Background for wallpaper: reviews of masters, types, how to choose and glue?

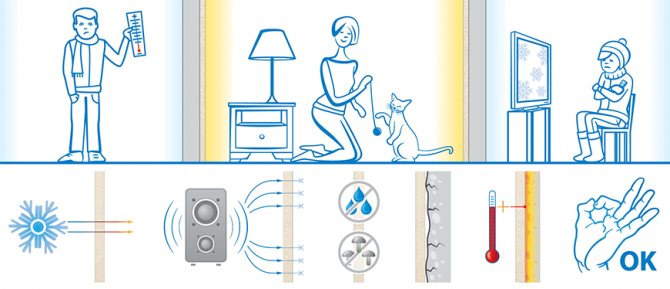

Wallpaper underlay can be used to reduce noise levels and improve thermal insulation.

Soundproofing underlay improves living conditions in a room by reducing noise levels in rooms.

From the text you will learn how to choose and how to glue the backing under the wallpaper.

Basis purpose

- Basis purpose

- Installation of the substrate

- Types of backgrounds for wallpaper

Wallpaper bases have been around for a long time. About 30 years ago, old newspapers were used for this, and then special paper came to replace them.

Modern foundations for wallpaper are high-tech materials that can not only facilitate the process of wallpapering walls, but also perform the functions of insulation and sound insulation.

Wallpaper backing is wall coverings with insulating qualities.

Typically, wallpaper backings are made of polyethylene foam, finished with paper sheets on the back and front sides.

Instead of polyethylene foam, cork or non-woven can be used to make the backing. The underlays can be glued under any type of wallpaper.

This finishing material has the following advantages:

- high strength - it is difficult to break it;

- environmental safety;

- prevents condensation;

- serves as soundproofing.

The backing under the wallpaper is a soft roll finish, but despite this, it has a high strength.

There are reviews on the background under the wallpaper, saying that it can withstand several wallpaper re-sticks. New wallpaper is simply glued onto the old backing without removing it from the wall.

:

The material prevents the appearance of mold on the walls, provides silence in the room. In addition, with a wallpaper underlay, you can even out unevenness on the walls.

Professionals are increasingly advising to stick wallpaper not on bare walls, but on substrates, since the level of sound insulation in modern apartments leaves much to be desired.

Despite the fact that wallpaper substrates are a versatile material with a lot of advantages, they also have disadvantages:

- not suitable for wet rooms;

- not suitable for thin wallpapers - in this case, the substrate may shine through;

- will not be able to isolate the room from extraneous sounds with a strong noise level.

Installation of the substrate

How to glue the backing to the wall:

- the surface is freed from wallpaper;

- remove water-based paint or whitewash;

- the grooves are leveled with putty or alabaster;

- the wall is primed with PVA glue

- 24 hours before the sticker, the backing is cut and allowed to rest on a flat surface.

When working with a non-woven substrate, the glue is applied not to it, but to the walls.

Tip: Immediately remove excess glue from the joints with a napkin.

Pasting starts from the window and moves in a circle. At the junction of two walls, the sheets should be butt-to-end - it is not allowed to paste over the corner with one sheet with a fold.

During the gluing, the sheets are coated on one side, kept for up to 10 minutes and glued end-to-end.

For gluing the substrate, polystyrene foam glue or an adhesive for massive wallpaper is used. The substrate is glued in the same way as the wallpaper - in a butt-joint method.

Air accumulations are removed by ironing the glued sheet with a plastic spatula or a piece of dry, clean cloth. Seams are sealed with adhesive masking tape.

The sound insulation must hang on the wall for at least a day before the wallpaper itself can be glued onto it.

Glued to the wall, the backing does not deteriorate for decades.The material of the leading manufacturers is guaranteed for 50 years!

The soundproofing and insulating effect of pasting the walls with a backing under the wallpaper will be especially noticeable in rooms, one of the walls of which goes into the entrance.

The concrete walls of panel houses have poor thermal insulation, and the apartment loses a lot of heat through the walls that open into the cold staircase.

Important: the material must not be glued if the room temperature is below 10 ° C and the humidity is below 70%. In such conditions, the sheets will not be able to adhere with sufficient strength.

After pasting the walls during the day, drafts should not be allowed in the room.

Key manufacturers of finishing materials in Russia and the CIS countries produce substrates under the following brands:

- Ecohit - produced by the Izhevsk Plastics Plant, removes cold radiation from walls, reduces noise levels. Ecohit does not absorb moisture, is not afraid of dampness;

- Polyform - protects walls from condensation, improves sound insulation, and reduces heating costs. Polyform is odorless, as it is made without freon and butane. The material does not crack when the foundation of a new house shrinks, is not damaged by molds and bacteria, does not collapse for 50 years;

- Penolon - insulation with a thickness of 7 mm. The closed porous structure makes it durable and warm. Decorating on both sides with paper allows you to stick the foam on any walls. It can be used for internal insulation of houses made of timber, concrete, brick, cinder blocks.

The listed manufacturers produce material in rolls 0.5 m wide, 14 m long.

Sticking tips:

- do not use the substrate in rooms with humid air;

- walls damaged by the fungus are cleaned with antifungal chemicals before pasting;

- if gaps appear after pasting, then they are sealed with narrow strips of paper using PVA glue.

The soundproofing effect of the backing sticker will not allow you to protect the room from strong noise - in this case, other, more effective soundproofing methods will be required.

The material is environmentally friendly and can be used in bedrooms and children's rooms.

The PE foam backing is easy to cut and the paper backing makes it easy to stick to the wall.

Despite its small thickness, the material helps to save heat - the total effect of its use throughout the entire heating season can be quite significant.

Types of backgrounds for wallpaper

Substrates can be made from the following materials.

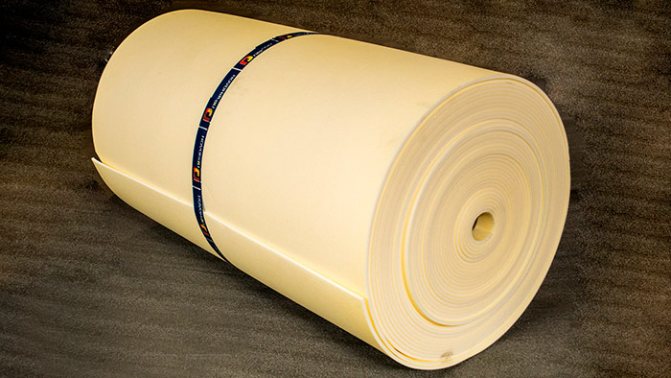

Polyethylene foam - in the trade network, this material can be sold under the name Polypom or Isolone.

All these names belong to one material - foamy, lightweight, capable of withstanding extremely high and low temperatures (from -60 ° C to + 90 ° C).

Heat-insulating specialists argue that polyethylene foam replaces a half-brick wall in terms of its thermal insulation qualities.

Polyethylene foam is used to insulate walls made of materials with low thermal insulation capacity.

For example, concrete freezes quickly at sub-zero temperatures, and foamed polyethylene glued to it from the inside will retain heat and increase the comfort of being in the room.

The cork cover is environmentally friendly, natural. It not only retains heat, but also has high sound insulation.

Cork backing is used in recording studios, that is, where it is especially important that extraneous sounds do not penetrate from the outside.

:

In a room whose walls are covered with cork under the wallpaper, you will not be disturbed by the barking of a neighbor's dog, crying of children, playing musical instruments, street noise and other unpleasant acoustics.

As a heater, cork is inferior to polyethylene foam, but only slightly. The weak point of the roll cork is the complete lack of water protection.

The material easily absorbs moisture, therefore, in case of flooding, it will definitely come off. The cork is sold in sheets, as it is too stiff and hard to roll into a roll.

Heat-insulating non-woven backing for wallpaper or repair non-woven linen appeared on the market of finishing materials recently, but professionals have already liked it.

Unlike polyethylene and cork, repair non-woven fabric has an important feature - it is vapor-permeable, so it can be used in rooms with high air humidity.

:

In addition, the material has increased elasticity and is excellent for leveling walls.

Repair interlining can be used to decorate any living room, it has one hundred percent environmental safety.

The disadvantage of this material is its high price - repair non-woven liner is more expensive than foamed polyethylene and even cork.

Rigid materials such as drywall or plywood can play the role of a wallpaper backing. Their disadvantages include more complicated installation than roll materials and a decrease in the volume of the room.

The layer of air trapped between the sheets and the wall surface serves as an insulating cushion, but it does not protect against sound.

In addition, cold and warm air meets in such a gap, which means that condensation forms, which leads to mold and rotting of wood and paper finishing materials.

Before starting work, you need to read the instructions. Products from different manufacturers may differ in the way they are glued.

Some types of underlays need to lie flat on the floor to even out. Other materials do not need this, since according to the technology, before gluing them, it is supposed to soak them with glue, after which they will become heavy and level off on their own.

Source: https://www.stoydiz.ru/oboi/vybor-i-poklejka-podlozhki-pod-oboi.html

Sticking

Be that as it may, let's take a closer look at how to properly glue this roll material. At the same time, you can easily stick it with your own hands, having done all the work yourself. In fact, in essence, the work is practically no different from gluing other roll wall coverings, with the only difference that a lining is used instead of wallpaper. However, the general technology remains the same. In any case, both according to the reviews of the masters and according to the testimonies of ordinary buyers, such an approach (using glue, then thick wallpaper) is quite justified, and the results are quite good.

So, first of all, you will need to cut the canvas into separate sections, the size of the height of the wall. Then they will need to be straightened. To do this, you can use small weights or any handy items of small size, but having sufficient weight to align the sheets.

Useful advice! After gluing, it is advisable to additionally glue the seams with masking tape or ordinary tape. It is desirable, at the same time, that they are transparent (this applies to scotch tape, since the masking tape cannot be transparent) or, at least, light. Something darker may appear during the subsequent gluing of wallpaper in white, beige, light green and pastel colors.

Another useful advice from the masters of their craft is that, both when gluing and after all work is completed, you should make sure that there are no "bubbles" left under the substrate. Otherwise, you risk getting unevenly pasted wallpaper and all the work will be down the drain: you will have to redo everything again. Background under the wallpaper Polyfom:

As noted above, it will be enough for you to glue the backing just once, and then re-glue the wallpaper many times. As for the preparation before gluing, then you need to remember about the following conditions:

- Apply a coat of wallpaper glue or primer ahead of time.

- After applying the glue to the substrate, it is not worth sticking it immediately after that. First, wait 10-12 minutes, and only then glue.

- If the air humidity is more than 70%, as well as at room temperature less than + 10C, it is better to temporarily stop gluing. So, you better either postpone work or use a heater that will raise the room temperature and lower the humidity.

- And finally, one more useful tip: Try to avoid drafts after applying the decal.

Penolon - background for wallpaper. Expert Reviews

In any house, no matter whether it is built of bricks, concrete, wood, it is important to create good heat and vapor insulation. It depends on these works how warm the room will be, and what the climate will be like there. In big cities and apartment buildings, sound insulation is also important. Not everyone is ready to hear the noise of cars, neighbors talking, crying children, etc. all day long.

In general, work with sound-thermal insulation materials is considered by engineers even at the stages of creating a house construction project. But not everyone manages to take into account all the nuances, and in the houses that were built decades ago, these materials did not fit.

Therefore, now, in order to ensure complete silence in their home and to preserve heat in it, they acquire heat and sound insulation materials for interior and exterior wall decoration.

How to calculate the required thickness of a layer of polyurethane foam (PPU) when spraying?

A special service has been developed for users of the site, which is called the "Dustman Calculator". Its purpose is to help in calculating all important parameters before starting insulation.

These parameters include:

- thickness of the polyurethane foam layer,

- consumption of components,

- cost at an average price.

The calculator was created by experienced professionals and guarantees accuracy. To start calculating the metrics, click here.

One of the first questions faced by a business owner in the field of thermal insulation, including in the field of spraying polyurethane foam (PPU), is the issue of calculating the required layer thickness of thermal insulation material. Indeed, there are a lot of variables in the task - the climatic zone, the thermal and humidity conditions inside the room, the purpose of the room, which part of the building structure is the area of insulation, the required temperature in the room, the resistance to heat transfer of the existing building structure, the properties of the heat-insulating material, moisture accumulation and some other factors. It is especially difficult when PPU spraying is used only for a separate part of the building structure, and not for the entire room.

On the one hand, there is a great temptation to please the Customer and offer a smaller layer of thermal insulation material in order to meet its budgetary expectations and to be competitive with other options for thermal insulation materials. But on the other hand, failure to achieve the very goal of insulation threatens with loss of reputation, financial costs for additional work, or even a lawsuit. In some cases, the opposite situation is also observed - the customer does not believe that a relatively small layer of polyurethane foam will be able to guarantee the desired thermal insulation protection. In our opinion, in both cases, a scientific and evidence-based approach to calculating the required thickness of the heat-insulating layer can become a solid foundation.

Let's try, without leaving the scientific jungle, to figure out together how to do this.

What is Penolon and what is it for

Penolone (expanded polyethylene) is a versatile polymer material. It has a paper base and a porous structure. It is lightweight, as it consists of many air bubbles. It is produced in various colors and thicknesses. Penolon comes in different rates of foaming, lamination and embossing.It is produced in the form of a polymer sheet, chips, plates and rolls.

Specifications

Specifications

The unique properties of Penolone have expanded its use in various directions. That is why this material can replace several others at once, performing their functions. It is produced in different thicknesses and has a low weight.

Penolone properties:

- environmentally friendly;

- does not rot;

- does not emit odors;

- there is no release of harmful substances;

- low coefficient of thermal conductivity - 0.037 W / m · K;

- vapor-tight - 0.001 mg / (m · h · Pa);

- reduces noise by 35-40 dB or up to 60%;

- operating temperature - from -60 to + 120 ° С;

- slight deformation, easily restores its original shape;

- has excellent water-repellent properties;

- easy to use, easy to cut;

- reduces impact noise;

- high chemical stability.

It is also compatible with various building materials: concrete, brick, wood and others.

Scope of use

Scope of use

Penolone, due to its excellent qualities, is used in many areas. It is used in technical industries and light industry.

Automotive

Since Penolon is lightweight, has good performance in noise and heat insulation, it is used in the manufacture of cars. This material is suitable both as a seal for doors, and as insulation, sound protection for the interior. Even when the air in the car is very hot, it does not emit hazardous substances and unpleasant odors.

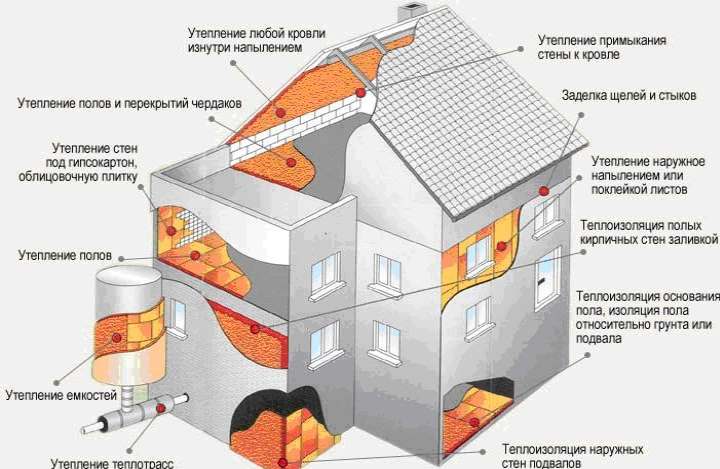

Building

Penolon is used in the construction or repair of any buildings, as a heat and moisture insulating material for walls inside and outside houses, floors, roofs, and is also used under a concrete screed. To protect against noise, substrates with Penolon are produced under wallpaper and various floor coverings. Tiled Penolon insulates loggias, balconies, basements, garages and attics.

Packing material

Elastic Penolon is used as a packaging material for the transportation of valuable and fragile items, household and medical equipment.

To avoid chips, scratches, moisture and dirt, easily damaged building materials and furniture are packed with slip sheets during transportation.

Since Penolone is non-toxic and has high thermal insulation properties, it is used to protect products from temperature extremes during their delivery.

Related article: Cork backing for wallpaper for noise insulation

Food industry

Thanks to its environmental, heat-retaining qualities and high water resistance. Penolone is used in the manufacture of products used for storing and eating food. It does not emit hazardous substances when combined with various liquids, therefore, seals, caps, bottle caps and thermal products are made from it.

Light industry

Penolon is used to make substrates or bottoms for bags and backpacks, as it is resistant to low temperatures. Also used in the manufacture of covers for musical instruments.

Installation features

Installation features

The use of Penolon as a heater for houses and other buildings requires compliance with the following installation rules.

Floor insulation

Floor insulation

Installation of thermal insulation under parquet or laminate flooring:

- The substrate is laid on a clean surface in 1 layer; it cannot be folded in several layers.

- The material is laid end-to-end and glued with tape.

- A gap is left between the laminate and the walls so that the sound from the floor does not pass to the walls, and the parquet board can expand freely with increasing humidity.

Thermal insulation of walls

Thermal insulation of walls

If the room is insulated with foil-clad material, then the metal side is placed inside the room, then the heat will be reflected back into the room. Thermal insulation based on the sandwich principle is carried out as follows:

- A layer of foamed polyethylene is attached with a stapler or glue.

- The joints are sealed with tape.

- Mineral wool is laid (a frame is required), foam or extruded polystyrene foam.

- The second layer of Penolon is laid and the seams are glued.

- A lathing is mounted for lining or other finishes.