Specifications

Gas boilers Zhitomir are manufactured in Zhitomir (Ukraine).

They are produced in two versions:

- Floor standing - installed on the floor or on special stands;

- Wall-mounted - placed on the wall using special hangers and brackets.

Both types of boilers, according to their purpose and design, can be:

- single-circuit, intended only for space heating;

- double-circuit, working for heating and hot water supply at home.

The table shows the main characteristics of single-circuit boilers "Zhitomir" floor-standing.

Indicators Numerical values

| Thermal power for the heating system, kW | 7…80 |

| Heated building area, sq. m | 70…800 |

| Maximum value of the coolant temperature, ° С | 90 |

| Boiler heat exchanger efficiency | 0,92 |

| Minimum value of gas pressure, Pa | 635 |

| Internal volume of the boiler, l | 14…70 |

| Maximum allowable pressure of the heating medium in the heating system, bar | no more than 2 |

| Average hourly consumption of natural gas, m3 / h | 0,76…8,72 |

| For double-circuit boilers only | |

| Hot water productivity, l / h | 175…1400 |

| Maximum water heating interval, ° С | 35 |

| Efficiency of the water heating circuit | 0,87 |

| Possible additional option | circulation pump |

The principle of operation of the floor-standing gas unit Zhitomir

Wall-hung boilers have a range of indicators shown in the table.

Indicators Numerical values

| Thermal power for the heating system, kW | 5…15 |

| Heated building area, sq. m | 50…150 |

| Maximum value of the coolant temperature, ° С | 90 |

| Boiler heat exchanger efficiency | 0,90 |

| Minimum value of gas pressure, Pa | 635 |

| Internal volume of the boiler, l | 5…17,5 |

| Maximum allowable pressure of the heating medium in the heating system, bar | no more than 0.7 |

| Average hourly consumption of natural gas, m3 / h | 0,56…1,67 |

| For double-circuit boilers only | |

| Hot water productivity, l / h | 160…345 |

| Maximum water heating interval, ° С | 35 |

| Efficiency of the water heating circuit | 0,86 |

| Possible additional option | circulation pump |

The information provided indicates that Zhytomyr boilers are designed for operation with gas supply at low pressure. This distinguishes these devices from the rest. There is also a drawback. The pressure of the heating medium in the heating system is limited to 2 bar for floor-standing boilers, and 0.7 bar for wall-mounted boilers.

Similar imported heat generators can be operated at pressures up to 3 bar. This allows them to be used for heating needs of three and more storey buildings.

The lineup

The price range largely characterizes the model range of Zhitomir gas boilers. The name of the boilers contains alphanumeric designations. The letters indicate the main features of the boilers. The numbers give a characteristic of the heat output.

Floor standing boilers

Floor standing boilers have a wider range of models. Their price depends on the power of the boiler. So, the most powerful boiler ZHITOMIR-3 KS-G-080SN has a thermal power of 80 kW. The floor-standing gas boiler is capable of heating a building with a heated area of up to 800 sq.m.

Floor-standing gas unit Zhytomyr

The presence of an additional letter "B" in the name, for example, ZHITOMIR-3 KS-GV-080SN, indicates a double-circuit gas boiler "Atem Zhitomir-3", which can not only heat the room, but also heat water.

The amount of hot water produced is proportional to the heat output of the boiler. This dependence is due to the presence of a copper coil inside the heat exchanger. For boilers with a higher heat transfer value, the surface of the coils is also larger. This explains the high performance for hot water.

Wall mounted boilers

Wall-hung boilers have a smaller size range. They are less often placed inside private houses. The main purpose of wall-mounted boilers ATEM ZHITOMIR is heating apartments in multi-storey buildings. Wall-hung boilers are much lighter in weight. In them, the heat exchanger area is lower. The limiting area of such devices allows heating up to 150 square meters of housing space.

Wall gas boiler Zhitomir

Wall-mounted boilers have a peculiarity - they are connected to coaxial chimneys that go through the wall.

Rules for filling the system with water before turning on the gas boiler

Before igniting the gas boiler and turning on the heating system, first it is filled with cold coolant, which, after heating, will circulate through pipes and radiators. During the first launch, everything is carefully checked so that the work in the future is uninterrupted, and the equipment does not require repair.

There is a special valve in the body of the unit, located near the branch pipe, for supplying the coolant to the system. During the filling process, the pressure in the system is monitored, thanks to the presence of sensors and manometers. They are already installed in modern boilers, and you do not need to purchase them additionally. When the device is filled with water, a mark rises on the sensor When it reaches the 1.5-2 atmosphere mark, the water supply is shut off and thus the filling is completed.

These pressure parameters can be changed, since they depend on the manufacturer's requirements for the operating pressure in the heating system. But the filling with cold water does not finally end there, since recharge will be required after the structure has been freed from air jams.

Removing air pockets before igniting the gas boiler

Before igniting the gas boiler, you need to fill the heating structure with cold liquid heat carrier. But filling with water alone is not enough. It will either not work, or the degree of heating of the room will be insufficient. A full-fledged first start is impossible without bleeding the air accumulated in the system. Often, modern gas boilers have a special system that automatically releases air when filled. But often its effectiveness is insufficient: you will still need to manually reset air jams. Only then can the launch be carried out.

It is necessary to remove air plugs before turning on the gas boiler not only from the heating unit, circulation pump, but also from all heating radiators. The process should start with batteries - for this, as mentioned above, they are equipped with Mayevsky cranes. They are opened by substituting a container from below. There will be a slight whistle at first, indicating that air is gradually escaping from the system. After removing the plugs, water begins to flow. Then the taps are closed. A similar procedure should be done with each of the radiators.

Switching on the boiler

- The gas boiler is plugged into an outlet.

- The switch should be set to zero.

- The gas supply turns on (the valve on the gas pipe opens).

Further steps may differ for different models of gas boilers.

For example, the switch for Aton or Danko boilers must be set to the "asterisk" icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located next to it.

The unit will respond with a characteristic click and hum. Then the regulator is released and the required power is set.

To turn on the Baksi boiler, you also need to turn on the gas, plug in the plug and press the "Start" button. Operation sound will appear. The device needs to be given a little time, and it will automatically ignite the flame. After that, you need to press the power button again and thus connect the heating circuit (the corresponding icon will appear on the display).In conclusion, using the buttons, the desired temperature is set.

Buderus brand heaters are characterized by high reliability. Gas boiler Buderus - a brief overview of popular models and their cost.

We will consider the types of generators for gas boilers here.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vybrat-dlya-chastnogo-doma.html discusses the main criteria for choosing heating equipment.

Feedback on the operation of boilers

As you might guess, the overwhelming majority of reviews are positive. When purchasing a heat source of a budgetary price category, the owners clearly understand the goal - to provide reliable heating of the home with a minimum investment. Here are a number of statements from real users.

Azalea, Nikolaev Ukraine

We moved to a private house 8 years ago and immediately started to repair the heating. The old boiler, left over from the former owners, was replaced with "Zhitomir-3". What I would like to note: the device functions without interruptions, the burner does not extinguish in strong winds. Every year we do flushing and cleaning, there are no problems in operation. We are satisfied with the boiler.

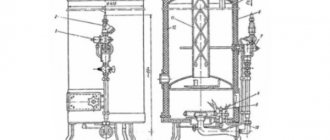

Layout of the universal apparatus "Zhitomir-10" with independent heating of the coolant and water

Alexander, Krasnodar, RF

I use a 25 kW Atem double-circuit boiler, floor-standing version. Fuel - main gas. Automation and heating works on a solid five, the DHW circuit is useless. To wash properly, you need to set the regulator to 6-7, the batteries are unbearable to fry.

Nikolay, Republic of Belarus

Since the heating system of the house is gravitational, I picked up a corresponding 16 kW Zhitomir-3 boiler to replace the old Lemax. At startup, I encountered a problem - the uninsulated chimney began to "cry" with condensate, the gases of the old unit warmed up more and this effect did not occur. 6 heating seasons have passed since the installation, the malfunction happened only once - the igniter went out. The gasman advised me on the phone to wipe the traction sensor contacts with alcohol, that was the end of the issue.

Larisa, Perm, RF

The Zhitomir hot water boiler has been operating in our house for the fifth year, no serious shortcomings have been found. The unit is simple, reliable and unpretentious; there is no need to put it on service in a service organization. We have no way to install an open expansion tank, so we made a closed system. Until the gas pipeline was brought up, the house of 80 squares was heated from propane cylinders. True, I had to hire a foreman to convert the boiler to liquefied gas.

Design features

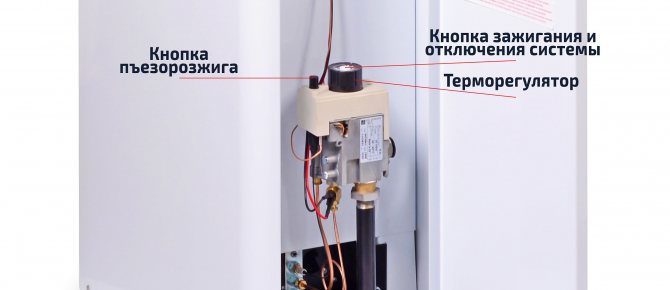

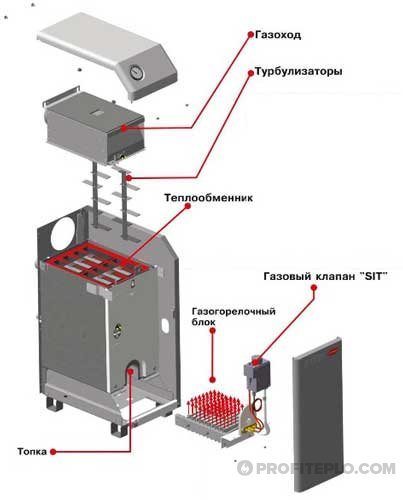

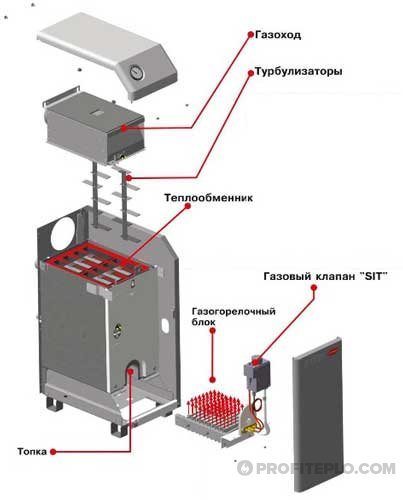

The main elements of the Zhytomyr boiler are:

- the case in which the main components and equipment are installed;

- gas burner block located in the firebox. Here the combustion of gas and the release of heat flow occurs;

- recuperative heat exchanger, in which heat exchange takes place between the combustion products and the coolant;

- flue gas system, its duties include the removal of combustion products outside the boiler and discharge into the chimney.

Boiler device Zhitomir

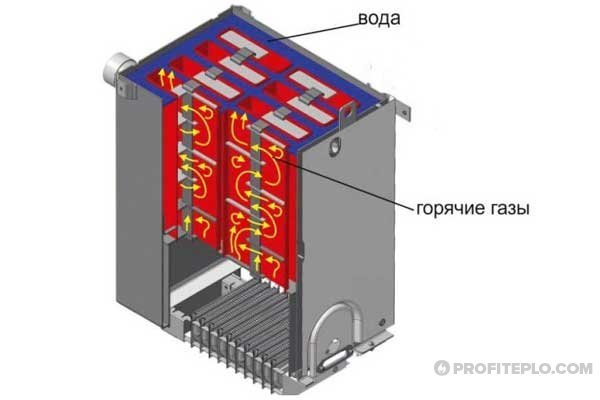

In order to increase the efficiency of heat exchange, the gas boiler Atem Zhitomir 3 has the following design features.

- Heat exchanger pipes made of heat-resistant steel have a rectangular cross-section, such a device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchanger up to 92%;

- To increase the area of interaction between the combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the underside of the turbolizers, keeping the pipe walls clean.To remove soot, periodically remove the turbolators and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhytomyr have a coil of copper pipelines around the heat exchange heating pipes.

Double-circuit gas unit Zhytomyr Atem

The POLIDORO gas burner device is used to organize a stable gas combustion process. Its distinguishing feature is a single stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows maintaining the combustion mode with different gas supply to the furnace. Even at low gas flow rates, the heating of the edges is sufficient to maintain a stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners, depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. With a decrease in the ambient temperature, the temperature of the coolant increases.

How much does a gas boiler Zhytomyr cost?

If you look at the reviews on the Zhitomir gas boiler, it becomes obvious that many users are attracted by the optimal combination of quality and cost. At the moment, the price of the Zhytomyr boiler is in the range from 12,000 to 45,000 rubles. And the higher the cost, the higher the productivity, which means that the equipment is capable of heating a large area. The product of this company is ideal for heating private multi-storey residential premises. If you need to heat a small house, then a boiler will be enough, the cost of which is up to 20,000 rubles. Thus, prices for gas boilers in Zhitomir are quite reasonable.

Varieties

To date, several types are involved in the production of Zhytomyr boilers - parapet (wall) and floor. In turn, floor products also have subdivisions for single-circuit and double-circuit.

Floor standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical. Equipping a single-circuit boiler "Zhitomir" primarily implies imported components. Thanks to them, the device can be turned on and off, if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from two-circuit options.

In terms of price demand, double-circuit boilers are slightly more expensive, but they also provide double pleasure to the consumer in their work.

In terms of their technical characteristics, floor standing boilers mostly have such similarities as:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure - 635 Pa.

But already when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same division as for floor-standing boilers is also present in wall-mounted boilers. They can also be single-circuit and double-circuit. The efficiency is the same for all devices. The same goes for gas pressure.

But still it is worth considering their characteristics p>

- the power of parapet boilers must be at least 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, the consumption of natural gas is considered; according to the standard - 0.56-1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but still the model "Zhitomir-3 KS-G-020 SN" is in great demand. This device differs from its counterparts not only in terms of affordability in terms of the price factor, but also has clear technical data.The design of the device is designed in a minimalist style; the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door, behind which is a button for turning on and adjusting the settings of the device. In the same part there is a control window, with the help of which it is necessary to monitor the performance indicators of the boiler.

The basic configuration includes a casing, which also includes heat exchanger elements. Outside, it is covered with thermal insulation material and a casing made of steel. The burners are presented in the amount of two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

If the temperature becomes more than +95 degrees, the shutdown sensor breaks the circuit to the valve, and the valve itself automatically closes the gas supply.

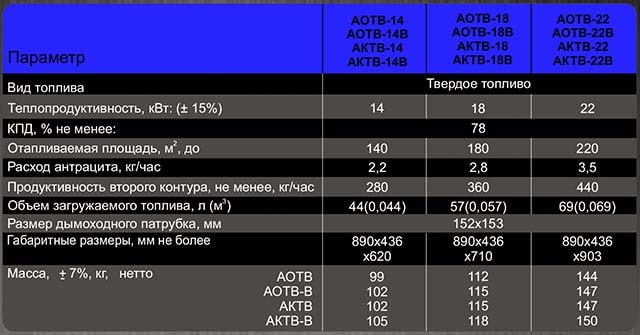

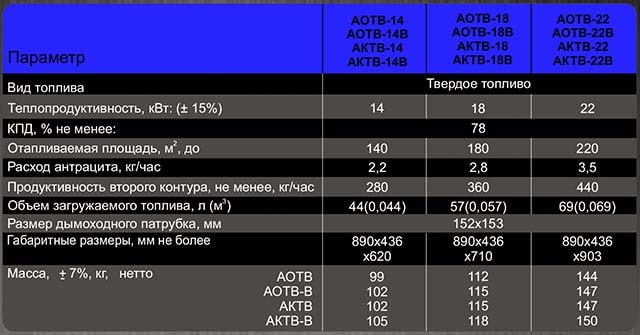

Solid fuel units

In recent years, the Zhytomyr plant has mastered the production of solid fuel boilers. The buyer can choose from 2 lines of heat generators:

- Classic heaters of the AOTV and AKTV series, designed for burning coal – anthracite and firewood.

- Pure wood-burning boilers of long burning "Zhitomir-D".

The first line includes 18 models with a heat output of 12 ... 25 kW with a steel fire-tube heat exchanger. The AKTV series is equipped with a cast iron hob, AOTV-V modifications are equipped with a copper coil that heats water for household needs.

We list the features and operating parameters of traditional coal-fired boilers:

- fuel combustion and flue gas emission occurs due to natural draft in the branch duct;

- air supply and combustion intensity are manually regulated by a special screw on the ash pan flap or by an automatic draft regulator on a chain (optional);

- a secondary copper DHW coil is located in the boiler tank;

- the manufacturer declares an absolutely real indicator of efficiency - 78%;

- working pressure of the coolant - 1.5 Bar, in versions with a round body - 1 Bar;

- the weight of the apparatus is from 88 to 208 kg, the volume of the fuel chamber is 44-69 liters, depending on the capacity of a particular model;

- burning time of 1 load of anthracite - 8 hours, firewood - 6 hours;

- the highest permissible temperature of the coolant at the supply is 90 ° C.

Note. The heat generator comes with a poker and a scoop for sanding and cleaning the ash chamber.

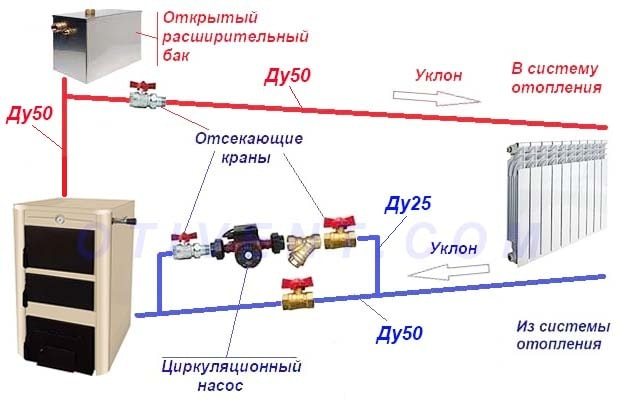

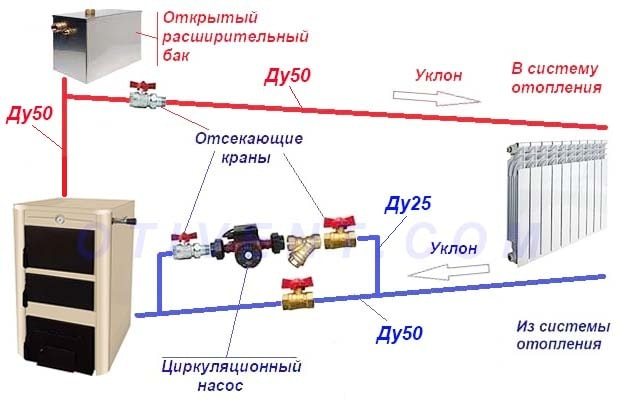

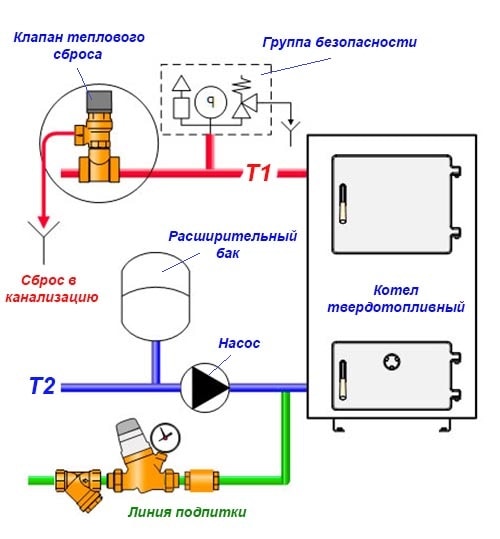

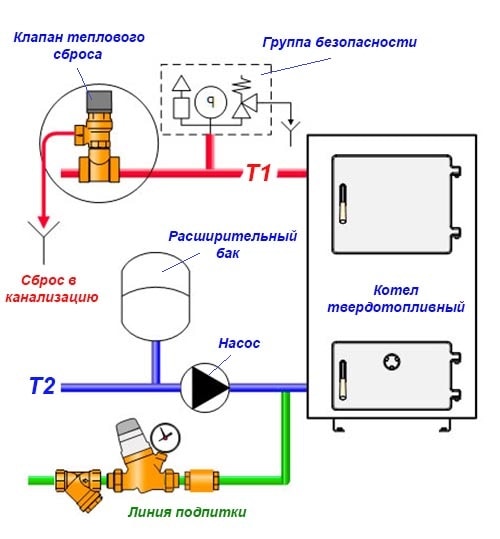

In the operating instructions, the manufacturer directly indicates: solid fuel plants are designed to work in heat supply networks with natural circulation of water and an open expansion tank. In fact, adding a circulation pump is quite acceptable, provided that the pressure of the coolant does not rise above 1.5 bar.

The circulation pump in the gravity system is placed on the bypass

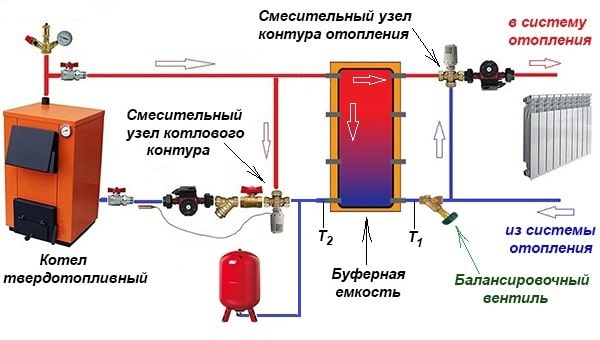

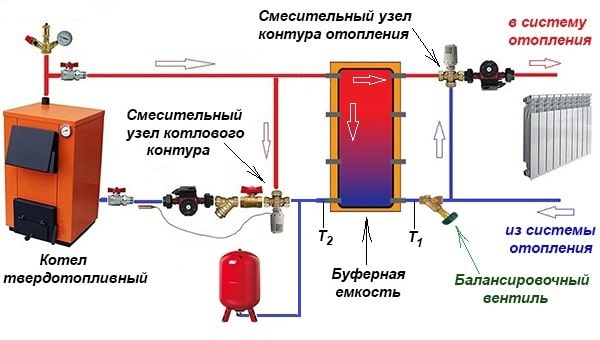

In closed heating systems, TT boilers must be used with a buffer tank (heat accumulator). Otherwise, in the event of overheating, the pressure in the pipeline network will reach 3 bar, causing the unit's water jacket to swell and crack. The warning equally applies to long-cycle heat generators "Zhitomir-D", whose characteristics are presented below:

- the line includes 3 heating units with a capacity of 12, 16 and 20 kW, the main fuel is firewood;

- the minimum duration of work from 1 full bookmark is 8 hours;

- the volume of the firebox is increased to 140, 195 and 250 liters, respectively;

- boiler tank capacity - 78 l;

- unit weight - 200, 250 and 290 kg;

- other parameters are identical to heaters of the AOTV series.

An important point. The manufacturer strongly recommends to operate long-burning boilers together with an accumulating buffer tank containing 0.35-1 m³ of heat carrier.

The long-burning boiler "Zhitomir-D" has an enlarged furnace, which makes it high

Positive and negative aspects of exploitation

In terms of ease of use and reliability, Atem TT boilers differ little from other heat generators in the budget segment:

- the heat source functions without electricity;

- combustion duration and efficiency are highly dependent on the quality of the fuel (wood, coal) and the operating mode;

- cleaning the firebox and ash pan is straightforward, access to the fire pipes is opened through the front door;

- subject to the rules of operation and the absence of overheating, the device will last 10-15 years;

- boilers of the AKTV series can cook food;

- burning firewood is a priori more economical than using other energy sources (excluding natural gas in the Russian Federation).

The most important advantage of Zhitomir-D heaters is the large volume of the fuel chamber, which determines the duration of combustion. Among the equipment of other brands, it is very difficult to find boilers of similar capacity. A real competitor is the Lithuanian Stropuva of 20 kW with a firebox volume of 260 liters, which is significantly more expensive.

For piping a unit with a large firebox, the manufacturer recommends the classic scheme with a buffer tank (heat accumulator)

It makes no sense to list the disadvantages common to all wood and coal boilers. Let's note the specific disadvantages of the Zhytomyr devices:

- The low threshold of the maximum pressure of the coolant does not allow quietly operating the TT boiler as part of a closed heating system, where the water pressure can reach 3 bar.

- According to the manufacturer's recommendations, the temperature in the return pipe should not drop below 45 degrees, otherwise condensation will be released in the firebox. With natural circulation, it is unrealistic to apply the classic piping scheme with a bypass and a three-way valve, which protects against cold return.

- Manual control of the air supply does not allow realizing the optimal operating mode and maintaining the desired temperature. The draft regulator only partially solves the problem. A wish for the manufacturer: equip 2-3 models with an automation unit and a turbocharger.

Video: operation of the Zhytomyr TT-boiler

However, the Zhitomir solid fuel unit can be connected to a closed system of a one-story house, where a low water pressure is maintained. In case of overheating, we suggest installing a thermal relief safety valve, as it is done in the diagram below. For more information on safety valves, see the related topic.

When heated to a critical temperature, an additional valve begins to discharge the coolant from the system, regardless of pressure. Cold water automatically flows into the boiler

Pressing and rinsing

Pressure testing of the system is not the most necessary preparatory stage, but it is desirable, since it will show in advance defects and leaks, if any.

Pressure testing is not always done, due to the lack of a special pump and reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check the new system and the one that, on the contrary, has been serving for several years.

The cost of crimping in construction companies from 3000 rubles. Additionally, they can take a fee for leaving the facility (about 2 thousand rubles). By the way, a manual pressure test pump will cost 4.5-6 thousand rubles.