All pipeline systems are equipped with shut-off and control valves, which include a variety of valves, taps, valves, gate valves. Their function is to regulate and shut off gas streams or liquid streams. In contrast to traditional closure assemblies in a ball valve, the closure has a spherical surface. In any of its positions, it is capable of pressing against the seat, which creates a cross-section for the flow of the medium (gas or liquid), up to its complete overlap.

The ball valve has been on the Russian market for almost twenty years and has received recognition among consumers. It has a graceful shape, as a design element, it fully meets the modern requirements of ergonomics. Ball valves are manufactured both with manual control and electromechanical actuators, allowing them to be operated in automatic modes.

Design features of ball valves

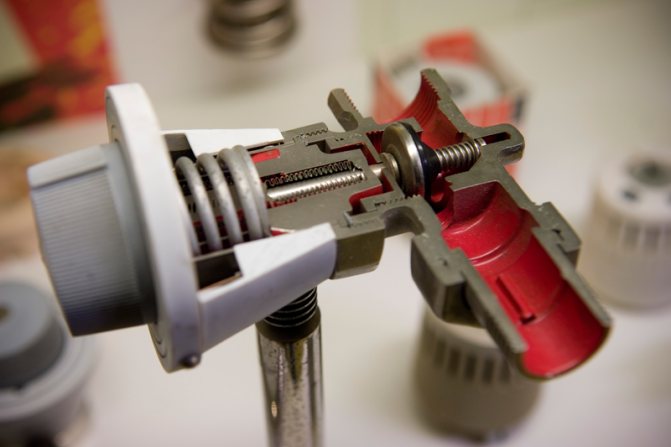

The design of ball valves retains the traditional concept of using a movable spindle, which, when the handwheel or handle (item 11) or the actuator of the electric motor is turned, imparts the working movement to the locking device in the housing. But instead of the classic spool and seat of the usual conical or cylindrical configurations, the ball valve design uses a saddle with a ball valve fixed in it (key 4). Ball - the shutter is securely fixed in the saddle, but rotates freely in it. The ball has a through hole, the position of which with respect to the flow of liquid or gas changes by rotating the ball around its axis. The degree of opening of the orifice section influences the flow parameters in the same way as with traditional valves.

To maintain a stable position of the ball valve, a threaded spindle or stem connection (pos. 3) with a spindle nut (pos. 8) is used, which is fixedly connected to the body. Its self-locking ability allows fixing the operating parameter of the flow.

The very invention of the ball locking mechanism for pipeline valves dates back to the beginning of the 20th century, but it did not receive proper application due to the lack of high-quality sealing materials in those years that could ensure the tightness of the valve. Currently, seals made of Teflon and fluoroplastic reduce the abrasion of the valve sealing shells to almost zero, which immediately expanded the scope of these valves. In the ball valve design, all mating parts and their connections (keys 5, 6, and 7) must be properly sealed.

Ball valve or butterfly valve? What's the best for plumbing?

Pipeline fittings are constantly being improved to more efficiently control the flow of the working medium. More recently, ball valves were used to regulate the flow rate or completely shut off it, but modern industry offers engineers to install butterfly valves. People have a choice, which means they need to figure out which is better for the water supply: a ball valve or a butterfly valve?

Ball Valves

The ball valve at one time became an excellent replacement for gate valves and valves. It is still used widely on the following systems today:

- Gas supply;

- Heating systems;

- Plumbing systems.

Cranes are installed on large highways, on pipelines in production shops and are often used in everyday life.

pros

Ball valves have gained immense popularity due to their advantages:

- Reliability;

- Small size and can be installed even in confined spaces;

- Ease of use;

- Wear resistance.

These characteristics provided cranes with immense popularity at the end of the last century, when they were first invented. Other fittings began to go down in history as a less advanced type of fittings, unable to meet the requirements of modern pipeline systems.

Minuses

No device can be perfect. This also applies to ball valves during operation, their negative qualities became known:

- Clogging by solid particles in the water;

- Sticking of the valve due to prolonged stay in the closed state. After downtime, the crane is difficult to open or completely stops functioning;

- Fear of water hammer. Many pipelines often experience a sharp increase in pressure, because of this, sensitive devices and ball valves become unusable.

With a few drawbacks, the ball valve is still used for flow control. Sometimes the ball valve is irreplaceable. Its production does not require any costs, the device is very cheap, easy to install and replace in case of breakdown.

Butterfly valves

Butterfly valves are a new type of pipeline fittings. They replaced ball valves quite recently and have already gained popularity.

Principle of operation

The principle of operation of the gates is fundamentally different from the operation of a ball valve. In this case, the disc serves as a locking element. It, in turn, rotates around its axis and is set at a certain angle to the axis of movement of the flow of the working medium. When the disk is located perpendicular to the flow, it is completely blocked, and if it is installed along the axis of movement, the through hole will be as open as possible. By installing the disc at an angle, you can quickly adjust the rate of passage of the working medium through the valve.

Benefits

All ball valves or butterfly valves offer the following benefits:

- Low weight;

- Durability;

- Compactness;

- Reliability.

At the same time, gates have several advantages that distinguish them favorably from ball valves:

- The ability to change seals;

- Tightness when blocking the flow in any direction;

- Lack of sticking;

- Resistance to water hammer;

- Convenience.

Only a specialist can determine what is best for a water supply system. All types of pipeline fittings have their own advantages and disadvantages and should be chosen based on the parameters of the pipeline and operating conditions.

Classification

The main criteria for the classification of ball valves are:

- Bandwidth;

- Functional purpose;

- Body shape.

Graduation of ball valves by capacity

The throughput is determined by a simple arithmetic ratio of the cross-sectional area in the valve ball-gate to the cross-sectional area Du of the pipe docked with it:

- For full bore valves, this criterion is 90-100%;

- For standard - 70-80%;

- For partial bores - maximum 50%.

Functional purpose

Despite the abundance of functional features of the valves, there are only three main working areas:

- Shut-off ball valves used to open - close flows in pipes. The requirement for them is to ensure a tight shutdown in a closed operating state and a minimum flow resistance in an open position;

- Controlling ball valves that change the flow rate in the pipeline;

- Special valves designed for work in aggressive environments.

Manufacturing material

For the manufacture of ball valves, steel, cast iron, brass and bronze, titanium and even polyethylene are used.When choosing a ball valve, the manufacturer of which is famous for its brand, you can run into counterfeit products of Chinese or "homemade" production. Valves made in Italy have deserved recognition. They are produced by hot pressing, which ensures a homogeneous product structure and, unambiguously, high reliability. Turkish and Chinese valves are made by casting, which provides less precision and tightness than Italian products.

The most reliable and most expensive valves are made of stainless steel. Manufacturers are located in Spain, Austria, Finland, Italy, Germany and many other countries.

It is important!

The ball valve is classified as an explosion-proof product due to the fact that the spindle and stem are inserted inside the body. Even with a pressure many times exceeding the working pressure, the possibility of unauthorized stem stickout is excluded.

The ball valve is a reliable industrial device. It is actively used for the installation of water supply, in heating and gas systems, in the production of oil and gas.

The tap serves as a reliable shut-off device. Differs in convenience of design and reliability in operation. This mechanism completely replaced the cylindrical and conical cranes. The main purpose of the ball valve is to regulate and shut off the movement of gas and liquid media and create complete tightness. It is an indispensable device when working with aggressive media.

The shut-off ball valve is a ball valve with a shutter and a spherical surface. The main elements of its design include: body, ball with a cylindrical hole, movable spindle, removable handle, seals for the spindle, stem. The device has a robust design and in any position creates a flow area of the pipeline, with a hermetically sealed passage.

Scope of use

Valves are used at large scale and small production levels. The most popular area of use is the gas pipeline. It is very important here to eliminate the possibility of gas leakage when it moves through the pipeline. The ball valve has high tightness and is used as a reliable shut-off device on the pipeline when transporting natural gas. It is suitable for indoor networks, networks with low pressure of gas supply, for controlling gas flow with high pressure.

The valve is able to effectively regulate the flow of water and viscous liquids, chemical aggressive media and steam.

The meaning of the phrase "ball valve"

The design of ball valves is not a novelty and has been known for over 100 years, but in early versions it did not provide a tight shutoff of the medium passage due to the difficulty of providing it with the metal surfaces of the ball plug and body seats. The emergence and introduction of such materials as fluoroplastic, synthetic rubbers for the manufacture of saddles in the valve industry led to the beginning of the widespread use of ball valves. New materials made it possible to ensure tight closure and significantly reduce the effort required to operate the crane.

The movable element (gate) of such taps is a spherical plug - a ball, along the axis of which a through round hole is made for the passage of the medium. In straight-through valves, to completely close or open the passage, it is enough to turn the ball 90 °.

By type, ball valves are divided into full bore and reduced (standard bore). Full bore ball valve - the diameter of the hole in the ball, which corresponds to the internal diameter of the pipeline on which the valve is installed. Hydraulic losses during the passage of the working medium through a fully open valve are very small, practically the same as when the medium passes through a pipe equal in length to the valve body, which is several times less than in other types of valves. This valuable quality made the valves of this type the main shut-off device on the linear part of the main pipelines. Reduced or standard bore ball valves - the diameter of the hole in the ball is one size less than the diameter of the pipeline. This type of ball valves is used on pipelines where partial head loss is not critical.

By the type of connection, ball valves can be: flanged, welded, coupled and combined. Flanged ball valves are used on pipelines that provide for partial disassembly / assembly, as well as in rooms where welding is prohibited. Valves with a welded connection type are used in particularly critical or hard-to-reach pipeline sections, due to the complete tightness of the overlap and the strength of the connection. Coupling valves have an internal tapered or cylindrical thread. They are mainly used in public utilities. Ball valves with combined connection, are universal and are used in various pipeline systems (connection thread / welding, flange / welding, etc.).

In addition to the above, ball valves have a number of other advantages, including:

simplicity of design;

high and reliable tightness;

small dimensions;

simple form of the flow path and the absence of stagnant zones in it;

convenient control;

short turnaround time;

applicability for viscous and contaminated media, suspensions, slurries and sludge.

As a disadvantage, the need for a "dead" zone for turning in cranes with a cantilever handle can be noted. This disadvantage can be compensated for by a tap with a wing handle.

The saddles in the body are made in the form of rings made of various types of plastics (mainly fluoroplastic), which ensures reliable tightness, ease and smoothness of the ball plug rotation, but limits the use of such valves for media with a temperature of no more than 200 ° C.

Ball valves are operated manually (on small diameters) and using a mechanized drive - electric, pneumatic and hydraulic, and for valves on gas pipelines it is possible to use the working medium transported through the pipeline as a control medium for a pneumatic drive. In everyday life, a ball valve can be called a semi-turn.

and its varieties

Depending on the engineering features, valves are classified into several types. By design, the cranes are divided into:

- straight-through;

- corner;

- mixing;

- checkpoints.

Depending on their functional features, the valves are divided into:

- shut-off;

- with the possibility of locking adjustment;

- special purpose valves.

Another feature for dividing mechanisms into subspecies is functional capacity. Here the taps are divided into:

- standard;

- full bore;

- partial bores.

To determine the bandwidth, the cross-sectional area of the hole in the ball valve is calculated to the cross-sectional area in the cylinder.

The purpose of the ball valve is also determined by the material of its manufacture: titanium, steel, polyethylene, cast iron, bronze.

Depending on the working direction, there are three types:

- Valves for opening and closing the flow in the pipe.The main requirement that they must comply with is to ensure tightness in the closed state and a minimum level of resistance in the open position.

- Ball valves with the ability to adjust - are used to change the value of the flow rate in the pipeline.

- Special purpose valves - to ensure high-quality work with aggressive media.

Installation of ball valves on batteries

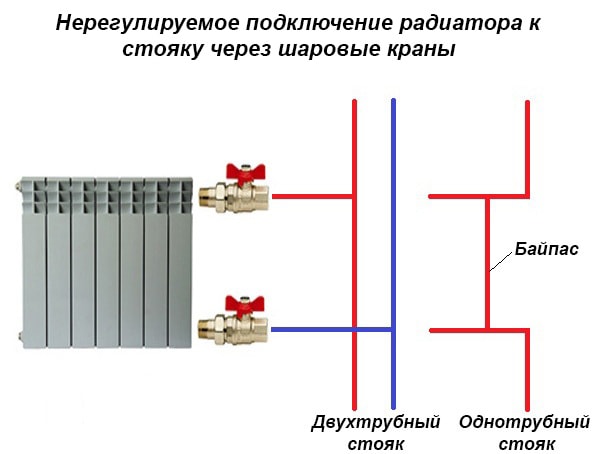

A conventional ball valve is only designed to switch to 2 positions: "open" and "closed". It is impossible to regulate the flow of the coolant through the radiator with it, only to shut it off. The figure below shows a simple connection diagram of a heater with this type of fittings:

The proposed scheme is the best option for unregulated connection of the radiator to the central heating risers in the apartment. You still do not have to balance it, and it is pointless to install a thermostatic valve due to the poor quality of the coolant. Instead of a ball valve at the outlet, the installation of a so-called shut-off valve is also practiced, its difference is only in appearance.

Depending on the arrangement of devices and heating pipes, you can choose a corner valve for a radiator with or without a decorative coating. Also, when choosing a product, it is recommended to pay attention to the working pressure indicated on the product body or in its passport. It must correspond to the pressure in the heating network of an apartment building.

Advice. Choose good taps made of thick-walled brass and a connection with an American union nut for mounting on a radiator. It will allow you to quickly disconnect the liners without rotating the elements. On a single pipe riser, remember to install a bypass with a slight offset away from the main pipe.

Flanged valve features

Special parts are used to secure the shut-off valve to the pipeline. These include: welded joints, flanges, pins and couplings. Flanged ball valves are used to withstand special loads. The equipment is installed on pipes with a diameter of up to 50 mm. Specialized gaskets provide the valve with perfect tightness.

In most cases, a flanged ball valve serves as an optimal device for heating and boiler networks. Its connections are convenient in the field of repair, dismantling and replacement of a depressurized area. In this case, welding work is not required.

The procedure for performing work when replacing and repairing crane towers

When replacing, the instructions for performing the work will look like this:

- first you need to stop the water supply and start dismantling the old device. The first step is to remove the flywheel cap;

- a bolt will be found under it, by unscrewing which, you can remove the valve;

- after that, you can unscrew the axle box itself from the seat with a key;

Dismantling the crane box

- after inspecting the threads and removing debris, you can start installing a new crane-axle box. The work is carried out in the reverse order - first the axle box itself is screwed in, then it is the turn of the decorative cap and valve.

Note! When choosing a new crane box, it is extremely important to choose the right size. It is definitely not worth making a choice by eye, as a result, you can get, for example, a crane-axle with a 3/8 inch diameter of the landing part, while a 1 2-inch axle box crane was needed.

The flywheel is installed only if it matches the number of splines on the fitting. It is clear that the valve of the axle box 18 splines and the flywheel with a square bore are simply incompatible.

As for the repair, in the case of worm gears, it usually consists in replacing the locking gasket. In this case, all that needs to be done is to dismantle the crane box and replace the old gasket with a purchased new one. If you wish, you can even cut it yourself out of a fairly dense and thick rubber.

The process of replacing the gasket is shown schematically.

It is much worse if the very bottom of the seat is damaged, as a result of this, even with a good laying of the crane-axle box, it will leak a little. In this case, it will be necessary to replace the entire crane, as a temporary measure, the installation of a thicker gasket can be considered.

As for ceramic crane boxes, then, most likely, if problems with tightness appear, only its complete replacement will help. But sometimes the cause of the leak lies in the abrasion of the ring, through which the plates are tightly pressed against each other.

Shown where the worn gasket was located

In this case, repair is possible with your own hands, for this it is enough just to cut out a new ring of approximately the same thickness (there is no need to observe the exact dimensions) and place it instead of the old one on the stock. On this, the possibilities of repairing ceramic crane axle boxes are exhausted.

Stem with new gasket

Flanged valve actuator

A mechanical, electrical and pneumatic actuator is used to regulate and control the flow of the flanged valve. The mechanical drive has handwheel equipment to manually open and close the flow. Such a drive is used when compactness is required.

Used when compressing air. This is the most unpretentious type of control of any transported substance, even the most aggressive one. The flanged ball valve is actively used on pipes with high pressure and high temperature conditions.

The electric drive is capable of fully automating the flow control from the inside of the pipe. The crane is selected according to the area of production. Barbed parts help open and close flow.

When purchasing a ball valve, it is important to know exactly the parameters of the coolant for which the valve is being selected. It will perform the function of constipating the water, not regulating it. If flow regulation is also necessary, you need to purchase a device with a servo drive. For a private house system, fittings with a coupling and a working pressure of no more than 10 Bar are sufficient. For a centralized heating system, use a ball valve with a pressure of more than 20 bar, and take into account the pressure reserve. Water hammer may be observed.

You should pay attention to the quality of the crane and not buy low-quality goods. The products of the Chinese manufacturer are not in great demand, since fragile, corrosive materials are used in the production, which significantly reduces the service life of the valve.

Three-way

Device and application

A three-way ball valve performs the task of redistributing the flow of transported media with the provision of switching the flow of the working medium between the pipeline system. Structurally, valves are divided into L-shaped and T-shaped type of connection to the pipeline system. Accordingly, they are called three-way L-shaped valve and three-way ball valve T-shaped. The valve body is made of steels of various grades (Steel 20, 09G2S, 12X18H10T), which allows their use with various types of working environment, both non-aggressive and aggressive, at temperatures from -40 to + 2000C.

Three-way ball valve design

The three-way manual valve has a design feature - providing the ability to simultaneously control the flow of the working medium in several pipeline branches. The flow division takes place in the plug and can be T-shaped or angular. A three-way ball valve with a T-shaped passage provides four working positions, when the plug is turned by 2700, three - when the plug is turned by 1800, two - when the plug is turned by 900. The three-way angle valve provides 3 operating modes, when the plug is turned by 1800 and two mode when turning to 3600. The three-way gost crane is equipped with a ball locking unit.Cranes of this type are used to separate the transported working medium or to mix it. They are often installed in a pipeline system to transport petroleum products, aqueous solutions or oils. A three-way stainless steel ball valve is approved for use in the food industry. The three-way water faucet is mainly used to regulate the temperature of the liquid in the heating system by mixing hot and cold water. You can buy a three-way valve for heating from an authorized dealer of the manufacturer. Cranes of this type are manufactured in two body versions - one-piece and collapsible body.

Production and control

All manual three-way valves manufactured by LZTA "Marshal" are manufactured on modern equipment using high-quality materials that have undergone full laboratory incoming control. In the production of cranes, each technological operation undergoes operational quality control by quality controllers, which practically excludes the delivery of defective products to the customer. You can buy a three-way ball valve by contacting our managers or placing an order on the website https: // lztamarshal ..