20. Lithuania. There is no auger for feeding fuel, the raw material is fed into the chamber by gravity. There is no auto ignition system, you need to turn on the gas burner. Installed 4 temperature sensors for fine tuning, control of the burner. The air is blown by a fan, due to which the power of the equipment can be changed. Fuel consumption 4 kg / h, bunker volume 90 kg. Continuity of work at maximum power 22.5 hours. With a power of 20 kW, the boiler heats up to 200 m2. Ash removal once a month, efficiency 90%, steel heat exchanger, 1 circuit, price $ 2,200 (158,000 rubles).

- Kupper PRO. Russia. Teplodar. A single-circuit boiler with an automatic pellet burner has a large power range of 4-22 kW, suitable for heating houses from 20 m2. The unit can be reconfigured for gas. The basic equipment is supplemented with a 6 kW heating element, therefore the universal boiler can also operate on electricity. There is a control panel, the automation controls the operation from the moment it starts, you just need to set the operating mode. The volume of the bunker is 120 kg, the consumption is 9 kg / h, at high power the boiler works up to 13.3 hours at one load of the bunker. Efficiency 95%, heat exchanger made of steel, heating with sawdust, wood is possible. The price is $ 1320 (92,400 rubles).

- Valday 22M2. Russia. Obshchemash. Single-circuit boiler with a maximum power of 22 kW, a minimum of 4 kW. It can be heated with wood pellets, husks, peat, wood with a moisture content of up to 35%. If you heat with wood, you will need additional grates. Efficiency when using pellets with a low ash content of 90%, on wood no more than 75%. There is a control unit with remote access. The boiler is equipped with overheating protection. The volume of the hopper is 160 kg, at maximum power and full load, the equipment can work up to 25.4 hours. Fuel consumption 6,3 kg / h. The heat exchanger is made of steel, the price is 1960 $ (137,000 rubles).

In addition to the listed models, there are good options for equipment from Belarusian and Korean manufacturers. The choice depends on the capabilities and requirements of the buyer.

Peat briquettes are biofuel

Manufacturers of peat briquettes claim that this is a biologically safe fuel, and this is one of the main advantages for many buyers.

This statement is based on the fact that such products are produced on modern equipment, and for this, the latest technologies are used. The technological process itself consists in the fact that when the press is operating under high pressure, moisture is displaced from the workpieces. Moreover, peat is preliminarily dried. As a result, buyers are offered light bars that look like large dark tablets. Thus, the production does not use additional chemicals or any other substances that could spoil the peat and its natural environmentally friendly qualities.

Advantages of solid fuel boilers with a water circuit

The coolant is heated only when the fuel is burning. Pyrolysis boilers belong to long-term combustion systems. Savings directly depend on the quality of the equipment and the ability to control the water temperature.

- Environmentally friendly boilers with minimal operator requirements.

- Combustion efficiency. 90% of the location of the fuel tank.

- Easy maintenance and cleaning even during operation.

- Comfortable work without frequent attachment.

A typical example is a steel exchange boiler system. These are most of the solid fuel boilers, as well as some gas boilers. These boilers require maintaining the temperature of the heat exchanger, which ensures the temperature of the returned boiler water. When the boiler is operated at lower temperatures, the life of the boiler exhaust gas is reduced.

The design features of the water circuit ensure maximum heat transfer during equipment operation. Solid fuel boilers for long burning, reviews of which can be found on the Internet, have the following advantages:

This phenomenon is often referred to as low temperature corrosion. In the case of solid fuel boilers, tar production and complete boiler discharge increase, which reduces the boiler efficiency. Pyrolysis boilers do not pyrolyze optimally. This leads to further reductions. Typically, users know that the cauldron is not “toasting” properly. The regulator's algorithm ensures that the boiler outlet is cleared so that the temperature drops below the alarm limit, but at the same time does not cause the boiler to break through the cold water.

Sudden changes in boiler temperature will damage the boiler structure and the boiler will operate at full capacity when low boiler output is required. The following system is commonly used to meet these requirements. The heating water temperature is calculated according to the behavior of the room thermostat, and it takes several hours to become familiar with the heating system to which the controller algorithm is applied. Solid fuel boilers provide the best economy at rated output.

- High reliability.

- Environmental friendliness.

- Profitability.

- Duration of operation.

- Attractive design.

- Simple maintenance.

Waste resulting from the operation of the equipment is an excellent fertilizer for the suburban area. If necessary, the boiler can be converted for gas or diesel fuel. A solid fuel heating system with a water circuit ensures an even distribution of heat throughout the house.

The "water jacket" that some boilers are equipped with is more efficient in terms of heat transfer. This is a complex type of water boiler, in which all walls are double. In the formed space (3-5 cm), a coolant circulates, which makes it possible for it to warm up very quickly.

A water circuit made of steel pipes with a diameter of 5-6 cm is considered to be no less effective than the previous version. A tubular profile bent by a coil runs at the top and along the walls of the firebox, water slowly circulates inside it and provides the premises with heat. The advantage of such models is that they are much easier to repair.

Benefits of heating with peat briquettes

As buyers who have already used this fuel to heat their homes have noticed, with the correct air supply, such briquettes maintain heat for about ten hours. This is very convenient because at night there will be no need to throw in additional raw materials. It is estimated that one ton of peat briquettes gives off the same amount of heat as four cubic meters of good quality wood.

You can also emphasize a number of other advantages that show good performance, thereby giving this type of fuel to conquer new sales markets.

- Peat briquettes can be used to heat all types of oven equipment.

- After incineration, only one percent of the ash from the total mass of the raw material remains from the peat briquette.

- When heating, little soot and smoke are emitted, so the chimney is not susceptible to clogging.

- Heat transfer during heating comes out from 5500 to 5700 kcal / kg.

- Affordable price.

- This fuel is easy to transport.

- Peat blocks do not lose their combustible qualities for several years.

- Natural product with minimal impurities.

Gardeners and gardeners have found another use for the waste that remains after burning peat briquettes. It turned out that the ash left over from the heating process is a good phosphorus and lime fertilizer.

Location of solid fuel boiler plants

It is advisable to install solid fuel boiler houses on coal or peat deposits, as well as on the territory of various woodworking enterprises. In this case, production wastes will act as fuel for the installation. The use of solid fuel plants will also be relevant in those territories where there are no power lines and gas pipelines.

The fuel supply mode can be either automatic or manual. It is important to note that automated fuel supply for low-power block-type solid fuel boiler houses is not advisable, since automation devices are not cheap, and their costs will not pay off in a short time. In such boiler houses, the fuel supply and clean furnaces are supposed to be done manually, therefore, it will not be possible to completely automate the processes. For its full-fledged work, the constant presence of service personnel is required. It is necessary to timely supply fuel to storage areas, which occupy rather large areas.

Classification

Peats are classified in relation to the composition of phytomass (trees, grasses, mosses), trophicity (the amount of nutrients contained in plants) into three categories:

- Top (or high) peat. Has high acidity and low degree of decomposition. Differs in moisture capacity up to 1200%, is characterized by high ash content and calorific value.

- Horse light (or transitional) peat. Refers to the upper layer of the deposit, the degree of decomposition of plant residues is about 15%. The weight of peat 1 m3 in such a layer is quite small, and amounts to 150 - 250 kg. In its natural state, it has a large gas and water absorption capacity (1 kg of such peat can absorb up to 10 liters of water).

- Low-lying peat (or bottom). This type includes ancient deposits, up to 30 thousand years old. Substance with a fine, light and moist structure. The degree of decomposition of plant residues is more than 15%, it has a high humus content, this is "mature" peat. The weight of a cubic meter is 350 kg / m3. The medium is slightly acidic, with a high content of nitrogen, phosphorus, potassium and other organic substances useful for garden plants.

- Fibrous peat is a special type of peat containing plants with a pronounced fibrous structure. Such peat is not sifted and molded like other types for further use, but only crushed into small lumps.

The best household pellet boilers

The most popular are the following models of pellet boilers:

- Kiturami units are manufactured in South Korea. The positive qualities of this equipment are called high efficiency, reaching 94%, a modified hopper and electronic burner control. The heater is protected against overheating and is fire resistant. The set includes a remote control. The double-circuit boiler is guaranteed for 2 years. Specifications:

- weight - 310 kg;

- power - 24 kW;

- bunker volume - 160 kg;

- fuel consumption - 5.5 kg per hour;

- maximum heated area - 300 m²;

- price - $ 3230 (210 thousand rubles).

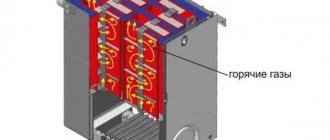

- Czech pellet heaters OPOP BIOPEL are made of heat-resistant steel. The appliance is suitable for domestic use or industrial heating. Vertical heat exchangers increase efficiency up to 92%. There is a possibility of remote control of equipment operation. The device has a system for ash removal and self-cleaning of the burner and heat exchanger. The heater power is within the range of 10-200 kW.

- Domestic-made Zota boilers are available with different capacities. The most popular unit has an automatic pellet ignition.The device comes with temperature sensors for indoor and outdoor installation. There is a possibility of remote adjustment of the equipment operation. The Zota Pellet 15A model is a combined unit that can operate on other types of fuel. Specifications:

- weight - 318 kg;

- power - 15 kW;

- fuel tank capacity - 293 liters;

- fuel consumption - 3-4 kg per hour;

- heated area - 150 squares.

- The Russian plant Teplodar produces different types of boilers. The most reasonable price for Kupper pellet units. Despite this, the heater has automatic ignition and automatic pellet feeding. These devices have a built-in heating element, which can work together with the burner or separately from it.

Also, the Svetlobor heaters are popular among the domestic consumer. The power of the units is in the range of 16-170 kW. By the degree of automation, the device is not inferior to its foreign counterparts. It has the function of self-cleaning, auto-ignition and automatic fuel supply to the compartment. A controller with a touch screen is installed to control the device. The basic configuration includes a weather-compensated control system.

Birch fuel briquettes type "RUF"

No bark or other additives. 100% environmentally friendly wood (fine birch dust + plywood production waste).

Depending on the delivery batch, there may be no RUF inscription on the briquettes.

| Options: | |

| Briquette size (WxDxH), mm: | 150x100x60 (brick-shaped) |

| Pallet size (WxDxH), mm: | 800x1200x1360 (96 packs) |

| Composition: | birch dust + veneer |

| Color: | white |

| Calorific value: | n / a |

| Humidity: | up to 8-10% |

| Density: | 830 kg / m3 |

| Ash content: | up to 0.7% |

| Packaging: | polyethylene |

| Weight of 1 package: | 10 kg (+/- 5%). in 1 ton - 100 packages |

| Packaged: | 12 briquettes |

Suitable for all types of stoves, ideal for solid fuel boilers, for home heating, for baths and saunas.

PRICES INFORMATION

Boiler pellet production

Do not confuse pellets and briquettes for the boiler. The former are small cylindrical granules, while the latter are larger and are produced in the form of bricks.

Industrial pellets are made from the following raw materials:

- straw from grain processing;

- wood waste (wood chips, sawdust);

- husk of buckwheat, sunflower.

The sequence for making pellets is as follows:

- First, the raw material is crushed and ground in industrial crushers.

- The mixture is dried to a moisture content of no more than 10%. All dryers work on the principle of heat energy release.

- In order for the granules to form better, they are treated with steam. Moreover, the moisture content of raw materials increases slightly.

- After that, the prepared raw material is pressed into granules on a special press. Pellets are molded under a pressure of 300 bar. A cylindrical die press is usually used.

- The finished product is allowed to cool and packaged.

Choosing a wood briquette boiler

The choice of a long-burning boiler on pressed wood briquettes can be difficult due to the large range of products offered. The domestic market offers models made in Russia, European countries and neighboring countries.

To facilitate the selection of equipment, all offered boilers for burning briquettes can be divided among themselves into several categories, according to the territorial principle - the country of manufacture:

- Germany - Bosch Solid.

- Czech Republic - ATMOS, Dakon (owned by Bosch), Wattek.

- Russia - Nibe Viking, Zharstal Dobrynya, Dragon.

- Turkey - Radijator.

- Poland - Heiztechnik.

- Italy - Ferroli.

The proposed list contains boilers for burning briquettes using the principle of pyrolysis combustion. All models enjoy constant popularity, which is clearly shown by the sales statistics.

Control systems

Solid fuel systems with a water circuit are equipped with a control and monitoring unit, so that it is possible in the water circuit. The thermostat is the simplest device that can be found on such equipment.

When the water temperature reaches the optimum, the blower automatically closes and air stops flowing into the firebox. According to the laws of physics, combustion decreases at this moment. When the water cools down, everything happens in the reverse order.

More advanced solid fuel boilers are equipped with accurate temperature sensors, pumps, which are needed for forced air supply. This ventilation provides top airflow, so the fuel is burned out with virtually no residue. But such equipment requires a power supply.

The circulation pump will keep the solid fuel boiler from defrosting in winter. That is, if a non-pumped operating system is left unattended for several days, the fuel will burn out completely, the water will stop circulating and freeze. In such a situation, the pipes will simply burst. But in the presence of a circulation pump, such a nuisance will not happen. Moving slowly through the pipes, even cold water does not freeze in winter.

The prices of long-burning solid fuel boilers with a hot water circuit are higher than those of conventional stoves. But this cost is quite justified. The boiler water can be used for a wide variety of needs.

Characteristics of modern solid fuel systems:

Features of briquette boilers

The briquettes are loaded into a hopper, from where they are gradually directed by a screw in a special burner. During the operation of the device, air is blown onto the burner, which contributes to the maximum complete transfer of heat. Depending on the type of burner, a flare or volumetric boiler on fuel briquettes is emitted.

Sources of

- https://kotel-otoplenija.ru/tverdotoplivnyj-kotel-na-pressovannyh-toplivnyh-briketah

- https://naruservice.com/articles/udelnyj-ves-torfa

- https://avtonomnoeteplo.ru/otopitelnye_kotly/227-otopitelnye-kotly-dlya-doma-na-tverdom-toplive.html

- https://kotel.guru/kotly/tverdotoplivnye/torfyanye-brikety-dlya-otopleniya-i-cena-na-etot-produkt.html

- https://lentoplivo.ru/brikety

- https://tt-kotly.ru/na-briketah/

[collapse]

Features of pyrolysis boilers

As mentioned above, pyrolysis boilers have two combustion chambers. In the first one burns directly the fuel, and in the other - the gases produced by this fuel. If you put raw firewood in the firebox, which is quite possible in winter, they begin to emit steam.

The second chamber eliminates the negative impact on the combustion process. Hot gas enters it and neutralizes moisture. On its way, the gas is saturated with air, which contributes to further combustion. A grate with firewood was used to separate the chambers. For the operation of the pyrolysis system, forced blowing is needed, it is provided by a smoke exhauster.

How does the pyrolysis system work:

- The fuel is placed on the grate.

- Fire up the boiler.

- Close the firebox damper.

- The smoke exhauster is started.

- Combustion creates a high temperature in the chamber, resulting in the formation of volatile combustion products in the form of nitrogen and hydrogen.

- These formations enter the second chamber and mix with the air stream.

- Complete combustion takes place, and the released heat is returned to the first chamber.

This process provides a very high temperature, due to which the waste of the burnt wood decomposes, and the fuel is used to the maximum. The heat generated by the burnt waste is used twice.

Along with the numerous advantages, pyrolysis boilers also have disadvantages;

- High price.

- Dependence on electricity.

- The power declared by the manufacturer does not always correspond to reality.

- If you use the equipment at half strength, there is a high probability of clogging the gas duct with tar.

The high cost of a pyrolysis boiler pays off over time, thanks to fuel savings For the operation of almost all models of pyrolysis boilers, the availability of electricity is required, which limits the possibility of installing such equipment in a country house where there is no electricity

Benefits of using solid fuel boiler plants

Modular solid fuel boiler houses have a number of advantages over other types of equipment.

- general availability of fuel;

- acceptable fuel cost;

- simplicity of equipment manufacturing;

- low operating and amortization costs;

- significant automation of a modular solid fuel boiler house;

- reliability and continuity of equipment.Boiler houses are capable of functioning in a harsh and difficult climate. The main requirement is the timely supply of fuel;

- rapid commissioning of a solid fuel block boiler house due to production debugging of the main units;

- creation of a project in a short time, since there is no need for its approval with supervisory and regulatory authorities;

- ensuring the autonomous operation of the equipment regardless of the functioning of the main sources of energy resources.

Modern boiler plants are not at all demanding in terms of maintenance. They can be used as a temporary or permanent source of heat energy to provide residential, administrative, and industrial structures and buildings.

Fast cost calculation

- We will advise

- We will offer options

- Let's calculate the cost

Solid fuel boiler room

Home> Boiler room> Solid fuel boiler room

A solid fuel boiler room is a good option for a small private house, or a garden house in SNT, it does not take up much space, it has the ability to turn off during the absence of the owner.

The choice in favor of a solid fuel boiler house is most often made in the event of a lack of gas, insufficient electricity supply, or due to environmental considerations (an unpleasant odor may occur during storage and combustion of a diesel engine).

Basic set of equipment for a solid fuel boiler room

To mount a solid fuel boiler room, you need to purchase a boiler, chimney, heating radiators, coolant, pipes, and a circulation pump.

Boiler selection

Solid fuel boilers differ

1.Fuel type used:

- Conventional, working on wood, peat, coal and require fuel loading every 2-4 hours

- Long-burning boilers with material loading up to 1 time per day

2. The material from which they are made

- cast iron;

- made of heat-resistant steel

3. The presence of an electric heating element

With built-in electric heating elements, they are most often used in boilers made of heat-resistant steel

4. Availability of replaceable burners

Replaceable burners provide the ability to work on different types of fuel

Optional equipment

If there is a need for the simultaneous installation of hot water supply from a solid fuel boiler, it is installed indirect heating boiler.

Collector purchased for use in the heating system of a 2-3-storey building to set the optimal temperature on each floor or separately in each room.

An uninterruptible power supply unit is not required for a top-filling system that does not use a circulating pump at the same time. If a circulation pump is used in the heating system, then uninterruptible power supply required, because the probability of a power outage during the operation of the boiler, which can lead to overheating and rupture of the boiler water jacket.

In some cases, it is possible to install in the heating system heat accumulator... This is a barrel with a volume of up to 200 liters, filled with a coolant. The principle of operation of such a device is as follows. A solid fuel boiler works at full load for a short time to heat the coolant in the heat accumulator, and the house is heated by taking heat from this barrel, which allows the boiler to be fired once a day.

Solid fuel boiler house price

The cost of a mounted solid fuel boiler house is determined individually and depends on the amount of materials and the complexity of the work.

For example:

The area of the house is about 100 m.

Two-pipe heating system with one circulation pump

Solid fuel boiler made of heat-resistant fabric with an electric heating element inside

Pipes made of polypropylene

Sectional aluminum radiators

————————————————

The cost of materials is 105,000 rubles.

The cost of the work is 55,000 rubles.

Attention! The cost of materials may vary depending on the exchange rate at the date of purchase, and the cost of work depending on the complexity of execution.

| Order form |

Main news

03.05.2020

Big discounts for the installation of water supply! The term of the promotion is limited!

more details

01.05.2020

Turnkey heating installation for 65,000 rubles. Details here!

more details

01.05.2020

Only until 31.05.2020 10% discount on heating installation!

more details