Types of heat exchangers

During the selection of the described device, you can find products of various types. Coil-shaped heat exchangers are most commonly used. Corrugated devices are also popular. In addition, many people use products in which air acts as a coolant.

By the type of heat carrier, almost all devices can be divided into those that use air and products that heat water. Devices of the first type have a simpler structure, but are less efficient.

If you wish, you can create a heat exchanger for installation on a chimney with your own hands. This will require tools such as a grinder and a welding machine.

Corrugation

To use this low-budget option, you need to take three corrugated aluminum pipes and wrap them around the chimney on the second floor or in the attic. The air in the corrugation will be heated from the walls of the chimney and can be redirected to any room. And in order for the heat transfer to be more efficient, you can wrap the corrugated pipes with food foil.

You can also install a special heat exchanger on the chimney in the attic, which works on the principle of a bell-type furnace - the heated air rises up, and when it cools down, it gradually descends. This design has a significant plus - as a rule, the metal chimney pipe heats up to such an extent that it is impossible to even touch it, and in this case the heat exchanger significantly reduces the risk of fire or burns.

Some craftsmen additionally cover the structure with a net with stones to collect and retain heat and decorate the base of the heat exchanger. The attic room becomes more comfortable, warmer and can even be used as a dwelling in the cold season.

As you can see, making an effective chimney heat exchanger with your own hands is not so difficult. It is enough to be able to handle the instrument, have the necessary materials and desire. By making a heat exchanger, you can not only make the room warmer, but also save money by reducing fuel consumption.

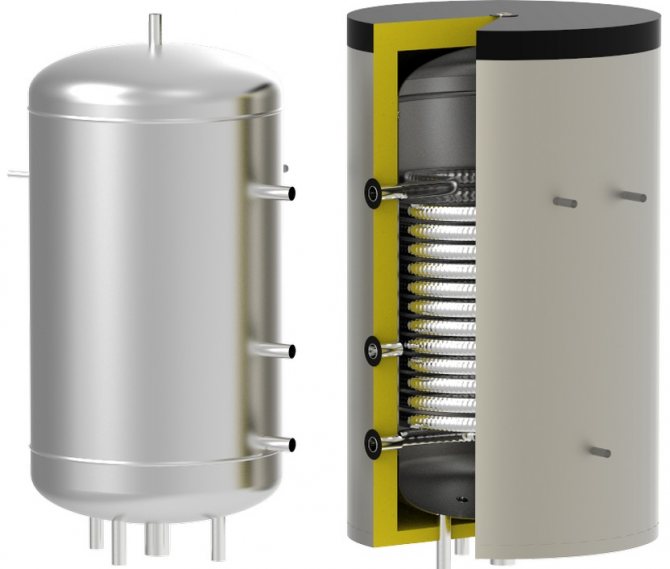

Liquid devices

During the manufacture of liquid heat exchangers, in order to make them safer, the core is placed in a metal case. At the same time, a heater is placed in it. Basalt wool is often used to create the described devices.

Such products are fixed on the chimney, which contributes to the heating of the coolant. If a coil is used, its ends are connected to the heating system. If the product is created by hand, a copper coil should be made. This is due to the fact that this material has a high thermal conductivity.

Some home owners use metal products, but to increase efficiency, you have to significantly increase the size of the structure.

The circulation of the coolant is carried out as follows:

- first, the liquid heats up, resulting in an increase in its volume;

- after that, she climbs the coil;

- after that, the liquid is directed to the radiator;

- the cooled coolant is displaced and directed to the heating element.

For the system to work effectively, it is necessary to calculate in advance such parameters as the length of the heating element and the diameter of the pipes used to create the system. If these parameters are not taken into account, the system will not work efficiently. In some cases, due to mistakes made during the creation of the system, a water hammer occurs.

When installing a heat exchanger on a chimney pipe, you should remember that the construction must be safe. Its heated parts must not come into contact with materials that could catch fire.

What materials can you use?

A high-quality chimney heat exchanger is made of food grade austenitic stainless steel. It works great under constant exposure to high temperatures. Nickel, which is contained in the alloy, forms a special film on the surface of the pipeline, which is resistant to the effects of an aggressive environment.

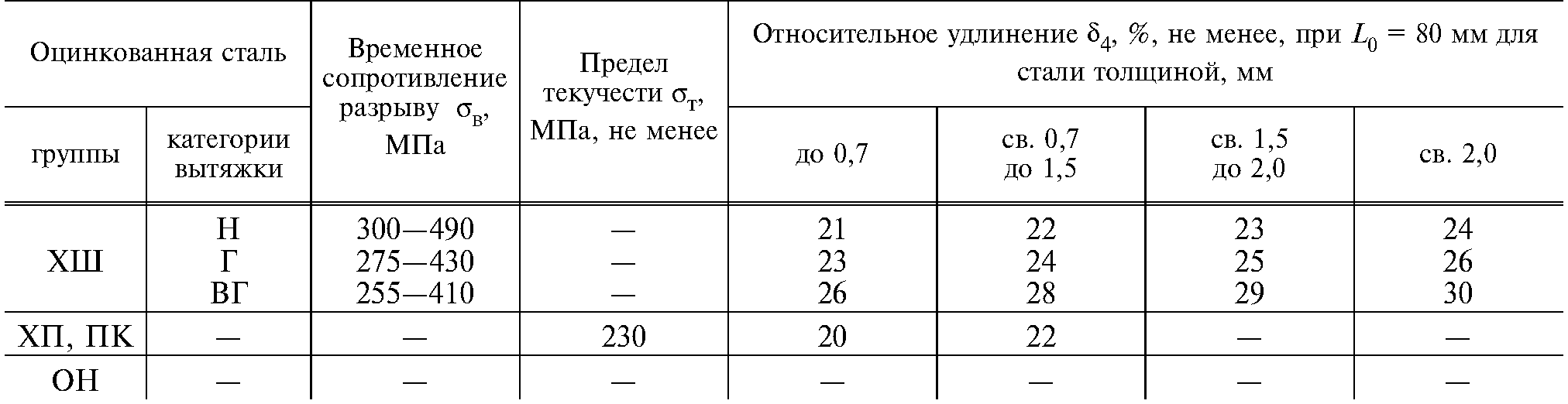

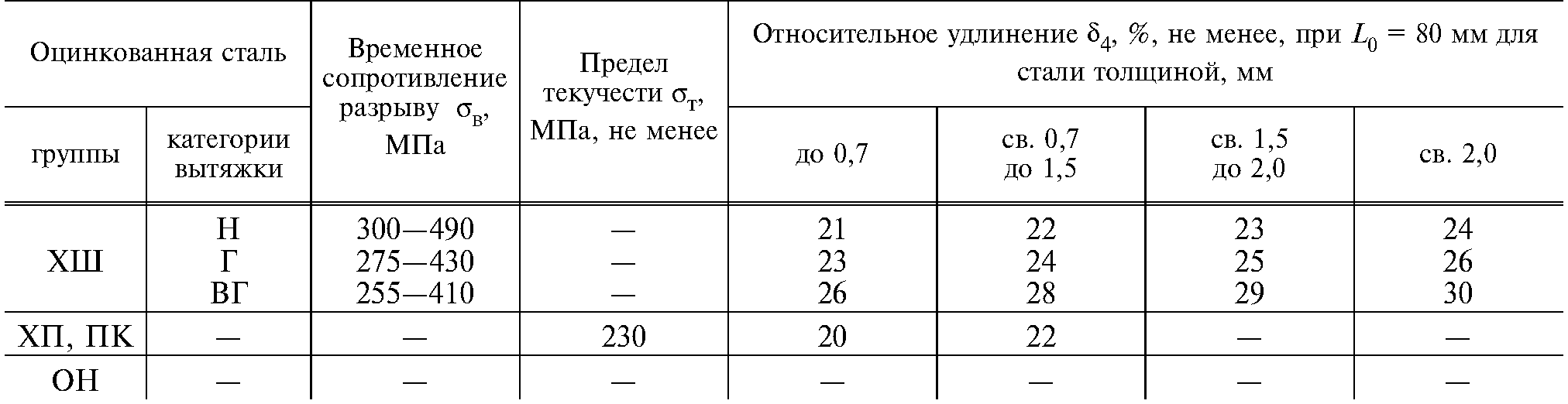

Tensile strength and elongation values for galvanized steel

Galvanized steel can be used as material for the heat exchanger tube. With strong heating above 200 ° C, zinc, which is contained in the metal, begins to evaporate. At a temperature of 500 ° C, its concentration in the air becomes dangerous to human health. But if your heating system will operate in a lower temperature range, this material is completely safe.

Disadvantages of liquid heat exchangers

The disadvantages of the described devices include:

- The complexity of manufacturing and making calculations. Before carrying out work on the creation of a device, it is important to take into account the area of the house and other parameters that can affect the efficiency of the system.

- The need for constant monitoring of such system parameters as coolant pressure and temperature.

- Increased liquid consumption associated with its evaporation from the expansion tank. Moreover, in winter, if the house is empty, the liquid must be completely drained.

But it should be noted that almost any person with knowledge of physics at the school level can make a liquid heat exchanger. But before manufacturing the device, it is important to draw up a drawing of the entire structure, which will display the dimensions of all elements.

When using a liquid device, remember that if the house is not being used during the winter, the liquid must be completely drained. If this is not done, it will turn into ice, which can lead to the destruction of pipes and radiators. If the heat exchanger is installed in a house that is used all year round, you can forget about this drawback.

Features of air heat exchangers

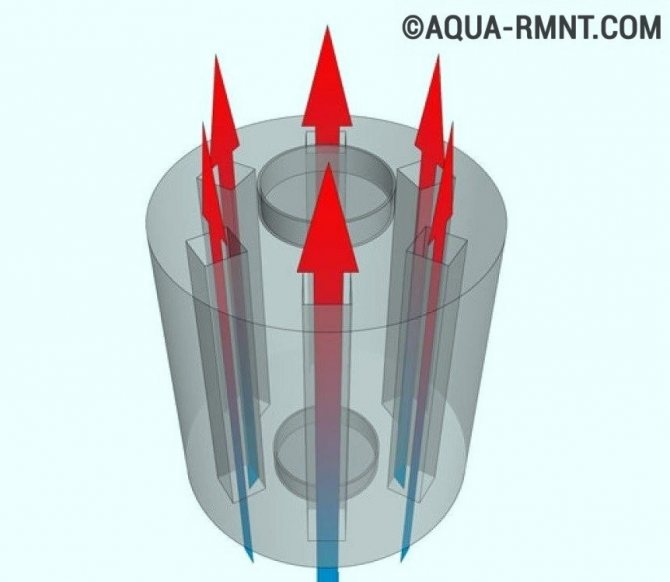

Devices of the described type consist of a metal case, inside which there are several nozzles. During the operation of the system, cold air heats up and enters the room.

If desired, you can make and install an air heat exchanger on the chimney with your own hands. To do this, you need to have several metal pipes of various diameters, a grinder and a welding machine.

Before work, you must purchase the following materials:

- a piece of pipe having a diameter of 50 mm;

- a pipe 2.4 m long and 3.175 cm in diameter;

- metal sheet 350x350x1 mm;

- 2 liter metal container.

The manufacture of a heat exchanger begins with cutting out metal circles. After that, in the center of the created circles, it is necessary to cut holes for a 5 cm pipe. Around the holes, it is necessary to mark the points at which 8 openings will be cut for a pipe with a diameter of 3.175 cm. This pipe must be cut into 8 sections. The result is 8 tubes 30 cm long.

The next step is to attach a pipe with a diameter of 50 mm to the central hole. Sections 30 cm long are welded to the side holes. As a result of the work carried out, a heat exchanger core will be created. After that, you can start creating the device case.

After the described actions, you need to cut off the bottom of the previously prepared metal tank with a grinder. On the sides it is necessary to cut a hole that is equal to the diameter of the chimney.

Then you need to connect the pipes.The created heat exchanger body must be put on the core and then welded to it. After carrying out such work, the structures should be covered with heat-resistant paint. When it is dry, you can install a heat exchanger on the chimney.

How to make a homemade chimney convector to heat the air? (+ detailed video)

To create the simplest convector that will improve air heating in the same room where the boiler is located, you will need:

- Welding machine.

- At least 8-10 thin steel tubes with a diameter of about 32 mm and a length of about 50-60 cm. Ideally, take food grade stainless steel. Worse, but also galvanized steel will do. In shape - usually take round tubes, but square or rectangular sections are also suitable.

Installation is carried out as follows: these pipes must be welded in a circle around the chimney, as close as possible to the firebox.

Rules and methods of chimney liner: comparison and step-by-step work

What is a chimney brush and how to make it yourself?

Similar posts

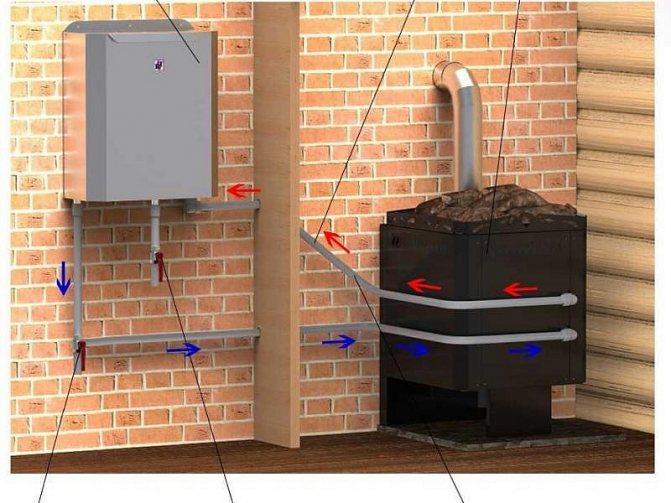

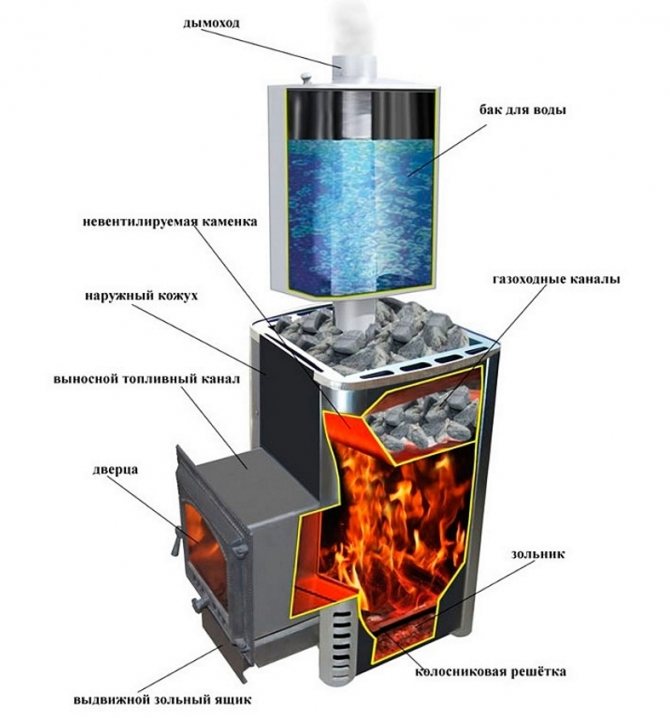

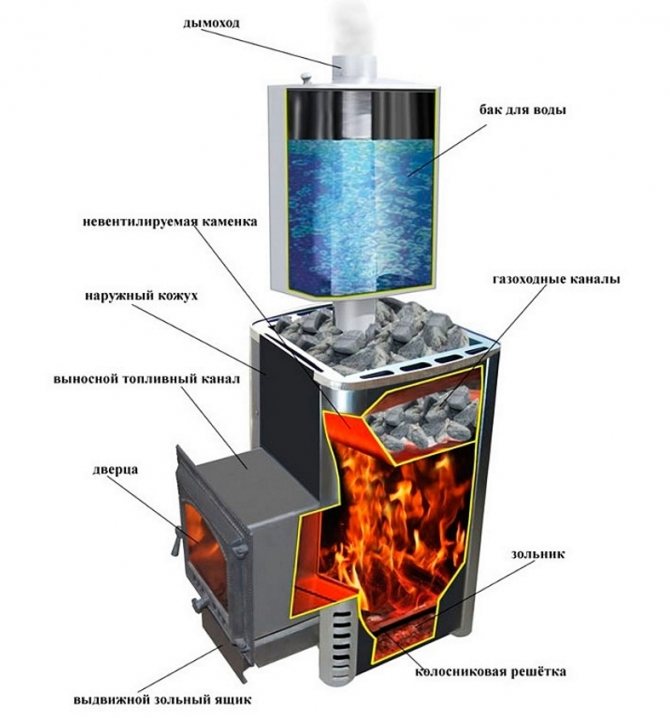

Features of devices used in the bath

By design, the described devices can be divided into built-in ones attached to the chimney. Products of the second type are often called samovar-type devices.

Built-in structures consist of a small cistern with a capacity of up to 5 liters. It is installed between the firebox and the heat generator casing.

A container with a volume of up to 100 liters is connected to the heat exchanger using pipes. After heating the heating system, hot water rises through the pipe. The cooled coolant flows back to the heat exchanger. Due to this, the required temperature of the coolant is maintained in the external tank.

Samovar-type devices are a sealed container encircling the chimney. In the process of heating the liquid, in this case, heat is used from the combustion products moving through the pipe.

Sauna stoves with heat exchanger

The advantages of the described structures include:

- Simultaneous solution of two tasks - heating the steam room and dressing room, as well as heating the water.

- Possibility of installing the tank in a room that is located closer to the steam room.

- Long term of use. This is due to the use of high quality materials.

- No need for maintenance of the structure.

- Small oven dimensions. This saves space in the steam room.

- The power of the furnace with a heat exchanger is sufficient for quick heating of the room.

When carrying out work on the installation of the heat exchanger, you should remember some rules. For example, it is necessary to connect pipes in the system in such a way that they are not rigidly fixed near the walls. This is due to the change in their linear parameters during heating of the coolant.

It should also be remembered that high temperature resistant materials must be used to seal the threads. The choice of the volume of the container installed in the bath should be carried out taking into account the fact that the heating is carried out within two hours.