Home / Gas boilers

Back to

Published: 26.07.2019

Reading time: 4 minutes

0

1081

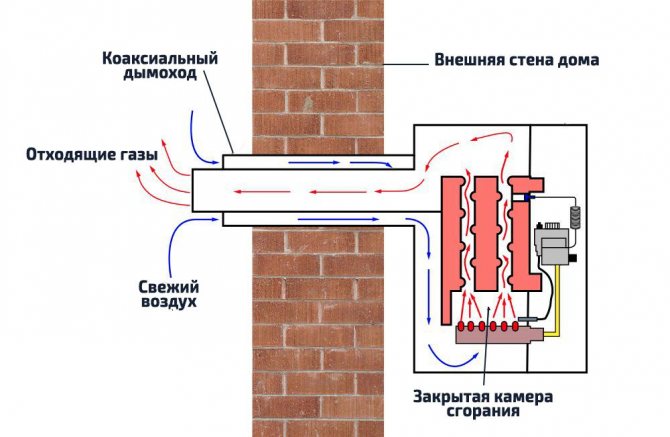

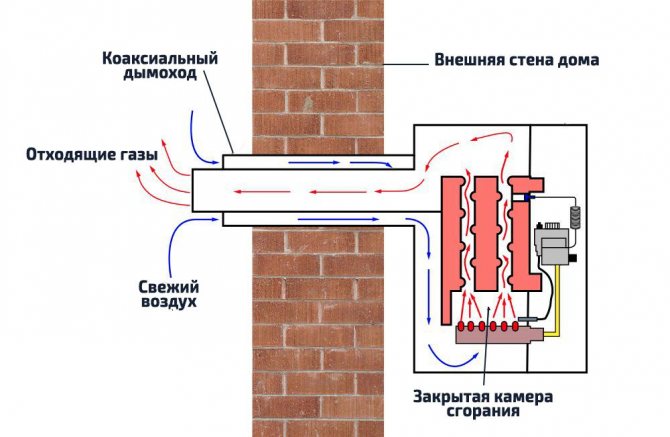

Many boiler owners have no idea what a parapet boiler is, although they have been using them for a long time. This modern unit belongs to the class of energy efficient devices and removes flue gases using a coaxial chimney mounted in a through hole in the building wall.

Units equipped with a closed firebox, it is allowed to install them in small rooms. Since the oxygen required for combustion is not taken from the living area, it is not hazardous. The heating unit is so compact that it can easily fit even in the kitchen under the windowsill.

- 1 What is a parapet boiler

- 2 The principle of operation of parapet gas equipment

- 3 Types and prices

- 4 Installation of a parapet boiler

About company

The history of the brand began in 1992, in the basement of the city of Taganrog. The company, having gone from a mini-firm, has grown to a large factory, and has taken a stable position in the domestic market. The equipment is manufactured on high-tech lines, which makes it possible to produce competitive products at prices attractive to domestic consumers. The boilers of the Taganrog plant correspond to the ideal ratio of the price-quality formula.

Comparison of gas boilers from different manufacturers

Gas boilers are a common type of heating equipment that is often used in private houses and summer cottages to heat rooms and heat water for domestic purposes.

Heat in such devices is released due to the combustion of methane or propane-butane. It is thanks to the economy, affordable price and ease of use of such fuel that gas equipment is one of the most popular and demanded types of heating equipment.

The main advantages of gas boilers:

- high efficiency (up to 95–97%) and relatively low fuel cost;

- affordable price and a large selection of both types and models of heating equipment from foreign and domestic manufacturers;

- simplicity in operation - the equipment does not require constant maintenance.

When buying a gas boiler, the consumer needs to consider several important criteria. It will be necessary to calculate the optimal power of the heating equipment, choose the type of gas boiler (wall or floor model). And also decide on the material from which the heat exchanger is made, and the availability of additional options.

In addition to these factors, you need to choose a gas boiler manufacturer, because a wide range of equipment from manufacturers from various countries is presented on the heating equipment market.

Rating of the best manufacturing companies of gas boilers

It is impossible to unequivocally answer the question of which company is a gas boiler better, because it all depends on the characteristics of the home and the needs of the owners themselves. But among the leading manufacturers of heating equipment, there are several of the most popular brands from different countries:

- German companies, including Vaillant, Viessmann and Buderus, are considered the leaders in the production of gas boilers. But in addition to high quality and reliability, German heating equipment also has a rather high price.

- Gas boilers of Italian companies are not inferior in quality to German technology, but at the same time they are distinguished by a more affordable price. Among the Italian brands, the most in demand are Ariston, Beretta and Alphatherm.

- Russian manufacturers of gas equipment adapt their equipment to the conditions of our climate and specialize in the manufacture of budget boilers with an optimal set of functions. It is worth highlighting several of the most popular and reliable Russian brands: ZhMZ, Borinskoye OJSC and Rostovgazoapparat.

Also noteworthy are Czech, French and Japanese manufacturers of gas boilers, which are represented on the heating equipment market by many companies.

Comparison of gas boilers from different manufacturers

Since Russian-made gas boilers in their operational characteristics are not inferior to foreign counterparts, but at the same time they are an order of magnitude cheaper, we will consider in more detail the advantages and disadvantages of popular domestic brands of heating equipment.

Gas boilers ZhMZ (Zhukovsky Machine-Building Plant)

A well-known Russian manufacturer of heating equipment, which produces three main lines of gas boilers. Most of the models are non-volatile equipment with good performance characteristics.

The main advantages of ZhMZ products include:

- a large selection of models with various powers from 11 to 68 kW;

- high efficiency;

- affordable price.

The disadvantages of ZhMZ gas boilers include weak automation, rather bulky dimensions and an outdated appearance of heating equipment.

Gas boilers Rostovgazoapparat

The Rostovgazoapparat company was the first in Russia to start producing gas equipment and presents three main lines of floor standing boilers:

- Siberia (power 11.6-35 kW);

- RGA (up to 17.4 kW);

- AOGV with domestic automation (11.6 -35 kW)

The main advantages of Rostovgazoapparat gas boilers are the presence of single- and double-circuit non-volatile models with good automation.

But the heating equipment of this Russian manufacturer also has its drawbacks:

- massiveness due to the use of heat exchangers made of cast iron and sheet steel;

- rude appearance;

- low indicators of environmental friendliness.

Borinsky gas boilers

has been producing heating equipment since 1992 and supplying to the domestic market more than 30 models of gas boilers with a capacity of 7–100 kW. Among the Borin gas boilers there are both single and double-circuit models, equipped with imported or domestic automation. All equipment manufactured by this Russian company fully meets modern safety, quality and reliability requirements.

Advantages of Borin gas boilers:

- Profitability. The company's engineers are constantly improving the designs of the boilers in order to increase their efficiency.

- Security. Any Borin boiler is equipped with an automatic shutdown system in emergency situations (lack of traction, reduced gas pressure, etc.).

- Energy independence. Heating equipment does not need to be connected to the mains, which is important for our country, where power outages often occur.

- Reliability. The boilers from have a fairly simple and reliable design, while they are perfectly adapted to the difficult conditions of the Russian climate.

- Easy to operate and maintain. Mosoblgaz employees carry out maintenance of the gas equipment of this company.

Another of the main advantages of gas boilers from this Russian manufacturer is a democratic price that attracts many consumers.

Note! It is Borin gas boilers that are recommended by Mosoblgaz for installation throughout the country, which confirms their high quality and durability.

In addition, maintenance and repair of Borin boilers can be carried out by Mosoblgaz employees, which is undoubtedly convenient in their operation.

Thus, gas boilers of domestic manufacturers are not inferior in their technical characteristics and functionality to imported counterparts, but they have a more affordable cost. And the products of AOA "Borinskoye", recommended by Mosoblgaz, deserve special attention from consumers who plan to buy high-quality and reliable equipment at a reasonable price.

Benefits

Judging by the reviews, the products of the Taganrog plant evoke more positive emotions from users than negative ones. It really deserves to be commended in terms of design, performance and economy. Its advantages include:

- High efficiency - 90-92%. This is a good characteristic for domestic gas appliances.

- External appeal - the heaters are distinguished by their ergonomic design and look beautiful in modern interiors.

- Safe operation - a reliable, multi-stage protection system is provided.

- Simple connection.

- Long service life - with proper operation and timely maintenance, they can work for a quarter of a century. The warranty is 3 years.

Features of the Lemax Patriot 16 parapet boiler

This model of equipment costs consumers 21,000 rubles. The boiler can work in conjunction with forced or natural heating systems. This does not require an electrical connection. The rectangular heat exchanger is based on high quality 2mm steel, which complies with the European standard.

The heat exchanger is covered with anticorrosive enamel and treated with an inhibiting composition, thanks to which the material is reliably protected from the effects of aggressive factors, namely mineral oils and salt solutions. The boiler can only be used in conjunction with a heating system that is equipped with original gas burner components. Heating can be connected from both sides.

The boiler power is 16 kW. The heated area reaches 160 m2. The front panel has openings that create a convection effect. You can not be afraid that the boiler will overheat, because the manufacturer has provided it with a special protection system. The boiler maintenance is quite simple, since the structure has removable cladding elements and profile accessories. You can observe the combustion of the pilot and main burners through the viewing window.

Floor models

Floor standing devices make up the lion's share of the products manufactured by the manufacturer. And the demand for them is greater among consumers. Such versions are usually used for heating a private house - they need more power and reliability. Wall-mounted versions are more often chosen by apartment owners - but they cannot compete with European brands. The principle of operation is simple - a burner built into the housing heats up the heat exchanger of the heating and hot water system - if there is a second circuit. Coolant circulation - natural (non-volatile) or forced (volatile). Piezo ignition is used. Floor-standing gas heaters are available with heat exchangers:

- With steel. Thickness - 2 mm. Steel single-circuit boilers of floor-standing type are non-volatile and operate only for heating. Double-circuit - simultaneously heat water for domestic needs. The models are economical - gas consumption is practically the same as that of Vailant.

- With cast iron. Thickness - 4 mm. The cast iron single-circuit heating boiler has the best characteristics in the entire Lemax model range. Cast iron is resistant to aggressive environments, not afraid of overheating. Heat exchanger type - sectional. Manufactured by VIADRUS (Czech Republic).

What are parapet gas boilers

Parapet gas boiler is a compact boiler unit used for heating (single-circuit) and supplying facilities with hot water (double-circuit).

In general, such models were initially developed as a non-volatile alternative to wall-mounted appliances, but unlike the latter, they are universal when choosing a place for installation, i.e.can be placed both hinged and floor-standing. The only condition is that it must be fixed against the outer wall of the room, preferably below the line of the window sills.

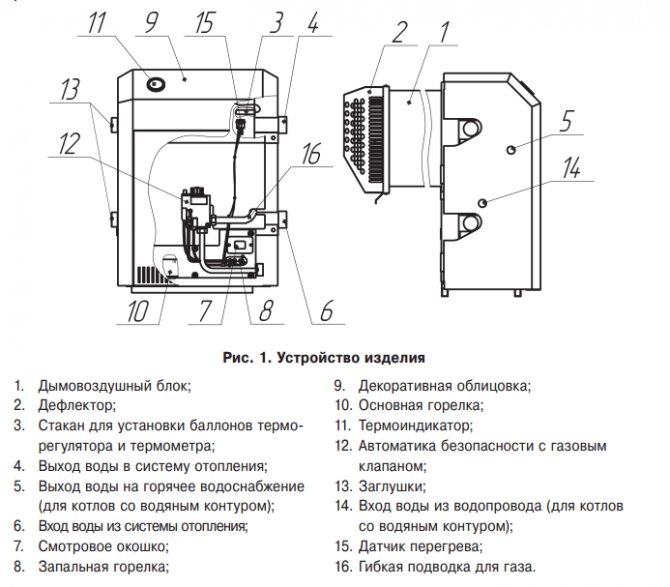

The device and the principle of operation of the equipment

In terms of functionality, parapet gas boilers are something in between a classic atmospheric heat generator and an air convector.

This combination is achieved by modifying standard assemblies.:

- closed combustion chamber - completely isolated from the living space, which excludes any effect of smoke products on the internal microclimate;

- primary heat exchanger - has dissipative turbulators, which increase the time of passage of air flows and prevent heat from escaping;

- air intake and smoke exhaust system - implemented through a short (from 25 cm to 53 cm) coaxial pipe, without complicated elbows, wiring and insulation;

- sealed steel body - equipped with a viewing window for direct visibility of the flame of the burners, as well as convection holes, so-called. ribs.

Schematic representation of the design and principle of operation of parapet models.

The principle of operation of parapet boilers is not quite typical: despite the closed combustion chamber, they function according to the scheme of natural air exchange (draft) - street oxygen is supplied through the outer part of the pipe from the bottom to the burner that heats the heat exchanger, after which the smoke is removed through the core of the pipe.

At the same time, in the room itself, continuous air circulation is also carried out: passing through the ribs, it heats up and, increasing in volume, displaces the cold mass. Thus, if the characteristics of the boiler are correctly selected, it will be sufficient not only for heating the heating circuit, but also for heating the space around it (without a radiator).

In what conditions is it most advisable to use such boilers

Parapet models are used to organize a heating and hot water supply (DHW) system in buildings whose design does not involve the construction of a full-fledged chimney, as well as problems with power supply and other aspects: stable pressure, soft water and high-quality fuel.

However, it is necessary to take into account the power limitation in the range from 4 to 46 kW, that is, in terms of similar indicators, "parapetniks" are seriously inferior to wall, and, especially, floor-standing units. This means that it is reasonable to put them only in relatively small rooms (from 30 to 250 m2), like private and country houses, trading floors, offices in shopping centers and, of course, high-rise apartments, in which they fit perfectly into a niche under the windowsill in the kitchen.

How to choose a room thermostat and save up to 30% per month on heating

Possibility of installing a parapet boiler in a wooden house

Almost any wooden house is allowed to be equipped with a parapet boiler: the exception is barracks and other old-style apartment buildings.

Installation is carried out according to the current SNiP rules 42-101-2003:

- the unit is placed on an external wall, while an empty gap should remain outside - from 0.3 to 3.1 m (depending on power), without facade elements;

- the exit of the chimney is prohibited near or directly in enclosed spaces (hallways, attics, entrances, balconies, loggias, etc.);

- the mounting wall is sheathed with fire-resistant material and covered with a sheet of steel so that there is a distance of 10–25 cm to difficult and light-combustible areas;

In wooden houses, the internal and external thermal insulation of the coaxial chimney is mandatory. - porous wood, in order to increase fire safety, is prepared in advance for overlap, processing with special mastics and impregnations in 2-3 layers.

Many companies still use asbestos to protect walls from fire, although today it is officially recognized as a material hazardous to health. Replacing it will help ceramic or silicate brick, GVP-plate, mineral wool, basalt insulation, a panel of foam, aerated concrete and even gypsum plaster.

Mounted models

The wall assortment is more modest. All models are volatile. Automation - made in Italy. The settings are factory defaults. During operation, nothing needs to be adjusted. The main thing is to ensure voltage stability. Automation, if desired, is connected to the unit of remote thermostats. There is protection against:

- overheating;

- blowing out the fire;

- soot formation;

- reverse thrust.

Minus - there is no protection against freezing and pump jamming. The modulating burner, like the automatics, is Italian. The modulation principle allows economical consumption of gas and increases the efficiency of the device. Connection is classic. Connection to a regular chimney is required.

Installation of boilers "Lemax"

The main components of any gas heater:

- Gas burner block - burner (POLIDORO, Italy), wick (igniter), piezo ignition. By pressing the button, the piezoelectric element is activated, and the wick is set on fire with it. The main burner is ignited by the pilot.

- Heat exchanger. Tubular type, nozzles are connected to the heating system. The coolant is heated in it. If there is hot water supply, it is necessary to take into account that when the water heater mode is turned on, the heating system stops working.

- Automation. Control board and sensors from NordGas. Gas valve Sit.

- Expansion capacity CIMM.

- Circulation pump Wilo.

The company independently develops the layout of elements and assemblies, operating instructions, expands the network of service centers. The brand has repeatedly become a sales leader among floor-standing boilers for autonomous heating of private houses and industrial premises.

The best known manufacturers and models: characteristics and prices

Lemax Patriot-12.5

This unit can be briefly described in two words - simplicity and efficiency. Despite the fact that the heat exchanger is made of ordinary steel, thanks to the coating with anticorrosive enamel and inhibiting composition, it is less susceptible to the action of aggressive substances: acids, salts and mineral oils and is able to last 12-15 years.

With a power of 12.5 kW, its fuel consumption will be no more than 0.75 m3, which is one of the best indicators. But the "picture" is spoiled by a rather clumsy rectangular body and an uninformative control system: of the devices for monitoring the current parameters, only the thermometer is turned on "by default".

Cost: 16 130 - 21 580 rubles.

Manufacturer: LEMAX (LEMAX), Russia.

ATON Compact-12.5EB

A relatively multifunctional boiler with a capacity of 12.5 kW stands out for its modest dimensions, which is not inherent in every double-circuit analogue: it uses an S-shaped coil made of copper for flow heating - it is more resistant to metal corrosion and with increased thermal conductivity, which lasts up to 17 years ...

The hot water supply rate t 35 ± 5 ° C can reach 5–6 l / min, while the fuel consumption will not exceed 1.53 m3 / h. Convenience of installation work will appreciate the model even more at its true worth - versatile outputs make it possible to connect it, both on the right and on the left side.

Cost: 23 350 - 27 500 rubles.

Manufacturer: ATON (ATON), Ukraine.

TERMOMAX C-12E

Another unit, devoid of any design hints. Despite this circumstance, you should not write it off, because the lack of visual appeal is compensated by economy, efficiency and real comfort of use: the main controls are located directly on the front of the outer panel.

On request, the boiler can be supplemented with an expansion tank and a circular pump (not included in the basic package), which will make it suitable for connection to complex heating systems, including those with high hydraulic resistance. The maximum gas consumption at a power of 12.0 kW is 1.39 m3 / h.

Cost: 15 860 - 20 340 rubles.

Manufacturer: TERMOMAX (TERMOMAX), Ukraine.

Hephaestus VPR KSG-10S

Perhaps this option is one of the best parapet gas boilers for heating a private house: it is understandable, practically silent (remarkably quiet at start-up) and rather highly efficient, given the possibility of operating in the "low flame" mode, which allows to reduce the average gas consumption to 0.60 m3 / h.

Despite the fact that the unit itself is assembled in Russia, it contains the well-known Italian automatic equipment of the "SIT" type, which, based on the current heat losses, maintains an optimal power level (within 10 kW), and also a slot burner of the "BRAY" type that does not require adjustment of the air flow.

Cost: 19 680 - 23 840 rubles.

Manufacturer: Gefest WPR (Gefest VPR), Russia.

Installation

Violation of installation rules leads to breakdowns and malfunctions. It is recommended to trust the installation to specialized specialists. The requirements for the installation of Lemax heaters are no different from the usual ones, but there are nuances that are important to consider:

- The automation unit contains a thrust sensor. If the combustion products are not discharged sufficiently intensively, the burner will turn off. During installation, it is necessary to provide for the creation of conditions for traction. The manufacturer advises to connect the device to a chimney made of sandwich pipes.

You don't have to spend time or money to connect and launch - everything is simple and fast. The settings, as mentioned above, are factory settings, and the adjustment is mechanical.

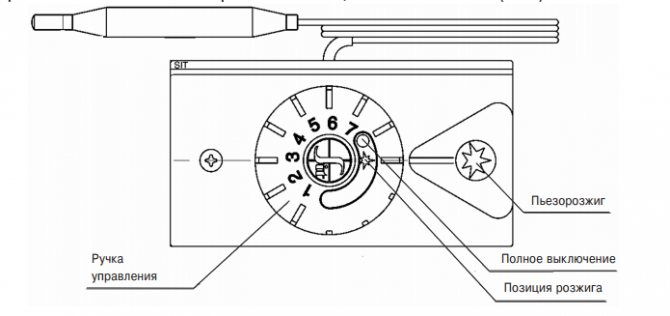

Automation unit

The gas valve plays a key role here. It is controlled by analog sensors (in non-volatile versions) or electronic controllers that receive data from electronic sensors (in volatile versions).

The valve of the combined type is assembled from two valves - simple and electromagnetic. The first is held open by a spring. During start-up, the second valve is opened by pressing a button - to ignite the wick. It is held for some time - the igniter warms up a special element that reacts to heating. This element starts generating electric current - it keeps the solenoid valve open, the user can release the button. When the igniter is blown out, the thermoelement cools down - the generation of electric current will stop, the solenoid valve will close. Another valve - with a spring, will close after a signal from the traction and temperature sensors.

Possible malfunctions

The equipment of Taganrog manufacturers undoubtedly requires some improvements. Often there are problems with water heating - the devices cannot provide users with the desired amount of hot water in the required volume. Therefore, it is more profitable to buy a single-circuit device, and already connect a BKN to it - an indirect heating boiler. You can also choose a hinged or parapet (with a closed combustion chamber) boiler. Possible problems:

- The burner shuts down spontaneously. The reason for this may be insufficient traction or breakdown of the thermostat.

- It smells like gas. Perhaps the leak is due to poor gaskets in the threaded connections - replacement is needed.

- Long, red-orange flame. Burners clogged or insufficient draft.

- Cooled batteries with a hot boiler - there is not enough coolant or installation errors were made.

Preparing for installation

Before installing the parapet gas boiler, it is necessary to prepare all the tools and fixing materials.

To make a hole in the wall for the chimney outlet, prepare a drill with a diamond crown corresponding to the diameter of the coaxial pipe. It is necessary to prepare keys and screwdrivers corresponding to the fasteners, rulers, level, marker, knife.

Personal protective equipment will also come in handy during installation: mask, glasses, gloves.

Service

Some malfunctions revealed during operation can be eliminated by yourself:

- Traction sensor problems. It can cause emergency shutdown with excellent traction.False operation occurs due to oxidation of the contacts - they need to be cleaned. If the sensor is completely broken, it is easy to replace it with a new one.

- Ignition problems. Ignition does not take place due to weak burning of the wick. How to fix the situation? Set the required flame power. You can read about this in detail in the instructions. Also attached to the equipment is a connection diagram and a data sheet.

In almost any specialty store, you can buy units and parts to be replaced. Repairs may only be carried out by an authorized employee.

Model overview

The manufacturer offers several lines, in which all possible designs of boilers are presented - atmospheric and parapet, single and double-circuit, steel and cast iron, floor-standing and mounted.

Wester clever

The line of four models is atmospheric convection boilers, differing only in power indicators. Wester Clever 20/30 is characterized by high heat transfer, the heat carrier at the outlet is heated up to 90 ° C. Wester Clever 30 specifications:

• efficiency - 90%.

• Heating power - 34,000 watts.

• Weighs 85 kg.

• HxWxD - 961x470x556 mm.

• Fuel consumption - 1.75 m3 / h.

Wester Clever 40 - has a higher throughput. It consumes fuel - 2.5 cubic meters per hour. Heating capacity 45,000 watts. Weighs 110 kg. The most powerful representative of the series is Wester Clever 61.

It can work non-volatile or be connected to the mains. The maximum gas consumption is 3 cubic meters. m / h. Works without interruption even at a pressure of 6 mbar.

Premium

Installed in rooms with chimneys. Power range in the line - from 8 to 100 kW. There are modifications with one and two circuits. Universal - can be connected from either side - left or right. Automatic regulation of the intensity of the fire. Made of 2mm steel sheets. Heat exchangers treated with anti-corrosion agents. Devices are provided to prevent the blowing out of the flame. As an example - Premium 16:

- The efficiency is 90%.

- Single-circuit. Atmospheric type.

- Volatile.

- Heating capacity 16,000 watts.

- Weight - 55 kg.

- Heats up to 160 m².

For heating large areas, Premium boilers 70-100 kW are suitable. These are powerful devices weighing up to 250 kg.

Premium Nova is an upgraded version of the Premium line. There is an automatic system that supports the specified parameters. Adjustment of the coolant pressure is provided.

Patriot

It is possible to work with any type of ventilation - natural or forced. Parapet and wall versions can be installed in apartments. Combustion products are discharged through a coaxial chimney. The heat exchanger is treated with an anti-corrosion compound. Power 6-20 kW. There are injection mini-torches and overheating protection. Features Premium -12.5:

• efficiency - 87%

• 12.5 kW.

• Parapet installation.

• Non-volatile.

• Closed firebox.

• 50 kg.

Wise

Material - Czech cast iron (4 mm). Ideal ratio of heat carrier volume to mass and heat exchanger area. They are not afraid of temperature and gas pressure surges. If desired, switch to liquefied fuel. It is also possible to connect indirect heating tanks, thermostats, remote climate control systems. Heating capacity in the line - from 16 to 60 kW. Wise 35 parameters:

• Single-circuit device. Floor installation.

• Open firebox.

• Heating capacity 35,000 watts.

• efficiency - 90%.

• There is an auto-ignition.

• 141 kg.

Types and prices

The advantage of such boilers is a large selection of models with different mounts: floor and wall. When choosing a boiler, the actual connection conditions are taken into account.

Boiler equipment from European plants, Russia, CIS countries and China is widely represented on the construction market. It is clear that the quality of equipment from the EU is higher than that of boilers from China, but the price is also much higher.

Popular parapet boilers:

- TERMOMAX-C - energy-independent compact boilers for individual heating of single-storey and multi-storey buildings, equipped with a flue gas discharge system through a coaxial channel, horizontally built into the outer wall.

Structurally, they are carried out as one or in a double-circuit design with E and EB markings and a thermal power from 7 to 16 kW. For heating systems with high hydraulic resistance, a circulation pump is provided. Control, protection and start-up are carried out via the EuroSit 630 gas valve. The burner is started by piezo ignition. TermoMax С 16ЕВ has an efficiency of 90% and is capable of heating rooms with a size of 120 m2, the cost of the unit is 20,100 rubles. - Another Russian model of a parapet boiler is Lemax Patriot 20 with a closed firebox. Steel heat exchanger treated with an inhibiting compound and covered with an enamel coating to resist corrosive processes. By type of installation - wall-mounted. Line of heat load of Lemax boilers from 6 to 20 kW. Gas-burning equipment from the Italian concern "SIT" with an injection flare burner "POLIDORO". There are special openings on the front panel to create a convection effect and increase heat transfer in the room. Features include: removable cladding elements, igniter, coaxial smoke exhaust system, non-volatile installation option. The cost of the unit is 25820 rubles.

- Two-circuit boiler "Slim 2.300 Fi", produced by the Baxi brand, with a heat load of 14.9 to 29.7 kW, capable of heating objects with a size of 140 -160 m2. The boiler is made of high quality materials, with a price from 120.0 to 140.0 thousand rubles.

- EcoCompact VSC D INT 306 / 4-5 190L, the boiler of the German brand Vaillant is a highly efficient unit, it can heat 160-180 m2, the price is 240.0 thousand rubles.

- Parapet boiler Danko, with a capacity of 7 to 18 kW, is equipped with a cast iron boiler with a wall thickness of 3 mm and a closed combustion chamber. The universal design allows for two-way connection of engineering networks, the control unit is located on the boiler operating panel. The units are equipped with Honeywell gas automatics, piezoelectric ignition and microflame burner, heating area up to 160 m2, price - 21 thousand rubles.

- Eurotherm KT TSY (P2) for individual heat supply in systems with natural and forced circulation of the heating circuit, with a water temperature of up to 90 C, thermal power 10 kW, gas consumption 1.13 m3 / h, efficiency 92%, weight 59 kg, warranty period 24 months., heating area 100 m2, price - 24 thousand. rub. Steel boilers are equipped with a copper recuperation system with a bypass channel. A copper coil of a special design is placed in the water cavity to generate hot water. Design features: heat recovery system with a receiving tank, housing, control and protection unit, air duct, gas duct, wind protection cover. The design allows the unit to be installed at floor level near a wall. DHW loop connecting pipelines are made on one side. The air intake duct passes through the outer wall with a thickness of 200 - 500 mm. Mounting on walls in a wooden house is not allowed without fire protection measures.

Leader

Equipment with cast iron heat exchangers. Their surface is silver-plated. At the bottom of the furnace is an injection burner. With only one circuit. 19-55 kW. They can heat from 150 to 500 m². Most expensive versions. Service life - 25 years. Automation - Nova Sit. Pressure and temperature are automatically regulated. They can function without electricity. Due to a special turbo nozzle, the intensity of the removal of combustion products increases. Leader 80 parameters:

- Weight 196 kg.

- 92% efficiency.

- Heating area 500 m².

- At the outlet, the maximum water temperature is 80 ° C.

- Open firebox.

- Auto ignition.

What you need to know about the model

The model is a whole series of parapet boilers that can be connected to the heating system on the left and right. The flue kit is not included, but can be purchased separately.The efficiency is 90%. The working gas pressure is 1274 Pa. The maximum consumption of natural gas is 0.8 m3 / hour. The leaving water temperature can be adjusted between 40 and 90 ° C. The maximum water pressure in the heating system can be 0.65 bar. The dimensions of the boiler are 672x627x266 mm. The volume of the water cavity is equivalent to 24 liters. The unit weighs 51 kg.