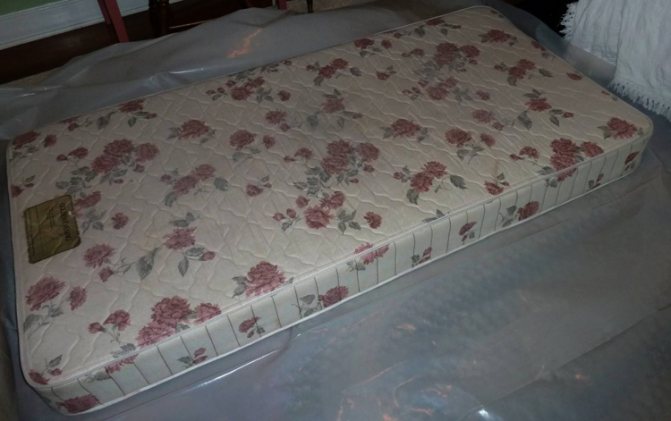

Polyurethane mattress, its properties

Polyurethane, the filler of these mattresses, is exclusively synthetic, but this does not mean that it is dangerous for the human body. This artificial material does not contain harmful substances and does not emit toxins, therefore it is ideal for making sleep items. Foamed structural polyurethane of various hardness is chosen for use as a filler; after hardening, air cavities are formed in its structure. It is thanks to this airy property that the material perfectly keeps its original shape, does not rot, attack by pests, it is not harmed by moisture and changes in air temperature.

The most effective are mattresses made of denser and more expensive polyurethane. It consists of hollow cells of different volume, which react differently to the pressure exerted on them. Small cells allow the mattress to be soft, while large cells retain elasticity, it is the combination of these properties that form the optimal quality of mattress rigidity.

When buying a mattress in a store, you should look at its label, the foam hardness parameters are the optimal indicator of 32 kg per 1 m3. The lower the cost of a polyurethane mattress, the less dense it is and the less comfortable it will be to sleep on it - you need to know this rule when buying. Considering that the price of orthopedic products for sleeping has never been low and the fact that polyurethane mattresses are not the most expensive of this category of products - to provide optimal body support during rest, you should not chase a low price, but choose the optimal combination of quality and price. ... However, it is not recommended to use polyurethane mattresses for babies under 1 year old, since they simply do not suit them in terms of rigidity. For these little ones, spring mattresses or coconut fiber mattresses are ideal.

The most important quality of a polyurethane mattress is its orthopedic properties. After a person's sleep, the mattress completely recovers its shape. A person rarely sweats on it due to the fact that the material "breathes", and vice versa, it will not freeze, again due to the air pockets. All these qualities will be possessed by a polyurethane mattress and will serve its owners for a long time, if it is properly operated and looked after.

Positive properties

Polyurethane foam mattresses have a number of positive features, thanks to which they have gained such distribution.

- If we are talking about mattresses that only partially consist of this material, then they are especially attractive due to the price. Their cost is not so high.

- Big choice. Due to its wide distribution, it will not be difficult to find a mattress of the size you need or make it to order.

- A large number of varieties of material. Thus, it is easy to choose a mattress that will have the properties that are most important to you (different density, ability to take shape, and so on).

- Due to their softness, these mattresses are easy to roll and transport.

Pros and cons of polyurethane mattresses

The advantages of polyurethane mattresses are obvious:

- The optimal combination of quality and price.

- Possesses orthopedic properties.

- Hygienic (does not rot, indifferent to pests).

- They do not cause allergic reactions.

- Completely safe filler.

- Long-term operation and preservation of qualities.

- Ease of care and cleaning (not afraid of water).

While sleeping on a polyurethane mattress, the filler adjusts to the contours of the human body, supporting it and relaxing the muscles. Despite this, the mattress is quite elastic, it correctly supports the spine, improves blood circulation, thereby eliminating congestion in the body. Polyurethane mattresses are recommended for overweight people, bedridden patients in the postoperative periods, or during periods of illness, as they prevent bedsores.

Undoubtedly, it is pleasant that the polyurethane mattress does not hold together, does not deform or wrinkle. If there is a need for transportation, it can be easily rolled up and transported to the desired place, after which it will again take its original shape.

With such significant advantages, polyurethane mattresses also have disadvantages. Namely:

- Quickly absorbs liquid, even vapor.

- Cheap polyurethane mattresses wear out and deform quickly.

- They require careful maintenance (ventilation, cleaning).

- Relatively short service life up to 10 years.

After the expiration of the service life (more than 10 years), polyurethane gradually collapses, it deforms and this immediately affects its orthopedic properties, the comfort of sleep and rest. The disadvantages of polyurethane mattresses are insignificant and they are fully compensated by its advantages, but to buy it or not, everyone must make a choice on their own.

Similar posts

- Steel h12mf for knives: characteristics, pros and cons

- Eucalyptus blanket: the pros and cons of choosing

- Steel 110x18 for knives: pros, cons and features

- Pros and cons of vacuum packaging

- Satellite TV: advantages and disadvantages

- Giro scooter: pros, cons and what you need to know

- Electric stove: advantages and disadvantages

- Solid fuel boilers - the pros and cons of choosing

How to make a foam mattress with your own hands

Experts recommend using exclusively orthopedic mattresses in everyday life, in addition to comfortable rest, this is also the prevention of diseases of the musculoskeletal system. Unfortunately, the price of factory-made mattresses is quite high and not everyone can afford it. Meanwhile, making a foam mattress with your own hands is not such a difficult task.

Factory Orthopedic Mattress Structure

When sewing a mattress, you can go in two ways:

- to simplify the task as much as possible and use a thick layer of highly elastic material as a filler. After cutting, it remains only to process the edges of the material, sheathe it with a cloth and place it in a cover. Foam mattress 10 cm created in this way will be quite convenient and comfortable;

- you can complicate the task and try to combine a layer of foam rubber and a spring base in the mattress. In this case, the output will be an analogue of factory orthopedic mattresses.

One of the best options is a spring base with independent springs. In this case, the person is guaranteed to be able to take a comfortable position. In the proposed design, the spring base will be placed in a box glued from pieces of foam rubber. For the side edges, you can use foam rubber with a thickness of about 30 mm, but for the upper and lower parts - at least 50 mm. You will also need felt, fabric for upholstering the mattress and sewing the cover, braid.

The main part of the mattress

The base of the mattress is a structure consisting of two layers of foam rubber, two layers of felt and a spring base located between them. After cutting out the foam rubber and felt, first a layer of foam rubber is laid on any horizontal surface, then there is felt, a spring base, again a layer of felt and this "cake" is covered with a layer of foam rubber. Felt is used here so that the springs under load do not damage the surface of the polyurethane.

The structure of the future mattress

On the sides, the free space must be closed with inserts made of the same polyurethane, as a result, a closed box should be obtained. For gluing the elements of the box, it is better to use special glue. You can do with ordinary PVA and or liquid nails, but, firstly, the drying time of the glue layer will increase, and secondly, a hard crust forms at the bonding site, which simply cracks during deformation.

Bonded mattress base

It is not necessary to additionally fix the felt and the spring base. They will not move during operation.

For additional strength, you can put a wide board on the foam rubber when gluing, and place a load on it.

Cover sewing instructions

For the cover you will need batting and fabric; when cutting, you just need to take into account the size of the foam "box". And, of course, leave a margin for processing the edges.

In the first step, the batting is sewn onto the fabric. On a flat surface, the batting and fabric are aligned with each other and manually stitched along the long side of the rectangle several times. After that, you can move on to processing the edges.

First, the excess batting is cut off, which protrudes beyond the limits of the fabric, after that, along the perimeter, the part of the future cover is stitched with an overcast seam. After that, you can sew the narrow parts of the cover into one piece.

Sew on large parts using a decorative tape that hides the seam. First, the braid is sewn along the perimeter of a large part, then the edge of the narrow part is applied to the same braid, the braid is folded and stitched. The zipper is sewn on the same principle so that the mattress can be reached when washing the cover.

Finished mattress

What is the danger of having foam rubber in a mattress

Environmental friendliness, durability, good orthopedic properties - that's what we need from a mattress. PU foam filler fully meets these requirements if it is made in compliance with the standards and meets the certification. The problem is that due to the fact that opening a small business for the production of foam rubber and products from it does not require large expenses, in recent years many small workshops have arisen. Some of them produce cheap low-quality foam rubber, from which inexpensive mattresses are assembled, which do not stand up to criticism in many respects. Knowing the basics of the technology for the production of various foamed polyurethanes, it is not difficult to identify possible problems. Here they are:

- The presence of foreign odors, the release of phenols and other harmful compounds.

- Sagging of foam rubber from load.

- Mechanical fragility of products.

The smell arises from use in the manufacture of low-grade components. European chemicals are more expensive than Chinese ones, and the desire to reduce production costs by using cheaper additives leads to the presence of unwanted impurities in the foam rubber. The inclusion of low-density polyurethane foam fillers in the composition of the mattress will necessarily lead to its early wear. The thin walls of the cells are deformed, and the foam rubber will not be able to restore its previous shape. Low elasticity, tensile strength become the reasons for mechanical damage and destruction of foam rubber. The process is accelerated in the absence of sufficient ventilation.

PPU is a fire hazardous material. Is it so?

Let's start with what we mean by combustible and non-combustible material. To do this, let us refer to GOST 30244-94 “Building materials. Flammability Test Methods ". In this document, building materials are divided into combustible (G) and non-combustible (NG). Non-combustible materials include metal (and even then not all alloys), stone, glass, expanded clay, basalt, etc. All wood-based or polymer-based materials are flammable and are divided into flammability groups:

- G1 - slightly flammable (for PPU, this means that it is not capable of ignition, is resistant to the effects of open fire and thermal radiation, but under the influence of flame it loses mass, smolders)

- G2 - moderately flammable (resistant to the effects of open fire and heat radiation, does not support combustion, in the absence of a flame extinguishes on its own)

- G3 - normally combustible (in the absence of a flame, it extinguishes on its own, cannot be a source of ignition)

- G4 - highly flammable (supports combustion and can be a source of ignition)

In addition, other factors are taken into account during the tests - flammability, smoke emission, weight loss, flame propagation speed, decay time, release of toxic substances and a number of other factors. After such comprehensive studies, a conclusion and a fire safety certificate are issued, which regulates the scope of application of a particular material in construction.

Polyurethane foam is good because, depending on its composition (type and amount of fire retardant used), it can belong to all four groups of flammability. And the choice depends directly on the scope and wishes of the Customer. So, for example, polyurethane foam with a flammability group G1 and G2 can be used as insulation in residential and industrial facilities with open access to the insulation (roofs, facades, plinths, etc.). While the use of polyurethane foam with a flammability group G3 and G4 is justified for refrigeration units, when the PUF is concluded between other non-combustible building structures, etc.

In the section "certificates" on our website you can see examples of fire safety certificates for PPU: https://himtrust.ru/products/certs/napylitelnye/

Is the layer of polyurethane foam insulation harmful for residential premises?

This question worries the overwhelming majority of amateur builders, since very often special additives are the secret of production, and it is not possible to find out how harmful polyurethane foam is. Any mixture produced undergoes rigorous tests to confirm its non-toxicity under various operating conditions. So the actual harm to PU foam is zero if you use a mixture from a trusted manufacturer that has all the necessary certificates of quality and safety.

PPU is an expensive material. Is it so?

Indeed, the cost of 1 m3 of polyurethane foam is more expensive than most other traditional insulation materials. But it’s not so obvious. After all, for some reason we also do not buy the cheapest things and do not drive the cheapest cars.

- First argument, installation costs. For the installation of PPU, no fasteners are needed, the cost of the insulation, as a rule, already includes work on "turnkey" spraying. Insulation sheet requires installation work and the purchase of a substantial amount of fastening material, as well as material for sealing joints. All this must be calculated separately.

- The second reason is that membranes are not needed. For the correct installation of mineral wool insulation in order to extend their service life and reduce the risk of getting wet, moisture and windproof membranes are required. These membranes also require fasteners and are an additional item in the contract cost estimate. In addition, membranes are very difficult to assemble tightly and to work effectively.

- The third reason is that the equivalent layer of thermal insulation can be very different. So, for example, 50 mm of polyurethane foam is equivalent to 100 mm of mineral wool or 80 mm of ball polystyrene. That is, to achieve a similar thermal insulation effect, you need 2 times less polyurethane foam than mineral wool.

- Fourth argument, logistics. When spraying with PU foam, the starting material is supplied in liquid form and consists of 2 barrels and 1 installation with tools. All this easily fits into a minibus or gazelle. To deliver a sheet of insulation, you will need a transport with a volume of 20-30 times more, while you will, in fact, transport air.Of course, this will be reflected in the budget.

- Fifth argument, service life. Not only that, the service life of the PU foam is comparable to the service life of the supporting structures, which is incomparably longer than the main competitors. It is also necessary to take into account changes in efficiency over time, which is associated with the loss of the original properties of the insulation. So for mineral wool insulation, the loss of thermal insulation properties ranges from 3 to 8% per year, depending on the operating conditions and the type of material. This means that in 5 years, heat loss and heating costs will increase by 15-40%. At the same time, the study of buildings of the 60-80s in Europe and Japan with the use of polyurethane foam allows us to say that for 25-30 years, changes in the initial physical-mechanical and thermal properties do not exceed 5-7%. At the same time, science has stepped far forward and the PPU formulations are now more perfect.

Orthopedic foam, foam rubber, polyurethane foam (PPU) - let's understand the concepts

Strictly speaking, any of the materials resembling an ordinary washing sponge in appearance and properties should be called foam rubber - in Russia the name of the chemical concern POROLON has long and firmly taken root as a general name for foam polymers. But consumers have the impression that this is a cheap, simple and short-lived product.

Watch the video at the end of the article, it clearly shows the difference between different samples.

Therefore, today sellers of mattresses proudly call the layers of fillers, at best, polyurethane foam, polyurethane foam, orthopedic foam. Some went further and registered their own trademarks - OrtoFoam, Ergofoam, etc. The fact is that foam rubber has such characteristics suitable for making mattresses that there is simply nothing to replace it with. It's easier to hide his presence behind a beautiful foreign word.

Layers of orthopedic foam in the mattress

All a serious manufacturer of sleep products can do is to keep up with the development of the chemical industry and use advanced technologies to create materials with improved properties. So you can achieve an increase in durability, set different rigidity, make the foam colored, non-combustible, superelastic. All the leaders of the Russian mattress market produce foam rubber at their own factories, and can give it the necessary qualities.

findings

Of course, we have not listed all negative opinions and not all the arguments for. But, I hope, we were able to make it clear that many fears are associated with ignorance or unsubstantiated rumors.

However, there is no smoke without fire. Probably, someone has come across unscrupulous or inexperienced contractors, perhaps even with a defect in the raw materials from which the PUF was obtained, or with non-compliance with the work schedule. If your Mercedes breaks down, this does not mean that all Mercedes cars are bad. Perhaps it was just necessary to change the oil on time.

In this regard, we recommend that you carefully approach the choice of a supplier of raw materials and a contractor. Choose only trusted, experienced teams with quality PU foam spraying equipment. Get feedback from their customers. Make sure the contractor has applied the raw materials with the stated requirements, ask for certificates. It is also not difficult to determine the density of the obtained polyurethane foam and its flammability right at the work site using a kitchen scale and a lighter. If in doubt, conduct a professional examination. It is better to do all this before the start of work or at the very beginning - it will save a lot of time and nerves.

The good news is that PPU continues to gain popularity and consumer confidence, at the same time occupying an increasing market share. More and more experts agree that PPU is the future in the field of energy-saving construction technologies.

For more information on this topic, see:

- PPU spraying - what is it?

- Thermal insulation (thermal insulation, thermal insulation)

- Density of polyurethane foam

Discussion

Please enable JavaScript to view the comments powered by Disqus.

What is a polyurethane foam mattress?

Modern production and a variety of technologies used in it make it possible to satisfy the tastes of any category of customers. Among the mattresses of a low price category, the best solution for the day is polyurethane foam mattresses

... This is an inexpensive analogue of various orthopedic mattresses. The quality is high enough. They are perfect for replacing mattresses on old beds, for garden furniture, for a guest room, etc.

Manufacturing technology

PU foam mattresses are made of a material that has come to us from ancient times - foam rubber. It is still actively used in the manufacture of furniture. The production technology may differ at different enterprises, but the main stages are unchanged:

- Two main components are mixed - polyisocyanate and polyol in the required proportions.

- Add water. The resulting chemical reaction produces carbon dioxide. It is he who foams all substances and gives a porous component.

- Process catalysts and foam stabilizers are used. The entire phase lasts no more than 20 minutes.

- The mattress block is left for a couple of days for final polymerization.

This technology allows you to make the mattress sufficiently elastic, durable, and most importantly practical. Does not lose material and its orthopedic properties.

Mattress composition

Chemical reactions are the basis for the production of foam, gas-filled plastics. All the main characteristics of the product depend on the proportions of the substances to be joined, namely, heat resistance, strength, durability, density.

There are different types of mattresses:

- Increased rigidity.

- Highly elastic.

- Standard.

- Soft.

- Viscoelastic.

- Super soft.

All highly and viscoelastic materials are applicable in the manufacture of mattresses.

But foam rubber alone, even produced using modern technologies, is not a mattress yet. Additionally, it is laid:

- linen felt;

- jacquard fabric or any other material suitable for creating a durable, wear-resistant surface.

Modern materials provide the best sleeping conditions

In the online store "MatrasHit" you have the opportunity to purchase quality orthopedic mattresses with delivery. This way, you can keep the time allotted for buying bedding to a minimum.

Today our company offers the most affordable prices and comfortable conditions in Moscow. We have made sure that every person interested in purchasing goods for sleeping can choose the best existing ones to equip their bedroom. With us you can always buy everything you need quickly and inexpensively!

How and what to feed kittens without a cat

07.09.2019

Car air conditioner cleaner - which one is better and which one to choose?

06.09.2019

A ginger cat in the house is a piece of the sun!

04.09.2019

Polyurethane foam and harm to health: how to avoid negative consequences?

Three main mistakes are made in working with PPU:

- Failure to comply with operating requirements

- Ignoring protective equipment in direct contact with liquid PU foam mixtures

- Using low-quality sprayers

Pro tip To minimize inhalation of vapors from spraying or deposition on interior surfaces, it is recommended that the area to be treated be well ventilated.

Our article on polyurethane foam spraying technology will help you avoid the first two mistakes. Regarding the sprayer, it is preferable to use high-pressure washers, which ensure uniform mixing of both phases of the mixture with 100% completion of the chemical reaction, so that the question of whether the components of the polyurethane foam are harmful is eliminated. In addition, such spraying provides guaranteed coating quality.

Selection features

The choice was made in favor of buying a polyurethane foam mattress, but in the market a person is lost from a variety of models. Which is better: spring or springless, thick or thin, of different rigidity.

It's easy to determine the thickness. The mattress 10 cm thick has all the useful properties, provides comfortable support for the spine, and is suitable for a person with a large weight.

Before choosing the level of stiffness, it is advisable, especially for people with spinal disease, to consult an orthopedic surgeon.

- It is better not to take soft ones, although they look very attractive, they do not contribute to a comfortable rest.

- Mediums are good for people with diseases of the upper spine and who simply love comfort. Sleeping on such a mattress is quite soft, you can have a great rest, sleep well.

- Hard ones, at least a little and scare away with their name, but "on close acquaintance" with them, it turns out that on such a bed you can have a great sleep, in the morning you can be vigorous, full of energy. Especially suitable for people with lower spine diseases.

It's easier to decide on the choice of size. To do this, it is enough to measure the bed:

- 120x200 cm is the most popular option on the island.

- 140x200 cm - one and a half bed.

- 160x200 cm - double.

- If the bed is of a non-standard size, you can easily solve the problem by ordering a PPU mattress from the manufacturer.

When purchasing a polyurethane foam mattress, one should not only be guided by one's tastes and state of health, but special attention should be paid to quality. It is better to overpay a little for a product from a well-known manufacturer than to buy an attractive cheap item that will quickly lose its properties.

If you are interested in a polyurethane foam mattress that meets modern high standards, in the online store "MatrasHit" you can always purchase it on the most favorable terms. Highly resilient polyurethane foam is used in many sleep products today, and each has specific responsibilities.

Its main characteristics are:

- Viscosity;

Elasticity;

The ability to respond to temperature differences between the air and the human body;

High wear resistance.

Polyurethane foam mattresses ensure correct load distribution and a high level of relaxation comfort. Typically, the foam is supplemented to stiffen with fillers such as felt or coconut, while latex or strutto may be used by manufacturers to provide softness. We offer you to use all the advantages of polyurethane foam mattresses while creating a comfortable environment for rest and sleep, and we guarantee that you will be satisfied.