The device and principle of operation of the three-way valve for the boiler

Three-way valve that regulates the temperature of the coolant in solid fuel boilers

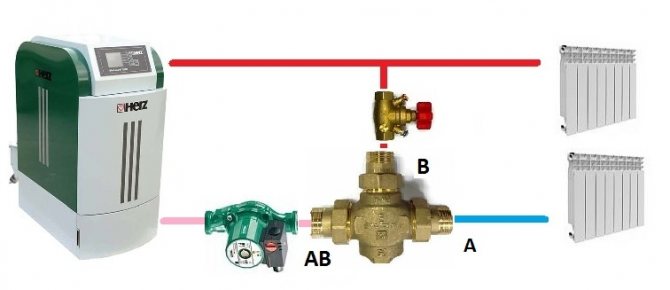

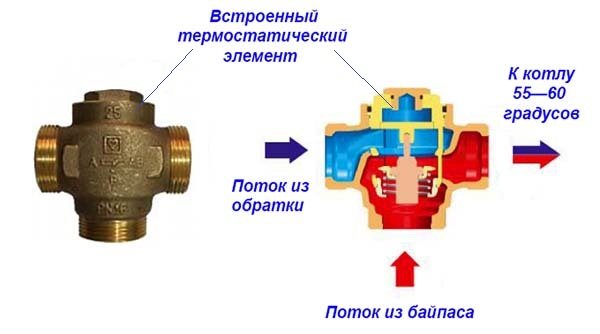

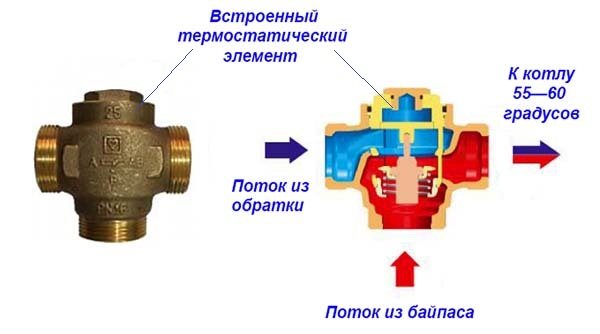

The design device of a thermo-mixing valve for a solid fuel boiler or other may differ significantly depending on the purpose of the element and the manufacturer, but the principle of operation remains unchanged. The thermostat has three outputs: one of them is always open, while the others overlap completely or partially during operation. According to the number of outlets, the valve is called 3-way. It is used for mixing or separation of liquid or gas streams, whereby the temperature of the coolant is regulated, switching from one circuit to another.

It looks like a tee. The internal device is represented by a locking mechanism and a rod, which ensures its movement - these are the main elements. Some designs have two seat rings to secure the valve. Supplementation with other elements is possible.

How does the valve work and what is it for

The desire to save energy resources leads to the creation of more and more types of equipment that allows you to solve this problem. By design, three-way valves combine a pair of two-way devices. However, they do not block the flow of the coolant, but perform the function of adjusting the intensity of the water flow to achieve the desired temperature regime.

Important. The three-way valve makes it possible, without changing the area of the radiators, to provide the room with the necessary amount of heat, exclusively within the limits of the power characteristics of the heating system.

The three-way valve has externally different configurations and different types of actuators, but the task is the same: to mix two streams of water of different temperatures into one stream with a set temperature level. In this case, the liquid will move from one branch pipe to another until the temperature reaches the required value. After that, the actuator will gradually admit the coolant from the third branch pipe to maintain the temperature at the required temperature level. Therefore, they call it a "three-way valve", since all actions take place in three steps.

The main purpose of a three-way mixing valve for a boiler is to maintain a comfortable heat balance in the room. Moreover, such a problem is solved not by reducing the temperature of the coolant, but by changing the amount of liquid. This is especially true in cases where the temperature of the coolant cannot be reduced in any other way. Despite the fact that the device performs such a complex task, it is quite simple in design.

Varieties of valves

The functionality of the valves is different. On this basis, three-way valves are divided into switching, mixing and separating.

Mixing

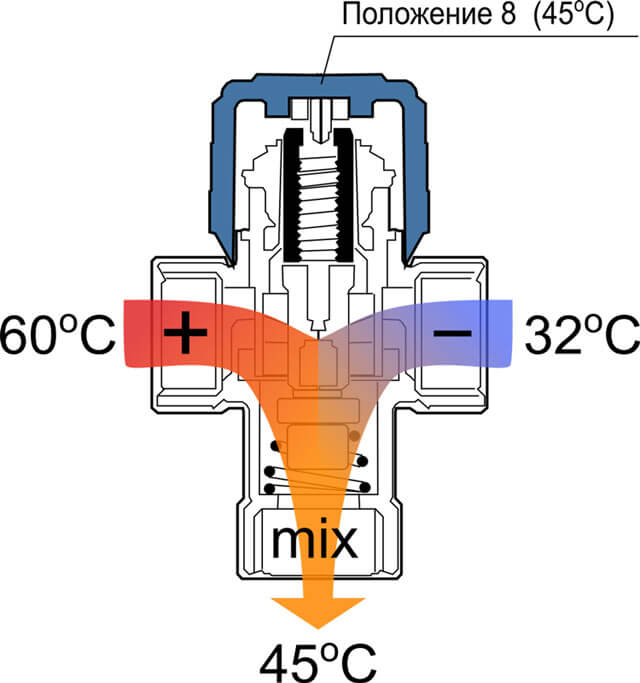

The principle of operation of a three-way valve in a heating system

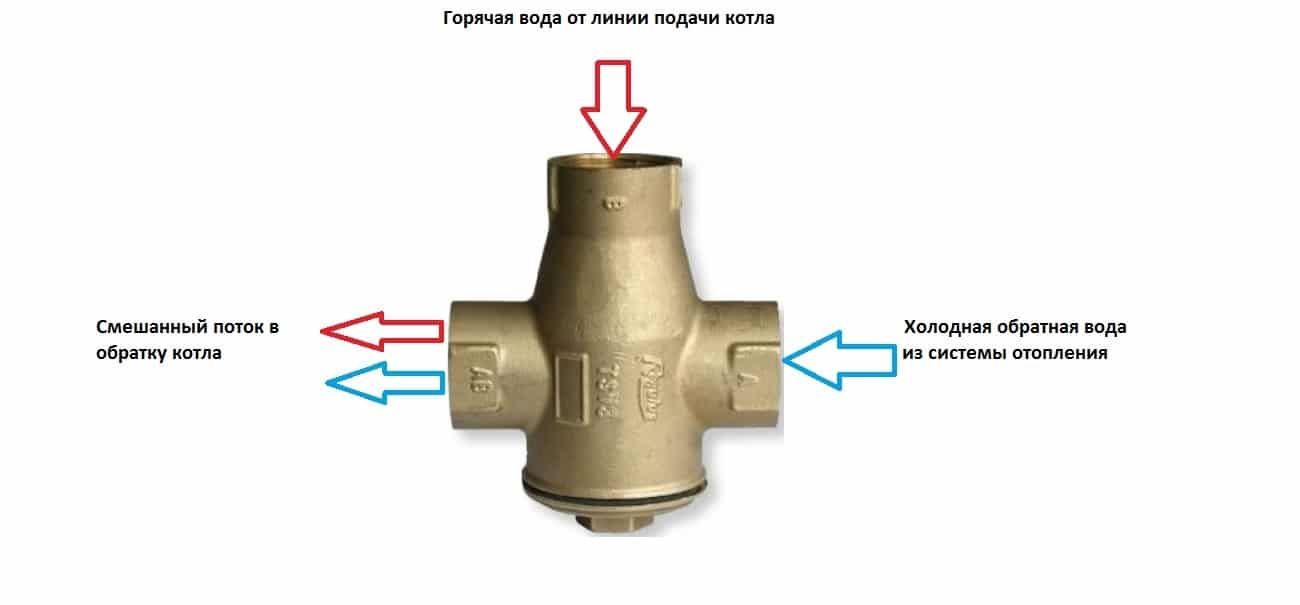

A cold stream is fed to one inlet, a hot stream to the other. At the outlet, they mix, forming one stream of a given temperature. Thus, thanks to the thermo mixer, the temperature of the coolant is regulated, in particular, the return flow is mixed into the coolant at the outlet of the boiler. For this, the valve is installed on the return pipe of the heating pipe.

Dividing

Isolation valves are also called control valves. They split one stream into two. They are used in the hot water supply system, piping of air heaters.

Switching

Changeover or changeover switches are used to switch from circuit to circuit, for example from heating to hot water supply. Switching is carried out using an electric drive.

How to install

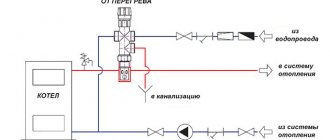

When installing the safety drain fittings, observe the following rules:

- Typically, the pressure relief valve in the heating system is installed in the household circuit in a single copy. Its main points of placement are directly above an electric, solid fuel, gas boiler at its outlet or next to a horizontally located pipeline. If this is not possible for technical reasons, the main condition for correct installation is installation in the supply line up to the first shut-off valve.

- The outlet side pipe is usually connected to a sewer or drainage system, if it is technically difficult or the volume of the coolant in the circuit is not high, you can use a flexible hose that is lowered into a container of a suitable volume.

- The liquid must be removed with a rupture of the jet through a funnel or a hydraulic seal to ensure the system is operational when the sewer is clogged.

- For installation in a pipeline, use a BOTTOM tee of a suitable diameter, the standard being 1/2, 3/4, 1 and 2 inches. The diameter of the pipeline inlet to the valve must not be less than that of the system.

Valve safety groups - varieties and price

Three-way valve control methods

Three-way valve with thermostatic head

Three-way valves according to the control method are:

- autonomous;

- manual;

- thermostatic;

- with an electric drive.

If there is no control possibility, the thermal valve is of a self-contained type. It is preset by the manufacturer to a certain temperature of the heat carrier, i.e. the temperature in the system will always be constant. The main advantages of such devices are low cost and the ability to maintain the same temperature. But it is impossible to change the preset settings, so the characteristics of the valve must meet the requirements of the system, it will have to be selected more carefully.

The manually operated 3-way valve is equipped with a manual adjustment device such as a control panel, rotary knob or valve. Control of the adjustment is carried out using special marks - a scale. Compared to a stand-alone regulator, the manually operated three-way thermal valve is more functional: it allows you to change the temperature mode depending on specific needs and will maintain the temperature at a given level. However, this valve "does not know how" by changing the temperature of the coolant to the transformation of the surrounding conditions.

Electrically operated valve

The design of the product with a thermostat includes a thermostat. The gaseous or liquid medium inside it reacts to changes in the temperature of the coolant. When it heats up to the preset temperature, the hot water pipe is closed off. By the type of power supply, this type of valve can be mechanical and electronic. Mechanical ones work autonomously, while electronic ones require a power supply or periodic battery replacement. Although this inconvenience is fully offset by the benefits.

The inclusion of a thermostatic valve for a solid fuel boiler into the system allows you to automate the process of changing the temperature regime according to the time of day, days of the week. The cost of a three-way element with a thermostat is higher than the cost of simpler analogs.

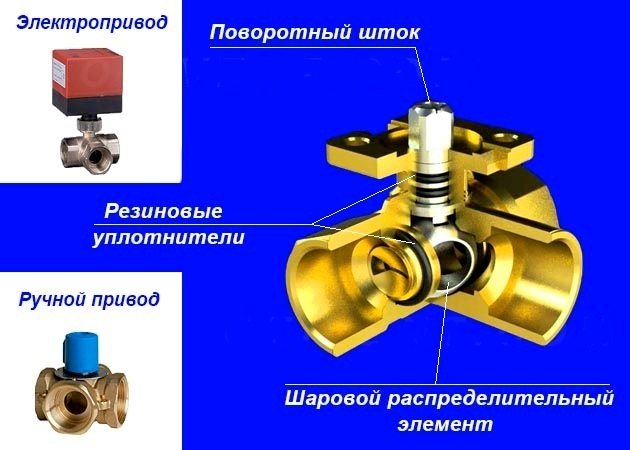

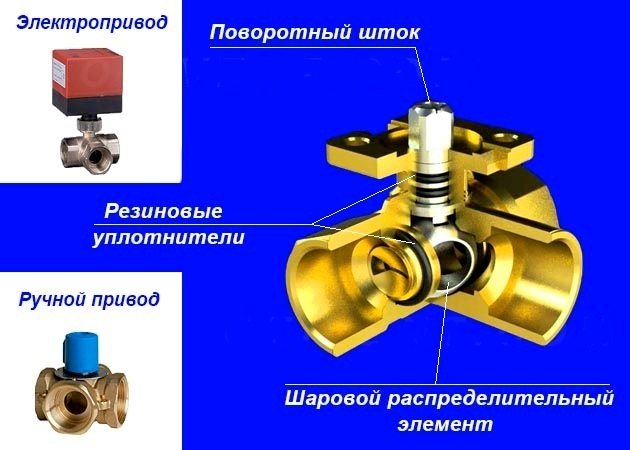

The most advanced models are electrically actuated thermal valves. In order for their work to be constant, it is necessary to install an uninterruptible power supply unit.The flow of cold or hot heat carrier is regulated by a controller, which registers temperature deviations from the set values, and a servo drive. The outlets do not completely overlap, but the volume of the coolant changes. Thanks to the operation of the automation, the heating circuit is always evenly warmed up, and the coolant temperature always exactly matches the set one. The possibility of changing the mode is also present, but you need to be prepared for a high consumption of resources: coolant and electricity. You will have to pay more for the thermal valve itself. A fully automatic device is more expensive.

How the part works

There are many types of valve available depending on the type of actuator used, configurations, control method, etc. According to the control system, as well as the type of drive, there are several models.

One of the most common is a valve using a thermostatic actuator, in other words, an actuator controlled by a thermostat is installed in the part. Such a device works due to the expansion effect of the element (in the case of expansion, the valve stem is pressed, after which liquids with different temperatures are mixed). This type of valve is the most popular.

Appearance

The second type, no less common, is the electrical control technique. In this case, the valve stem is activated after a signal from the electronic control unit.

The third type is distinguished by a control element - the stem is pressed by means of a thermostatic head. The reaction takes place depending on the change in air temperature, which is determined by the head itself, or by means of a sensor carried out to the outside by means of a capillary tube.

Such a drive is most relevant in the case of installation and further operation of floor heating systems.

The valve is also necessary because it prevents the formation of carbon deposits (if cold water flows to the jacket, then the condensate appearing on it will mix with the ash, thereby creating carbon deposits, and this, in turn, reduces the efficiency of heat exchange, which reduces the efficiency of the boiler itself and system in which it is installed).

Purpose and functions

Mixing of flows is necessary so that condensate does not form in the boiler due to cold return

The three-way valve is installed for the following purposes:

- So that the cold coolant does not succumb to the boiler and condensate does not fall out on the inner walls of the furnace. In addition, if a cast iron heat exchanger is used in a hot water boiler, it may crack from temperature extremes.

- To regulate the temperature of the coolant in the circuits. This need may be due to the complexity of the system, where the temperature requirements for each circuit are different. When connected to a heat accumulator, as well as when the heat carrier is used in the heat exchanger of the air handling unit, which is part of the air heating system.

- To be able to control the heating of the coolant in the underfloor heating circuit. The optimum temperature for underfloor heating is no more than 50 ° C. The temperature of the coolant coming from the boiler can exceed this figure by 10-35 ° C. The cooled water that has passed through the underfloor heating circuit will mix with the coolant from the boiler, a three-way valve installed on the distribution manifold will mix the return flow.

The regulator should not be installed if several heating sources operate in the system one by one; if the length of each loop of the water floor is no more than 50-60 m (then RTL heads are installed instead of a three-way valve); if the heating is organized according to a gravity system.

Valve types

So, in more detail about the two existing types of valves, you can read below:

- 1. The three-way thermostatic valve for the boiler is an automatic model.It will maintain the set temperature level without additional human intervention. At the same time, the most functional models are equipped with an additional security system that blocks the movement of the coolant if there is no circulation through one of the incoming pipes. Thus, boiling will not occur in the batteries.

- 2. The three-way thermo-mixing valve for the boiler can be completed with both automatic and manual control. The fundamental difference will be the need to regularly check the state of the system so that it does not overheat. To date, mechanical devices have practically been abandoned, since they have been replaced by more advanced units.

Basic parameters when choosing valves

Brass products have an increased service life, do not crack due to mechanical stress

The three-way valve should correspond to the features of the system as much as possible, therefore, when choosing, all parameters should be checked: design device, technical characteristics.

- First of all, it is necessary to cut off options that are made of unsuitable metal. Silumin low-cost three-way valves are eliminated immediately, since the aluminum-silicon alloy is of low strength. Such thermal valves crack and literally crumble during operation.

- Cast iron 3-way valves do not corrode and are strong enough under static loads, but a point mechanical impact or a sharp temperature drop can cause it to break. Such devices cannot be repaired.

- Steel devices are inexpensive and durable, but rust over time. In order to protect against corrosion, the products are coated with nickel and chromium.

- Thermal valves made of stainless steel are more expensive, the metal is not subject to oxidation and corrosion, so they will serve for a long time.

- Brass and bronze 3-way valves are preferred because the material best meets the requirements for durability and corrosion resistance. Brass products cannot be installed in a system where the coolant is heated to temperatures exceeding 200 degrees. Bronze devices are built into a heating circuit made of copper.

The internal locking mechanism in some products may be ceramic. If the operating conditions are observed, ceramics perform in the best possible way: they do not rust and serve for a long time. But the coolant in the system must be of high quality. In the presence of mechanical impurities, ceramic elements will quickly fail.

For underfloor heating, it is preferable to install valves with a servo drive

The type of valve is selected taking into account the characteristics of the system:

- To protect the boiler from condensation, a valve with an internal thermostat set to a constant temperature of the heating medium is sufficient.

- If the system consists of several branches and it is necessary to control the heating of each, a regulator with a thermal head and a remote sensor is installed.

- When self-assembling the system, a mixing valve is recommended for installation. It is easier for a beginner to understand the scheme of its work, how to put it, remove it.

- Saddle types, in contrast to rotary ones, more accurately allow you to regulate the temperature of the coolant and the pressure.

- For underfloor heating, electric models with a servo drive are recommended.

- For DHW - dividing valves, for heating - mixing valves.

The diameter of the thread on the valve must match the diameter of the heating pipes

As for the technical characteristics, it is necessary to take into account:

- connection method - it can be threaded and flanged;

- inner diameter of pipes - must match the diameter of the pipes at the installation site;

- maximum working pressure;

- the maximum temperature of the coolant at the installation site;

- average water consumption per hour - conditional throughput;

- dynamic range of regulation (30: 1, 50: 1, 100: 1) - indicates the difference in throughput when the valve is fully closed and half open.

Valves with a range of 100: 1 offer a wider range of adjustments.

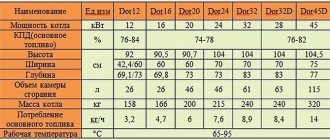

Models depending on the volume of the heating medium, ESBE brand

The data is indicated in the passport for the product. In order to correctly select the valve according to the parameters of the system, it is also necessary to calculate the flow rate of the coolant in the installation line, because the valve must pass the required volume of water at different positions of the stem.

Last but not least, the parameter is the manufacturer. Popular:

- Esbe (Sweden);

- Danfoss (Denmark);

- Honeywell (USA);

- Herz Armaturen (Austria);

- Caleffi (Italy);

- Icma (Italy);

- Valtec (Russia).

It is recommended to choose products of well-known brands, then you can be sure that the marking and the declared characteristics correspond to the real parameters of the three-way valve.

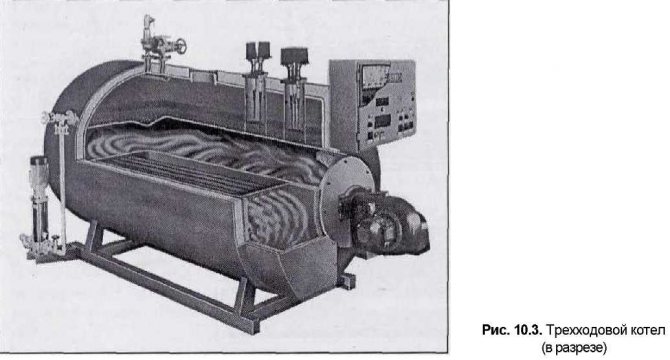

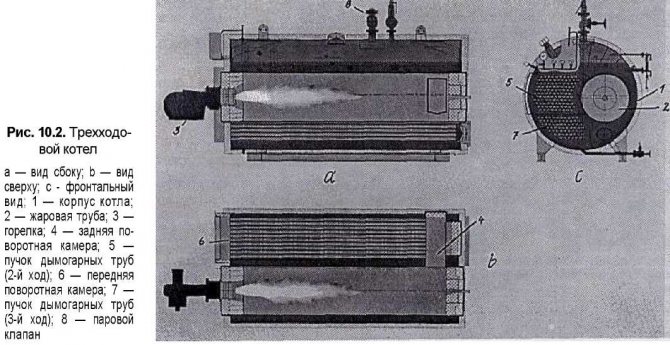

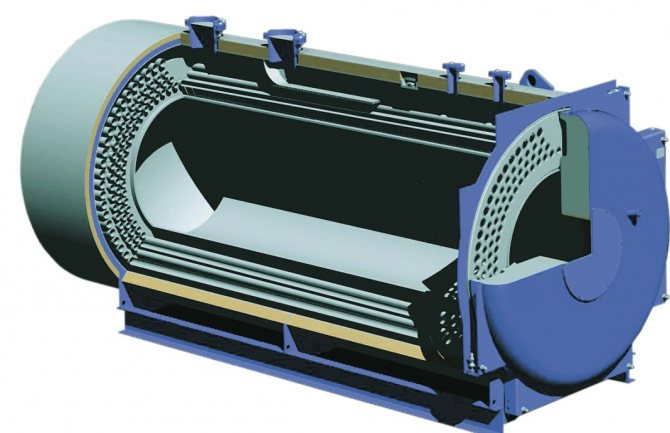

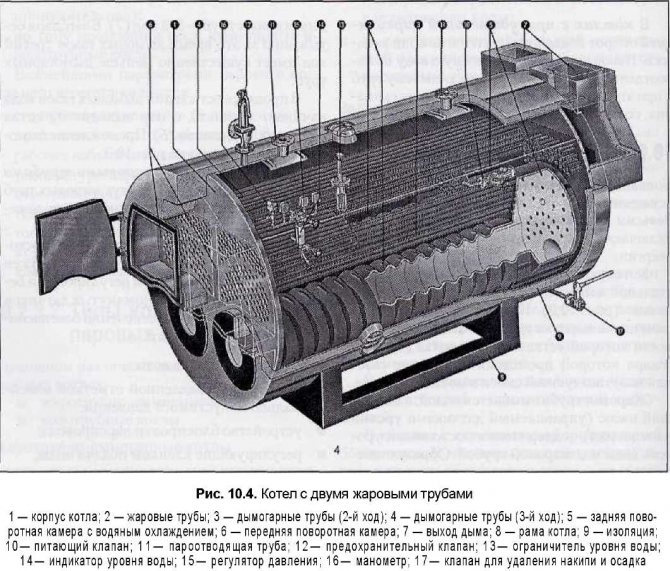

Selection criteria for two- and three-pass boilers

Efficiency is just one of the parameters to be considered when choosing the right type of fire tube boiler. In many cases, the task is simplified by the required amount of steam consumption. The fact is that the use of a two-pass scheme is optimal in boilers with a capacity of up to 5 tons of steam per hour. This is due to the peculiarity of thermal processes occurring in furnaces with a reversible flame development. On the one hand, the reversal of the torch promotes more intense heat exchange due to more uniform heating of the flame tube walls. Also, due to the active recirculation of a part of the combustion products in the root of the burner flame, the emission of nitrogen oxides is reduced. However, this unnecessarily intensifies the heating of the tube sheet and the initial sections of the smoke tubes in the front of the boiler, which can lead to overheating of the metal. Considering these features, most manufacturers of fire tube boilers limit the scope of use of furnaces with reversible flame development to boilers with a capacity of up to 4-5 tons of steam per hour. Accordingly, only three-pass steam boilers with a large water volume serve as the basis for high-capacity boiler houses. In the ICI line, Caldaie is the GX series.

GX series

1700 ÷ 25000 kg / h3 - 25 bar

This series of industrial boilers provides high performance with an efficiency close to 90%. The boilers are automated and, provided that they are equipped with an appropriate security system, they can operate in unattended mode for up to 72 hours. For additional optimization of energy consumption, boilers can be equipped with economizers that increase efficiency from 90 to 95%.

Apart from the topic of choosing between a steam boiler with a water volume and a once-through steam generator, the choice of a boiler for productions with a low steam demand is also predetermined. Most often, small production facilities are located in small spaces, which also imposes such a requirement on the boiler as compactness. Technological equipment with steam consumption from 100 to 500 kg per hour is effectively serviced by two-pass boilers in a compact monoblock body. Corresponding models can be found from many manufacturers. Among them, ICI Caldaie equipment is favorably represented by steam boilers of the FX series in single and double versions (FX DUAL).

FX / FX DUAL Series

50 ÷ 300 kg / h 5 bar

Boilers of this model range are one of the most compact solutions on the market. The double model FX DUAL allows you to design a boiler room with a reserve boiler in a very limited space. Boilers are in demand by service enterprises - laundries, dry cleaners, service workshops. The issue of compact placement in rented space is a key factor in reducing fixed costs for such companies. Additional opportunities for reducing operating costs are provided by economical fuel consumption.

Simplified budget items

Cheap models made of silumin have low strength and are damaged during operation.

Three-way valves of a stand-alone type are considered to be simplified. Their internal structure is really simplified, since neither a thermal head with a controller, nor a stem are provided in them. The thermostatic element is installed inside and is designed for a specific temperature (often 50 ° C or 60 ° C). It will not be possible to change the settings, the flow temperature at the outlet from the valve will always correspond to the set ± 2 ° С. This option is for those who install the valve in simple heating systems and want to save money. The cost of simplified elements is about 30% lower than the average cost of the bulk of regulators.

The thermostatic three-way valve is necessary in complex systems that include several circuits: hot water supply, heating, underfloor heating. It allows you to save fuel by using the heat energy generated by the boiler more efficiently. Despite the many advantages, the installation of the valve is not always justified, therefore, you should consult with a specialist regarding the advisability of installing it.

Valve actuator types and operating principle

All product modifications differ from each other in certain indicators:

- Shutter mechanism: tension or stuffing box;

- plug configuration: L / T / S-shaped;

- gate type: cylinder, ball, cone;

- type of connection to the system: coupling, flange or welding.

The distribution of the coolant is carried out by the drive, which are grouped according to the following types:

- Hydraulic action;

- manual control;

- electromechanical movement;

- pneumatic actuation.

Electromechanical actuators are manufactured by thermostatic and cap type. In them, the signal for the process of mixing different temperature media comes from the control unit.

In servo-driven versions, control is carried out directly by the controllers. Manual control of the TC functions by rotating the adjusting cap.

Varieties

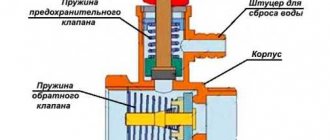

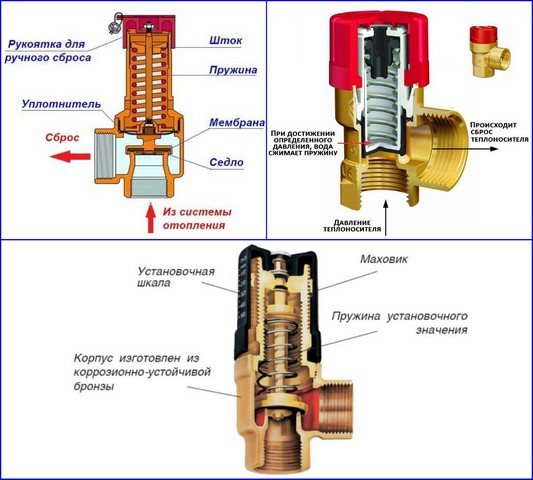

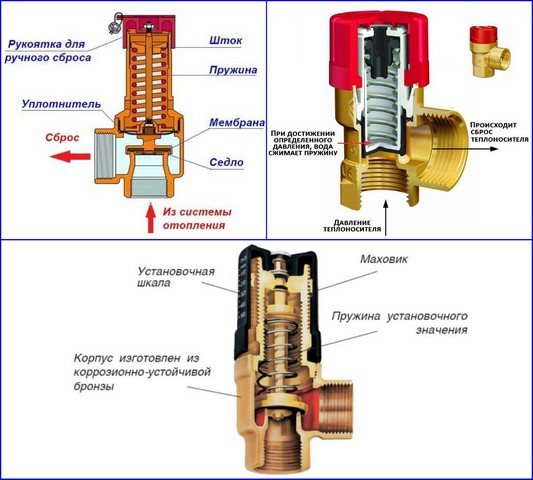

The existing types of valves are capable of working with boiler equipment from leading foreign (Vaillant, Baxi, Ariston, Navien, Viessmann) and domestic (Nevalux) manufacturers on gas, liquid and solid fuels in situations where automatic control over the operation of the system is difficult due to the type of fuel. or broken when the automation fails. Depending on the design and the principle of operation, safety valves are divided into the following groups:

- According to the purpose of the equipment in which they are installed:

- For heating boilers, they have the above design, they are often supplied on fittings in the form of a tee, in which a pressure gauge for checking the pressure and a vent valve are additionally installed.

- For hot water boilers, there is a flag in the design for draining water.

- Containers and pressure vessels.

- Pressure pipelines.

- According to the principle of actuation of the pressure mechanism:

- From a spring, the clamping force of which is regulated by an external or internal nut (its work is discussed above).

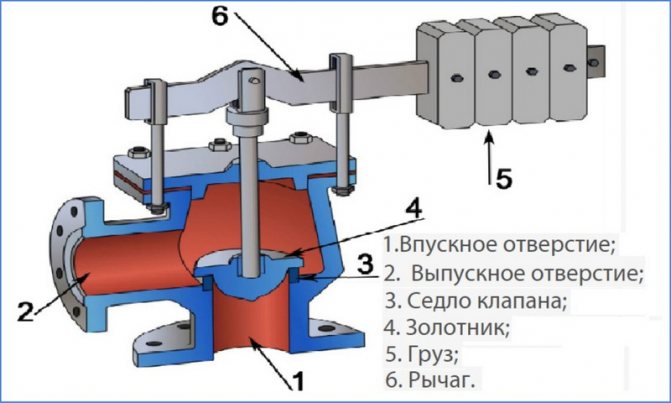

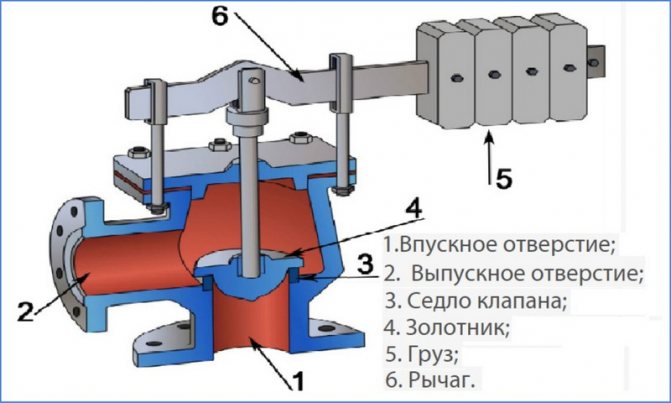

- Lever-cargo, used in industrial heating systems designed to discharge large volumes of water, their response threshold can be adjusted with suspended weights. They are suspended from a handle connected to the shut-off valve by the principle of a lever.

Lever-load modification device

- Locking mechanism response speeds:

- Proportional (low-lift spring) - the sealed lock rises in proportion to the pressure and is linearly related to its increase, while the drain hole gradually opens and closes in the same way with a decrease in the volume of the coolant. The advantage of the design is the absence of water hammer at various modes of movement of the shut-off valve.

- Two-position (full-lift lever-cargo) - operate in open-closed positions. When the pressure exceeds the response threshold, the outlet opens completely and the excess volume of the coolant is vented. After the pressure in the system is normalized, the outlet is completely closed, the main design flaw is the presence of water hammer.

- By adjustment:

- Non-adjustable (with caps of different colors).

- Adjustable with screw parts.

- According to the design of the adjusting elements of the compression of the spring with:

- An internal washer, the principle of operation of which was discussed above.

- Outside screw, nut, models are used in household and communal heating systems with large volumes of coolant.

- With a handle, a similar adjustment system is used in flanged industrial valves, when the handle is fully lifted, a one-time drain of water can be performed.

Designs of various models of drain valves

Boiler repair

In case of leakage, we repair fire-tube boilers in the following sequence:

- We study the documentation and device diagrams.

- We search for the problem area and localize it.

- We clean the surface near the crack to a pure metal 15-20 mm wide.

- We carry out welding works at an ambient temperature above + 50C. We use electrodes 2.5 mm or 3 mm thick. We weld the seam from the side of the drum 2-4 mm more than from the pipe. Welding direction from the middle of the crack to the edges simultaneously using two welding machines.

- We clean the seam to a shine and look at its quality. If necessary, we eliminate imperfections: uncooked areas and sinks.

- We are testing the boiler.

Fire-tube hot water boilers are used in boiler rooms, for heating private households, in industry and other areas.

Sometimes, in the device of fire-tube boilers, due to improper operation, it becomes necessary to replace the damaged area. For these purposes, the flame method is used. In this case, the dimensions of the damaged part must be at least 200 mm or the diameter of the pipe. First, the site is localized, then it is cut out with a grinder to the metal preserved in thickness and properties, after which a patch of steel of the same composition is cleaned and welded.

Fire-tube hot water boilers are used in boiler rooms, for heating private households, in industry and other areas. This is due to their high heating efficiency and economical fuel consumption, reliability and unpretentious operation. The device of fire-tube boilers is relatively simple, so they can be easily repaired even on your own without the involvement of specialists.

Why the valve can leak

The pressure relief valve in the heating system can leak for various reasons. In some situations, this is an acceptable natural process, in other cases, a leak indicates a malfunction of the device.

Leakage of the protection valve can be caused by the following reasons:

- Damage to the sealed rubber cup, disc as a result of repeated use. If, during repair, the replacement part cannot be found on sale or it is not included in the package, you will have to change the device completely.

- In spring types, the opening of the side drain pipe occurs gradually, with boundary pressure values or short-term surges, the valve may partially work and drip, which does not indicate a malfunction.

- Leakage can be caused by incorrect settings or malfunctions of the expansion tank - damage to its membrane, air escaping through a depressurized housing or a damaged nipple. In this case, sudden pressure surges are possible as a result of water hammer, causing periodic short-term flow of the coolant through the safety valve.

- Some adjustable valves are leaking because fluid seeps down the stem from the top during actuation.

- If a back pressure is created at the branch pipe above the instrument response threshold, a leak also occurs.

Appearance, cost of some brands of drain valves

The safety valve of steam boilers is designed to protect them from overpressure in the system caused by various factors, and is an indispensable element in the operation of this type of equipment. A wide range of safety devices from Chinese, domestic and European manufacturers are available for sale at a relatively low cost. When buying, it is rational to choose a protective group from several devices, which additionally include a pressure gauge and an air drain valve.