Ventilated facades are very popular among private developers. The design under consideration allows you to simultaneously provide high-quality insulation and a beautiful appearance of a residential building. Anyone can handle the arrangement of a ventilated facade with their own hands. However, before starting work, you need to consider the main features of the system and select materials for assembling the battens, wall insulation and finishing cladding.

DIY ventilated facade

General information about ventilated facades

First of all, you need to study the features of hinged ventilated structures and understand their main purpose.

Ideally, the finishing decorative coating should have good vapor permeability. In the course of their life, people release a lot of moisture: cooking, bathing procedures and other household activities - all this leads to an increase in air humidity. Some of the moisture escapes through the ventilation system along with the exhaust air, while the remaining moisture must escape through the pores in the facing material.

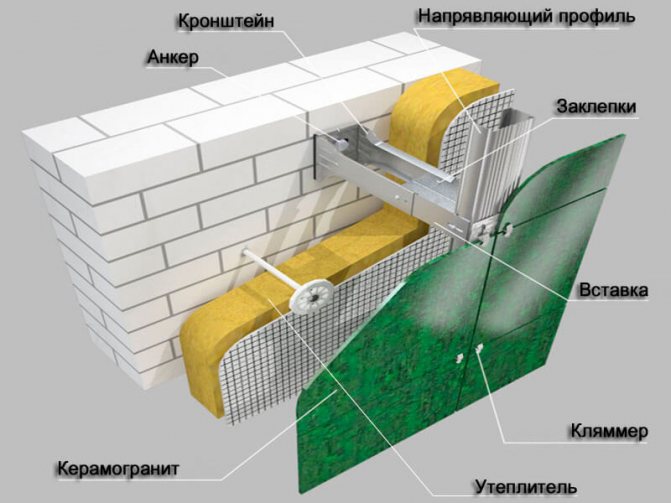

Ventilated facade made of porcelain stoneware

The vapor barrier should be equipped in such a way that the wall material is as vapor-permeable as possible inside the room and has minimum performance on the outside. This rule is relevant for all types of facades. Violation of this recommendation usually leads to a deterioration in the thermal insulation qualities of walls and a decrease in their durability.

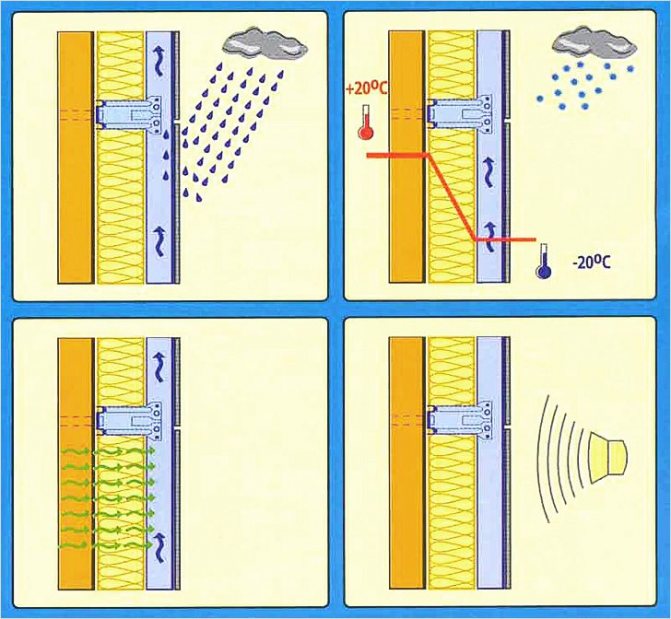

At the same time, the facade of the house must be reliably protected from atmospheric precipitation. In this case, it is best that the outer part of the walls does not get wet, because this will lead to a reduction in the service life of the structure.

The most progressive façade system is a curtain-type ventilated façade.

Some logical contradiction follows from the information given. But there is a completely understandable and simple solution: to ensure optimal waterproofing and vapor permeability, the protective facade coating must be fixed at a certain distance from the wall surface, while simultaneously providing high-quality ventilation of the gap. It is this design that is commonly called a ventilated facade.

Installation procedure

The technology of installation and insulation of ventilation facades is as follows:

- Preparatory work. At this stage, crumbling and fragile plaster is knocked down, if there is destroyed brickwork, it must be restored. The prepared wall is marked out, maintaining the standard distance between the brackets for fasteners - horizontally, the distance should be within 400-600 mm, vertically 800-1400 mm.

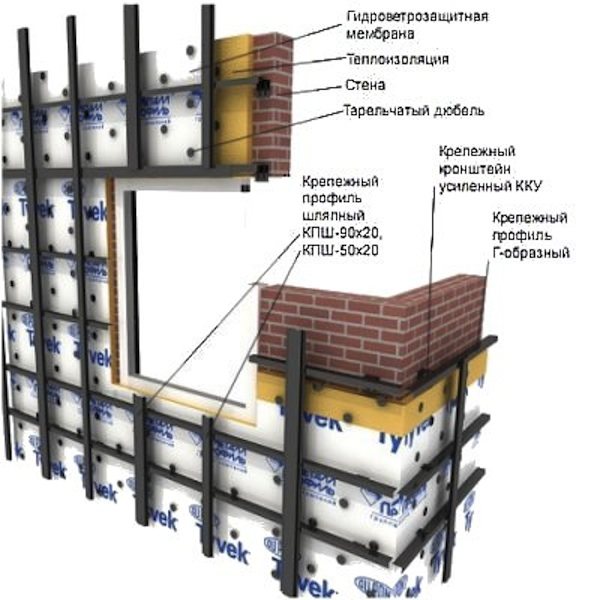

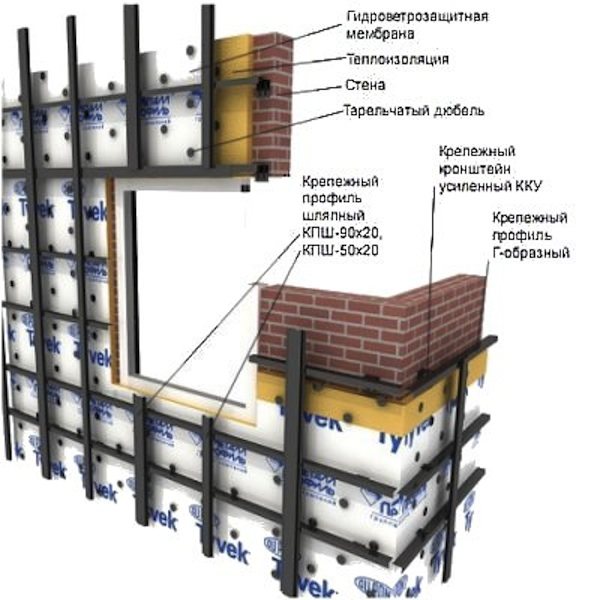

- Manufacturing and installation of a lathing frame for facing. The frame elements are mounted with screws directly on the wall. The parameters of the fasteners are determined at the design stage. It should be borne in mind that it is forbidden to drill a hole for dowels in hollow bricks and building blocks using a hammer drill. After installation, the brackets are leveled into a single work plane.

- Laying heat and waterproofing. At the stage of thermal insulation, the slabs selected on the basis of thermal engineering calculations are fixed with mushrooms or stickers, depending on the selected material. Laying starts from the bottom row and continues from bottom to top.When performing double thermal insulation, after installing the insulation, a material is laid that protects the sheets from moisture - this layer is also attached using disc-type dowels.

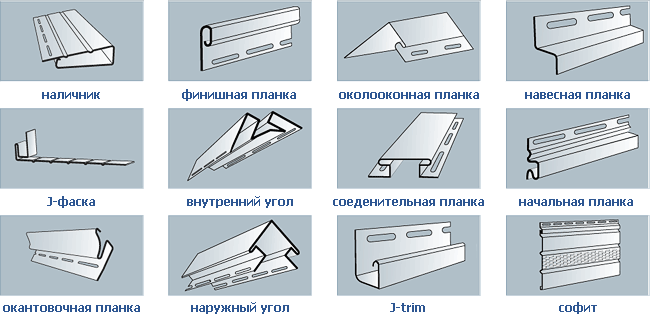

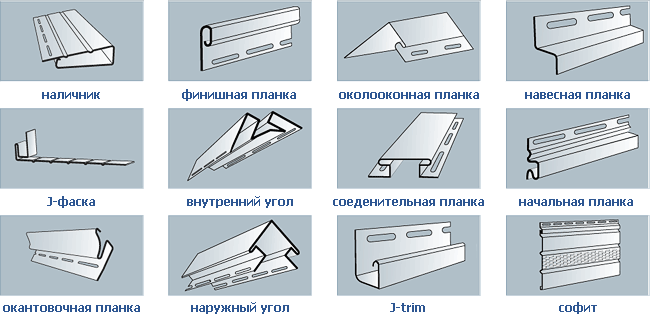

- Installation of a ventilated facade system. L-shaped strips are installed on the mounting brackets using screws. After installation, the surface of each plank is leveled into a single surface. At the final stage, the cladding is attached. Bones, as a finishing material, you can use aluminum panels, siding, porcelain stoneware, fiber-cement and asbestos-cement panels, natural stone, granite and so on.

In general, the installation of a ventilated facade is a complex technological process, which often requires the involvement of special equipment. That is why the installation of facade systems should be entrusted to specialists.

A ventilated facade is a structure that provides thermal insulation and serves as a cladding.

Features of the structure of a ventilated facade

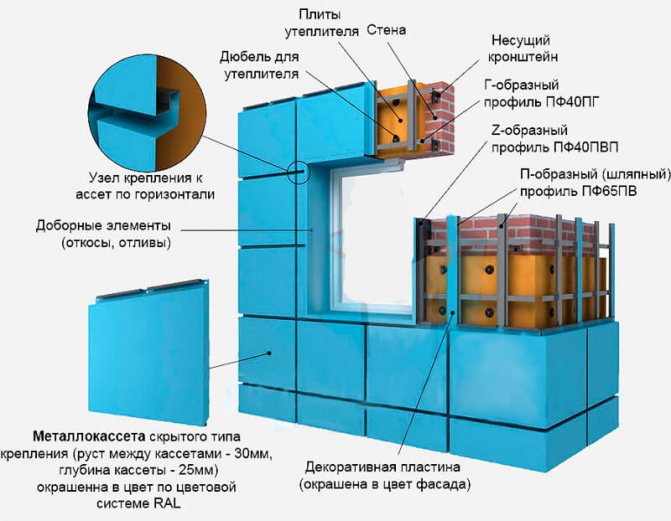

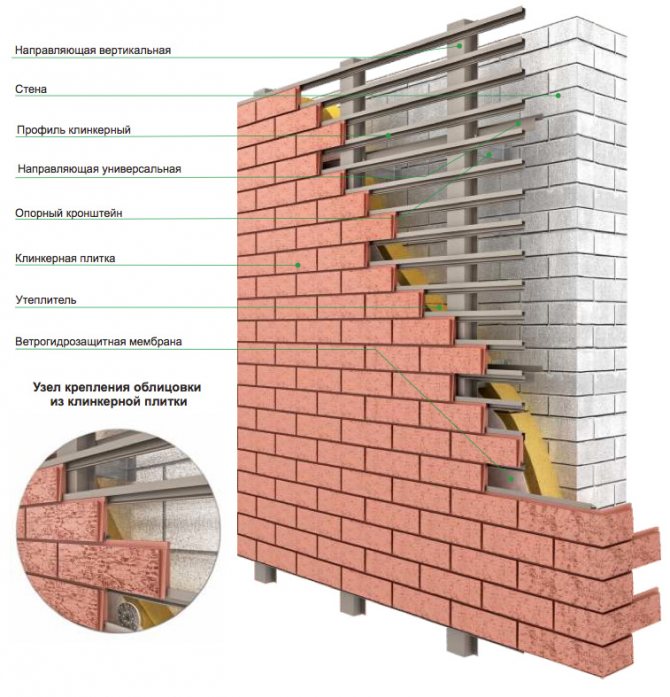

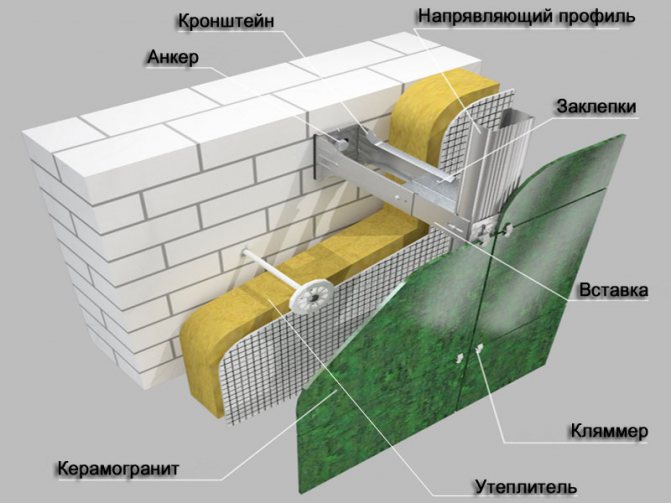

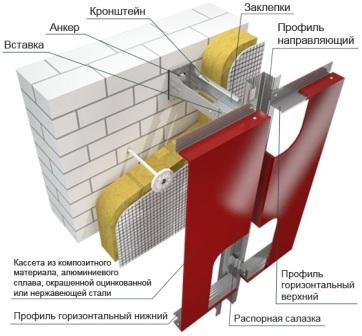

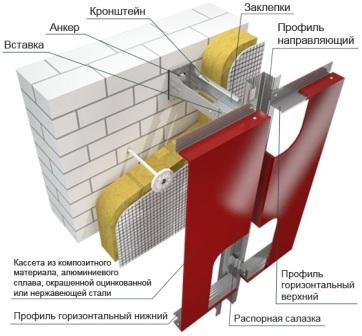

The ventilated façade consists of thermal insulation, fixings and cladding panels. The load-bearing basis of the façade is the elements that secure the cladding material. These include vertical and horizontal guides, brackets and other accessories. A space is formed between the thermal insulation and the facing material, the size of which depends on the length of the brackets. The insulation plate is tightly attached to the wall using brackets and dowels. The reliable load-bearing base of the façade is usually made of stainless steel or aluminum.

The choice of insulation

Mineral wool insulation is used as thermal insulation, which can be installed in one or more layers. The choice of insulation should be determined by such factors as:

- bearing wall material;

- the purpose of the building;

- climatic region.

The thermal insulation material must be fire-resistant and have a low thermal conductivity coefficient, thereby ensuring effective heat conservation. Insulation boards must be rigid, durable and elastic in order to prevent violation of their geometry and facilitate the installation process.

TechnoNICOL Corporation has developed a group of materials TECHNOVENT STANDARD and TECHNOVENT PROF especially for ventilated facades. They are made using rocks of the basalt group.

"Pluses" of ventilated facades

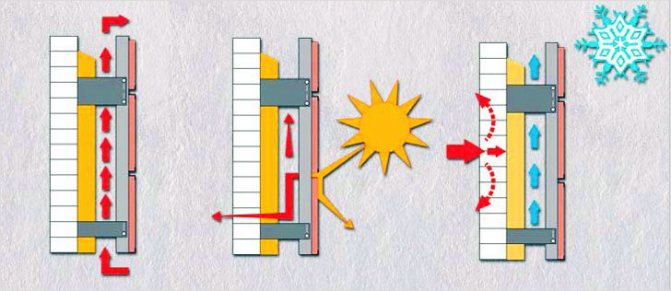

Ventilated facades protect the walls from the negative impact of the environment (precipitation, sunlight, etc.) After installing the curtain facade, a significant decrease in heat loss and energy consumption is observed, and the microclimate in the room improves. Ventfasad is also a profitable solution, because such a facade is not whimsical in maintenance and has been serving for more than a dozen years. In addition to excellent technical characteristics, hinged facades have a beautiful stylish design.

Design advantages and disadvantages

Hinged ventilated structures have a number of advantages. But, like in principle all existing ones, such systems have some disadvantages.

Benefits

Among the main advantages of ventilated facades are the following provisions:

- insulation allows you to significantly save on heating the house;

- waterproofing in combination with a ventilation gap eliminates the risk of moisture retention on the walls, which significantly increases the service life of the materials used;

- ease of arrangement. You can handle the installation of all elements of the ventilated facade with your own hands;

- increasing the soundproofing properties of the walls.

disadvantages

Among the disadvantages, moreover, relative, can only be attributed to the high cost of the structure. However, at this point, it is imperative to pay attention to a significant reduction in heating costs after installing a ventilated facade.All expenses for insulation, cladding and other things pay off quickly enough.

Tips before you get started

In order for the finished structure to retain its high performance characteristics for a long time, for its arrangement it is necessary, firstly, to use high-quality materials, and secondly, to follow the rules for installing all components. Follow the instructions and there will be no problems.

Do not skimp on the purchase of building and finishing materials. High-quality material cannot cost much less than its average market value. Buy all the necessary items in trusted places, giving preference to reputable manufacturers.

Facade siding

Pay due attention to the choice of facing material. For example, tiles in many of its varieties are very suitable for finishing the facade. However, the tile has a very big problem - the tearing off of at least one cladding element leads to the so-called. “Domino effect”, as a result of which the usual gust of wind can tear off nearby tiles.

As a result, a hole will appear, due to which the characteristics of the entire structure will decrease. Therefore, if possible, it is recommended to refuse such a facing.

Facade cladding with siding

The best finishing cladding for ventilated facades is siding. Subject to proper installation, the appearance, service life and other important characteristics of such a finish will not be inferior to other popular materials. You will receive more detailed information on the properties of siding below.

Finishing

We have already mentioned the undisputed champion of this market segment - vinyl siding. The material has many advantages over existing alternatives, namely:

Vinyl siding

- siding is sold at an affordable cost. The difference becomes especially noticeable when comparing siding with porcelain stoneware or clinker tiles;

- the material is easy to process. You can use a simple hacksaw to cut the siding;

- siding is lightweight, so you don't have to worry about increasing the load on the foundation and walls of the house;

- a large selection of siding of a wide variety of colors and textures is available for sale, which allows you to choose the ideal finishing option for any site.

Vinyl siding

Ventilated Facade Installation Guide

First step. Assemble the crate. Attach the bars to the wall vertically, in increments of a couple of centimeters less than the width of the insulation plates. It is more convenient to first fix the extreme slats, pull the string between them and, guided by the rope, fix the intermediate elements at the same level.

Metal frame lathing

Second step. Place the insulation between the battens of the battens.

Step three. Cover the insulation with a vapor barrier membrane. Lay the vapor barrier strips horizontally with an overlap of about 10 cm.

Fourth step. Fill over the battens of the battens with the perpendicular bars of the counter battens. This will create the required ventilation gap.

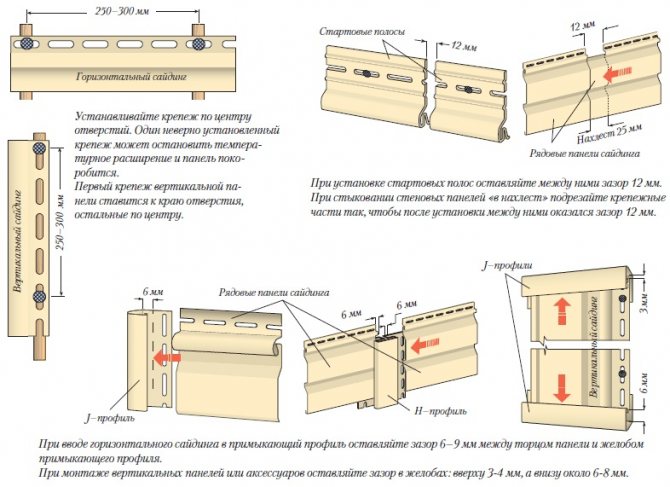

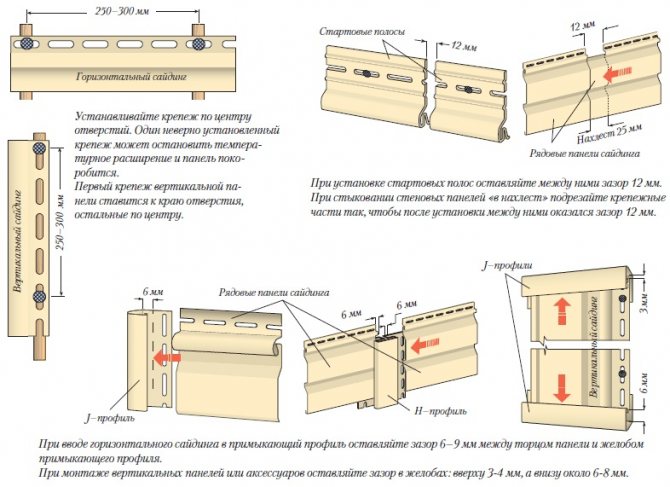

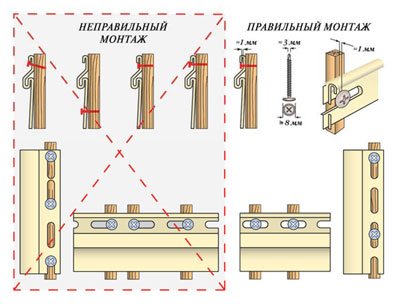

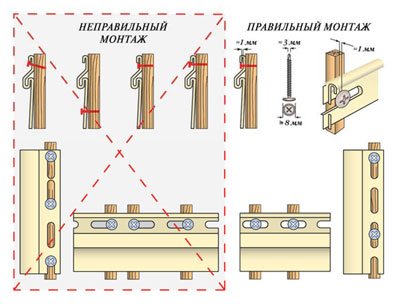

Fifth step. Attach the siding to the finished sheathing. The cladding is made of polyvinyl chloride. This material changes its size when the temperature changes, so rigid fastening of the planks is unacceptable. A small gap (3-5 mm) must be left between the panels. Hammer in the fasteners (screw in) not reaching the end by about 2 mm. Fasteners must be placed strictly in the center of the holes intended for them.

Vinyl siding

Installation instructions

Correct installation method

Insulation laying

Foam insulation

When the lathing is done, you can start laying and securing the insulation.Everything is simple here - the foam is cut to the required size, an adhesive is applied to it, and then it is inserted into the space between the slats. The insulation must be additionally fixed, for example, with "parachutes". A vapor barrier film is laid on top of the foam. In this case, the formation of gaps between the sheets should not be allowed. You can fix the material with a stapler.

Recommendations of professional builders

To make the work as easy as possible, and the finished ventilated facade retains its original characteristics for a long time, follow a few simple recommendations of professional builders.

Ventilated facade

- First of all, when installing a structure, you need to focus on an individual project developed specifically for your home. The project will allow you to competently plan the scope of work and calculate the required amount of materials.

- When choosing fasteners, be sure to check the quality of the dowels. Consider the parameters of the battens, insulation and cladding.

- The ventilated facade must not be built on walls made of hollow bricks, foam concrete and other materials with a density not exceeding 600 kg / m2.

- Thermal insulation materials are necessarily accompanied by the manufacturer's instructions, which describe in detail the procedure for fastening the material. Follow the recommendations. For example, a mandatory rule for all thermal insulation materials is some displacement of vertical seams.

- Insulation and finishing material must be fixed strictly according to the level. Even a 5mm error for a 10m facade is an unacceptable deviation.

- The holes for the dowels are prepared exclusively with a drill. It is prohibited to use a hammer drill for these tasks.

- The design of a ventilated facade requires the presence of a counter-lattice. Thanks to this element, the gap necessary for ventilation of the space will be created.

Ceramic ventilated façade

Thus, there is nothing super complicated in the independent arrangement of a ventilated facade. It is enough to understand the basics of work, choose the most suitable materials and complete all planned activities in accordance with the instructions. Do not forget the recommendations received, and the ventilated facade of your house will serve as long as possible, while maintaining its original performance characteristics.

Happy work!

Selection of the required materials

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

Insulation of a ventilated facade is an important point in installation. In this case, you need to make the right decision.

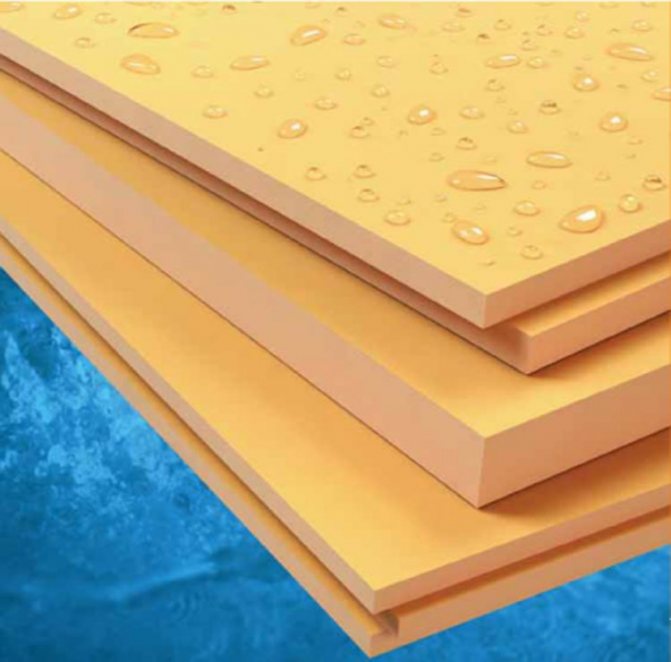

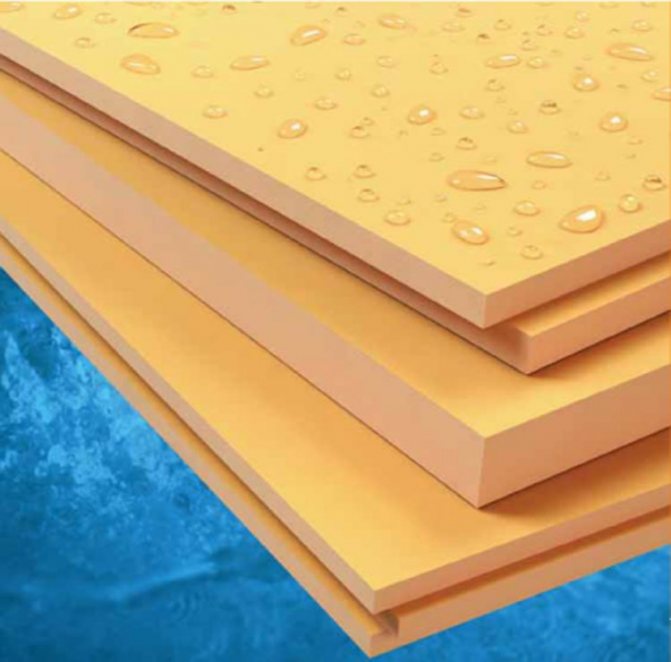

The first option is polystyrene (insulation for ventilated facades). Thanks to this material, excellent thermal insulation of the room is formed. Compared to mineral wool, foam has excellent performance at the same thickness. Also, another advantage of this material is vapor barrier. The vapor barrier of the foam is so strong that it will be impossible for steam to squeeze through the created barrier.

Styrofoam

Extruded polystyrene foam is the next material to look at. This object is a synthetic thermal insulation material. In terms of mechanics, this synthetic material is quite durable. But as a heater, this is not the best option. The cost of extruded polystyrene foam is high compared to the previous material. The vapor barrier of this heat-insulating object is low.

Extruded polystyrene foam

The most correct choice is the installation of mineral wool. The cost of mineral wool is acceptable, since the thermal insulation and vapor barrier are at the highest level.

There is such a material as basalt wool. This object is distinguished by its fire resistance, and it has superiority over mineral wool. As a heater, basalt wool is the best material.

Basalt wool