Published by lpunity in 12.11.2018

Any buildings and apartments that are connected to the district heating network use heat to organize and maintain the optimal temperature for consumers. The device that organizes the control of the amount of energy is called a heat meter. Such a device must meet the requirements for heat metering units in accordance with the contract concluded with representatives of the heating network. It can also monitor readings and parameters during the operation of heat carriers (water and steam circulating in heating devices) at consumers.

Rules for the organization of commercial metering of heat energy

When using a heat meter under a contract, the consumer pays only for the amount of heat produced. This device is needed to organize the savings in the amount of consumed heat and reduce fuel consumption in accordance with the signed contract after the adoption of the act. Technical metering of heat energy is a necessary organization in a modern building to control the equipment of power grids.

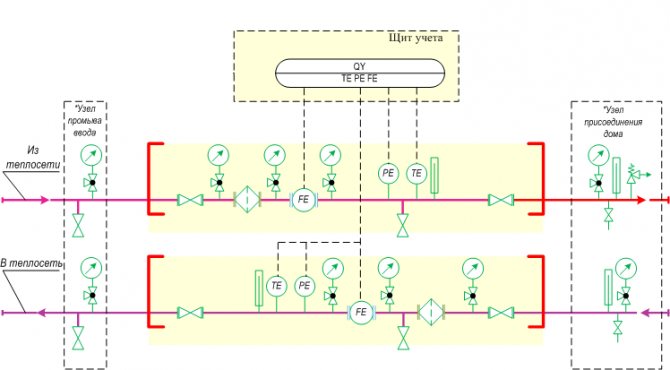

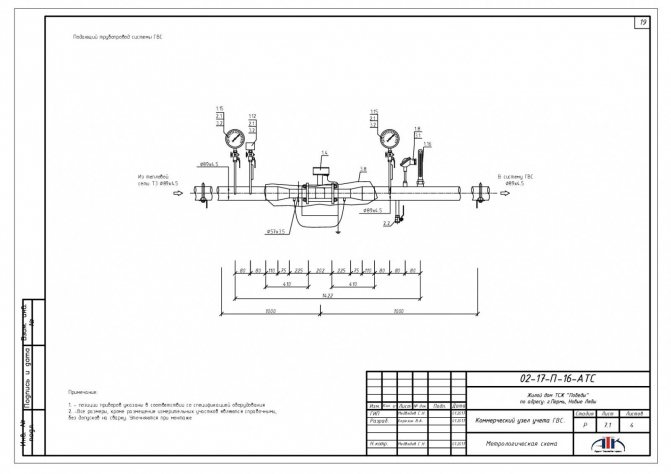

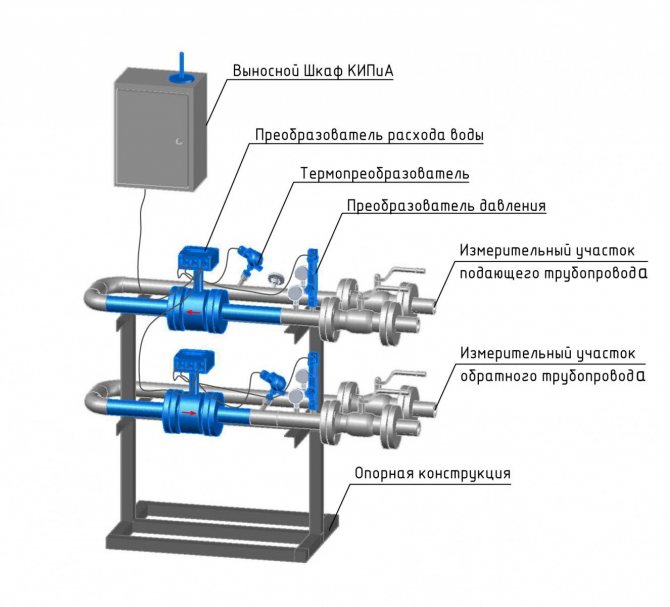

The requirements for commercial heat metering units say that these are devices for organizing the measurement of temperature and volume of heat energy. According to the rules, they consist of a flow meter, temperature sensors at the inlet and outlet, and an electronic calculator. Taking into account the information on the mass of the flow, the consumer can determine the volume of water and steam that the equipment produces by the meter.

To organize measurements of parameters, consumers can use the following formula: the produced mass of heat is equal to the volume of heat supplied through the flow meter multiplied by the difference in temperature in the supply and return pipelines. This indicator is multiplied by the heat transfer coefficient, which characterizes the parameters of the equipment according to the operating contract.

The current technical conditions and the passport of the heat metering unit determine the installation rules. For example, a heat meter must be included in the register of measuring instruments, like any other metrological device.

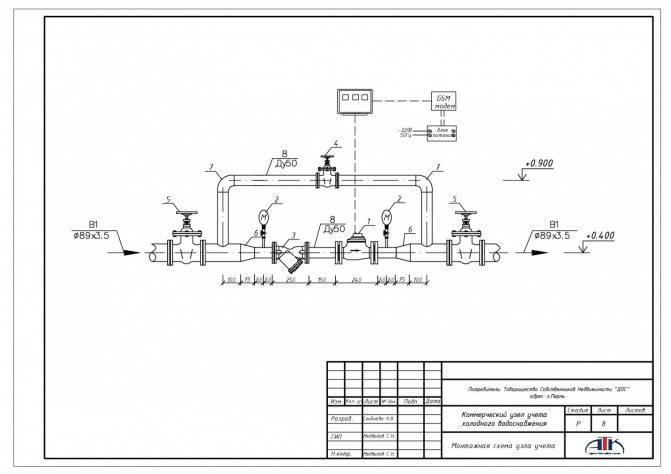

In accordance with the technical specifications for the organization of the installation of heat energy meters, they are mounted on straight sections of the system, and temperature sensors - on pipelines with a diameter of at least 70 mm with the inclusion of additional fittings (filters, ball valves, measuring manometers and thermometers). The work is performed by representatives of the heating network.

According to the rules of the organization, this set of equipment for the heat supply system is called a commercial metering unit. Requirements for work on its installation are regulated in Article 19 (Organization of commercial metering of heat energy, heat carrier Federal Law "On Heat Supply").

Heat meter service

Natural questions arise from the owners of the heat meter

- If the heat meter was installed by the state, then who should pay for the state verification?

- Do we need a service organization?

- Is there a law to have it?

- What awaits us if we cancel the service?

- What is included in the maintenance service?

Let's figure it out, with all the questions in order.

The heat meter, on the part of the owner, does not require special care. The lithium battery from which the heat meter is powered is not suitable for reuse, but requires disposal.There is no need to take special care of the battery, the service life declared by the manufacturer is at least six years, as a rule, no more than five years, and this is equal to the service life of the meter before it is checked (the period of state verification is four five years for different heat meters). A specialist who checks or maintains a heat meter is obliged to change the battery approximately every four years. If your flow transducers are also powered by batteries, then they must be replaced every two years.

Thermal resistance - maintenance free.

This is a theory - let's analyze it in practice.

Heat meter.

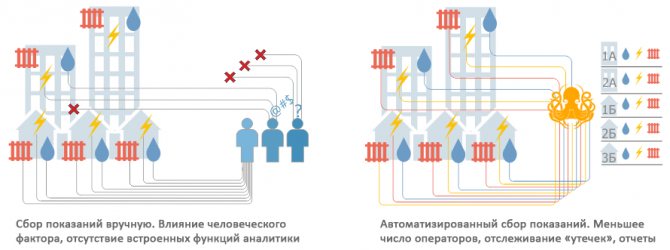

Clause 23. Rules for commercial metering of heat energy, coolant dated November 18, 2013 N 1034 states that the readings of metering devices (including those using telemetric systems - remote readout systems) are carried out by the consumer.

Clause 80. Within the period established by the contract, the consumer or a person authorized by him (read the organization serving the heat meter) submits to the heat supply organization a heat consumption report signed by the consumer. The agreement may provide that the heat consumption report is submitted on paper, on electronic media or using dispatching means (using an automated information and measuring system).

Therefore, all heat meter maintenance work and daily monitoring of the correct operation of the heat meter is entrusted to the consumer.

Clause 89. If any violations are detected in the functioning of the metering unit, the consumer is obliged notify the service organization about this within 24 hours and a heat supply organization and draw up an act signed by representatives of the consumer and the service organization. The consumer submits this act to the heat supply organization together with a report on heat consumption for the relevant period within the time frame specified in the contract.

Clause 90. In case of untimely notification by the consumer about violations of the functioning of the metering unit, the calculation of the consumption of heat energy, coolant for the reporting period is made by calculation.

Now we analyze our costs for servicing the heat meter.

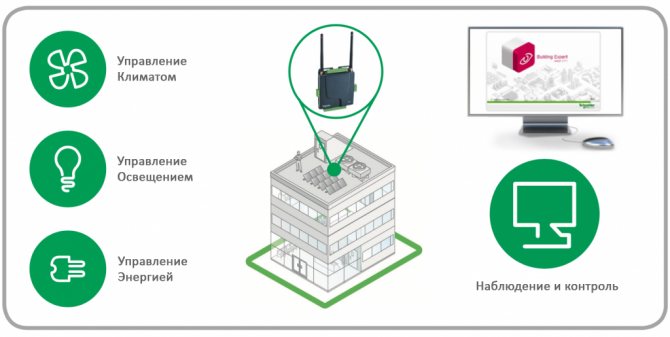

The heat register has been canceled by the new rules, this is good, but we, as before, are obliged to appoint responsible person for monitoring the correctness of work heat meter. And in order to notice a malfunction in time, he must understand well how the heat meter works and, most importantly, have free time for this. An ideal option if a remote reading system is installed at the metering station, then maintenance will be reduced to monitoring readings without going down to the basement and visiting the heat meter.

All parameters of heat consumption will be visible on the computer, the person responsible for metering will control without leaving home. Such control will also not be disinterested, money will be demanded from you - how much? If a person is retired and has a conscience - 500 rubles, a young person is not less than 1000 rubles.

We comply with paragraph 80 of the commercial accounting rules. They carried the printout to the heating networks - they have a legitimate question: Who did it? Wrong shape? In light of the fact that very often they try to forge printouts, they must know the person and require a printout in the unchanged form of the manufacturer. The question was settled - and on this point we are working calmly. By the way, we also spend a lot of time on a visit to the heating networks, at the end of the month, and the report is usually received within 2 - 3 days, there are always queues.

We analyze our actions under clauses 83-85 of the accounting rules, instrument failure. If the counter fails, then an error code is displayed on the display of the calculator of the amount of heat energy, and will be displayed until a specialist removes the breakdown. To make maintenance as easy as possible, the screen displays the clearest information possible. In practice, this is a small blinking icon, somewhere in the corner.A symbolic letter or number that is understandable only to a specialist. 99% of people do not notice it.

The failure in the heating networks was not reported on time, and in accordance with paragraphs. 90 (in case of untimely notification by the consumer about disturbances in the functioning of the metering unit, the calculation of the consumption of heat energy, coolant for the reporting period is made by calculation.) Rules we were charged for heat according to the calculated heat loads specified in the Agreement. They also lost a lot of money.

The question is, what would the service organization do in this case?

Having the right to dismantle, install, check and repair equipment, using special means, she will find the day and hour of failure, restore the lost readings and heat networks will accept her data.

It seems that they have decided that they need to have a service organization. Now let's decide what other work, hidden from our eyes, is needed at the heating unit.

Thermal resistances - theoretically they do not require maintenance, but this is the main element responsible for the correct temperature readings. For ease of maintenance, they are universally installed not directly into the coolant, but through a thermowell. In the common people a cartridge case. It should always be filled with oil, and quite liquid, not thickened - turned into resin under the influence of temperature. The presence of oil must be checked monthly. It is desirable that the service organization be able to check the contacts of the lead wires. The basis of thermal resistance is a coil with a wire - copper, platinum, etc. By measuring the temperature, we actually measure the resistance of this coil. For example 119.708 ohms is 50 degrees, 123.613 ohms is 60 degrees. Even the presence of a slightly oxidized or loose contact is 3-5 ohms. For those unfamiliar with electrical engineering, I explain - very, very little. An analysis circuit built into domestic heat meters will halve the error. Two Ohms on the table is about 5 degrees. Applied to a five-story building with four entrances, 9.2 t / h x 5 gr = 0.046 Gcal / h. At a Gcal price of 1200 rubles, 0.046x24x30 x 1200 = 39744 rubles. Good mistake? Approximately 6 rubles per square meter of total area. In imported heat meters, the principle is somewhat different, there are no wire resistance compensation schemes (in our case, read errors), but their resistance is platinum 500 or 1000 ohms. Due to this, the error is slightly less, but the diameter and length of the wires from the heat meter to the heat energy calculator are very strongly influenced.

If the thermal resistance is installed directly into the coolant, then once a year, before the start of the heating season, the surface of the thermal resistance must be descaled. It's like in a teapot after long-term use. Scale also introduces a large error in the readings. How to check the thermal resistance on the spot, if payment for heat depends so much on it. For these purposes, control thermometers are necessarily installed at the heating point. True, their readings are less accurate than those of thermal resistances, the accuracy class and the measurement principle are not the same. A good service organization has special devices for these purposes - electronic pyrometers. Their accuracy class is very high (except for cheap Chinese ones). Pyrometers measure the temperature not of the coolant, but of the surface of the pipelines, but the difference in readings between the direct and return pipelines is accurate. It is this value that is used in the calculations.

Annual cleaning and flushing (read dismantling) require flow meters all types except water meters. At metering stations with water meters, they are limited to rinsing with special solutions and blowing the insides of the devices with compressed air. The procedure must be carried out very carefully, according to the instructions and only by trained personnel. Otherwise, there will be more harm from it.

Special control is required Power supplies, voltage stability is the key to the correct operation of the heat meter.

If your heating unit contains Pressure Sensors (new rules require the installation of pressure sensors), it is necessary to check their readings monthly with the readings of mechanical pressure gauges. And last but not least, the state of the wires and wiring, grounding and grounding. If the company that installed the metering unit saved money on them, or your basement is damp, or even worse, it is flooded with water, after three or four years they may become unusable. And the presence of grounding and grounding must be monitored monthly and measured annually.

And yet, is there a law prescribing to have a service organization?

In the rules of commercial accounting about the service organization, there is only one line in clause 89. If any violations in the functioning of the metering unit are detected, the consumer is obliged to notify the service organization and the heat supply organization about this within 24 hours and draw up an act signed by representatives of the consumer and the service organization. It follows from it that you can shoot, but if there are problems without a service organization, they will not talk to you, they will write what they want. There is also the 261-Federal Law "On energy saving and on increasing energy efficiency and on amending certain legislative acts of the Russian Federation", article 13, paragraph 7 of this law says: "Owners of metering devices for energy resources used are obliged to ensure the proper operation of these metering devices, their safety , timely replacement ". Clause 12 of the same article "organizations (meaning those who installed the metering device, or who supply heat) in case of revealing the facts of non-fulfillment by the owners of the metering devices of the used energy resources of the obligation to ensure the proper operation of these metering devices and not eliminating such non-fulfillment before the expiration of two months from the moment of its detection are also obliged to start operating these metering devices with the attribution of the costs incurred to the owners of these metering devices. The owners of these metering devices are obliged to ensure the admission of these organizations to the metering devices of the energy resources used and pay the expenses of these organizations for their operation, and in case of refusal to pay the expenses on a voluntary basis, pay the expenses incurred by these organizations in connection with the need for enforced collection. " Well said. It is worth considering.

Let us summarize all of the above: heat meter maintenance services consist of:

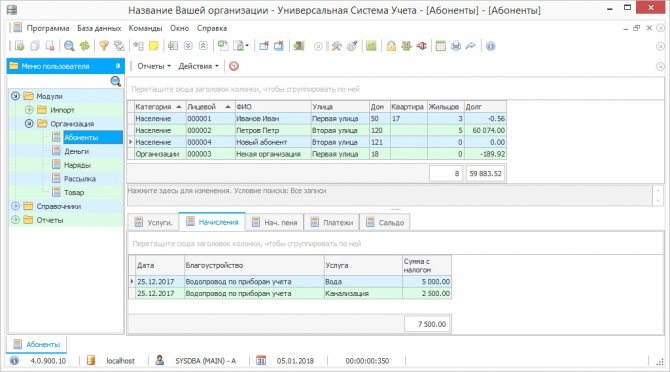

1. Keeping records of heat consumption and taking meter readings once a month (compulsory archival storage, in electronic form, at least 2 years).

2. Service for the analysis of the state of peripheral equipment and the performance of the heat meter.

3. In some cases, services for the repair and adjustment of the heat meter are provided. It is very good if, for the duration of the repair, you will be provided with a replacement heat meter, and in general it is fine if it is free.

4. Service for the transfer of the report of the heat supply organization. By the way, it is very profitable, do not stand in lines, do not listen to "nagging", and you receive the bill for the heat by mail.

6. Service for dismantling and installation of the meter to check it or prepare for the heating season.

7. Service for state verification of metering devices.

How much can all this cost and at what stage is it better to conclude an agreement?

The prices listed below are relevant for the city of Rostov-on-Don and the Rostov region. Do not be surprised if it seems expensive to you, 50% of an honest company goes to taxes, 10-20% depending on the type of contract for services, consumables, transport. And only the rest for the salary.

1. Only taking readings from the company 1100-1350 rubles.

2.Taking readings, monitoring performance, transferring reports to heating networks 1500-1800 rubles.

3. Taking readings, monitoring performance, eliminating minor flaws without removing the seals of the heat supply organization, transferring reports to heating networks 1800-2000 rubles.

4. Taking readings, monitoring performance, eliminating minor flaws without removing the seals of the heat supply organization, setting up after repair, transferring reports to heating networks -1800 rubles.

5. The same as point 4, plus the call of the heating network specialists to remove the seals before the repair and sealing after the repair 1850 rubles.

P.S. Calling specialists upon commissioning a new unit and after state verification, as well as once a year before the start of the heating season, is free, the rest depend on the region and may be paid.

6. Service with repair and provision of a replacement heat meter from 2400 rubles. The cost of state verification depends on the number of peripheral devices at the facility and the type of heat meter. From 25,000 rubles for a monoblock with two thermal converters, and 28,500 rubles for a standard facility with hot water supply (4 pipelines). The distribution of funds here is as follows, 55% payment for state verification services (center of standardization and metrology - UCM), 25% pouring services, 20% dismantling, installation of devices.

As you can see, your service organization will receive small money for the work, but the responsibility is huge, and the adjustment after verification is like at a new facility. If you are offered to perform this service cheaper, most likely no one will do anything, they will share it with whoever they need to, or even fake seals. There are a lot of such cases, and such savings will definitely turn out to be bad for you.

When is the best time to contract with a service provider?

Our opinion immediately. Of course, if the node was installed by a reliable organization, you have a dry basement, there are no power outages, the new insulated pipelines will definitely work for a year or two without repair. But before the start of the heating season, flow meters and thermometers require flushing, you would have done it for free, now for money. The next admission to operation before the start of the heating season will also reveal flaws, minor flaws, etc. And they will all be eliminated at your expense.

And finally, it is very good if all residents of the house have access to the readings for the heat received. The chairman and the service company can be calm, no one will accuse them of theft or collusion with the heat workers. But how to do it in the next article.

If you have any questions related to the maintenance of metering units for heat energy and coolant, please call us at the numbers listed on the contacts page, or send an e-mail

Paramonov Yu.O. Rostov-on-Don. 2012-17

What else to read on the topic:

Related entries:

- Encyclopedia of heat metering for HOA and housing and communal services

- Who should pay for the state inspection of the heat meter?

- Why install a heat meter

Installation of measuring equipment

According to the rules for installing heat metering devices, there are two ways to install measuring devices:

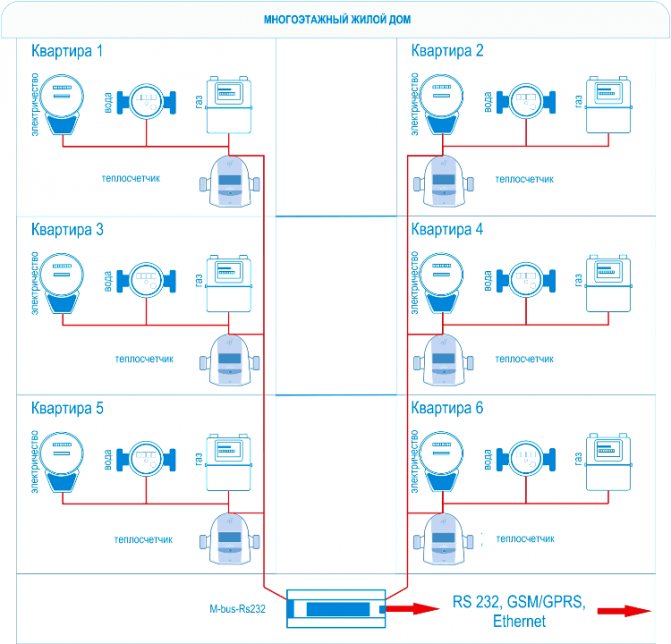

- Measurement of temperature and energy mass requires the organization of heat meters on each heat carrier. To get the total consumption of heat mass for an apartment, the consumer needs to add data on all equipment in the reporting period.

- The organization of one metering device for heat consumption in the riser and temperature sensors is carried out on each heat carrier at consumers. In this case, the amount of work on reprogramming is determined by representatives of the heating network. They also add data for each pipeline to get the total consumption by consumers.

Only one-pipe horizontal systems allow measurement with one heat meter. However, such devices are equipped only in industrial and industrial buildings.Therefore, an effective solution to the problem, which does not require significant investment and renovation of the premises, is the installation of commercial temperature measuring devices.

Methods for processing readings of measuring heat complexes.

Measuring complex heat can perform the following functions: - input and change of initial conditions and data (adjustment procedure);

- periodic polling and calculation of all parameters of the coolant;

- calculation of the flow rate, volume, temperatures and pressure of the coolant and calculation on their basis of the consumed amount of thermal energy;

- displaying information on the current values of the measured and calculated parameters (flow rate, volume, pressure, temperature, etc.);

- display on call of the current values of the sensor readings, as well as the consumed the amount of heat energy and the values of all entered and calculated parameters;

- remote transmission using an additional modem through a standard interface of all calculated, entered and stored in the memory of the corrector upon request or according to a given program;

- determination of external unauthorized influence in order to influence the process of calculating the volume and the provision of reports on emergency situations, accidents, unauthorized interventions;

- hourly archiving of the main parameters for 12 months;

- diagnostics of functional blocks operability;

- displaying the values of the measured parameters with the indication of time and date;

- display of daily consumption of heat energy and its parameters for the current and last month;

- displaying the serial numbers of the components of the complex.

The above functional capabilities of the measuring complex allow obtaining the necessary information without additional processing.