The greatest drawback of solid fuel boilers is their cyclicality: at maximum load and combustion, a peak (often excessive) thermal power is reached, which constantly decreases to 0 (complete attenuation) and is renewed by a new fuel load. This cyclical nature does not allow for a stable, quickly and accurately controlled heating system.

Smoothing the uneven heat transfer of the TT boilers allows the buffer tank (it is also a heat accumulator), which accumulates excess heat during peak operation of the boiler unit. However, there are many nuances in choosing and calculating the required volume of a heat accumulator.

What is a buffer tank for a solid fuel boiler

A buffer tank (also a heat accumulator) is a tank of a certain volume filled with a coolant, the purpose of which is to accumulate excess heat power and then distribute them more rationally in order to heat a house or provide hot water supply (DHW).

What is it for and how effective is it

Most often, the buffer tank is used with solid fuel boilers, which have a certain cyclicity, and this also applies to long-burning TT boilers. After ignition, the heat transfer of the fuel in the combustion chamber rapidly increases and reaches its peak values, after which the generation of thermal energy is extinguished, and when it dies out, when a new batch of fuel is not loaded, it stops altogether.

The only exceptions are bunker boilers with automatic feed, where, due to a regular uniform supply of fuel, combustion occurs with the same heat transfer.

With such a cyclicity, during the period of cooling or attenuation, thermal energy may not be enough to maintain a comfortable temperature in the house. At the same time, during the period of peak heat output, the temperature in the house is much higher than the comfortable one, and part of the excess heat from the combustion chamber simply flies out into the chimney, which is not the most efficient and economical use of fuel.

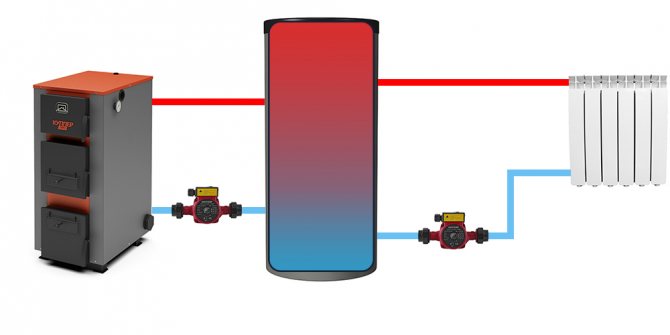

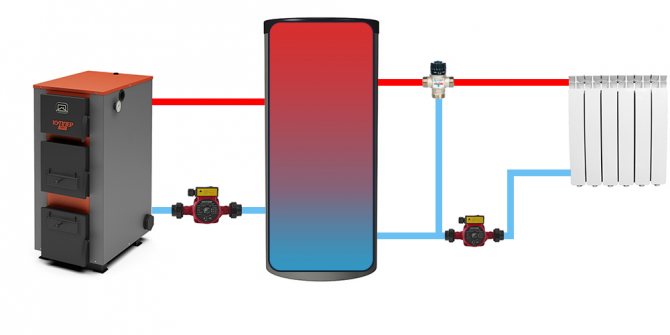

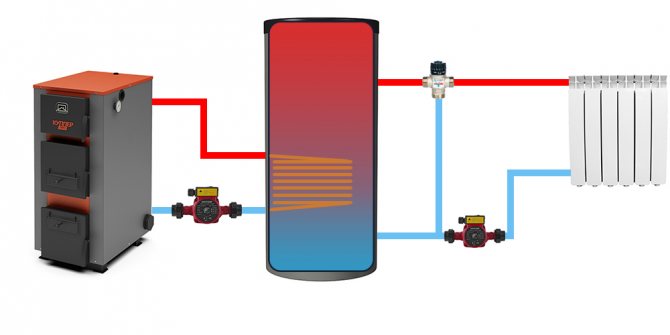

A visual diagram of the buffer tank connection, showing the principle of its operation.

The efficiency of the buffer tank is best understood on a specific example. One m3 of water (1000 l), when cooled by 1 ° C, releases 1-1.16 kW of heat. Let us take as an example an average house with a conventional masonry of 2 bricks with an area of 100 m2, the heat loss of which is approximately 10 kW. A 750 liter heat accumulator, heated by several tabs to 80 ° C and cooled to 40 ° C, will give the heating system about 30 kW of heat. For the aforementioned house, this is equal to 3 additional hours of battery heat.

Sometimes a buffer tank is also used in combination with an electric boiler, this is justified when heating at night: at reduced electricity tariffs. However, such a scheme is rarely justified, since in order to accumulate a sufficient amount of heat for daytime heating during the night, a tank is needed not for 2 or even 3 thousand liters.

Device and principle of operation

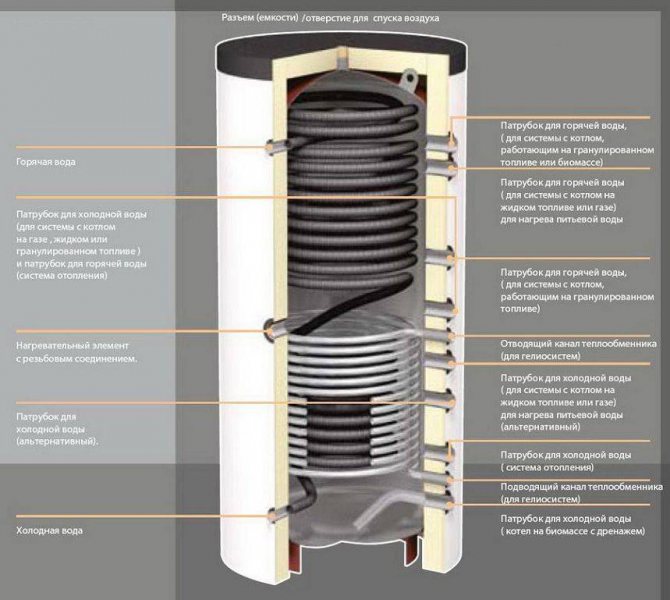

The heat accumulator is a sealed, as a rule, vertical cylindrical tank, sometimes additionally thermally insulated. He is an intermediary between the boiler and the heating devices. Standard models are equipped with a tie-in of 2 pairs of nozzles: first pair - boiler supply and return (small circuit); the second pair - the supply and return of the heating circuit, divorced around the house. The small circuit and the heating circuit do not overlap.

The principle of operation of a heat accumulator in conjunction with a solid fuel boiler is simple:

- After firing up the boiler, the circulation pump constantly pumps the coolant in a small circuit (between the boiler heat exchanger and the tank).The boiler supply is connected to the upper branch pipe of the heat accumulator, and the return to the lower one. Thanks to this, the entire buffer tank is smoothly filled with heated water, without a pronounced vertical movement of warm water.

- On the other hand, the supply to the heating radiators is connected to the top of the buffer tank, and the return is connected to the bottom. The heat carrier can circulate both without a pump (if the heating system is designed for natural circulation), and forcibly. Again, such a connection scheme minimizes vertical mixing, so the buffer tank transfers the accumulated heat to the batteries gradually and more evenly.

If the volume and other characteristics of the buffer tank for a solid fuel boiler are correctly selected, heat losses can be minimized, which will affect not only fuel economy, but also the comfort of the furnace. The accumulated heat in a well-insulated heat accumulator is retained for 30-40 hours or more.

Moreover, due to a sufficient volume, much larger than in the heating system, absolutely all the released heat is accumulated (in accordance with the boiler efficiency). Already after 1-3 hours of the furnace, even with complete damping, a fully "charged" heat accumulator is available.

Types of structures

| Photo | Buffer tank device | Description of distinctive features |

| Standard, previously described buffer tank with direct connection at the top and bottom. | Such designs are the cheapest and most commonly used. Suitable for standard heating systems, where all circuits have the same maximum allowable operating pressure, the same coolant, and the temperature of the water heated by the boiler does not exceed the maximum allowable for radiators. |

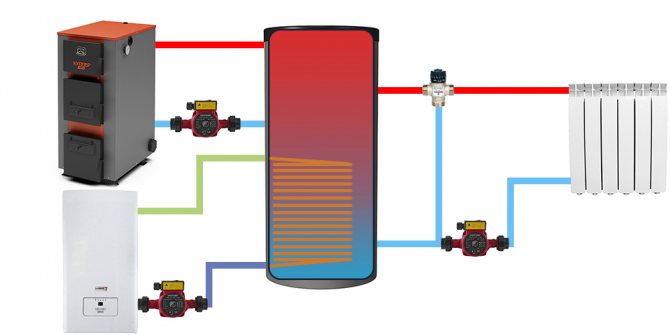

| Buffer tank with an additional internal heat exchanger (usually in the form of a coil). | A device with an additional heat exchanger is necessary at a higher pressure of a small circuit, which is unacceptable for heating radiators. If an additional heat exchanger is connected with a separate pair of nozzles, an additional (second) heat source can be connected, for example, TT boiler + electric boiler. You can also separate the coolant (for example: water in the additional circuit; antifreeze in the heating system) | |

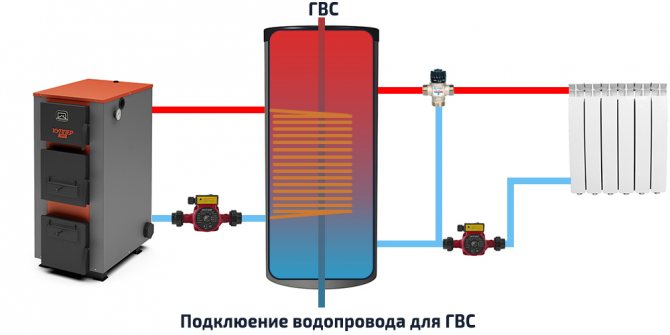

| Storage tank with an additional circuit and another circuit for DHW. The heat exchanger for hot water supply is made of alloys that do not violate sanitary standards and requirements for water used for cooking. | It is used as a replacement for a double-circuit boiler. In addition, it has the advantage of almost instantaneous hot water supply, while a double-circuit boiler requires 15-20 seconds to prepare and deliver it to the point of consumption. |

| The design is similar to the previous one, however, the DHW heat exchanger is not made in the form of a coil, but in the form of a separate internal tank. | In addition to the benefits described above, the internal tank removes the limitations in hot water capacity. The entire volume of the DHW tank can be used for unlimited simultaneous consumption, after which time is required for heating. Usually, the volume of the internal tank is enough for at least 2-4 people bathing in a row. |

Any of the above types of buffer tanks can have a larger number of pairs of nozzles, which makes it possible to differentiate the parameters of the heating system by zones, additionally connect a water heated floor, etc.

Scopes of heat accumulators

The container can work with any type of equipment, but is most often used in combination with solar collectors, solid fuel boilers or electrical devices.

Heat accumulators in solar systems

Solar collector - equipment that extracts energy from solar heat, light. It is used in regions with a sufficient number of sunny days, but without a buffer capacity, it works inferiorly due to the unevenness of the energy supply - changing the time of day, seasons.

So that the owners of the house do not have difficulties with supplying hot water to the heating system or hot water supply, the installation of a heat accumulator is required. To work in the system, the device uses a high heat capacity of water, at which the liquid, cooling by 1 degree, gives the potential for thermal heating of 1 m3 of air by 4 degrees.

The principle of operation is simple - a buffer storage tank for heating in the form of an accumulator collects excess energy during the period of activity of the sun, that is, it accumulates heat, and gives off energy after sunset, providing heating the volume of the coolant in the heating system and supplying hot water to the hot water supply.

Buffer tank for solid fuel boilers

For a solid fuel type heating device, a characteristic feature of the operation is cyclicality. First, the raw material is loaded into the furnace, then the heating medium is heated. The maximum energy parameters are reached at the peak of combustion of raw materials, then the heat transfer decreases and when firewood, coal burns out, the process of generating heat energy stops.

It is not possible to configure the boiler to generate heat with reference to a specific time, such a function is available only to electric or gas boilers, therefore, during the period of peak heat output, there may be too much energy, and after the combustion process is completed, there is little fuel. The connection of the storage tank will help to solve the problem. Such a heating system with a heat accumulator will allow heat to be transferred to the main line, through which hot water will flow, heating the room and not affecting the cooled boiler.

Thermal accumulator for electric boiler

Here you cannot do without a buffer, because electricity is expensive, and it is the capacity that will reduce costs by 30-45%. It is most convenient to use the equipment at night when tariffs are reduced. To stock up on a sufficient amount of heat, a tank of considerable size is needed for as much heat accumulation and energy transfer as possible during daylight hours.

Reviews of household heat accumulators for boilers: advantages and disadvantages

| Benefits | disadvantages |

| Much more efficient use of solid fuels, resulting in increased savings | The system is only justified with constant use. In case of intermittent residence in the house and kindling, for example, only on weekends, the system takes time to warm up. In the case of short-term work, the effectiveness will be questionable. |

| Extending cycle times and reducing the frequency of solid fuel filling | The system requires forced circulation, which is provided by a circulation pump. Accordingly, such a system is volatile. |

| Increased comfort due to more stable and customizable heating system operation | Additional funds are required to equip a heating system using an indirect heating boiler. The cost of inexpensive buffer tanks starts from 25 thousand rubles + security costs (a generator in case of a power outage and a voltage stabilizer, otherwise, in the absence of coolant circulation, at best, overheating and burnout of the boiler may occur). |

| Possibility of providing hot water supply | The buffer tank, especially for 750 liters or more, is of considerable size and requires an additional 2-4 m2 of space in the boiler room. |

| The ability to connect several heat sources, the ability to differentiate the coolant | To ensure maximum efficiency, the boiler must have at least 40-60% more power than the minimum required to heat the house. |

| Connecting a buffer tank is a simple process, it can be done without the involvement of specialists |

To summarize: What are the advantages and disadvantages of using buffer tanks?

To the explicit "Pluses" autonomous solid fuel heating systems with a heat accumulator include the following:

- The energy potential of solid fuels is used to the maximum extent possible.Accordingly, the efficiency of boiler equipment increases sharply.

- The operation of the system will require much less human intervention - from reducing the number of boiler loads with fuel to expanding the possibilities of automating the control of operating modes of various heating circuits.

- The solid fuel boiler itself receives reliable protection against overheating.

- The system becomes smoother and more predictable, providing a differentiated approach to heating different rooms.

- There are ample opportunities for modernizing the system, including with the launch of additional sources of thermal energy, without dismantling the old ones.

- In most cases, the problem of hot water supply at home is also solved at the same time.

disadvantages very peculiar, and you also need to have an idea about them:

- The heating system equipped with a buffer tank is characterized by a very high inertia. This means that it will take a lot of time from the moment of the initial ignition of the boiler and until reaching the nominal operating mode. It is unlikely that this will be justified in a country house, which in winter the owners visit only on weekends - in such situations, rapid heating is required.

- Heat accumulators are bulky and heavy (especially when filled with water) structures. They require ample space and a well-prepared, solid base. Moreover - near the heating boiler. This is not possible in every boiler room. Plus to this - difficulties with delivery, unloading, and often - also with the container drifting into the room (it may not go through the door). All this should be considered in advance.

- The disadvantages include the very high price of such devices, which sometimes even exceeds the cost of the boiler. This "minus", however, brightens up the expected savings from more rational use of fuel.

- The heat accumulator will fully reveal its positive qualities only if the passport power of the solid fuel boiler (or the total power of other heat sources) is at least twice as high as the calculated value required for effective heating of the house. Otherwise, the purchase of a buffer tank is seen as unprofitable.

And how to calculate the required heat output for heating a house?

Such heat engineering calculations must be carried out both when buying a boiler and when planning the installation of heating radiators. You can carry out the calculations yourself - if you use the algorithm described in detail in the publication of our portal dedicated to calculation of heating by area of premises... There you will also find a handy calculator.

How to choose a buffer tank

Calculation of the minimum required volume

The most important parameter that should be determined right away is the volume of the container. It should be as large as possible to maximize efficiency, but up to a certain threshold so that the boiler has enough power to “charge” it.

The calculation of the volume of the buffer tank for a solid fuel boiler is made according to the formula:

m = Q / (k * c * Δt)

- Where, m - the mass of the coolant, after calculating it is not difficult to convert it into liters (1 kg of water ~ 1 dm3);

- Q - the required amount of heat is calculated as: boiler power * period of its activity - heat loss at home * period of boiler activity;

- k - boiler efficiency;

- c - specific heat capacity of the coolant (for water, this is a known value - 4.19 kJ / kg * ° C = 1.16 kW / m3 * ° C);

- Δt - the temperature difference in the boiler supply and return pipes, readings are taken when the system is stable.

For example, for an average house with 2 bricks with an area of 100 m2, the heat loss is roughly 10 kW / h. Accordingly, the required amount of heat (Q) to maintain the balance = 10 kW. The house is heated by a 14 kW boiler with an efficiency of 88%, firewood in which burns out in 3 hours (the period of boiler activity). The temperature in the supply pipe is 85 ° C, and in the return pipe - 50 ° C.

First you need to calculate the required amount of heat.

Q = 14 * 3-10 * 3 = 12 kW.

As a result, m = 12 / 0.88 * 1.16 * (85-50) = 0.336 t = 0.336 cubic meters or 336 liters... This is the minimum required buffer capacity. With such a capacity, after the bookmark burns out (3 hours), the heat accumulator will accumulate and distribute further 12 kW of heat. For the example home, this is more than 1 extra hour of warm batteries on one tab.

Accordingly, the indicators depend on the quality of the fuel, the purity of the coolant, the accuracy of the initial data, therefore, in practice, the result may differ by 10-15%.

Calculator for calculating the minimum required heat storage capacity

Number of heat exchangers

Copper internal heat exchangers of the storage tank.

After selecting the volume, the second thing you should pay attention to is the presence of heat exchangers and their number. The choice depends on the desires, requirements for CO and the tank connection diagram. For the simplest heating system, an empty model without heat exchangers is sufficient.

However, if natural circulation is planned in the heating circuit, an additional heat exchanger is needed, since the small boiler circuit can only function with forced circulation. The pressure is then higher than in a natural circulation heating circuit. Additional heat exchangers are also required to provide hot water supply or to connect underfloor heating.

Maximum allowable pressure

When choosing a buffer tank with an additional heat exchanger, you should pay attention to the maximum permissible operating pressure, which should not be lower than in any of the heating circuits. Tank models without heat exchangers are generally designed for internal pressures up to 6 bar, which is more than enough for the average CO.

Inner container material

At the moment, there are 2 options for manufacturing an internal tank:

- soft carbon steel - Coated with a waterproof anti-corrosion coating, has a lower cost, is used in inexpensive models;

- stainless steel - more expensive, but more reliable and durable.

Some manufacturers also install additional wall protection in the container. Most often this is, for example, a magnesium anoid rod in the center of the tank, which protects the walls of the tank and heat exchangers from the growth of a layer of solid salts. However, such elements need periodic cleaning.

Other selection criteria

After determining with the main technical criteria, you can pay attention to additional parameters that increase the efficiency and comfort of use:

- the ability to connect a heating element for additional heating from the mains, as well as additional instrumentation, which are mounted with a threaded or sleeve (but in no case welded) connection;

- the presence of a layer of thermal insulation - in more expensive models of heat accumulators there is a layer of heat-insulating material between the inner tank and the outer shell, which contributes to even longer heat retention (up to 4-5 days);

- weight and dimensions - all of the above parameters affect the weight and dimensions of the buffer tank, so it is worthwhile to decide in advance how it will be entered into the boiler room.

Battery operating modes: buffer and cyclic

High-quality and durable operation of the battery is not only a positive economic effect for the owner, but also a pleasant component of operation. Agree, the failure of the battery in the first 2-3 years of operation and the failure of the battery for 7-10 years of operation cause opposite emotions.

Important performance characteristics are: temperature mode of operation (+10 .. + 25 degrees Celsius) and a correctly selected mode of operation and a charging method selected for this mode of operation. It is worth noting that we will analyze the options and operating modes of batteries that are used in the UPS, and in the next article we will analyze how to properly charge the batteries in the UPS.Batteries for UPS are, as a rule, lead-acid maintenance-free and sealed, produced according to the main two technologies: AGM and GEL (gel battery for UPS).

What determines the longevity of a battery?

A well-known fact and logical confirmation is the following: the battery life is mainly determined by the number of charge-discharge procedures and its depth of discharge. In other words: the less often we discharge the battery and the less deep this discharge is, the longer the battery will last.

Among the myths that have become established among users, there is the following: it is necessary to periodically discharge the battery "to zero" and charge it to 100%, otherwise it will deteriorate. For middle and high-end batteries - this will remain a myth, and for low-quality batteries - this myth will become an instruction manual. In low-quality batteries, the absence of shake in the form of deep discharge and full charge can really affect the resource of its operation. In cheap batteries, materials of poor quality are used (for example, recyclable lead) and arising in the battery, because of this, internal oxidation (plaque) must be somehow removed. In contrast to cheap ones, high-quality batteries need constant recharging (buffer charge) in which there are almost no deep discharges.

We cannot get around the topic of "memory effect" in rechargeable batteries. The essence of the memory effect is to reduce the capacity of the battery. Loss of capacity in such batteries occurs due to incomplete discharge and subsequent charging up to 100% - the battery "remembers" the level of incomplete discharge and below this "does not want" to be discharged. It is believed that if you "train" the battery by deep discharge and full charge, the capacity can be partially restored. This effect can occur in batteries manufactured using several technologies and is completely absent in batteries that are used in UPS. The memory effect is characteristic of batteries produced by the technology Nickel-metal-hydride (Ni-MH), Nickel-cadmium (NiCd), Silver-zinc battery.

Now we will consider two modes of battery operation - buffer and cyclic, as well as how to properly charge batteries in these modes.

Battery operation in buffer mode

The buffer mode of operation of the battery implies periodic non-systemic use. In other words - in this mode, batteries are used in emergency situations, for example, in a UPS. In the buffer mode, the battery is constantly recharged with a specially set charging voltage and current, and in this mode of operation it can work for the entire period declared by the manufacturer, and sometimes even more. Batteries with a small charge-discharge cycle are suitable for the buffer mode of operation, and these batteries are slightly cheaper than high-cycle ones.

Cyclic operation of the battery

Cyclic mode of operation - a mode when the battery is fully charged and fully discharged with a clear frequency. Examples of such a mode of operation are: electric vehicles, scrubber driers, electric forklifts, alternative energy - all those industries where batteries have a constant frequency of use. Cyclic operation of rechargeable batteries is the toughest test for them. Therefore, before buying a rechargeable battery, it is advisable to find out the mode of its operation.

© Material prepared by specialists of the company NTS-group (TM Elektrokaprizam-NO!), 2020

The best known manufacturers and models: characteristics and prices

Sunsystem PS 200

A standard inexpensive heat accumulator, perfect for a solid fuel boiler in a small private house with an area of up to 100-120 m2.By design, this is an ordinary tank, without heat exchangers. The volume of the container is 200 liters at a maximum allowable pressure of 3 bar. For a low cost, the model has a 50 mm layer of polyurethane thermal insulation, the ability to connect a heating element.

Price: an average of 30,000 rubles.

Hajdu AQ PT 500 C

One of the best models of buffer tanks for its price, equipped with one built-in heat exchanger. Volume - 500 l, allowable pressure - 3 bar. An excellent option for a house with an area of 150-300 m2 with a large power reserve of a solid fuel boiler. The line includes models of different sizes.

From a volume of 500 liters, the models (optionally) are equipped with a layer of polyurethane thermal insulation + a casing made of artificial leather. Installation of heating elements is possible. The model is known for extremely positive owner reviews, reliability and durability. Country of origin: Hungary.

The cost: 36,000 rubles.

S-TANK AT PRESTIGE 300

Another inexpensive 300 liter buffer tank. By design, it is a storage tank without additional heat exchangers with a maximum permissible operating pressure of 6 bar. The inner walls, as in the previous cases, are made of carbon steel. The main difference is a significant, environmentally friendly layer of thermal insulation made of polyester material according to the NOFIRE technology, i.e. high class heat and fire resistance. Country of origin: Belarus

The cost: 39,000 rubles.

ACV LCA 750 1 CO TP

A high-performance, expensive 750 l buffer tank with an additional tubular heat exchanger for hot water supply, designed for boilers with a large power reserve.

The inner walls are covered with protective enamel, there is a high-quality 100 mm thermal insulation layer. A magnesium anode is installed inside the tank, which prevents the accumulation of a layer of solid salts (there are 3 spare anodes in the kit). Installation of heating elements and additional instrumentation is possible. Country of origin: Belgium.

The cost: 168,000 rubles.

A brief overview of models of heat accumulators for solid fuel boilers

To complete the picture, you can give a brief overview of models of heat accumulators from well-known manufacturers that guarantee the high quality of their products:

| Model name, manufacturer | Illustration | Brief description of the model | Average price level (as of 10.2016) |

| "Tesy V 200 60 F40 P4", Bulgaria | Inexpensive, compact and lightweight heat accumulator without additional heat exchangers. For boilers up to 10 kW. Pressure up to 3 bar. Internal volume - 200 liters. Dimensions: height 1200 with a diameter of 600 mm. Weight without water - 43 kg. Models of this line with a volume of up to 500 liters are equipped with non-removable thermal insulation. More voluminous - thermal insulation is supplied as an option, at the request of the consumer. | 35 thousand rubles. | |

| SunSystem P 500, Bulgaria |

| "Empty" buffer tank without internal heat exchangers, but with the provided possibility of connecting electric heaters (TEN). Volume - 500 liters, pressure - up to 3 bar. Recommended for solid fuel boilers up to 17 kW. Dimensions: height 1660 with a cylinder diameter of 850 mm. Empty weight - 111 kg. | 48 thousand rubles |

| "S-Tank AT 1000", Belarus | The 1000 liter model belongs to the range of inexpensive buffer tanks without an integrated heat exchanger. Possibility of connecting solid fuel boilers and other alternative heat sources. Working pressure - up to 6 bar, thermal insulation thickness - 70 mm. Multidirectional, 90º angled mounting holes with 1 ½ ”female thread for circuits, and ½ for instrumentation. Model size - 2020 height with a diameter of 920 mm. Empty weight - 130 kg. The product line includes heat accumulators with a volume of 300 to 5000 liters. | 50 - 60 thousand rubles. | |

| "Hajdu PT 750 C", Hungary |

| Buffer tank with one built-in heat exchanger and the possibility of installing additional heating elements. Volume - 750 liters, maximum pressure - up to 6 bar, suitable for boilers up to 25 kW.It is important - the products are not equipped with thermal insulation - they either do it independently, or order it as an additional option for a fee. Height - 1910 mm, cylinder diameter - 790 mm. Empty weight - 171 kg. | 78 thousand rubles |

| "S-TANK AT MONO 1000", Belarus | A model similar in structure and dimensions to the "S-Tank AT 1000" shown above, but with a built-in one heat exchanger, which expands the possibilities of using other heat sources. Empty weight - 175 kg. | 85 thousand rubles | |

| Austria Email PSRR 500, Austria |

| High quality efficient model with two built-in heat exchangers. The volume of heat exchangers is 7.9 and 11 liters with an active heat exchange area of 1.2 and 1.8 m², respectively. The inner tank is made of high-grade steel St 37-2. Reliable thermal insulation ECO SKIN 2.0 is provided, which minimizes heat loss. The volume is 500 liters. Allowable pressure - up to 3 bar. Suitable for boilers with heating outputs up to 13 kW. Dimensions: height 1275 with a diameter of 850 mm. Weight without water - 113 kg. The manufacturer provides a 7-year warranty. | 105 thousand rubles |

| Heatleader MB215 500-0-0, Russia |

| Buffer tank with a flow-through circuit for hot water supply, with the possibility of organizing it according to a recirculation scheme. The volume is 500 liters. Removable casing with 50 mm thermal insulation. The set includes a safety group with a valve calibrated for a maximum pressure in the tank of 6 bar. Dimensions - 2000 × 600 × 700 mm. Empty weight - 200 kg. | 120 thousand rubles - with a boiler steel tank. 150 thousand rubles. - with a stainless steel tank. |

| "Nibe BUZ 750 / 200.91", Sweden |

| Products of a well-known Swedish company specializing in the production of heating equipment. High quality model with built-in storage tank for hot water supply. The total volume is 750 liters, of which 200 liters is occupied by a built-in tank. Plus, there is a built-in heat exchanger with a heat exchange area of 2.74 m². Maximum coolant pressure: in the tank - up to 3 bar, in the coil - up to 16 bar. Accordingly, temperatures are 95 and 110 degrees. Dimensions: 1468 × 964 × 1042 mm. Empty weight - 330 kg. | 208 thousand rubles. |

So, you can see that the purchase of a buffer tank is a very expensive purchase. All the more reasons to approach the justification of the need, and then to the choice of the optimal model with maximum responsibility. Learn about energy-saving electric heaters for your home at the link.

You may be interested in information on how long-burning solid fuel boilers work.

In conclusion - an informative video with a justification of the need for a buffer capacity in heating systems with a solid fuel boiler:

Prices: summary table

| Model | Volume, l | Permissible operating pressure, bar | Cost, rub |

| Sunsystem PS 200, Bulgaria | 200 | 3 | 30 000 |

| Hajdu AQ PT 500 C, Hungary | 500 | 3 | 36 000 |

| S-TANK AT PRESTIGE 300, Belarus | 300 | 6 | 39 000 |

| ACV LCA 750 1 CO TP, Belgium | 750 | 8 | 168 000 |

Where are buffer tanks used

Buffer tanks are used in the following systems:

- in heat pumps;

- in solar collectors;

- in solid fuel boilers;

- in refrigeration systems;

- for a supply of hot (DHW) or cold (cold (cold) water).

It should be noted that our company can manufacture for you a buffer tank according to an individual special order, taking into account all your needs and wishes. After manufacturing the buffer tank, all products undergo quality control and tank tightness control.

Also, in addition to the manufacture of tanks and reservoirs, we can supply buffer-accumulators manufactured by Viessmann, Buderus, De Dietrich, Vaillant, Zani, Unical.

Wiring and connection diagrams

| Simplified pictorial diagram (click to enlarge) | Description |

| Standard wiring diagram for "empty" buffer tanks to a solid fuel boiler. It is used when there is a single heat carrier in the heating system (in both circuits: before and after the tank), the same permissible operating pressure. |

| The scheme is similar to the previous one, but assuming the installation of a thermostatic three-way valve. With such an arrangement, the temperature of the heating devices can be adjusted, which makes it possible to use the heat accumulated in the tank even more economically. |

| Connection diagram for heat accumulators with additional heat exchangers.As already mentioned more than once, it is used in the case when a different coolant or higher operating pressure is supposed to be used in a small circuit. |

| Diagram of the organization of hot water supply (if there is a corresponding heat exchanger in the tank). |

| The scheme assuming the use of 2 independent sources of thermal energy. In the example, this is an electric boiler. Sources are connected in order of decreasing thermal head (top-down). In the example, first comes the main source - a solid fuel boiler, below - an auxiliary electric boiler. |

As an additional source of heat, for example, instead of an electric boiler, a tubular electric heater (TEN) can be used. In most modern models, it is already provided for its installation by means of a flange or coupling fastening. By installing a heating element in the corresponding branch pipe, you can partially replace the electric boiler or once again do without kindling a solid fuel boiler.

It is important to understand that these are simplified, not complete wiring diagrams. To ensure control, accounting and safety of the system, a safety group is installed at the boiler supply. In addition, it is important to take care of the operation of the CO in the event of a power outage, because there is not enough energy to power the circulation pump from the thermocouple of non-volatile boilers. The lack of circulation of the coolant and the accumulation of heat in the heat exchanger of the boiler will most likely lead to a rupture of the circuit and an emergency emptying of the system, it is possible that the boiler burns out.

Therefore, for the sake of safety, it is necessary to take care of ensuring the operation of the system at least until the bookmark is completely burned out. For this, a generator is used, the power of which is selected depending on the characteristics of the boiler and the duration of combustion of 1 fuel insert.

L rechargeable batteries. For UPS and beyond.

The most common batteries are those with a buffer life of 5 years. But batteries with a service life extended to 10 years are also produced. They are often the same size and weight as 5-year batteries, but noticeably more expensive. Their name often contains the letter L (from the English Long - long). In particular, CSB has a series of 10-year GPL batteries. UPS batteries made up of such batteries actually last much longer - their aging is slower. But, like any batteries for UPS (or other power systems), the GPL likes proper charging, they do not like high temperatures and frequent discharges.

The principle of operation of the buffer tank

The principle of operation of the buffer tank is as follows:

- The boiler heats the water, and with the help of the first circulation pump (there are two of them in the boiler), this water is supplied to the buffer tank.

- The same volume of water, but cooled down, is returned to the boiler.

- The second pump delivers hot water from the top of the buffer tank to the radiators.

- The same volume of water (cooled down) is returned to the lower part of the buffer tank. It should be noted that the first pump works when the boiler is on fire. A room thermostat is connected to the second pump, which can turn on / off the pump depending on the temperature in the house.

- Now let's see how the "extra" power is accumulated in the buffer tank. With the help of the first pump, the heat output (water heated by the boiler) is transferred to the buffer tank. The second pump supplies power to the radiators (compensates for heat loss). It is important to understand: how much heat power comes into the buffer tank, the same amount goes to the radiators.

- If the capacity of the two pumps is the same, more hot water will enter the buffer tank than go out. Accordingly, the water temperature in the buffer tank will rise. This is how heat accumulates.

- Now let's see how we give up the collected heat. The boiler burned out and the first pump turned off. Heat is no longer supplied to the buffer tank.But the second pump continues to work in the same mode, taking hot water from the buffer tank and returning cold water. Thus, the temperature in the buffer tank drops.

It should be noted that our company can manufacture for you a buffer tank according to an individual special order, taking into account all your needs and wishes. After manufacturing the buffer tank, all products undergo quality control and tank tightness control. Also, in addition to the manufacture of tanks and reservoirs, we can supply buffer-accumulators manufactured by Viessmann, Buderus, De Dietrich, Vaillant, Zani, Unical.