Industrial steam boiler classification:

- energy (steam generation to ensure the operation of turbines of power plants that generate electrical energy);

- industrial (ensuring the functionality of various systems at technological enterprises);

- allows the substation to operate normally at ambient temperatures from -60 to +40 0С) under wind and snow loads.

A specific feature of the operation of industrial equipment is that the composition of the exhaust gases contains many small particles that are in a solid, gaseous or liquid state. They are formed during the operation of the equipment at a high temperature in the furnace.

Steam boilers make it possible to use the heat of waste gases, which increases the fuel utilization rate, reduces the temperature of the process raw material removal and makes it possible to capture it. The mode of supply of gases to the waste heat boiler is also an important factor.

Practical application of waste heat boilers

Oil refineries and metallurgical plants can be cited as a real example of the use of waste heat boilers. In the process of oil refining or metal smelting, a huge amount of energy is generated, which cannot be used in the production process except for sending it to a waste heat boiler and using it for other purposes, such as space heating, hot water supply (DHW), air conditioning (cold production), or the production of steam to cover third-party technological needs.

Thermal oil waste heat boilers are used at the refinery, in which the temperature of the coolant can reach 350 degrees Celsius. This temperature is quite enough to constantly maintain high viscosity oil products, such as fuel oil, tar and bitumen, in a liquid state. This makes it possible at any time to pump oil products and ship them to the consumer.

In metallurgical plants, waste heat boilers are transferred to water by means of waste heat boilers. As a result, a large amount of steam is generated, part of which is used to support the steel smelting process, and part is used for domestic needs (heating, water heating).

Waste heat boilers have become an integral part of the following facilities:

- Ferrous and non-ferrous metallurgy enterprises;

- Oil refineries;

- Gas turbine and gas piston power plants with unit capacity from 1000 kW to 18 MW;

- Gas pumping compressor stations;

- Bakery factories;

- Manufacturing of rubber products;

- Pharmaceutical enterprises;

- Production of resins and plastics;

- Manufacturing of electronic components;

- Printing enterprises.

Signs by which waste heat boilers are divided into groups:

1. From the temperature of the gases that enter the boiler:

- low temperature (<900 ° С). Heat transfer by convection;

- high temperature (> 1000 ° С). Heat transfer by radiation.

2. By steam parameters:

- low pressure (P = 1.5 MPa, t = 300 ° C);

- increased (4.5 MPa and 450 ° C);

- high (10-14 MPa and 550 ° C).

3. According to the principle of mutual movement of steam:

- water tube;

- gas pipe.

4. Depending on the method of water movement in the evaporation circuit, the water-tube heat exchanger:

- with forced circulation;

- with natural circulation.

5. Depending on the design of the layout and heating surfaces (horizontal, tunnel, tower types):

- low-temperature (principle of a coil convective heating surface);

- high-temperature (radiation-convective surfaces).

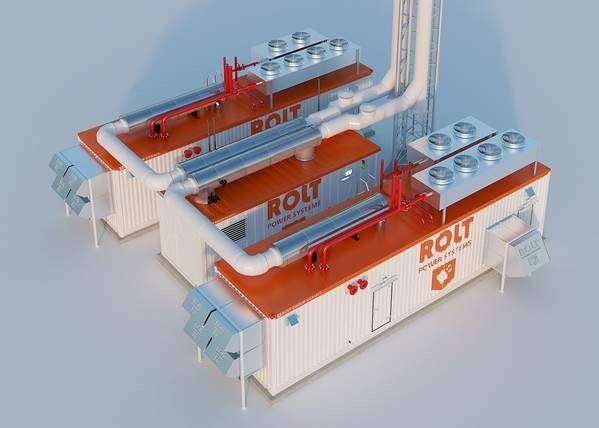

Steam boilers ROLT are produced strictly in accordance with the individual requirements of the customer and the submitted technical specifications. Boilers from world market leaders are used as the main heat generating equipment.

Waste heat boilers performance

The performance of waste heat boilers depends on the temperature and the amount of flue gases, and the efficiency of the boiler unit is significantly influenced by the state of the surface of the heat exchangers (their contamination with impurities contained in the flue gases significantly reduces the efficiency). Especially high efficiency can be achieved by using thermal oxidizers of volatile organic compounds in front of waste heat boilers. In cases when the utilization of heat energy is required only periodically, or is required in part, then the supply of hot gases to the waste heat boiler can be regulated using an automatic "bypass" system that bypasses gases to the chimney past the WHB. Also, the bypass control can be carried out using an external analog signal that regulates the closing angle of the bypass damper, or using a dry contact in the Open / Closed modes.

Technical characteristics of a steam boiler on the example of a completed project:

- Waste heat boiler SGCD-26.9-900-1800 / 4000-1H-1AX-VR-10

- Thermal power 1782 (2х891) kW

- Steam productivity 2640 (2х1320) kg / h

- Steam pressure 7 bar

- Steam characteristics Saturated steam

- Feed water temperature 90 ° С

- Feed water consumption 2 × 1320 kg / h

- Maximum pressure 10 bar

Waste heat boiler classification

Waste heat boilers are classified according to their purpose and design features.

By designation, boilers can be hot water, steam or thermal oil.

The division by design features makes it possible to distinguish two groups: coil, serving for heating diathermic oil and generating steam, as well as fire-tube, used for producing steam and hot water.

In addition, waste heat boilers with vertical and horizontal heat exchangers can be distinguished. Another structural difference of waste heat boilers is the presence or absence of superheaters.

We are recommended

Operating principle

Gas-tube waste heat boiler

This installation is carried out in a vertical or horizontal design and is mainly used in conjunction with open-hearth furnaces and kilns, which do not operate at high temperatures and do not have high power.

The device operates in the following order:

- The low-temperature gas mass is transferred from the smoke collection unit to the chamber located in the lower tank of the heat recovery unit.

- The chamber consists of many metal sheets that reflect and direct the flow of heat. Excessive heat generates circulating steam from the water. At a temperature of about + 400ºC and a pressure of 5 atmospheres, about 8 kW of electricity is generated.

- Uniform gas supply is ensured by the operation of the storage and dispenser.

Horizontal waste heat boiler The gas turbine type is often used in industrial facilities to maintain the temperature in equipment that has few waste gases, but has high power.

Waste heat boiler

Aggregates of this type are more widely used in the industrial sector. They are characterized by forced movement of steam, liquid and heat, as well as regulation of temperature and flow rate using a control unit. Water tube or waste-heat boilers divided into independent sections with low-power pumps. This arrangement allows the energy to be collected separately and converted by the reflectors into a general flow of steam or electricity.

The water supply to the system is regulated by an economizer. From there, it enters the evaporator circuit, which is equipped with perforated walls to remove steam.Due to the work of steam in the system, such a unit is also defined as waste heat boiler... The cooling of the gas mixture occurs due to the fact that a lot of heat energy is spent on the formation of steam. This removes heat from the work equipment, reducing workload and making production energy efficient.

The waste heat boiler is a rather simple unit, but in order for it to make production more economical and more productive in practice, qualified service and repair is required. Presented in our catalog storage boilers manufacturers accompanied by a guarantee of reliable operation for several years.

news

All news

02/21/2020 Congratulations on Defender of the Fatherland Day!

02/17/2020 Electricity and steam provided

01/15/2020 Energoservice in the Smolensk region

12/23/2019 Happy New Year 2020 and Merry Christmas!

Waste heat boilers Babcock Wanson

For over a century, Babcock Wanson has been developing and supplying waste heat boilers for various purposes and capacities to its customers. All Babcock Wanson waste heat boilers fully comply not only with the customer's requirements, but also with international norms and standards. Boilers are designed taking into account the temperature and pressure of both the exhaust gases and the heat carrier (water or oil).

All boilers manufactured by Babcock Wanson are very easy to install, as they are produced as a ready-made block for connection to all utility networks and configured for commissioning. They have special nozzles or openings for supplying exhaust gases to the boiler and for connecting pipelines for inlet and outlet of the coolant.

Thanks to this, the installation of Babcock Wanson waste heat boilers can be carried out very quickly and will start to be profitable from the first seconds of commissioning.

For questions related to the equipment of the BABCOCK WANSON company, you can contact the official representative in the Russian Federation, LLC SETAL.