Introduction

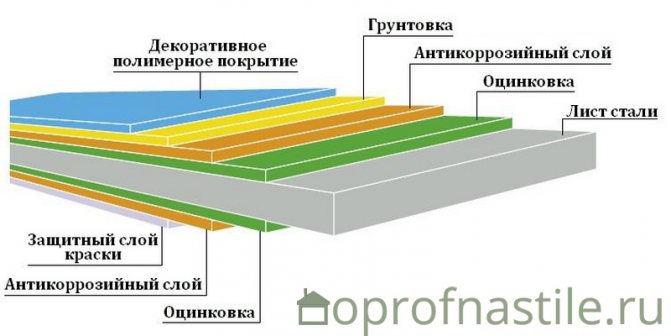

Profiled sheeting (also profiled sheet, corrugated sheet) - profiled sheets of thin sheet rolled steel with a thickness of 0.35 to 1.2 mm, with different corrugation heights from 6 mm to 260 mm, depending on the type of profile. Manufactured by cold rolling on automated profiling lines. During manufacturing, it is profiled (wavy, trapezoidal and other shapes are given) to increase rigidity. Decking can be made of galvanized steel, or with a protective coating, such as polymer.

The main properties of the profiled sheet

Profiled sheet - a thin metal panel made of galvanized steel. To increase the rigidity of the material, each piece has “ribs” of the wave or trapezoid, which are repeated with a certain step. During the production process, each sheet is coated on both sides with polymer paint, therefore it has an aesthetic appearance.

The main properties of the profiled sheet are as follows: high mechanical strength; long service life: 30-45 years; resistance to wind, ultraviolet rays; different sheet thickness: from 0.6 to 1 mm. Profiled sheet is used not only for the installation of ventilated facades, but also for laying the roof, installing fences.

The professional sheet can be colored. Different types of paint are applied to the galvanized surface: polyester, polyvinyl chloride, acrylic. As for the decorative layer, it can also be different: glossy or matte, with a texture like brick, stone or wood.

Due to its good strength, the specified material can be dismantled if necessary, and then reused.

Sheathing with corrugated board - the advantages of this type of finish

House sheathed with corrugated board

When cladding a house, special attention is paid to the quality of the building material. Corrugated sheets are used for fencing, finishing facades and roofs, building prefabricated structures (hangars and sheds).

Corrugated sheets are in demand because:

- the material is easy to clean, does not absorb dust;

- the corrugation has a neat, presentable appearance;

- quite strong, resilient;

- has a reasonable price;

- building material easily undergoes various manipulations;

- steel sheet covered with a protective polymer layer is resistant to fading, rust, temperature extremes, ultraviolet radiation;

- the possibility of using heat-insulating plates of various thicknesses;

- the corrugated board perfectly tolerates high humidity, subject to the installation technology following the example of the under-roof space;

- the surface of the building does not require additional leveling and cladding, the processed sheets become the "face" of the facade;

- building material provides a great opportunity for the realization of design imagination;

- profiled sheet is an economical type of home decoration.

We take into account the nuances

- The surface heats up strongly under the rays of the sun, therefore, on hot sunny days, it is necessary to work with construction material extremely carefully.

- In places where the protective layer is damaged, if the technology of cutting the corrugated board is violated, metal corrosion is possible over time.

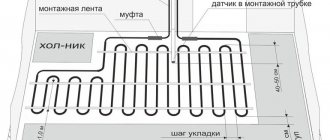

- For good ventilation, it is recommended to equip a vapor barrier system. This element will allow the accumulated condensate to be removed without hindrance. The absence of an air gap acts destructively for a building, creates conditions for mold and mildew to multiply inside. An air gap is created between the insulation layer and the corrugated board.

Ventilated facade substructure

Completing of the work

Laying of insulating materials

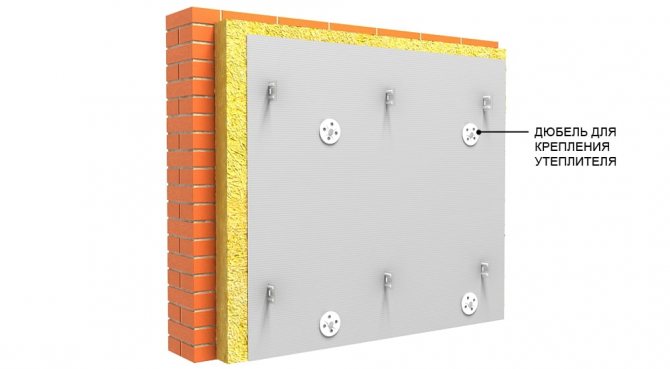

After installing the brackets, you can proceed to the insulation measures. At a minimum, a layer of insulation should be installed - in the form of a roll material or a plate. Installation is made from bottom to top. The slab segments are fixed as tightly as possible to each other without large gaps. If, due to the structural features of the material, there are still gaps, then after installation, sealant should be performed. Fastening of the facade cladding with profiled sheet with insulation is carried out with disc dowel-anchors with spacers. On average, 6-7 pieces are spent on 1 m2. For the convenience of work, the plates should be drilled in advance at the appropriate attachment points. After the heat insulator, you can lay a wind and moisture protection film. The sheets are laid with an overlap and fixed with a self-adhesive mounting tape.

How to prepare the surface and make the markings

We pay attention to the surface. We give a perfectly clean state. Any delamination can be repaired with conventional construction tools. The wall is carefully primed with a deep penetration consistency using a brush.

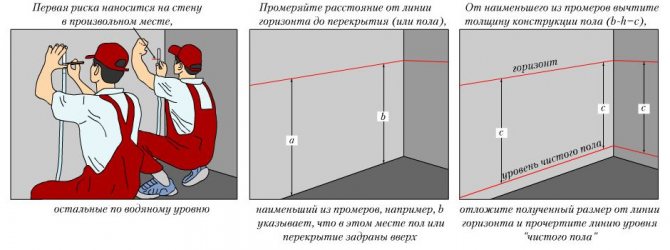

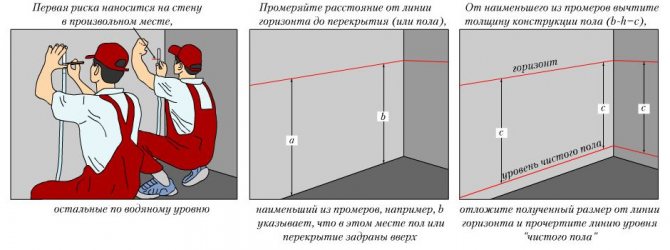

Marking is applied to a well-dried plane. It is necessary to ensure that the installation line is as parallel to the horizon as possible. Transfer of points to other surfaces is carried out using a hydraulic level. As a result, the points are connected using a nylon thread. The size is marked and the marks are connected in one line. The end result should be the correct installation lines.

How to make markup

Attention! The bottom of the finishing fragments rests not on the ground, but on the blind area. It may not exist, then you will have to make a pouring out of crushed stone, pour the mass with cement mortar.

Facade device made of profiled sheet

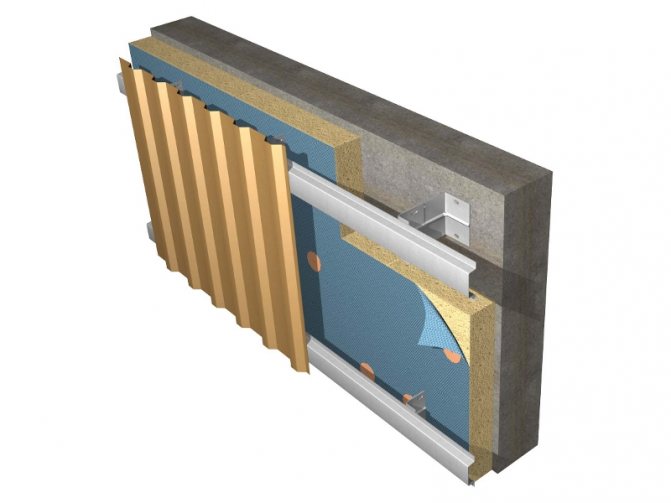

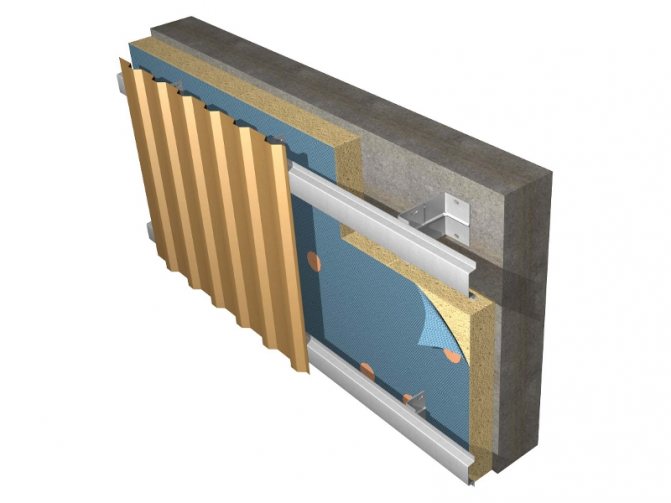

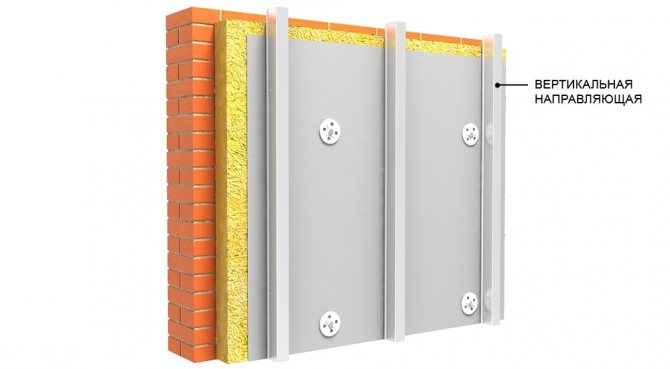

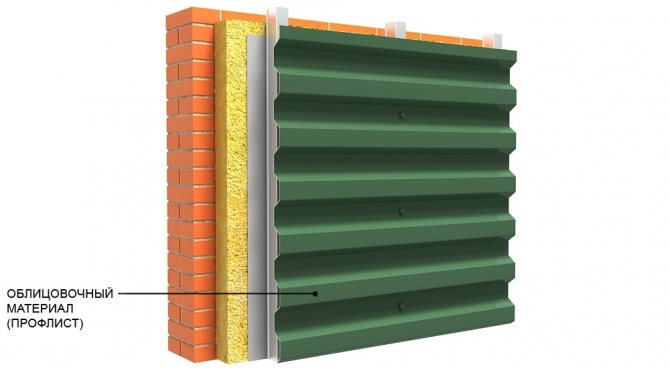

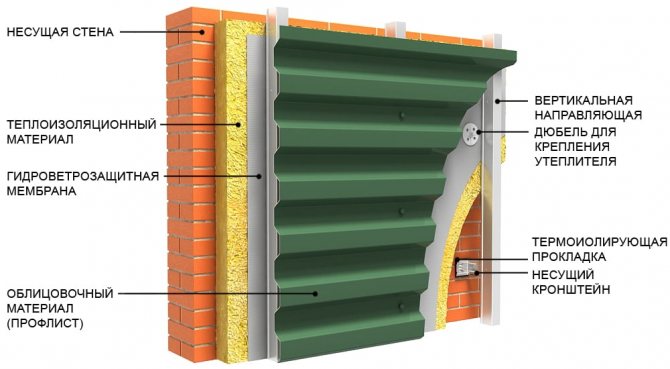

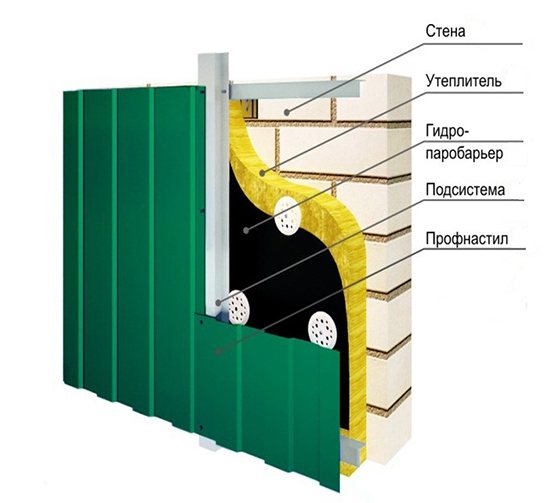

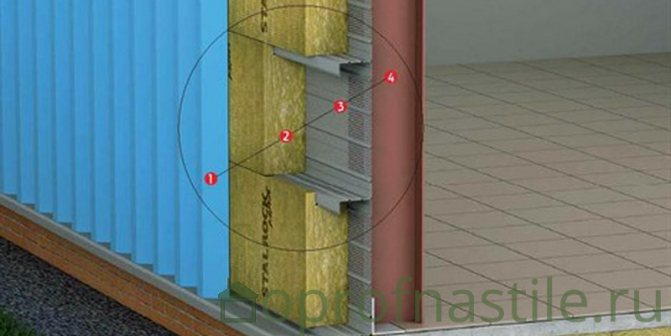

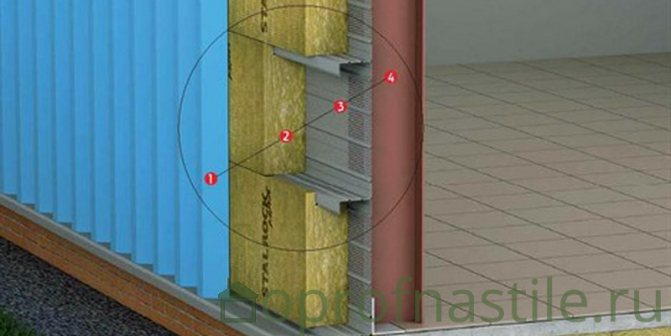

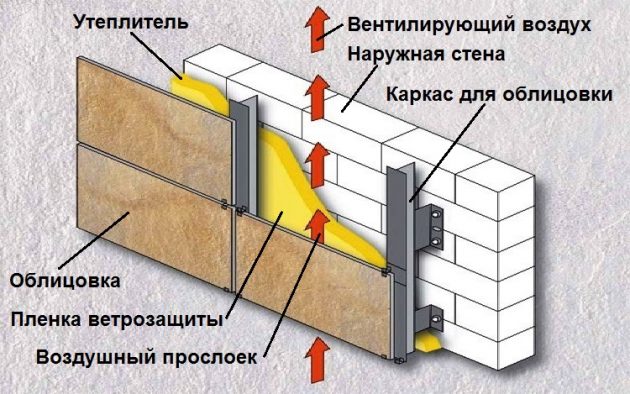

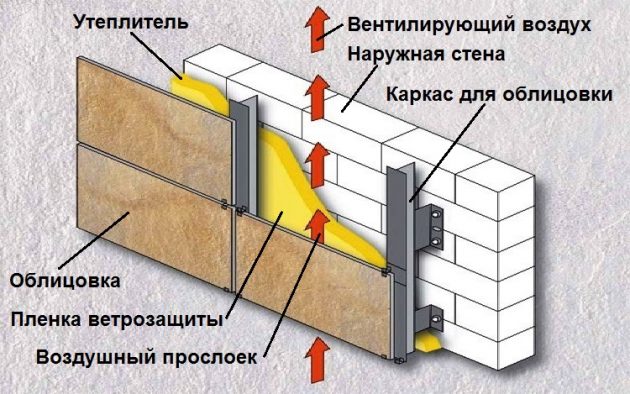

The ventilated façade is like a kind of "cake" and consists of several layers.

First of all, a frame is mounted from Z-, G- or H-profiles and brackets. The latter are securely attached to the wall using anchor dowels.

Corrugated ventilated facade - installation technology

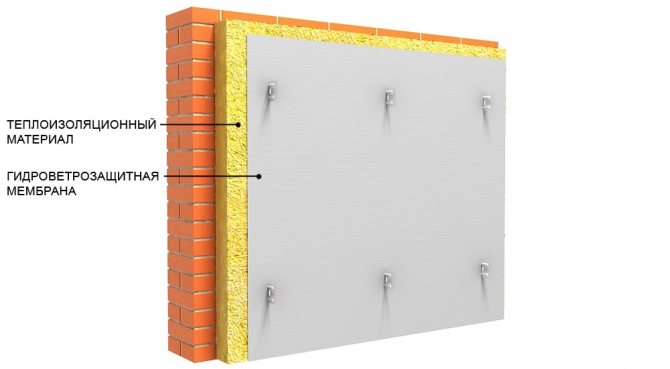

Next, the heat-insulating material is laid and fastened with disc dowels. It is best to use basalt fiber slabs as insulation, since they are quite fireproof compared to other common options.

Then, without fail, a layer of waterproofing and wind protection is laid. Some modern materials perform both functions at the same time.

And, finally, the direct installation of the profiled sheet on the facade is carried out. In this case, it is very important to correctly attach the sheets so that moisture does not penetrate between the self-tapping screw and the surface. To do this, it is necessary to use special screws with a rubber lining, which seals the screw-in place and protects the metal from corrosion.

The installation of the facade from the profiled sheet is completed by installing the corners and processing the joints with a sealant.

Top ↑

How to assemble a frame for sheathing a house with corrugated board

Frame for cladding the house with corrugated board

The frame is made of wooden blocks (pre-treated with an antiseptic) or Z-shaped profiles. The latter parts are in demand, as they provide excellent air circulation between the insulation and the facing material. You will also need brackets.

Special dowels are the optimal fastening system. A hole is made in the plane with a drill and the connection is made.

Pay attention! The self-tapping screw is bought a couple of millimeters more from the cross-section of the plastic dowel hole. Only in this version can we talk about a reliable fastening.

The principle of attaching a profile to a plane

- The corrugated board is cut to the required size and fastened along the original line.

- Tying is done along the lower and upper contours.To fasten the transverse profile, the fishing line is pulled along the diagonals of the strapping.

- According to the thickness of the insulation, the transverse profile is attached along the height. Make sure that the material after manipulation does not change its geometric shapes. A small gap will allow good air circulation.

- This is followed by a vapor barrier and installation of thermal insulation material. Films are cut to a certain size and overlapped by at least 5 centimeters.

- The hydro-barrier is followed by a heater, which is attached with special "fungi".

Facade cladding with corrugated board

What is a ventilated facade?

In a nutshell, it is a curtain wall. It got its name due to the fact that a gap is specially left between the insulation (outer wall) and the cladding, through which ventilation is carried out.

It is due to the air circulation between the wall or insulation and the hinged structure that condensation is removed. This circumstance allows the facade to "breathe" and makes it vapor-permeable.

The device of the ventilation facade is a guarantee of the long service life of the walls of the building. The constant removal of moisture from the surface of the wall, insulation and cladding saves them from the harmful effects of water, which is the worst enemy of any insulation system.

How to make a calculation for insulation when sheathing a house with corrugated board

It is important to calculate the amount of building material.

To do this, you need to take into account a number of factors:

- determine the surface area. If the length of the walls is 6 and 5 meters, and the height is 3 meters, then the surface area will be (6x3) + (5x3) = 33 meters. The resulting number is multiplied by another 2 and you get 66 square meters of the processed surface;

- from the total, it is necessary to subtract the elements of window and door openings. The height and width of each opening is measured. Then the width is multiplied by the height, and the summed values are added. It turns out the perfect finishing area;

- the area of the profiled sheets is calculated. The resulting amount of the profile is increased by 15% (compensation costs).

Insulation of the house outside

The corrugated board has more advantages. And you will like them

To begin with, this material is easy to install, pleases the eye with a bright palette of colors and, of course, a pleasant cost. Here's a simple example for you: if we compare the finishing of a house with a profiled sheet and siding, then in the first case we will get a decent saving of time - all the work can be done 2 times faster.

And here are other strengths of corrugated board:

- Maximum durability: each sheet can last up to 50 years. You will forget about the need for repairs for a long time. Profiled sheeting does not need to be constantly tinted or greased, like other materials.

- Resistance to negative factors. This material is resistant to temperature extremes, shock loads, vibrations, hail, corrosion and discoloration.

- Perfect look at the lowest cost. Decking is profitable already at the stage of purchase and installation, plus the house looks neat for many years.

As you can see, the corrugated board has practically no drawbacks. But the advantages are enough to make the right choice and not regret it.

How to mount corrugated board

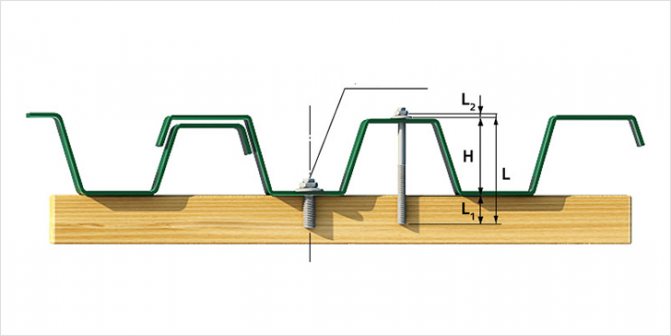

The installation of a profiled sheet is its fixation to the frame.

With a galvanized self-tapping screw with a rubber gasket, the corrugation is attached with a pitch of 35 cm. The self-tapping screws for the corrugated board have a thread and a special tip in the form of a drill. They are usually produced from high-strength alloyed carbon steel grade C1022 with a finishing zinc coating. The design of a self-tapping screw with such a tip allows them to be attached to the frame without pre-drilling holes.

So self-tapping screws for corrugated board with a diameter of 4.8 mm can drill metal with a thickness of 2.5 mm.

Rubberized gaskets protect the cavities of the building material from moisture.

The sheets are always stacked with an overlap of 5 cm. When cutting metal, the burrs are removed so as not to cut themselves.

Additional elements are fixed along the entire perimeter of the house (corners, doors, windows). Then the building gets a complete and neat appearance.

Attention! Punch and nails cannot be used.

Fastening the corrugated board with self-tapping screws

Which profiled sheet is suitable?

Cold-formed steel sheets with trapezoidal corrugation are recommended for outdoor applications. In addition to the zinc coating, polymer processing is also required, which will protect the material from aggressive chemical influences. Products marked C8, C10, SP20, HC35, etc. are produced especially for facade decoration. As for the dimensional parameters, the length can vary from 50 to 120 cm, the width is 90-120 cm, and the height of the corrugation is about 8-15 cm. The average weight of the profiled sheet per 1 m2 is 3.7-4.2 kg. The weight depends on the thickness of the sheet, which, in turn, varies from 4 to 6 mm. You should immediately calculate the aesthetic qualities of the material, since we are talking about the most prominent part of the house. The design choice, in principle, is not rich in this segment, but you can give preference to a color scheme that will fit optimally into the overall composition of home ownership with a roof and garden landscape objects.

Sheathing of the gable of the house

The pediments are a continuation of the wall spans at the ends of the structure. The fragments are placed between the roof slopes. The low weight of the profiled material reduces the pressure on the supporting structure of the building, on the foundation.

Installation work is carried out individually. Sheets are attached with self-tapping screws for iron. Scaffolding and a safety belt must be used.

Sheathing of the gable of the house

Advantages of corrugated board for the pediment:

- wide range of colors of polymer coating;

- convenient cutter;

- the plating process is simple;

- easy replacement of the damaged part of the sheet;

- due to the low weight, cladding is carried out even for frame buildings;

- sheets are easy to cut;

- ease of caring for corrugated board.

See also the article "How to properly sheathe a pediment with siding"

Calculation of material for installation

The area of the pediments is carefully determined, taking into account their geometric shapes. The area of the window openings is not taken into account. The necessary additional elements are determined. These are framing, drainage, corner. Self-tapping screws are screwed at a maximum distance of one meter.

Installation

The sheet is fixed to the prepared wooden slatted frames. They should be pretreated with a special antiseptic against material decay. Qualitatively assembled wooden slats or brackets into a single frame will make the facade ventilated.

The windproof film is attached to the insulation. The facade is closed at the finish. The pediment is the last.

Algorithm of actions:

- The corrugation is cut according to the additionally created patterns.

- Attachment starts from the bottom corner.

- At a maximum distance of one meter, the sheets are overlapped.

- Self-tapping screws are attached to the pre-made hole in the sheet deflection.

- A 5 mm gap is left between the wall and the outer sheathing sheet for the metal corner of the side element.

The trend of corrugated board can be different, however, the horizontal direction is widespread today. Closing the gable of the house with corrugated board is the finishing procedure for construction. As a result, the object takes a complete form. Often the same finishing sheet is used for the cladding as for the façade. Installation activities are simple and do not require special equipment, the involvement of highly qualified personnel.

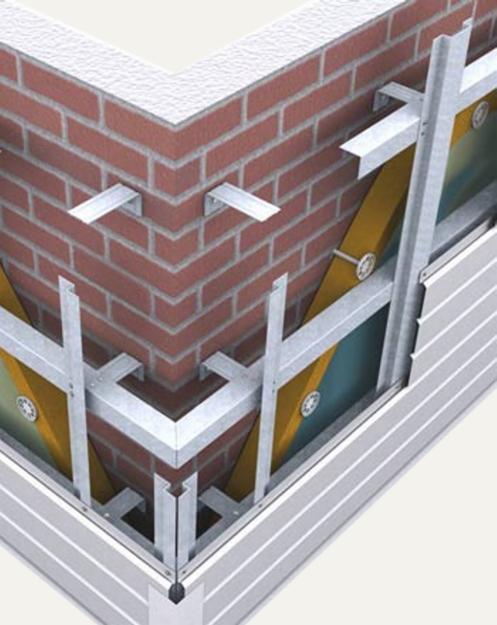

Elements of structures and materials facade decoration

In this chapter, we will consider what structural elements are used in the installation of metal siding on buildings under construction in Tobolsk. In private construction, such a frame can be used on cottages made of brick, monolithic or block walls.

The frame of the ventilated facade is exposed exactly regardless of how your walls are laid.

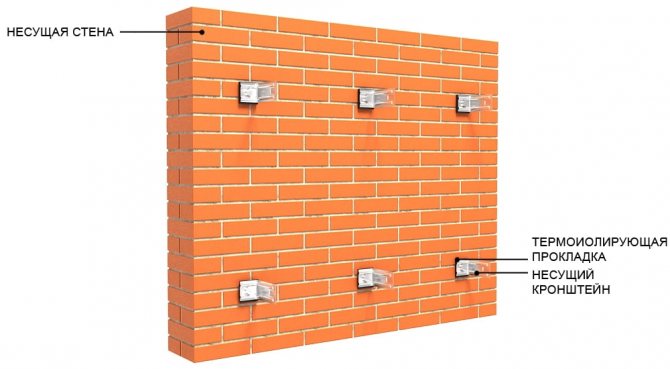

The installation of the ventilation façade fasteners begins with the installation of a paranite gasket, it is installed to tightly connect the bracket to the building wall and prevent the metal bracket from contacting the concrete or brick wall of the house.

Next comes:

- The adjustable bracket is fixed to the wall with dowels

- Galvanized corner, which is mounted to the bracket with rivets.

After the frame has been mounted, the insulation is attached in our case, these are mini-wool slabs in two layers 20 centimeters thick. The thickness of the insulation depends on the climatic region in which the building is located.

Holes are made in the insulation plates and placed on the brackets, additionally fixed with plastic dowels to the wall of the building.

Next, the insulation is covered with a windproof waterproof vapor-permeable membrane (film) to prevent air from blowing out of the insulation. In addition, a waterproofing membrane has the property of allowing moisture to pass through only from one side.

Thanks to this, the steam emanating from the walls of the building does not condense on the inside and does not allow the insulation to get wet.

And the penultimate part of the facade finishing is the installation of a metal profiled sheet. As mentioned above, the finishing material is porcelain stoneware slabs, plastic siding, metal cassettes, metal siding are mounted with a gap between the insulation, and not tightly.

The gap should be at least 40 millimeters, this allows the flow of rising air to circulate between the cladding material and the insulation. Hence the name ventilated facade.

In conclusion, they frame windows, doors with strips, window sills.

Stages of finishing the facade with a metal profile

All construction work begins with preparation. Before finishing the facade, it is necessary to purchase a tool, prepare a place for storing materials, complete and install scaffolding, or agree on an aerial platform. When working at height, protect the area dangerous for people below.

Organizational and preparatory activities are carried out in accordance with SNiP 3.01.01-85 "Organization of construction production". When working at height, to prevent accidents, you must familiarize yourself with the rules of SNiP 3.03.01-87 "Supporting and enclosing structures" and safety regulations SNiP III-4-80.

Tools used in facade finishing work:

- Lace;

- Level;

- Roulette;

- Plumb line;

- Building level;

- Construction pencils or marker;

- Perforator with a drill for concrete;

- A hammer;

- Riveter;

- Bulgarian for metal.