25.08.2015

When planning the installation of a stove or fireplace in a house and connecting a chimney made of galvanized steel, you need to familiarize yourself with all possible options, as well as consider the strengths and weaknesses of each of them. For many centuries, brick or stone structures have been used for heating. We will not argue, they are still found now, but the creation of new materials allows the use of lightweight and reliable structures that meet standards and norms.

The most popular are high-quality steel products made of stainless steel or galvanized metal. But the topic of today's article is precisely a galvanized chimney pipe, its design characteristics, advantages and varieties.

Galvanized chimney pipe

- 1 About the main enemy - rust

- 2 Galvanized pipes 2.1 Video - Chimney sections

- 4.1 Option No. 1. Single-circuit products

- 6.1 Video - Installing a galvanized chimney

About the main enemy - rust

Corrosion is dangerous for all metal products. In particular, this applies to iron, because it is more susceptible to the negative effects of moisture and atmospheric phenomena. For this reason, designers are constantly developing new ways to protect against rust.

Note! Different steel alloys solve the problem only partially, but a zinc layer applied to the surface of metal products is an excellent barrier to rust.

They do it like this: steel is immersed in a molten mass, after which, by the action of special substances, iron combines with zinc and, as a result, a new protective ball is formed. The thickness of this layer is different, but not more than 60 microns. This technology both protects metal products and increases their service life.

Chimney and its features

The chimney is the most important channel that removes combustion products in a gaseous state outside. Very dangerous is its clogging or initial poor quality performance.

The smoke, passing through the pipes, should go out into the street, and nothing should interfere with this process.

Pipes and structural parts for chimney assembly

And since pipes are the main component of this element, their choice is a responsible matter.

Of all the variety of materials and means for arranging a chimney, I would like to highlight a galvanized pipe. The fact is that this material is most optimal for the function of removing smoke.

Galvanized pipes

As many years of practice have shown, galvanized chimneys are many times superior to their stone and brick "competitors". As you know, when any fuel is burned, gases appear, which, when passing through the chimney channel, are cooled and condensed. And moisture already has a detrimental effect on both brick and metal, but the situation is aggravated by the presence of soot in it.

It contains acids that form oxide, which, in turn, leads to the destruction of the walls of the chimney. From the inside, drips often appear, as well as roughness; soot and fumes "catch" on it. This causes a deterioration in draft, due to which gas enters the house through the combustion chamber and poses a serious threat to the health of people living in it.

The situation can be corrected by regular cleaning, but not for long, since the condensate cannot be completely eliminated. For this reason, experts use such products as a chimney in which the appearance of condensation is minimal. These include a galvanized chimney pipe.

Coaxial chimney, what is it?

Previously, we described the main advantages, technical characteristics and features of the installation of a coaxial chimney, we recommend that you read this article in more detail Learn more here

Video - Chimney sections

Chimney maintenance

Besides the correct installation of pipes, they must be properly maintained. It is very important to know how to clean the chimney from the deposits formed there. There are three main ways: ⦁ Mechanical... In this case, a special tool is used - a brush or a metal brush. For severe blockages, a heavy metal weight attached to a chain can be used. The chimney brush has been known for a long time and is still considered one of the most effective devices. It allows you to precisely regulate the force and control the movement along the chimney. If thick deposits have formed on the chimney, then before cleaning the chimney, a weight should be lowered there and, swinging it from side to side, knock on the walls of the chimney, which will cause the layers of soot to collapse, which should then be removed through the hole in the base of the chimney.

Chimney brush

Advice! Before cleaning, close all the dampers, otherwise a cloud of soot can enter the boiler room or other room where the boiler is installed.

⦁ Chemical. For this, special chemicals are used, produced in solid or liquid form. They must be added to the fuel used and burned in the firebox. Liquid formulations are used to impregnate the walls inside the chimney, which in itself prevents soot deposits. ⦁ People's. It can only be used for cleaning chimneys made of refractory bricks. To get rid of soot, a high temperature flame is ignited and maintained in the firebox, which leads to complete burnout of the soot. In this case, the fuel can be potato peelings, aspen firewood or a special log - "chimney sweep". This is the easiest way to remove soot with your own hands.

Advantages of using galvanized pipes

The main advantage lies in the presence of the protective layer described above. We found out that when exposed to condensate, any metal begins to rust, and therefore the tightness of the chimney channel and the efficiency of its functioning are violated. But if the product is well protected from moisture, then it will serve much longer. Because of this, galvanized chimneys have become increasingly popular lately.

Note! High-quality sheet steel is used in the manufacture. Before shaping, it is immersed in a zinc solution, where a chemical reaction occurs under the influence of reagents. The protective layer created in this way is quite sufficient for a significant extension of the service life.

And chimneys made from this material have the following advantages.

- High heating rate and, as a result, almost instant traction. This allows heating appliances to work as efficiently as possible.

- Such chimneys include several modules, which, if necessary, are easy enough to assemble.

- Installation of products can be done on any heating devices. Simply put, their versatility can be considered another advantage.

- All galvanized pipes are fire resistant, which means they are fireproof. And this is especially true for wooden houses.

- The installation requires a minimum free space.

- A wide variety of variations.

- High resistance to condensation (especially against the background of brick analogs). Only chimneys made of "stainless steel" are more effective in this regard.

- Finally, thanks to the smooth surface, soot does not collect on the walls, making cleaning faster and easier.

Note! In the light of all of the above, we come to the conclusion that galvanized products are much better than brick products, and are inferior in quality only to stainless steel pipes. Consequently, their main advantage is considered savings (both on the purchase and on installation work).

But remember that often saving on the quality of the purchased material is fraught with significant costs for maintenance and repair work.

Varieties

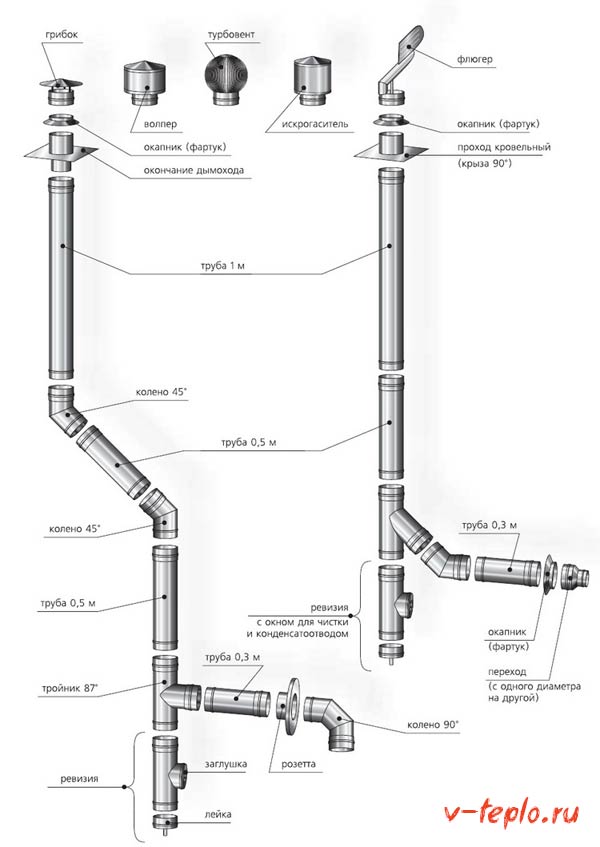

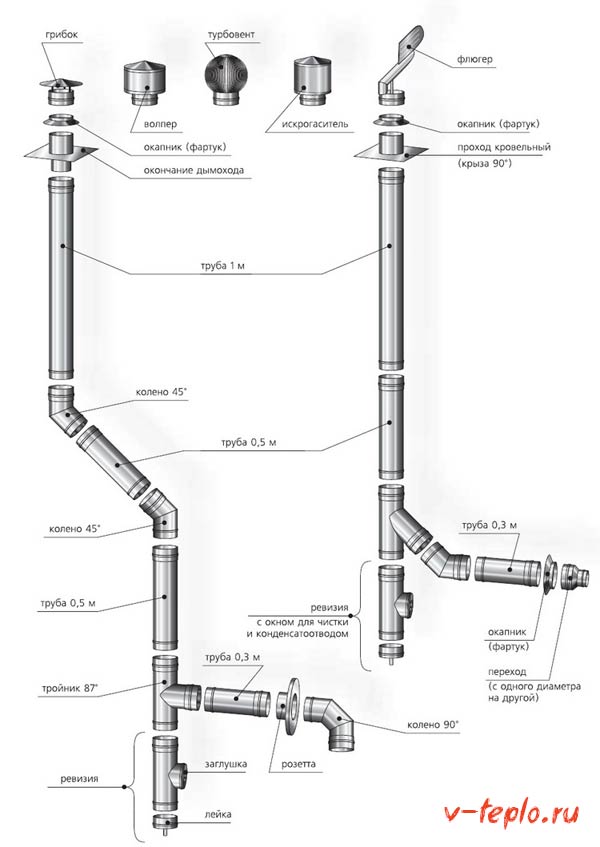

Galvanized pipes of two types are produced: one - and two-circuit. Both varieties are available ready-to-assemble, with all the necessary connecting and functional elements.

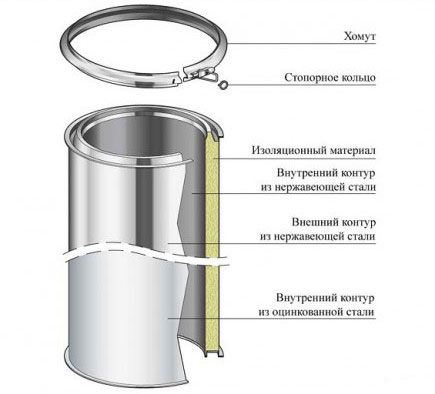

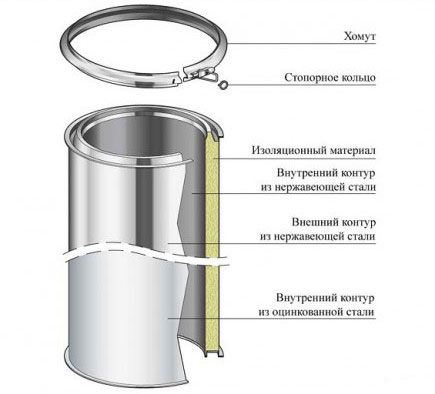

Double-circuit pipe

The easiest to install are double-circuit sandwich pipes, which you just need to buy and assemble, like a designer.

Each section consists of two pipes and a layer of thermal insulation between them. Shaped elements have a similar structure and do not require modification.

We recommend that you familiarize yourself with: What is fire protection for air ducts for and how to choose it correctly

This design allows you to erect a chimney without much effort: the inner pipe plays the role of a smoke channel, and the outer one serves as a protective casing, and to equip a full-fledged working system, it is enough to simply assemble the sections in the right order.

The chimney can be assembled inside the house or outside. In this case, the inner part of the sandwich chimney will be absolutely fireproof, since its shell does not get very hot.

The sandwich chimney located outside is reliably protected from natural whims, since the insulating layer prevents heat exchange between the smoke channel and the external environment, and the external galvanized pipe protects against mechanical and chemical influences.

In addition, the assembled double-circuit pipe is a completely aesthetic structure that can be successfully used in any design projects.

Single-circuit pipe

For the construction of the internal part of the chimney, for arranging a smoke channel in a combined structure or for a barbecue, single-circuit pipes are used. A single-wall pipe and corresponding fittings are cheaper than a double-circuit pipe.

However, when choosing, you should evaluate the features of the structures, which in different situations can be both pluses and minuses:

- when the heater is in operation, the outer surface heats up strongly, which can be a fire hazard, but on the other hand, such a pipe will quite cope with the role of an additional heat source in the room;

- a single-circuit chimney on the street cannot be installed without insulation and a protective shaft or casing, however, for location inside an existing brick or asbestos-cement chimney, such a pipe is ideal;

- the use of a single-wall pipe in the construction of a combined chimney or chimney for outbuildings will significantly save energy and money.

Classification of galvanized chimneys

The products described in this article are produced in two types - one- and two-circuit (with a layer of insulation). Let's get acquainted with each of them in more detail.

How to make a chimney cap on your own

Earlier we told you about how to properly install the hood on the chimney, we advise you to read this article additionally.

Option number 1. Single-circuit products

They consist of such basic components as pipes and other fittings (these include tees, adapters, various kinds of revisions, and so on). The most popular uses are as follows:

- use as an in-house chimney;

- use inside a brick chimney.

Such designs are not without drawbacks, the main of which are large volumes of condensate, especially when the heating system is connected to modern equipment with a low temperature of the exhaust gas and excellent efficiency. In order to eliminate this problem, the chimney is insulated or, as an option, the rate of condensation formation is reduced and heat loss is minimized.

As we just said, such a galvanized chimney pipe is often used for efficient and prompt repair of brick smoke channels. The purpose of this is extremely simple: instead of repairing half-destroyed masonry, a modular structure of the required size is mounted in the channel. A special mineral heat insulator is installed between the new element and the brickwork, which significantly increases the efficiency of the structure.

Note! The use of galvanized pipes from the outside is undesirable. But if there are no alternative options, then the pipe should be properly insulated.

Option number 2. Double-circuit products

For obvious reasons, such designs are also called sandwiches. Of course, predominantly stainless steel is used for their manufacture, but galvanized pipes are also quite common, often due to their lower cost. There are several sandwich chimneys made of galvanized steel, consider them.

- Only the outer contour of the structure is galvanized, while the inside is a stainless steel pipe.

- Two pipes are galvanized at once.

And due to the fact that the bulk of the loads falls on the inner pipes, the material from which they are made should be at least 0.6 millimeters thick. If we talk about the outer pipe, then 0.5 mm is quite enough for it.

Note! The outer surface of the structure is covered with special heat-resistant enamel and powder coatings, which give them a more aesthetic appearance.

The described double-circuit chimneys increase the efficiency of heating devices, and also increase the efficiency of their functioning. Of course, metal pipes are not very aesthetic, which is why they are often not combined with the overall design of the house. But this kind of drawback is quite easily eliminated by brick laying along the contour of the structure (although any other material can be used for this).

Making galvanized pipes with your own hands

The production of galvanized steel casings and cylinders includes three stages:

- Preparatory. It starts with marking and ends with cutting out the finished "pattern".

- Molding. At this time, a given profile of the chimney or ventilation duct is formed.

- Final. At this stage, the opposite edges of the workpiece are connected to each other.

And now let us dwell in detail on the step-by-step manufacture of galvanized pipes by hand.

Cutting out the workpiece

Tinplate is easy to cut with scissors

Take a sheet of galvanized sheet and sketch the product. Then proceed in this way:

- Cut out the resulting measured piece of the sheet on which you drew the outline of the product you need.

- Roll out a galvanized sheet on a flat area of the workbench. Measure the length of the box from the top edge and make a mark there.

- Take a square and draw a line from the product length mark perpendicular to the side edge of the sheet.

- Mark on the upper edge of the workpiece and the marked line of the length of the product the size of the perimeter of the ventilation duct or the circumference of the chimney cylinder.

Note! The actual circumference or perimeter must be increased by 15 mm to form the joint edges.

- Connect the resulting marks at the top and bottom.

- Cut the pattern out of the sheet by making a side and longitudinal cut.

On a note! To measure the circumference of a galvanized chimney pipe, use a tape measure or calculate it by the diameter of the product using the school geometric formula. Add all sides of the box to determine the perimeter.

Profile formation

It is better to bend the sheets with pliers.

Now we start forming the profile of the future structure.

- Mark the fold fold line along the workpiece (0.5 cm on one side, 0.5 cm twice on the other).

- Bend the folds at an angle of 90˚ to the plane of the workpiece, which was previously placed along the steel corner (its edge should coincide with the fold fold line).

- Deform the sheet with hammer blows until it touches the second plane of the corner.

Important! The shape of the leaf should be changed gradually, slowly moving along the fold line. Do the work with pliers first.

- Make a 1 cm L-shaped fold along the 0.5 cm line parallel to the plane of the workpiece.

- Now start shaping the chimney body. Place the workpiece on a calibrating plane and tap the zinc plated with a hammer until you get the profile you want. The folds at the end must meet.

Butt weld processing

To crimp the butt seam, line up the vertical folds. Fold the horizontal part of the L-shaped fold downward so that it wraps around the vertical fold of the other edge of the structure. Bend the protruding "sandwich", pressing it against the plane of the chimney.

The question of how to make a galvanized pipe yourself has been resolved. We wish you every success!

Comparison of stainless steel and galvanized

As already noted, in some respects, galvanized structures are inferior to those of stainless steel. People who are poorly versed in this want to know which option is better and why. In order to answer the question, we will compare the most important specifications.

- The condensation resistance of stainless steel is higher than that of galvanized steel.

- In terms of fire safety, both options are not inferior to anything. They are, in other words, equal.

- In double-circuit versions of a galvanized structure, we recall that a heater is used. But sandwich chimneys made of stainless steel have not yet been manufactured.

- They have about the same warm-up time. Both designs provide good traction in record time.

- Finally, both options can be installed on any heating appliance. They are not oversized, so they take up little space. Their installation is extremely simple and quick enough. To do this, you don't even need to hire professionals, but do everything yourself!

As you can see, both options are good, but you will have to pay more for quality (read: stainless steel).

Production of galvanized pipes with a diameter of 100 mm

- First you need to take a whole sheet of galvanized iron and cut off the workpiece. Its width should be 340 mm on the one hand, and 330 mm on the other. This is done so that in the end result the pipes can enter each other, that is, according to the "mom-dad" principle. It is better, of course, to mark the entire sheet completely so as not to be distracted by this operation once again. If the pipes will not be connected one-to-one, but with the help of other elements, in this case each side of the workpiece should be 340 mm.

- Then, along the meter sides, it is necessary to make seams for the pipe. To do this, using a mallet, on a metal corner, you need to bend 7 mm on each side of the sheet. The bend is made in opposite directions from each other, under 900.

- After that, the workpiece must be turned upside down and finished off with a wooden mallet to about 1400.

- Next, we set the workpiece on a corner, with a protrusion of 1 cm and again make a bend. This must be done so that the mallet clearly lies on the plane of the corner, no deviations can be made, or the seam will simply flatten.In this case, the blows must be confident, dense and strong.

- Then around the pipe of the "gun" you need to squeeze the workpiece with your hands. Remove it from the pipe and hook both bends to each other. Again, put the workpiece on the pipe "gun" and with the help of a mallet you need to beat at the place of engagement of the corners. First, gently tap the seam along the entire length of the workpiece, and then, increasing the impact force, beat until it is completely flattened. Having completed this operation to the end, we get a ready-made pipe.

- To facilitate the joining of pipes with each other, the pipe must be expanded a little on the wide side, and to ensure rigidity, roll rings from both ends, although in its original form the pipe is quite suitable for operation. And if no mistakes were made during the marking, it will very easily be docked with other elements, even factory-made ones.

It should also be noted that galvanized steel pipes can be used not only for gutters. They are also used for various chimneys and ventilation systems. And the fact that you learn to do them yourself will come in handy more than once in everyday life.

Installation features

The diameter of a galvanized chimney pipe depends on a number of factors, including:

- heater power;

- number of devices connected to the system;

- the type of fuel used for heating.

If the purchase of a galvanized sandwich is too expensive for you, then you can make its own analogue. For this, the galvanized pipe is wrapped in a layer of refractory insulating material and all this is placed in another pipe, painted or also galvanized.

Note! If the structure consists of several modules, then with each part the diameter should decrease - so moisture does not penetrate into the chimney from above.

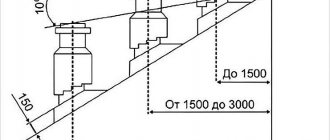

It is advisable to cover all joints with a refractory sealant. In the absence of any gaps, the traction will be excellent. In addition, the joints of the elements must be secured with clamps. For this, fixing brackets are installed along the length of the pipe in increments of about 150 centimeters (although this depends on the strength of the structure).

Note! If horizontal sections are planned, then know that their length should not exceed 1 meter!

In addition, when installing a galvanized chimney, fire safety requirements must be observed. This means that it must not touch the gas line, electrical wiring or combustible materials. If the structure was placed in a brick casing, then additional fasteners should be equipped in the attic to increase the strength of the chimney. Where the pipe connects to the oven, a hole must be made for cleaning and servicing the device (it will be closed during operation).

Video - Installing a galvanized chimney

What are the operational benefits of this choice?

The main advantage of using the described option is the presence of a protective layer. Any metal in contact with condensate begins to rust. It is she who becomes the reason for the violation of the tightness of the chimney and a decrease in the efficiency of its work. But if the metal is reliably protected from moisture, the whole structure serves well for a long time. Therefore, in recent years, the galvanized chimney pipe has become so popular.

For its manufacture, durable sheet steel is used. Before creating the mold, it is dipped into a liquid solution of molten zinc. Both elements enter into a chemical reaction, during which the molecules of steel and zinc interact with each other. Thus, it is possible to form a very thin, but reliable protective layer, the thickness of which does not exceed 60 microns. This layer is sufficient to protect the steel and allow products made from it to last for long service lives.

Chimney elements

If chimneys are made from such material, they acquire a lot of advantages:

- The design of the finished chimney consists of several parts, which are not difficult to put together.

- Any galvanized pipe is fire-resistant and fireproof, which is very important for buildings made of wood.

- The described chimney can be installed on almost any fireplace and stove equipment. Versatility is one of its most valuable positive qualities.

- The steel structure heats up very quickly, so the thrust is formed almost instantly. Thanks to this, the heating equipment itself works more efficiently.