Home / Boiler houses

Back to

Published: 27.10.2019

Reading time: 5 min

0

3590

A boiler plant (KU) consists of an interconnected set of equipment for generating steam and hot water in generation processes (CHP, IES, NPP), production of various types of products and in central heating systems. Therefore, it is subdivided into energy, industrial and heating.

The source of steam generation in the WHB is drinking water, and the source of energy is natural fuel. The heat transfer process is carried out through convective and radiative heat exchange using boiler tubes.

The organization of heat transfer occurs due to the coordinated work of complex units and elements of the steam generator, which are classified as main or auxiliary equipment.

- 1 Basic equipment

- 2 Boiler room auxiliary equipment

- 3 Boiler room automation

- 4 Plants for the production of boiler equipment

Subsections

BurnersGas control points (GRPB) Industrial boilersGas cleaning filtersBurner nozzles

All boiler equipment is selected in accordance with the current regulatory documentation, according to the terms of reference and the customer's questionnaire. The selected equipment is fixed to the floor or frame of the boiler room on supports and brackets, without special foundations.

Basic boiler equipment

- hot water boilers, fire-tube and water-tube boilers;

- burners for various types of fuel;

- heating system pumps of the "Wilo" or "Grundfos" brand;

- water treatment equipment in the boiler room;

- mixing valve "ESBE";

- membrane expansion tanks with a design capacity.

The number of boilers is determined by the heating capacity of the boiler house, the design scheme, and the availability of backup equipment; maximum (peak) and minimum loads for heating and hot water supply.

The coolant is supplied to the heating networks through a pipeline of the design cross-section by one of two network pumps of the Wilo or Grundfos brand, with the required capacity. The available water pressure at the outlet of the boiler room is 4.0 kgf / cm². Return network water with a temperature of up to 70 ° C, a pressure of 2.0 kgf / cm² enters the boiler. The pumps (1 working and 1 standby) work alternately and supply the coolant (chemically treated water) to the boiler. At the outlet of each boiler, a bypass line with a check valve is provided. A three-way mixing valve is used to mix part of the return water into the direct network water, which is controlled by a microprocessor-based measuring regulator of the TPM brand. To compensate for temperature expansion in the heating system, a membrane expansion tank from Reflex is installed in front of the pumping group.

All pipelines of the heating system and hot water supply are thermally insulated to reduce heat losses inside the boiler room, as well as in accordance with sanitary and hygienic standards.

Basic equipment

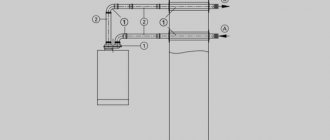

Schematic execution of a boiler room with a deaerator

The main elements are structurally located within the boundaries of the boiler and serve to ensure the processes of generating heat energy in the form of steam or hot water. The types of boiler equipment include:

- The boiler is a heat source. They are hot water, producing hot water for central heating and with a maximum T up to 150 C and steam, producing saturated or superheated steam over 1 MPa.

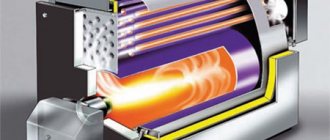

- The combustion device or firebox provides complete combustion of the energy carrier.The process of fuel oxidation with the formation of thermal energy takes place in it.

- The boiler lining is necessary for thermal protection of the boiler unit structures in order to reduce heat losses into the atmosphere and ensure the gas tightness of the heat generator. It consists of refractory materials that are rigidly attached to the unit frame.

- The frame is a metal structure to ensure the relative position of the working elements and the boiler.

- The superheater is used to heat the steam leaving the drum and separator at a T above the saturation point. Structurally, it is made in the form of heat-resistant steel coil pipes.

- The water economizer is used to heat the water entering the boiler feed circuit by lowering the temperature of the flue gases, thereby increasing the efficiency of the boiler. It is performed in the form of a boiling and non-boiling type. In the first, the water heats up to T boiling, and in the second it never reaches it. Structurally, the devices of the first type are made of packages of steel pipes, and the second - of cast iron.

- The air heater performs the task of heating the primary air in front of the boiler by cooling the combustion products; the process takes place in recuperative heaters.

- Shut-off and control valves are plumbing devices installed on the gas, water and steam paths of the boiler to regulate the flow rate of the medium at the inlet and outlet of the unit. Shut-off - used to open / close sections of the thermal circuit. Regulating - used to maintain the specified operating parameters of the medium in terms of pressure and temperature. Safety, in the form of relief valves, is used in safety systems for emergency closing when high values of monitored safety parameters are reached. Special fittings include condensate traps and fuel filters; they are installed in the water and fuel supply systems of the boiler.

- The set of the unit is used for servicing the gas-fired path of the boiler. These include: manholes, hatches, doors, air dampers, explosive valves on gas ducts and soot blowers for cleaning boiler pipes from soot.

Water treatment equipment for hot water boilers

- rough mechanical cleaning;

- automatic installation of filtration and deferrization;

- automatic installation of softening.

The source water enters the coarse filter, where mechanical impurities are removed from the water. After treatment of water from coarse mechanical impurities, the water enters the deferrization station. Removal of iron compounds from water is carried out by filtration through the loading layer "Sorbent-AS". In the boiler house, for the implementation of the filtration and deferrization process, two installations of AQUAFLOU filtration equipment are used, operating in parallel. Each unit consists of a filter housing and a control unit. The housings have an upper threaded hole for installing a drainage and distribution system, loading filter materials, fixing the control unit. The method of sodium cationization is carried out on a continuous operation unit of the AQUAFLOU SF series. The pressure of the water entering the installation must be at least 2.5 and not more than 6.0 kgf / cm².

Regeneration of the ion exchanger in the columns occurs automatically and is initiated by the water meter after a predetermined amount of water has passed. For accounting of measurements and registration of heat transferred to the consumer in the boiler room, it is planned to install the equipment of the heat meter "TEM-150/150/15" with electromagnetic flow converters and thermal converters. For the heating circuit, the thermal circuit provides for the accounting of the make-up water consumption using an electromagnetic converter included in the heat meter kit.

For the source of water supply, according to the buyer's technical assignment, a questionnaire for boiler room equipment and laboratory research protocols, an external network of a drinking water supply system or water from an artesian well is taken. The raw water used is counted using a mechanical cold water meter with a bypass.

Boiler plants

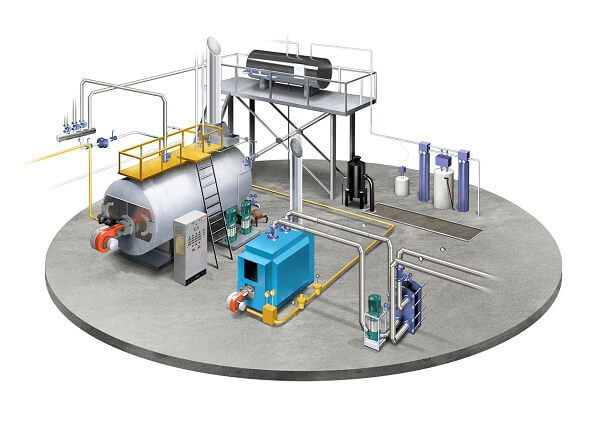

Boiler installations is a complex of equipment for a boiler room designed to convert the chemical energy of fuel into thermal energy in order to obtain hot water or steam of specified parameters.

Depending on the purpose, the following boiler plants are distinguished:

- heating boiler plants - to provide heat to heating, ventilation and hot water supply systems;

- heating and industrial boiler plants - to provide heat to heating, ventilation, hot water supply and process water supply systems;

- industrial boiler plants - for process heat supply.

The boiler plant consists of a boiler unit, auxiliary mechanisms and devices:

The boiler unit includes a combustion device, a pipe system with drums, a superheater, a water economizer, an air heater, as well as a frame with ladders and service platforms, lining, gas ducts and fittings.

Auxiliary mechanisms and devices include smoke exhausters and blowing fans, feed, water treatment and dust preparation plants, fuel supply systems, ash collection systems (when burning solid fuel), a fuel oil economy (when burning liquid fuel), a gas control station (when burning gaseous fuel), control and measuring devices and automation.

In the process of obtaining hot water or steam for heating, production, technical and technological purposes, water, fuel and air are used (the working fluid is water).

In industry, agriculture and municipal services, various types of boilers are used:

- A steam boiler is a device with a furnace, heated by the products of the fuel burned in it and designed to produce steam with a pressure above atmospheric, used outside the boiler plant.

- A hot water boiler is the same device, but designed to heat water under pressure above atmospheric and used as a heat carrier outside the boiler plant.

- A waste heat boiler is a steam or hot water boiler that uses hot gases from the process as a heat source.

- Boiler-boiler is a steam boiler, in the steam space of which there is a device for heating water used outside the boiler, and a free-standing boiler is included in the natural circulation.

Stationary is a boiler installed on a fixed foundation, mobile is a boiler that has a chassis or is installed on a mobile foundation.

Various auxiliary equipment is used in boiler plants:

- Superheater - is a device designed to superheat steam above the saturation temperature corresponding to the pressure in the boiler, as a result of the transfer of heat to it by flue gases.

- An economizer is a device heated by fuel combustion products and used for heating or partial evaporation of water entering the boiler.

- Air heater - designed to heat the air entering the combustion device with the heat of exhaust gases.

- Feed unit - consists of feed pumps for supplying water to the boiler under pressure, as well as corresponding pipelines and fittings.

- The draft device consists of blowing fans, a gas duct system, a smoke exhauster and a chimney that provide the required amount of air to the combustion device, the movement of combustion products through the gas ducts, and their removal outside the boiler unit.

- The thermal control and automatic control device includes instrumentation and automatic devices that ensure the uninterrupted and coordinated operation of the boiler plant to generate the required amount of steam at a certain temperature and pressure.

- The device for the preparation of feed water includes apparatuses and devices that ensure the purification of water from mechanical impurities and scale-forming salts dissolved in it, as well as the removal of gases from it.

- The ash and slag removal device consists of hydraulic systems and mechanical devices: trolleys or conveyors, or both. Boiler plants operating on pulverized fuel are equipped with crushers, dryers, mills, fuel feeders, fans, as well as a system of conveyors and dust and gas pipelines.

- The fuel storage is used to store fuel.

List of equipment in a boiler house with a capacity of 2.5 MW

| P / p No. | Boiler equipment | amount |

| 1. | Steel structure: 7.2 x 2.4 x 3.1 m. (Wall and roof panels 100 mm) | 2 sections |

| 2. | Steel structure: 7.2 x 2.25 x 3.1 m. (Wall and roof panels 100 mm) | 2 sections |

| 3. | Steel water-heating boiler "KVANT-1.25". (Power 1.25 MW) | 2 sets |

| 4. | Gas block burner "VEKTOR-57/170". | 2 sets |

| 5. | Heat exchanger (heating) 1.6 Gcal / hour. | 2 sets |

| 6. | Gas supply scheme P = 10.0 kPa. | 1 set |

| 7. | Automatic gas control system SAKZ-MK –2 100 SD. | 1 set |

| 8. | Electromagnetic gas valve DN100. | 1 set |

| 9. | CO signaling device. | 1 set |

| 10. | CH4 signaling device. | 1 set |

| 11. | Gas filter FN4-1. | 1 set |

| 12. | Thermosensitive shut-off device DN100. | 1 set |

| 13. | Commercial gas metering unit consisting of:

| 1 set |

| 14. | Differential pressure sensor PROMA-IDM-DD (v) -6. | 2 sets |

| 15. | Flanged gas valve DN100. | 5 sets |

| 16. | Flanged gas valve DN80. | 2 sets |

| 17. | Flanged gas valve DN20. | 3 sets |

| 18. | Continuous sodium-cation exchange water softening system. (Make-up volume: 0.1 m³). | 1 set |

| 19. | Normally closed solenoid valve DN = 25 (mains make-up + boilers make-up). | 2 sets |

| 20. | Expansion tank for the heating network circuit 1000 l. | 1 set |

| 21. | Expansion tank for the boiler circuit 800 l. | 1 set |

| 22. | Expansion tank for source water 100 l. | 1 set |

| 23. | Electromagnetic heat meter TEM Du100 / 100/15 with pressure sensors. | 1 set |

| 24. | Honeywell valve 3-way DR100GFLA actuator M6061L1043 (heating). | 1 set |

| 25. | Industrial controller OWEN TRM32 for control and regulation of temperature in heating and hot water supply circuits | 1 set |

| 26. | Cold water meter VSX - 15 (HVO). | 1 set |

| 27. | Cold water meter VSX - 15 (source water) with bypass. | 1 set |

| 28. | FMF 150 filter (on the return water of the heating system circuit). | 1 set |

| 29. | Mechanical filter DN25 (source water). | 1 set |

| 30. | Reducer for HVO Du25. | 1 set |

| 31. | Fan VO-3.15-220. | 2 sets |

| 32. | Pump control SAU - MP 11. | 3 sets |

| 33. | KPI pump control. | 2 sets |

| 34. | Excessive pressure transducer PD100DI. | 1 set |

| 35. | Differential pressure sensor YNS-C106XWM08. | 3 sets |

| 36. | Network heating pumps: IPL 65 / 155-7.5 / 2, Q = 86m3 / h, H = 22m. | 2 sets |

| 37. | Boiler circuit pumps: Wilo-BL 65 / 130-5.5 / 2, Q = 86m3 / h, H = 17m. | 2 sets |

| 38. | Initial water pumps: MHI 203 0.55kW 3 ~ Q = 1.2m3 / h, H = 28m + frequency. | 2 sets |

| 39. | Security and fire alarm. | 1 set |

| 40. | Dispatching is a personal computer. Data transmission - GSM. | 1 set |

| 41. | Fire extinguisher, first aid kit. | 1 set |

| 42. | Chimney. Height 15.0 m | 1 set |

| 43. | External gas ducts, length 3.0 m. | 2 sets |

For all questions, please call the phone number listed in the "header" of the site.