Rank: 3 174

Despite the fact that the heating system of the premises is already quite developed, there are still moments that were previously missed, and therefore modern heating technologies appear, one of which is gas heat generators for air heating of a house.

So, for example, for semi-industrial premises, where previously separate small rooms for the furnace were used, mechanisms that were not expensive to use, install and purchase appeared - gas heat generators for air heating of a house. And what, perhaps, is the most important thing in them - you do not need to hire an additional person who will monitor the level of warm-up.

Design features of gas heat generators

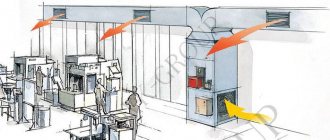

Air heating is most effective in showrooms, production facilities, film studios, car washes, poultry farms, workshops, large private houses, etc.

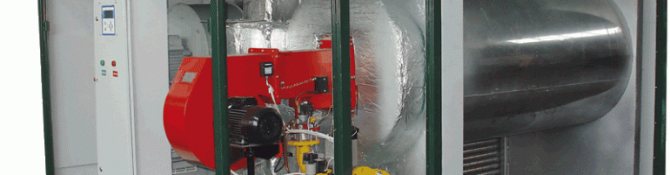

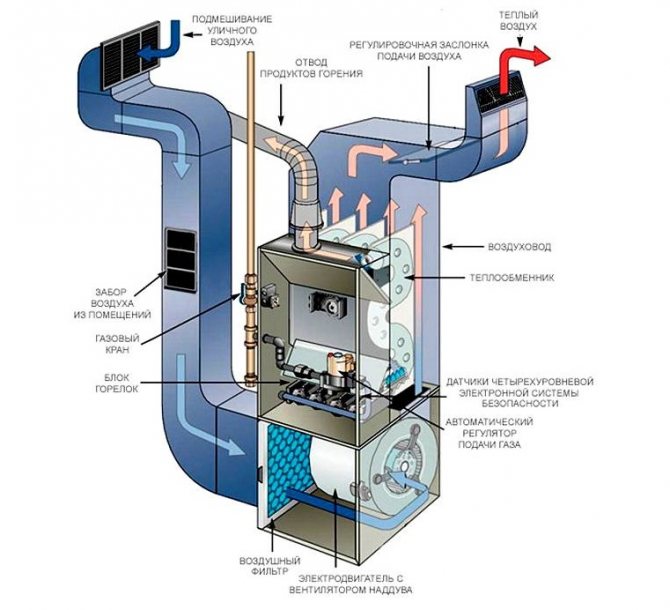

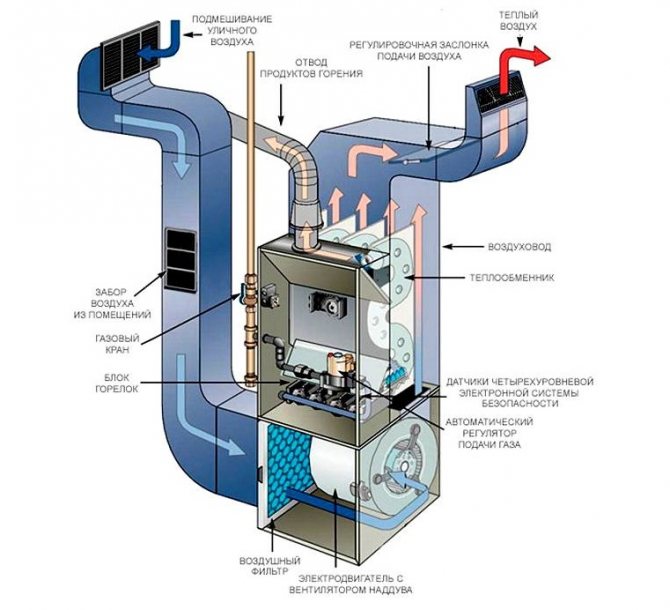

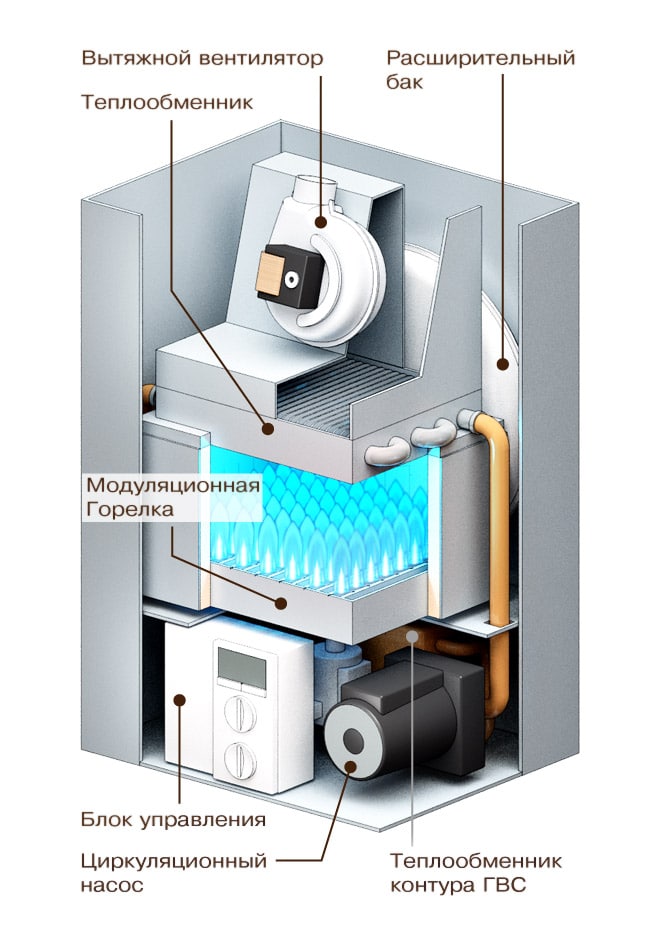

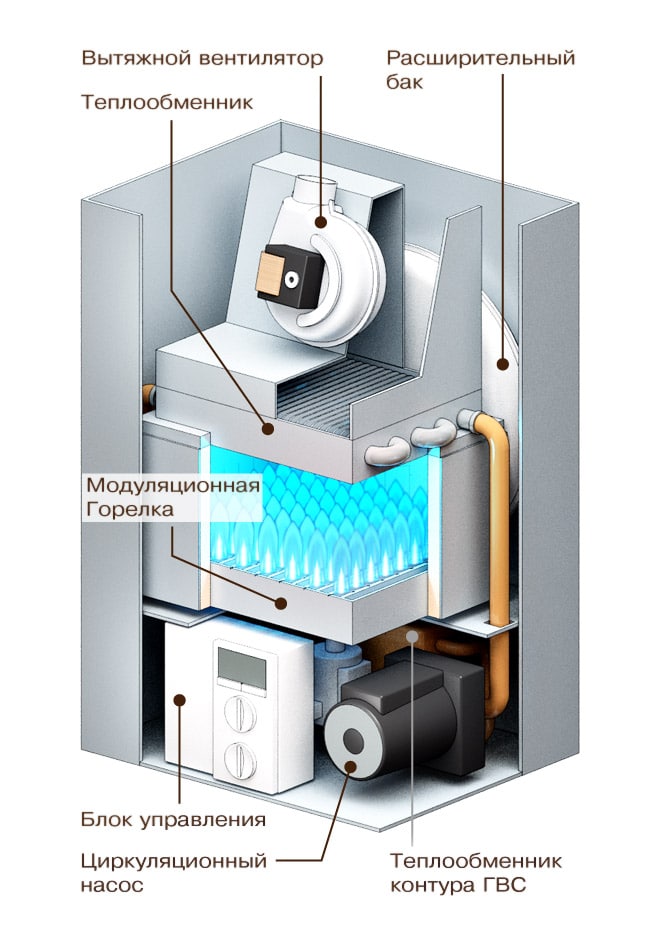

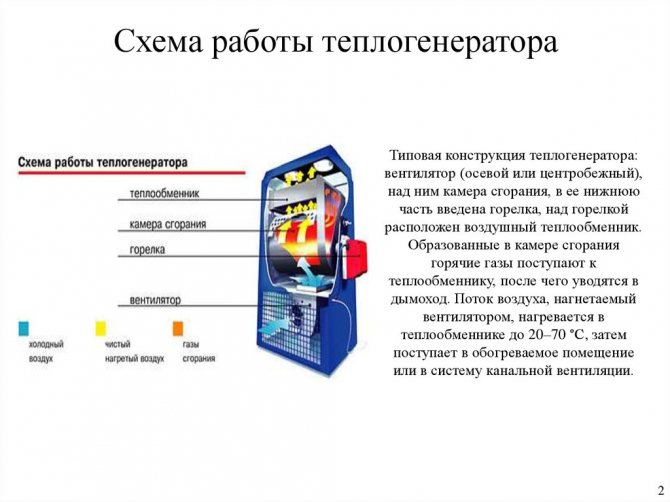

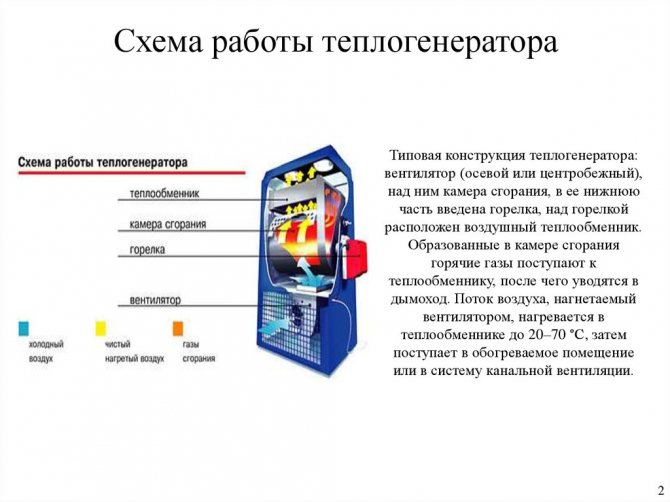

A standard gas heat generator for air heating operation consists of several parts that interact with each other:

- Housing... All components of the generator are hidden in it. In its lower part there is an inlet opening, and at the top there is a nozzle for already heated air.

- The combustion chamber... Fuel is burned here, due to which the coolant is heated. It is located above the supply fan.

- Burner... The device supplies compressed oxygen to the combustion chamber. Thanks to this, the combustion process is supported.

- Fan... It circulates heated air throughout the room. Located behind the inlet grille at the bottom of the cabinet.

- Metal heat exchanger... A compartment from which heated air is supplied to the outside. It is located above the combustion chamber.

- Hoods and filters... Limit the ingress of flammable gases into the room.

Air is supplied to the case by means of a fan. Vacuum is generated in the area of the supply grille.

An air heating device costs 3-4 times cheaper than a "water" circuit. In addition, airborne options do not threaten the loss of thermal energy during transportation due to hydraulic resistance.

The head is concentrated opposite the combustion chamber. By oxidizing liquefied or natural gas, the burner generates heat.

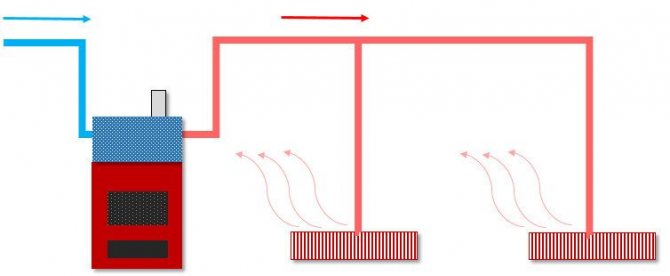

The energy from the combustion gas is absorbed by a metal heat exchanger. As a result, air circulation in the housing becomes difficult, its speed is lost, but the temperature rises.

Knowing the power of the heating element, you can calculate the size of the hole, which will provide the necessary air flow

Without a heat exchanger, most of the energy from the combustion gas would be wasted and the burner efficiency would be lower.

This heat exchange heats the air up to 40-60 ° C, after which it is supplied to the room by means of a nozzle or bell, which are provided in the upper part of the housing.

Fuel is supplied to the combustion chamber, where, during the combustion process, a heat exchanger heats up, transferring thermal energy to the coolant

The environmental friendliness of the equipment, as well as its safety, make it possible to use heat generators in everyday life. Another advantage is the absence of liquid moving through the pipes to the convectors (batteries). The heat generated heats the air, not the water. Thanks to this, the efficiency of the device reaches 95%.

Air heating system contract and full set of documents

Our company works with legal entities and individuals.We conclude an agreement for all services provided, which is a document that clearly defines the cost and timing of work. Pre-negotiated terms reduce the risks for both parties, and also ensure the benefits of the transaction for the seller and the buyer. The signing of the acts of completion and the acceptance and transfer of equipment means the successful completion of the work. We provide a full package of documents, including invoices, acts, invoices and cash receipts for cash payments, commissioning certificates, system settings. After completing the work, we continue to work with you as a consultant and service organization.

Departure of an engineer to calculate the cost of work is free of charge

Our company provides services for the installation of air heating, ventilation and central air conditioning of private houses, industrial and warehouse enterprises, commercial buildings. All engineering solutions of the projects comply with the SNiP requirements.

How does the heating system work?

The fan blades capture air and direct it to the heat exchanger. The air stream heated by it circulates through the building, carrying out several cycles.

The main advantage of the design of the gas heat generator is that the location of the chambers and compartments prevents the mixing of the decay products of the spent fuel with the air from the room.

During the operation of the equipment, there is no need to fear that the pipe will burst and you will flood your neighbors, as is often the case with water heating systems. However, in the heat generating device itself, sensors are provided that in emergency situations (threat of breakdown) stop the fuel supply.

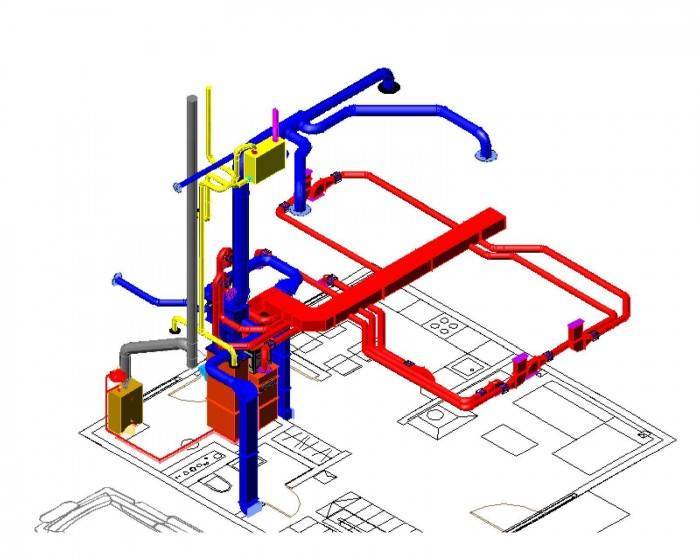

Heated air is supplied to the room in several ways:

- Channelless. Warm air flows freely into the treated space. During circulation, it replaces the cold one, which allows maintaining the temperature regime. The use of this type of heating is advisable in small rooms.

- Channel. By means of a system of air ducts connected to each other, the heated air moves through the air ducts, which makes it possible to simultaneously heat several rooms. It is used for heating large buildings with separate rooms.

Fan or gravity stimulates the movement of air mass. The heat generator can be installed indoors and outdoors.

The use of air as a heat carrier makes the system as profitable as possible. The air mass is non-corrosive and is not capable of damaging any elements of the system

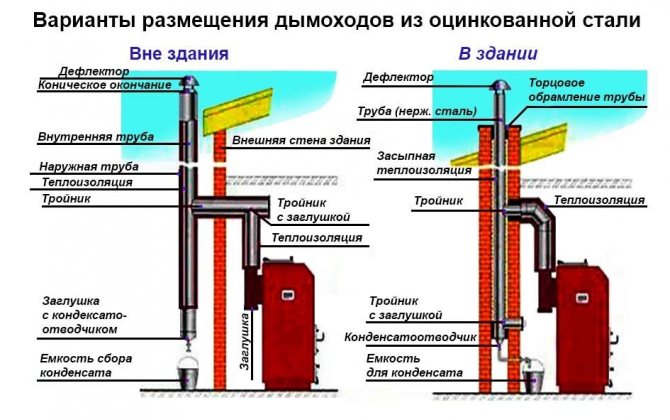

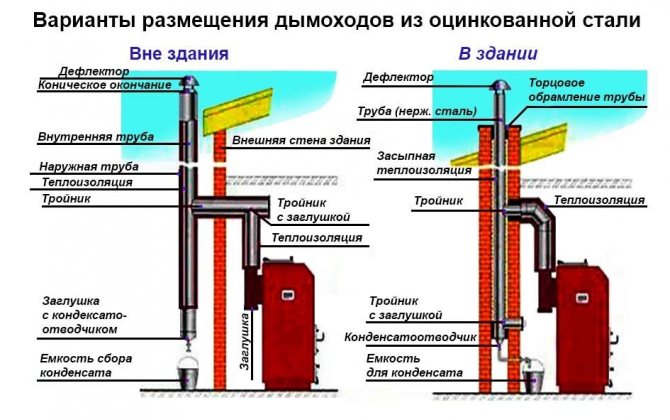

In order for the heating system to function correctly, the chimney must be correctly connected to the gas heat generator.

If the flue duct is not installed correctly, it will more often become clogged with soot build-up. A narrowed and clogged chimney will poorly remove toxic substances.

Advantages of air gas heating at home

Among the indisputable advantages of air heating, it will be most correct to single out the following:

- this heating option is distinguished by high productivity and economy due to the fact that the air is heated not in the boiler room, but directly in the living room;

- this heating method makes it possible to completely warm up the house in just 1 - 2 hours, which is a very fast time for any heating system;

- a small amount of financial resources spent on the maintenance of the heat generator, since the installation of these devices is not difficult, and during operation they do not require increased attention from the owners due to the fact that they are fully automated. In addition, in the case of heating at a low temperature, you can also save money on a low volume of gas consumed;

- the functionality of the gas stove is very high, since in addition to the standard heating function, it is also capable of ventilating the room and playing the role of an air conditioner;

- the probability of such a system leaking is very low due to the absence of a coolant in it as such, as well as a pipe system;

- there will be no need for central heating, which will also reduce operating costs.

Air heating on gas is an excellent heating option both in terms of economy, safety, and environmental friendliness, since all harmful substances, as already mentioned, do not accumulate at the bottom of the room, but go up.

Equipment advantages and disadvantages

The popularity of gas heat generators is associated with a number of advantages:

- gas is the most accessible and inexpensive fuel;

- the device heats not the coolant, but the air, which makes it economical and safe;

- Efficiency - 95%, which allows you to heat a large room within an hour;

- thanks to the air duct system, you can independently adjust the volume of the heated area;

- the ability to move the device;

- all processes are automated, as a result of which any user can control and manage the system;

- the device is also used for ventilation and air conditioning of the building;

- in some models it is possible to change the burners for liquefied and natural gas;

- there is no need to carry out a pipe system and install heating radiators, as a result, the cost of the system is reduced;

- the heat generator can be installed outside the heated building;

- simplicity and speed of installation.

Some consumers are intimidated by the high cost of equipment, but the system pays for itself within one year.

An air heating system has one drawback - rapid heat loss. The presence of temperature sensors in the gas heat generator allows you to automatically start it to maintain a comfortable temperature without human intervention

Minor disadvantages are also the need to obtain permits for connecting gas equipment and installing a chimney.

Design and calculation of an air heating system

To install air heating, it is necessary to draw up a preliminary project. To do this, you need to calculate the following indicators:

- heat loss of the room; - the required power of the heat generator; - heated air supply speed; - diameter and aerodynamic characteristics of air vents.

A professional calculation by our specialists will help you avoid drafts in the room, noise and vibration in the house, as well as overheating of the heat generator. It is better to think over the place of installation of equipment in advance.

With air heating from a single heat generator, it is necessary to resolve the issue with the distribution of air ducts. To achieve the most efficient heat distribution in the room, it is necessary to place the warm air flow as close to the floor as possible, since in this case efficient heat distribution by convection is achieved at a low air flow rate. The heated air itself tends to rise from the floor to the ceiling, evenly warming up the entire volume of the room. But, since the air intake comes from below, the air ducts have to be covered with decorative coatings or laid under the floors between the logs.

Can air ducts be installed under the ceiling? Can. Technically, it's much easier. But then you will face the following problem: in order to "push" the heated air into the room up to the floor, you will have to significantly increase the pressure in the system and increase the air flow rate. At the same time, energy costs increase sharply, as well as acoustic effects in air ducts (noise, whistle, knock, vibration).Additional discomfort will be created by the noise of the air flow at the exit from the distribution grilles (remember the thermal curtains at the entrance to shopping centers and imagine that they are making noise in your room).

The option is somewhat easier to install when air conditioners or heat pumps are used for air heating. In this case, warm air is produced by the device directly in the room, so air ducts are not needed. Freon lines are used here for heat exchange. They are much thinner than air ducts and can be easily positioned under the ceiling.

How to calculate an air heating system

To make a heat engineering calculation of air heating - combined with ventilation or performed by a separate wiring - heat engineers take into account many parameters:

• Heat loss of the room (depends on the material and thickness of the walls, the number and area of windows, etc.); • The number of people who will be in the room; • The number and capacity of additional heat sources; • Heat gains from operating equipment or devices, etc.

The simplest scheme looks like this: 40 watts of thermal power per one cubic meter of the heated room. For the regions of the Far North, taking into account extreme temperatures in winter, a coefficient of 1.5-2.0 is adopted. Another approximate scheme for buildings with a ceiling height not higher than 2.5 - 2.7 m. Here, a heat generator with a capacity of about 1 kW is taken to heat 10 m2 of the building area. For areas with severe frosts, increasing coefficients are taken into account.

Varieties of gas heat generators

In comparison with diesel, solid fuel and universal heat generators, gas equipment for air heating is most popular.

Devices are differentiated by size and weight:

- mobile - easy to transport;

- stationary - installed in one place.

Mobile models of gas-fired heat generators are less popular, since their operation requires gas cylinders filled with liquefied propane-butane mixtures. The most prominent representative of portable heating equipment is a heat gun.

Most often, heat guns are used for a one-time increase in temperature on construction sites and in shopping malls. In everyday life, they are used in extreme cases (turning off the heating in the house).

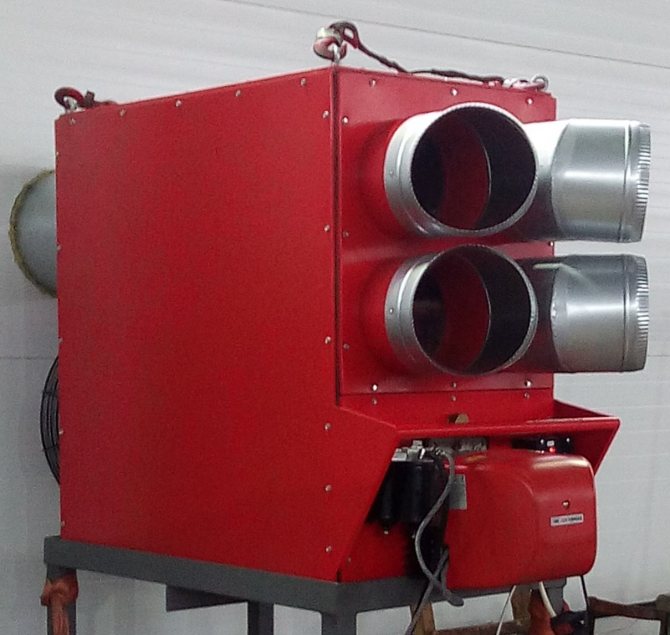

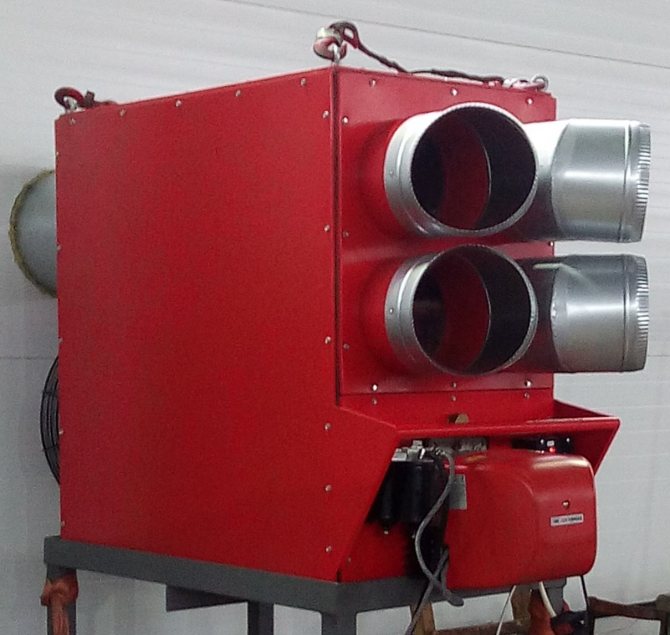

Stationary models of gas heat generators can be:

- hinged - they are hung on brackets mounted in the walls;

- floor - installed on the floor.

Wall-mounted models are used to heat small objects, their power usually does not exceed 35 kW. Floor standing equipment is recommended for heating small areas. In the range of floor-standing units, there are models that can be mounted outside the building, i.e. on the street.

In order for the gas processing equipment of the atmospheric type to work constantly, it is necessary to ensure a constant supply of air to the combustion chamber.

Depending on the distribution of heated oxygen and the method of gas combustion, the equipment is divided into:

- horizontal;

- vertical.

For rooms with high ceilings, vertical devices are used, and for rooms with low ceilings, horizontal devices.

Types of heat generators

All existing heating generators can be divided into two types:

- Mobile - devices can be both compact and have rather impressive dimensions. The latter can be moved on trolleys specially mounted for them.

They are called "mobile" for the reason that they are not connected to the gas pipeline, but work from gas cylinders, respectively, they can be installed in any place. Most often, such devices are used to heat production workshops. It should be noted that devices of this type especially require effective ventilation, since the heated air is removed with the combustion products.

Suspended stationary apparatus

- Stationary - are connected to the gas pipeline.

These devices, in turn, are divided into two types:

- Suspended - designed, as a rule, to heat one room. Such devices are most popular in country houses, since they do not take up useful space, they quickly warm up the room, besides, the instructions for their installation are extremely simple.

- Floor standing - are more bulky devices that are designed to heat large rooms or the whole house. Most models allow you to connect a duct system to them to evenly distribute heat to all rooms in the house.

Floor standing gas heat generator

Of course, in order to ensure effective gas-fired air heating, it is necessary to choose the right type of heater, as well as its power. It is better to entrust the calculation of the heating system to specialists, or use special formulas that can be found on our portal.

Advice! In order for a gas air heating oven to work as expected, it is necessary to provide a constant flow of fresh air into the room. For this, a ventilation system is used, which not only provides an inflow of oxygen, but also removes carbon dioxide outward with excess combustion.

Here, perhaps, are all the main types and features of gas-air heat generators that you need to know if you decide to equip a heating system in a house in a similar way.

How to choose a heat generator?

When choosing heating equipment, you need to take into account a lot of details. First of all, it is important to assess the area of the heated room. The larger the building, the more powerful the heat generator should be.

The heat capacity of a building is calculated using the formula:

p = V ΔT k / 860

p is the required heat capacity;

V - heated area (the height, length and width of the room are multiplied);

ΔT is the difference in temperature indicators in the building and outside;

K - thermal insulation (indicators of the material with which the building is insulated).

Indicators of the most commonly used materials:

- double layer of brick - 1-1.9 W / m ° С;

- single layer of brick - 2-2.9 W / m ° С;

- wooden panels or corrugated board - 3-4 W / m ° С;

- modern heat and waterproofing - 0.6-0.9 W / m ° C.

The indicator of the number of kilocalories in kilowatts is 860. Generally accepted standards - for 1 kW of heat generator power, 30 cubic meters of forced air is required.

The capacity of the air heater must exceed the burner capacity by at least 15%. Such equipment is reliable and efficient in any situation. Its use reduces energy costs

Knowing the value of the heat capacity, you can select equipment that can heat the entire area of the room.

Nuances when choosing a heat generator

Before purchasing heating equipment, you must:

- equip a chimney for the release of toxic gases;

- think over a system of ventilation ducts for circulating heated air;

- use the formula to calculate the power of the device.

After completing all these steps, you can safely go for the purchase.

If the room has problems with the arrangement of ventilation, it is recommended to install a powerful floor generator and synchronize its operation with ventilation that draws air directly from the street.

To select a high-quality model of a gas heat generator, you need to pay attention to the following nuances:

- burner type and design - relevant if fuel change may be required;

- warranty card and technical passport - a guarantee of the purchase of original (not defective) equipment;

- high-quality components - such equipment is more expensive, but its service life is much longer.

Considering these factors, the selected heat generator will serve for many years.

Tips for choosing reliable equipment

By following simple guidelines, you can avoid purchasing a low-quality product:

- It is better to make a purchase at certified points of sale. Often, at wholesalers and on the Internet, defective products are sold under the guise of high-quality equipment. The trap is the cost halved.

- If it is not possible or you did not have time to calculate the required power of the device, then the consultants in the store will do it for you. To do this, you only need to know the area of the house, the height of the ceilings and the thickness of the walls. After making calculations, experts will offer the best model for your home.

- It is recommended to purchase brands that have positive reviews on the Internet. You can also find out in advance how the equipment behaves during operation and other features.

For home use, such models as Airmax D 28, Titan 25 (30, 35), Fuela, TG-7.5, Dragon 12 will be ideal.

How to choose a heat generator?

For each room, it is necessary to select a heat generator based on its heat output, fan performance and design. Accurate selection of the parameters of the air heater will allow to achieve efficient heating with minimal costs and high reliability of the system.

|

The heat output of one air heater can be from 20 to 1300 kW. Thus, one air heating unit is capable of heating a room with a volume of 600 to 39,000 m3. Often, several heat generators are used to heat large rooms.

To select the parameters of the heat generator, it is necessary to make a thermal calculation of the room, calculate the head of the device, select the type of installation and climatic version.

The specialists of TC Group Energia LLC will carry out the calculation of the heat generator for you, draw up a project for an air heating system at the best price, supply, install and commission industrial air heaters in any region of Russia.

More about the device and calculation of heat generators ...

Order us a calculation of your heat generator:

Installation requirements

To connect a gas heat generator for air heating of a house, it is necessary to bring preparatory work and purchase:

- flexible air duct, which is a galvanized tube for circulating heated air;

- tees are needed to create an air line and connect pipes;

- for intake of cold air and supply of hot air - a grate;

- for the tightness of the line connections - aluminum tape;

- mounting fasteners;

- knife.

You should first take care of the duct.

You can install a gas heat generator with your own hands, but representatives of the gas service must connect it to the gas pipeline, with which an agreement was concluded for the supply of blue fuel and maintenance of equipment

The ideal option is the design of airways - channels at the stage of building construction.

To carry out the installation of heating in a finished house, you need to erect false walls and false ceilings. Pipes will be masked in the formed niches.

Conclusions and useful video on the topic

The following video will introduce additional information on the topic:

Gas heat generators for heating systems are a highly efficient and cost-effective solution. Due to its safety, reliability and ease of use, the equipment can be used in residential buildings and at industrial facilities.

If a gas heat generator is installed in your house, you have additional information about the advantages and disadvantages of the equipment or know which generator is better to buy for heating a private house, share your experience and knowledge with readers in the comments.

disadvantages

There are few disadvantages of these heating devices, however, they are available:

- As in the case of connecting any other gas equipment, before installing a heat generator, it is necessary to obtain permits.

- The need to equip a chimney when installing stationary heat generators.

These devices have no other disadvantages. The only thing that can be added here is the need for the participation of specialists when debugging powerful equipment.

The main units of the heat generator