Features of different types of fuel

Consider the two main, most common, types of solid fuel raw materials - firewood and coal.

Firewood contains a significant amount of moisture, so the moisture evaporates first, which requires a certain amount of energy. After evaporation of moisture, intensive burning of wood begins, but, unfortunately, the process does not last long.

Therefore, in order to maintain it, it is necessary to regularly add firewood to the firebox. The ignition temperature of wood is about 300 ° C.

Coal surpasses wood in terms of the amount of heat generated and the duration of combustion.... Depending on the age of the fossil material, the mineral is divided into types:

- brown;

- stone;

- anthracite.

Types of coals and their properties

All coals mined from our depths and suitable for combustion in the furnaces of boilers and furnaces are divided into 3 groups:

- brown;

- stone;

- anthracite.

Of all the listed brown coals, they are considered the youngest, include many volatile impurities and are distinguished by their brown color, hence their name. This fuel contains up to 70% pure carbon and up to 40% moisture. For this reason, the heat transfer and combustion temperature of brown coal are the lowest among others. It ignites easily, since the lowest ignition temperature is only 250 ºС, but the heat of combustion is also low - about 3600 kcal / kg, and the combustion temperature is about 1900 ºС.

Due to its low calorific value, the fossil in its natural form is very rarely used as an energy source for heating private houses. Another thing is briquetted coal, its heat transfer is 5000 kcal / kg.

Coal coals are next in age, they are really older and lie even deeper in the depths than brown coals (up to 3 km). Pure carbon in them is up to 95%, water - 12%, and volatile impurities - up to 30%. Due to this, the heat transfer of stone fuel is 7000 kcal / kg, although its ignition requires a temperature of 400 ºС. This fuel theoretically burns at 2100 ºС, although the combustion temperature of coal in the furnace never reaches such values. The maximum that can be is 1000 ºС. In practice, it is the most common type of fuel used as an energy source for heating buildings.

The oldest and deepest species is anthracite, which is 95% or more carbon. It practically does not have impurities and moisture, it has the highest specific heat transfer (about 8500 kcal / kg). But such fuel is not easy to ignite: the lowest-calorie anthracite variety ignites at a temperature of 600 ºС. The theoretical combustion temperature is 2250 ºС. Anthracite is an excellent fuel in all respects with low ash content and low smoke, but its price is high.

For reference.

Bituminous coal of a certain type is used for processing into coke used in metallurgy. And, although the combustion temperature of coke coal is not higher than that of hard coal, after enrichment and heat treatment at T = 1000 ºС it turns into coke with the highest calorific value and temperature.

Fuel composition of different types

Brown coal belongs to young deposits, therefore it contains the greatest amount of moisture (from 20% to 40%), volatile substances (up to 50%) and a small amount of carbon (from 50% to 70%). Its combustion temperature is higher than that of wood, and is 350 ° C. Calorific value - 3500 kcal / kg.

The most common type of fuel is bituminous coal. It contains a small amount of moisture (13-15%), and the content of the fuel element carbon exceeds 75%, depending on the grade.

The average ignition temperature is 470 ° C. Fugitive gases in coal 40%. During combustion, 7000 kcal / kg are released.

Anthracite, which occurs at a considerable depth, is among the oldest deposits of solid-fuel fossil. It contains practically no volatile gases (5-10%), and the amount of carbon varies between 93-97%. The calorific value ranges from 8100 to 8350 kcal / kg.

Charcoal should be noted separately. It is obtained from wood by pyrolysis - combustion at high temperatures without oxygen. The finished product has a high carbon content (70% to 90%). When wood fuel is burned, about 7000 kcal / kg are emitted.

You can read about the features of using peat briquettes in this article:

Combustion of fuel

It is very important to organize a continuous supply of oxygen to the fuel. In order for it to burn completely, an excess air supply is made. In other words, the air volume must be higher than the theoretical value. The negative side

such a supply is a loss of heat, some of which simply leaves through the pipe.

Fuel types for the boiler

Solid fuel boilers can use: wood, coal of various brands, briquettes and other solid fuels. It is very difficult to heat the house with wood, brown coal and briquettes. The fact is that these fuels contain a lot of water. As a consequence, constant heat generation is required to maintain combustion. Otherwise, the evaporating water quickly cools the fuel, and the fire goes out. Thus, these fuels can burn quickly, releasing some heat, but they are completely unsuitable for maintaining a slow, long burning, while coal can burn slowly for a long time. This is because carbon is not volatile. When the supply of primary air is limited, it can be in a heated state in the boiler, not to cool down. When the primary air begins to flow again (the coolant has cooled down, the primary air damper has opened), then carbon begins to oxidize, releasing heat.

Long-flame coals, coke, anthracite, brown coals are usually used for heating. Most boilers operate optimally on long-flame coals. Coke and anthracite do not burn in all boilers and can be used as additives, but not as the main fuel. Brown coals are generally poorly suited for heating, as they burn poorly, give little heat and a lot of ash. I am heated with long-flame coal (WPC - long-flame coal).

Unfortunately, errors are periodically encountered in articles, they are corrected, articles are supplemented, developed, new ones are being prepared. Subscribe to the news to stay informed.

If something is not clear, be sure to ask! Ask a Question. Discussion of the article. messages.

More articles

Heating with gas cylinders, bottled liquefied gas, propane, about ... I share my experience of heating a house with bottled gas ....

Why is it cold at home, where does the heat go, heat loss…. Why is it cold at home? Where does the heat go? How to keep it warm? Those losses ...

Stove, stove heating. Calculation, design, costing. Calculate ... Calculation of stove heating. Dimensions, weight and power of the oven. Heat loss analysis….

Household gas cylinders. Connection, application, operation, use ... Safe operation of household gas cylinders ....

Knitting. Stitches, Small horseshoes, Parallel chains, Dense ripples. With ... How to knit patterns. Detailed description Stitches, Small horseshoes, Parallel chains ...

Knitting. The Cherry Orchard. Eskimo. Drawings. Patterns patterns ... How to knit the following patterns: Cherry Orchard. Eskimo. Detailed instructions with explanatory ...

Knitting. Moths.Patterns, drawings ... How to knit the following patterns: Moths. Detailed instructions with explanations ...

Knitting. Butterfly. Drawings. Patterns patterns ... How to knit a pattern - Butterfly. Detailed instructions with explanations ...

For homeowners who use various types of solid fuels to heat their homes, such a parameter as the temperature of coal combustion is of considerable interest. Logically speaking, the higher this temperature, the more heat can be obtained by burning fuel. But this is theory, but in practice everything happens a little differently. The real burning of this valuable fossil will be discussed in this material.

Combustion process

Depending on the type and grade, the fuel is divided into short-flame and long-flame. The short-flame ones include anthracite and coke, charcoal.

When burned, anthracite generates a lot of heat, but to ignite it, you need to provide a high temperature with a more flammable fuel, for example, wood. Anthracite does not emit smoke, burns odorlessly, its flame is low.

Long-flame fuels are burned in two stages. First, volatile gases are released, which are burned above the coal layer in the furnace space.

After the gases are burned out, the remaining fuel begins to burn, which in the meantime has turned into coke. Coke burns with a short flame on the grates. After carbon burnout, ash and slag remain.

Which coal to choose for the furnace?

What is coal? It is a vegetable product that contains carbon and non-combustible impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the "age" of the fossil fuel, that determines the coal grade. Experts distinguish between several varieties.

The "youngest" type of coal is lingitis. It has a rather loose structure. If you pick up a lump of lingitis, it quickly crumbles and loses its shape. Such coal is most often used in thermal power plants, but lingitis is not suitable for heating a house.

In addition to lingite, brown coal, coal, anthracite are also mined - the most ancient carbon deposits. All varieties have different moisture levels. In brown coal, for example, the moisture content is 50%, in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal / kg.

Material for coal-fired stoves is the main criterion for choosing a fuel and stove. Let us examine these qualities in more detail.

When the kindling of the stove is successfully completed and the firewood is blazing merrily in the firebox, it remains only to monitor the thermal mode of operation and put new logs in time. As for the mode, it is recommended to maintain it constantly at the same level, avoiding overheating.

This is important because, with alternating high heating and cooling, the furnace body often expands and contracts, which contributes to the formation of cracks.

Maintaining an optimal thermal regime and putting logs on time is the best way to properly heat the stove with wood, although it is not very convenient at night. No one wants to get up in the middle of the night, although this cannot be avoided in a severe frost on the street, otherwise the house will be dry by morning. During continuous heating for several days, the ash pan has to be cleaned {amp} amp; on the go {amp} amp;

to ensure the flow of air into the combustion chamber. The operation is carried out with the help of an iron scoop at the moment when the bulk of the wood is burned out and a few embers remain in the firebox. It is necessary to make a shurovka in the combustion chamber with a poker, cover the view, and then open the blower door and quickly remove the ash with a scoop into a metal bucket.

Important. There should always be a sheet of metal up to 1 m wide on the floor in front of the oven doors.

Regardless of whether coal or firewood will be used as the main fuel, the ignition is performed in the same way. First you need to clean the ash chamber and firebox using a poker, scoop and broom. After cleaning, do not forget to remove ash residues from the door sills with a broom, otherwise they will not close tightly.

To light the stove, you must act according to the instructions:

- lay a few crumpled sheets of paper and a few thin splinters on the grate. It is unacceptable to use liquid fuel for kindling;

- from thin logs, make a bookmark for about 2/3 of the volume of the firebox. Firewood can be folded {amp} & house {amp} amp; or crosswise, making gaps for air. This is where the short stacks mentioned earlier will come in handy;

- open the view about halfway, open the blower door a quarter;

- set fire to the paper through the open door of the main chamber, then close it. It is good when you have a panoramic glass stove insert installed, then the process is clearly visible. If there is no glass, the door is left slightly ajar and the combustion is monitored by adjusting the air supply with the ash pan door. Usually, at first, it is opened halfway, and when the wood catches fire, it is covered.

Advice. In each specific case, the owner determines how much better to plow the ash pan during firing up and stoking, as well as the optimal position of the view. When the stove makes a hum, the draft is great and a lot of heat flies into the pipe, the valve should be closed. Red flames, smoke and sluggish burning indicate a lack of thrust, then the view opens slightly.

Burning

Consider the process of burning fuel in a conventional stove, which is used to heat private houses. It consists of the main parts:

- furnaces;

- blower;

- chimney with a pipe.

The firebox is connected to the blower through a special grate (grates) located at the bottom of the firebox... Fuel is placed on the grate, and air from the blower through the grate enters the firebox.

Combustion formulas

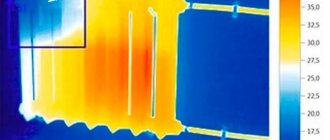

Ignition temperatures of different fuels (click to enlarge)

When fuel (wood, coal) ignites, a chemical reaction takes place with the release of heat.

Carbon dioxide reacts with the carbon in the fuel in the upper layers to form carbon monoxide.

This is not the end of the combustion process, because when rising up in the furnace space, carbon monoxide reacts with oxygen from the air, the inflow of which occurs through the blower or open door of the furnace.

Its combustion is accompanied by a blue flame and heat release. The resulting carbon monoxide (carbon dioxide) enters the chimney and escapes through the chimney.

Smoldering with minimal oxygen supply will produce non-toxic carbon monoxide, giving even heat.

Application

The main use of fuel is combustion to generate heat. Heat is used not only for heating a private house and cooking, but also in industry to support technological processes that take place at high temperatures.

Unlike a conventional stove, where the oxygen supply process and the combustion intensity are poorly regulated, in industrial furnaces, special attention is paid to controlling the oxygen supply and maintaining a uniform combustion temperature.

Let's consider the basic scheme of coal combustion.

- Fuel heating and moisture evaporation is in progress.

- As the temperature rises, the coking process begins with the release of volatile coke oven gases. Burning out, it gives the main heat.

- The coal turns into coke.

- The combustion process of coke is accompanied by the release of heat sufficient to start coking the next portion of the fuel.

In industrial boilers, the combustion of coke is separated into different chambers from the combustion of coke oven gas. This allows for the inflow of oxygen for coke and gas with different intensities, achieving the required combustion rate and maintaining the required temperature.

On burning coal in furnaces

The above temperatures in degrees for each type of fuel are theoretical. That is, they are achievable under ideal conditions for the combustion of an energy carrier, which does not happen in real life, and even at home. Moreover, it makes no sense to overheat a brick stove or a metal boiler. They are not designed for such regimes.

By and large, the intensity of coal combustion in the stove depends on the amount of air supplied. Coals give off heat best with 100% air supply, but in practice this does not happen, since we limit the amount of it with a damper or damper. Otherwise, the temperature in the combustion chamber will rise too much, and so it is in the range of 800-900 ºС.

As for a solid fuel boiler, an excessively intense combustion mode can cause a rapid boiling of the coolant and a subsequent explosion. Therefore, this type of solid fuel is burned in boilers in two ways:

- traditional, with loading into the furnace and limiting the amount of air.

- with the help of a metered feed, implemented in automatic boilers.

Using charcoal

Charcoal is used in everyday life for cooking meat on the grill.

Due to the high combustion temperature (about 700 ° C) and the absence of flame, an even heat is provided, sufficient for cooking meat without charring.

It is also used as a fuel for fireplaces, cooking on small stoves.

In industry, it is used as a reducing agent in metal production. Irreplaceable charcoal in the production of glass, plastics, aluminum.

It is possible to make charcoal yourself. Details:

Activated carbon

Activated carbon is a type of carbon with a high specific pore surface area, which makes it even more adsorptive than wood charcoal. Charcoal and coal, as well as coconut shells are used as raw materials for its production. The starting material is subjected to an activation process. Its essence is to open the clogged pores by the action of high temperature, electrolyte solutions or water vapor.

During the activation process, only the structure of the substance changes, therefore the chemical formula of activated carbon is identical to the composition of the raw material from which it was made. The moisture content of activated carbon depends on the specific pore surface area and is usually less than 12%.

A source