A ventilated facade for a wooden house is an ideal solution for those owners who do not want to overpay for heating.

Such multi-layer structures are more often used for brick buildings, since wood is traditionally considered a warm material.

At the same time, despite its characteristics, it is quite expensive to heat a wooden building in a cold winter.

Installation of a high-quality facade will allow you to save on heating the amount spent on the purchase of all the necessary materials and their installation in just a few seasons.

Advantages and disadvantages

The use of a ventilated facade on wooden walls has many advantages. These include:

- improvement of thermal insulation parameters;

- long service life of the structure and structure;

- protection of wooden walls from moisture, direct sunlight or temperature changes;

- if necessary, worn out casing can be easily replaced;

- it is not required to regularly repair wooden walls or cover them with protective compounds;

- high quality ventilated facades do not impair the characteristics of wooden walls;

- after the construction of the object, there is no need to finish the wooden walls, so they are not even covered with paint or varnish;

- the ecological cleanliness of the building does not deteriorate;

- panels that have a beautiful appearance or imitate wood are easily selected.

Therefore, with the help of a ventilated facade, it is possible to improve the basic characteristics of a wooden structure. The only drawbacks are the need for additional costs, and during installation, mistakes must not be made that lead to a deterioration in the design parameters.

Attention! Ventilated facades are presented in a special way of finishing the walls of the building, which consists in the presence of a ventilation layer between the walls and the cladding.

Usually, insulation systems are used immediately, which make it possible to improve the thermal insulation parameters of the house. Thanks to ventilation, steam is removed from the walls of the building, so they do not rot or become moldy. A properly made structure is highly flexible, so it does not deform with changes in temperature and humidity. If mistakes are made, then this leads to cracks or other problems.

What is a ventilated facade, its advantages for a wooden house

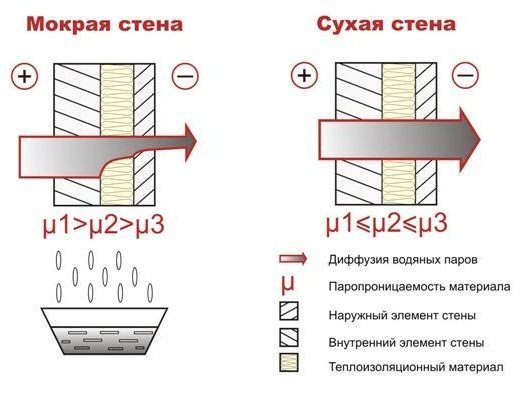

Parody movement from the premises to the street.

Ventfacade is a technique for finishing the outer walls of a building, where ventilation is assumed under the cladding. Often used in conjunction with insulation. It is not difficult to make a ventilated facade with your own hands, the main thing is to follow the installation technique.

Ventilation is needed in order to remove the steam that squeezes out of the house. In this case, the heated room is a high pressure zone, and the street is a low pressure zone. The correct microclimate in the house is possible only when the natural process of paromotion is not disturbed. That is, all materials must be vapor-permeable. The issue is especially acute when arranging a ventilation facade for wooden houses.

The tree breathes, in the process of use it constantly changes its shape. That is why a ventilated facade for a house made of timber is the only way out.

The structure of the ventilation façade is flexible enough to withstand the seasonal deformations of wooden walls. Installation is simpler, minor errors are not noticeable. For example, mistakes in external wall insulation using the wet facade method lead to cracks, which are not uncommon.Yes, and you need to be able to plaster, deduce corners, slopes - it's all not so easy.

Due to the presence of ventilation:

- walls cool in summer;

- ice does not form in winter;

- no mold appears in the insulation.

The ventilated facade technique is applicable for a house made of bricks, foam blocks, monolith and wood, of course. And in the latter case, there are even no alternatives.

When soldering polypropylene pipes for heating, you must not overheat and underheat the connecting parts.

The non-galvanized metal pipe for heating is still used today. For detailed information here.

Types of wooden facades

Curtain walls are made from different materials. Wood products are usually used for wooden buildings, as they allow you to maintain an attractive appearance of the house. To create such facades, different types of wood are used:

- Conifers such as spruce, pine or cedar. They have a reasonable price, are easily subjected to various types of processing, and they also contain a resin that does not allow the decay process to begin.

- Larch. From it, panels are obtained that easily cope with the effects of moisture, and also do not rot. The material is strong and durable.

- Heat-treated wood. It is represented by natural wood, which is dried at a temperature of 180 degrees. This allows you to get a durable, beautiful and moisture resistant material. Even with sharp and constant changes in temperature, it retains its shape and dimensions. Soft rocks are used to create thermowood.

- Decorative breeds. They come from the tropics and have an unbeatable look. They are distinguished by their high density, therefore, to fix them, a strong and reliable crate is required. The disadvantage of such wood is its high cost.

Attention! In the process of choosing a material, the climatic features of the area are taken into account.

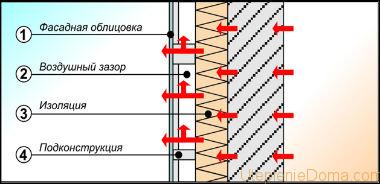

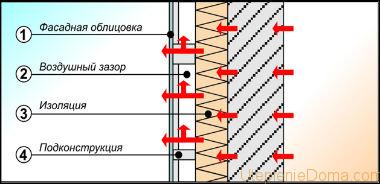

Facade system device

Wooden ventilation facades are suitable for houses made of different materials, but they are usually chosen for wooden buildings. Such a system consists of a frame, sheathing and an empty space between these parts. It can be filled with vapor barrier, waterproofing and thermal insulation materials.

The system is presented in two versions:

- Complex. Initially, the walls of the house are sheathed with heat-insulating materials and films, and then the cladding is fixed. A ventilation gap is left between the insulation and the casing. Thanks to this design, the house is insulated, and the walls are protected from various atmospheric factors.

- Simplified. It consists of a frame and cladding, so there are no additional materials between the walls of the house and the cladding. The system allows moisture to be removed from the walls of the house, and also protects the wood from the atmosphere. This option is suitable for warm regions of Russia.

For cold regions, a complex system is chosen. Thanks to it, the cost of heating the house is significantly reduced.

Types of facade structures

Today, a ventilated facade can be arranged in two ways:

- With the use of insulation. This option is recommended if there is a need to increase the heat-holding capacity of the walls of the house. This is very important for buildings erected in areas with a harsh climate, where the thickness of the timber may not be enough to ensure the proper temperature;

- Facing the house without the use of insulation. Suitable for old and rebuilt houses, as the timber darkens over time and becomes ugly. Two goals are achieved here - protecting the facade from external influences and improving the decorative characteristics.

The technology for constructing a ventilated facade for a log house is quite simple and, if you have certain skills, you can implement it yourself.An important point: you can start work only after the period of intense shrinkage is over. If waiting for some reason is impossible, special sliding brackets are used, but since they are made of metal, condensation begins to accumulate on them with all the consequences that follow from this fact.

The choice of insulation

When creating a ventilated facade on a wooden house, the owners prefer not to save money, therefore they use an integrated system. It involves the installation of not only the frame and cladding, but also heat-insulating material. You can choose different heaters, but the types are usually bought:

- mineral wool, produced in the form of slabs;

- ecowool;

- penoizol.

Only mineral wool is an environmentally friendly and safe material that does not contain synthetic components. Therefore, it is ideal for timber construction. It is bought in the form of slabs, which are cut into separate elements, which are fixed to the walls of the building between the frame elements.

Insulation layer size

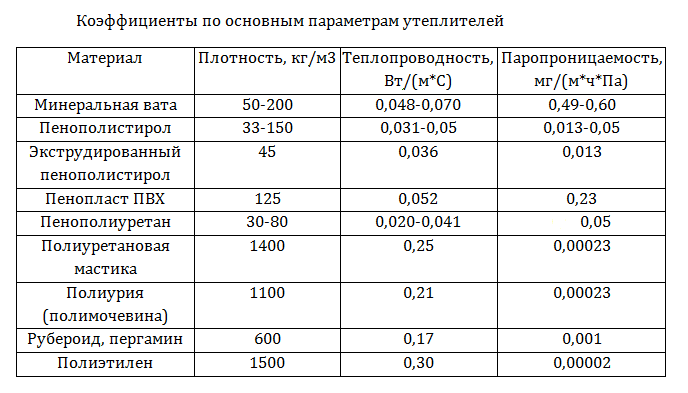

The materials with which it is planned to insulate the facade of a wooden house are selected depending on the preferences of the owner or on which technology was chosen (wet method, ventilated facade or subsequent siding). But the thickness of the layer is determined based on the climatic conditions of the region in which the building is located. The table shows the average thickness of the insulators used.

| Region | The optimal size of the insulation layer, cm |

| Leningrad region | 10 |

| Moscow region | 10 |

| Novosibirsk region | 15 |

| Sverdlovsk region | 10 |

| The Republic of Mordovia | 10 |

| Samara Region | 10 |

| Republic of Tatarstan | 10 |

| Krasnodar region | 5 |

| Volgograd region | 10 |

Help from the "facade"

If your region is not in the table, ask in the comments, we will definitely answer you!

Choosing a protective film

The correct technology for mounting the structure is to use special films. They provide protection of the insulation from moisture and wind, and also allow steam to pass through easily.

Usually a windscreen or a universal diffusion membrane is chosen. The latter option is the most acceptable, since the material allows air to pass through, but protects the insulation from moisture. But the diffusion membrane is expensive, so it costs a lot to cover the whole house.

Ventilated facade installation

As soon as the necessary materials for the work are selected and purchased, the direct installation of the structure begins. For this, successive steps are performed:

- preparation of walls, which must be clean and strong, so all rotten areas are removed and mold is treated;

- a crate is formed, and for wooden buildings, slats are considered the ideal choice, and not metal profiles;

- insulation plates are laid between the parts of the frame;

- erection of the second level of the frame, which is installed perpendicular to the first layer;

- installation of a second thermal insulation layer, and the procedure is performed in such a way as to overlap the seams of the first layer;

- overlapping membrane or film installation with gluing of seams;

- the formation of a counter-lathing;

- installation of plates.

Attention! The structure of the ventilated facade should not contact the ground in any way, and if there is a plinth, then the installation is carried out on a special metal ebb.

Insulation laying rules

The insulation process depends on the material chosen. Usually, mineral wool slabs are used to insulate a wooden house. They are cut into separate elements, which must fit tightly into the gaps between the frame elements.

Sprayed thermal insulation is considered more simplified. It is applied with special equipment.It turns out a seamless and durable layer, but a lot of money is spent on its creation, and you will also have to use modern equipment.

Sometimes rolled thermal insulation is used, so the rolls are simply rolled along the wall between the parts of the frame, fixed with brackets or other fasteners.

What is the best insulation for a wooden house?

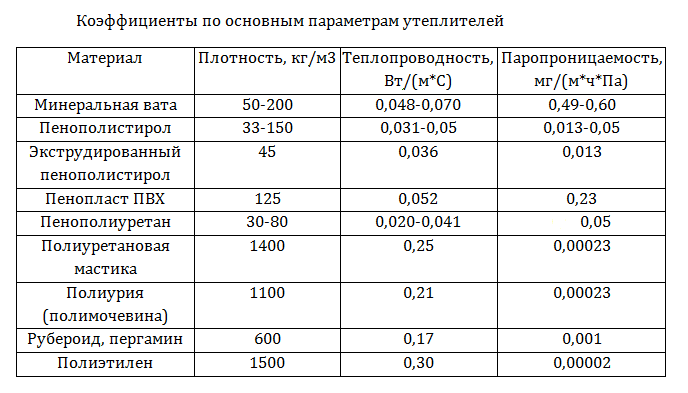

Usually they choose among two types of insulation - mineral wool and expanded polystyrene (conventional or extruded).

The regulations do not prohibit the use of expanded polystyrene as insulation for the walls of a wooden house. In the same table 4 of SP 23-101-2004, it is recommended as a type of material for various technical solutions and it has the best thermal insulation properties.

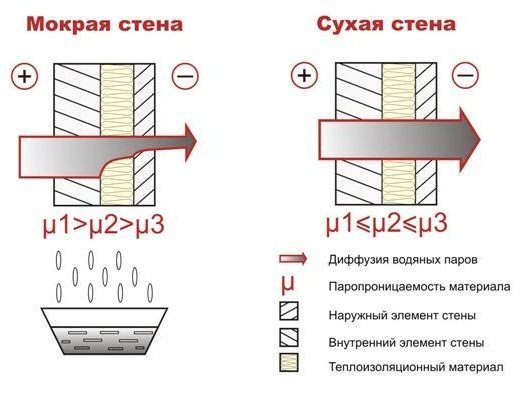

But below in clause 8.5 there is a requirement that the location of the layers should exclude the creation of conditions for the accumulation of moisture in the enclosing structure and contribute to its drying - the weathering of water vapor. And in this case, the vapor permeability of each layer is important.

To prevent the structure from getting wet, the vapor permeability of the materials of multilayer walls must increase (or be equal) in the direction "from the inside out".

Wood is a unique building material with non-uniform breathability, and this must be taken into account. Pine has the lowest vapor permeability coefficient along the grain, and across it is the lowest.

But rounded logs and beams, like any lumber, have a surface of cut fibers, so their vapor permeability across the fibers is higher than that of a log.

And the condition for the correct arrangement of layers according to this indicator corresponds to the only insulation - mineral wool. Neither expanded polystyrene nor polyurethane foam (sprayed insulation)

In some articles, you can find references to PVC foam. In terms of vapor permeability, it is the best in its class of heat-insulating materials, and in terms of strength it belongs to structural ones, but it is very expensive. For reference: PVC foam elements are used as insulation for hulls of small ships (yachts and boats).

Therefore, to the question of what is better to insulate a wooden house, the answer is unequivocal - with mineral stone wool.

Installation of cladding

This process is the final step in creating a ventilated façade. The rules for its implementation include:

- cladding slabs can be placed vertically or horizontally;

- they are fixed with self-tapping screws through special holes made at the factory;

- only zinc fasteners are used, which are protected from the corrosion process;

- slabs are equipped with special grooves and spikes, with the help of which they are firmly connected to each other, forming an even coating;

- the styling procedure is performed from the bottom up;

- from below, the elements are fixed and closed with a special mesh, which prevents insects or rodents from penetrating under the sheathing;

- a drain is provided for water flowing from the roof;

- in the corners, you will have to cut the panels, for which a grinder is used, equipped with the necessary nozzle.

Attention! The indisputable advantage of the ventilation facade is considered to be a small mass that does not exert a significant load on the foundation of the building.

During installation, only high-quality and certified materials with positive parameters are used. It is recommended to abandon Chinese or fake items that quickly fail, deteriorate under the influence of atmospheric factors and quickly lose their attractiveness.