Repair of a gas water heater, in terms of its complexity and the number of possible technical problems, cannot be compared with any other home appliances. More complex and saturated with possible technical nuances can only be the repair of gas boilers at home. If you can still try to repair the water heating device with your own hands, then it is best to entrust the maintenance and repair work of the heating boiler, regardless of the number of built-in automation, the presence of a second circuit and the manufacturer, to a certified specialist.

What can be repaired in a gas water heater with your own hands

Of course, the gas water heater does not always wear out or break down so thoroughly and irrevocably that you cannot do without the help of a specialist. According to the same locksmiths of the gas maintenance service, in 70% of cases, the repair of gas water heaters is reduced to routine maintenance and the elimination of minor defects, usually associated with low quality parts or improper adjustment.

The list of works available for repairing gas water heaters at home can include the following activities:

- Minor repairs and repackaging of pipe couplings and nuts;

- Replacing the elastic membrane in the water-gas column regulator;

- Cleaning and adjusting the operation of the traction sensor;

- Cleaning and flushing the heat exchanger;

- Ignition board repair.

An operation such as repair and soldering of heat exchangers can be distinguished into a separate category.

It is clear that there is a certain category of expensive water heaters saturated with automation and electronics, which simply does not make sense to even try to be repaired at home. For example, repairing Electrolux or Vaillant gas water heaters will be cheaper at a service center due to the high cost of spare parts. The exception is especially critical components, such as a three-way valve or an ignition board, it is better to buy them from an authorized dealer, even if the price is higher. This is the only chance to carry out repairs and not kill an expensive Italian or German column with substandard spare parts.

Repair of the gas water heater Oasis

Chinese water heaters Oasis attracted the attention of the domestic market, first of all, by their low price and simplicity of design, which provides do-it-yourself gas water heater repair in almost any problem situation. The device and format of the main parts are very similar to most domestic systems, so there are no problems with disassembly and repair, even if there is no repair manual or diagram for the Oasis gas water heater.

It is known from practice that the Chinese Oasis gas appliances suffer from three types of defects:

- Fast discharge of batteries;

- Failure of the spark plugs;

- Leakage of water at the gland of the membrane water pressure sensor.

In the first case, the problem with the batteries appears rather unusual, the indicator board pleases with a blue or green light, but when you try to turn on the gas water heater, nothing happens. Repair of such a defect is performed by simply replacing conventional salt batteries with alkaline cells with an increased charge capacity. They should be enough for at least a year.

We disassemble the Oasis for repair

If drops of water began to appear under the column, then this most likely means that one of the units of the flowing part of the water heating apparatus will need to be repaired. The Oasis must be dismantled in order to determine the cause of the water leak and carry out repairs. First of all, it is necessary to remove the outer casing of the apparatus. For this, the handles are removed and the self-tapping screws are unscrewed in the lower part of the case.

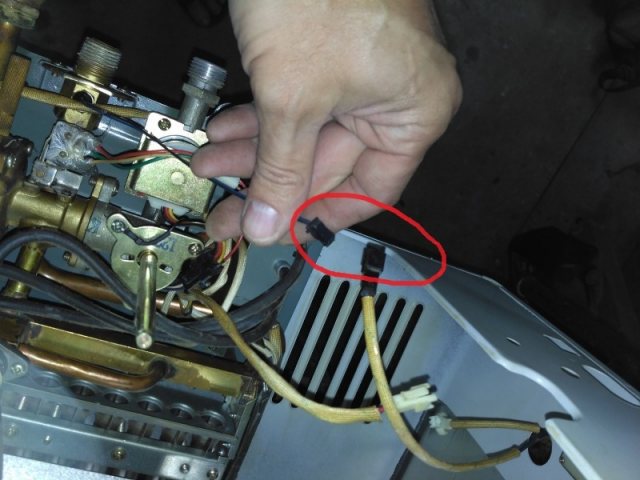

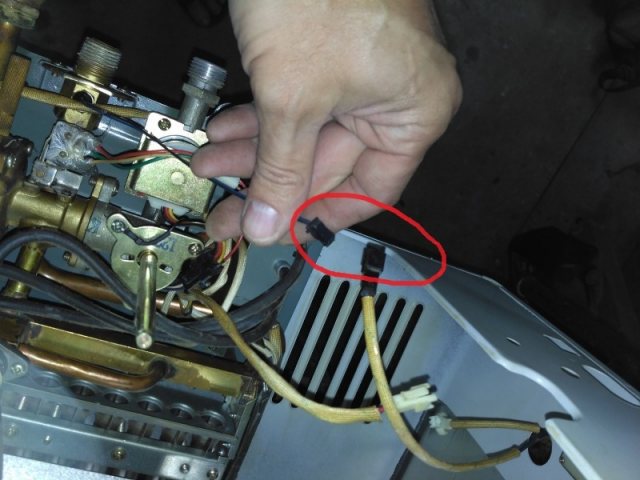

The next step is to disconnect the connectors from the indicator board and microswitch.

We get access to the future place of repair - a membrane water pressure control unit.

We repair the gas water heater block regulator

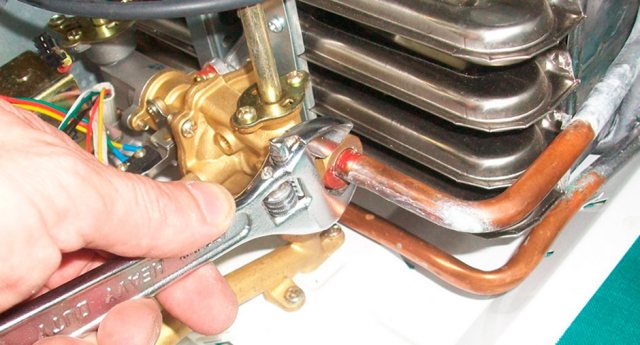

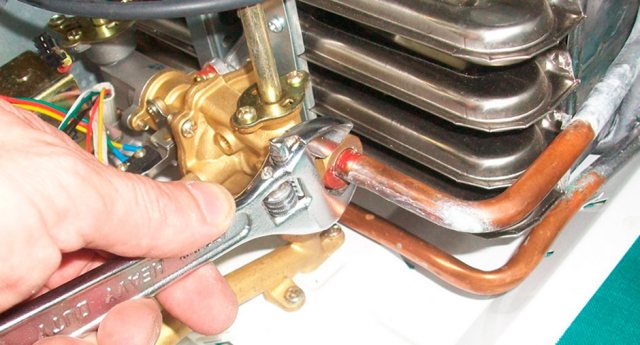

In order to remove the pressure control unit, it is necessary to carefully disconnect the microswitch connector and unscrew the two screws securing the heat exchanger flange to the unit body.

It is clear that before repairing the gas column, the water must be shut off, the water pressure remaining in the system must be relieved by opening the tap.

For repairs, it will be necessary to additionally remove the gas block of the water heater and the burner.

The removed unit can be disassembled for repair by removing the four steel screws. Usually, steel fasteners strongly adhere to brass, therefore, the joint is preliminarily treated with VD-5 or brake fluid.

The pressure control unit works as follows:

- There is a cavity inside the body, which is divided into two parts by a membrane. On one side, water comes up, in the second cavity there is a round float, on which water presses through the membrane;

- The float contains a stem that passes through a rubber gland. When the hot water tap is opened, the flow fills the cavity in the block, squeezes the stem through the gland through the membrane and the float, and squeezes the contact on the microswitch;

- The circuit closes, gas opens, and the ignition device is triggered.

It is clear that the surface of the steel rod, in contact with rubber, intensively corrodes and becomes cavernous. Each movement of such a rod leads to a catastrophic depletion of the oil seal, which begins to flow after a year. In addition, for any repair, at the first opportunity it is necessary to change the membrane to a high-quality rubber membrane.

Often there is a situation when, before repairing the oil seal, the gas column begins to boil and spit steam. This suggests that the membrane also needs to be cleaned of dirt and, if possible, replaced.

Repair of the electrode system of the gas column

Chinese manufacturers of Oasis gas water heaters always like to save on the quality of the materials used. As an example, we can cite a situation when a new, fully serviceable gas water heater stops igniting even with a serviceable water and gas control unit and an ignition board.

The reason is the failure of one of the three spark plugs of the burner flame. The design of the burner is such that all three candles must be in good working order to ignite the gas.

Repair of the gas column ignition system begins with the identification of a faulty spark plug. To do this, you need to remove the cladding, turn off the lights and shade the room. When you start the gas column, you can see how on one of the candles an electric discharge hits not into the gas flow, but much lower into the body.

The situation is extremely dangerous and requires urgent repair of the gas-air flow ignition system in the column. It is impossible to postpone repairs, even if the column lights up for the second or third time it starts up. When launched, a large amount of a mixture of gas and air is injected into the fuel chamber and the exhaust device, and if the ignition of the column is triggered with a long delay, an explosion and fire are possible.

For repairs, it is necessary to dismantle all three candles, clean them from carbon deposits, oxidation products. One candle accurately punches the body, the rest is not known in what condition, so all three are put in an insulating heat-shrinkable polymer tube, at least three to four layers. During the repair, it will be necessary to insulate the clamping bar in the same way, with which the candles are fixed on the burner body.

Features of ignition of Bosch gas water heaters

A flow-through gas water heater, which has received the common name "gas water heater", is a technical device in which water is heated with the help of energy released during the combustion of household gas.

Different models of the brand's water heaters, differing in functionality and design, also have a different type of ignition. Therefore, the reasons for the problems with the ignition of the flame may differ. But, in order to diagnose them, for a start it is advisable to familiarize yourself in general terms with the speaker device.

Bosch geysers, despite the many modifications differing in the type of ignition and performance, correspond to the general assembly scheme and consist of the following elements:

- gas fittings - a curved metal tube through which gas flows and gas supply control elements;

- gas wick - device for ignition of a flame;

- burner - the place where the gas combustion process takes place;

- heat exchanger - a special tank through which a tube with running water passes; this is the place where the water is heated;

- combustion gas temperature sensors - a necessary element to control the proper working capacity of the column;

- buttonpiezo ignition - required to start the column;

- column modulation knob - it is used to increase the gas supply power;

- combustion products removal.

Columns of different series may differ in the type of ignition, a set of sensors and other structural elements. Next, we will get acquainted with the main ones, which are important in the case of self-diagnosis of a malfunction.

Therm 2000 O series

Affordable version. Average productivity: in 1 minute it heats up to the required temperature of 10 liters of hot water. The device of this series is equipped with automatic ignitionpowered by batteries.

Also included in the design are sensors and sensors for gas supply control, flame control, traction control.

Therm 4000 O series

Models of this series are available in 2 versions: with automatic ignition from batteries and piezo ignition ... Different in power, they can heat from 10 to 15 liters of water per minute.

Geysers of this model have a number of advantages:

- uniform regulation of the column modulation, which allows you to maintain the set water temperature;

- heats water even at low pressure of the flow head (sufficient pressure - 0.1 Atm).

To distinguish between the type of ignition in the designation of these gas water heaters, the letters are used B - columns with automatic ignition, and P - speakers with piezo ignition.

Therm 4000 S series

Columns of this series are often installed in apartments with problematic chimney routing. The intake of air and the removal of combustion products takes place in a coaxial chimney located on the outside of the wall.

Also installed on the front side electronic control panel... This makes it possible to monitor the performance of the column (in case of a violation, information about the malfunction is displayed on the panel), as well as to set the minimum error in the water temperature - 1 degree.

The capacity is in the range of 12-18 liters of water per minute. The main disadvantage is that in the absence of electricity, the column will not work.

Therm 6000 O Series

Used in this series of gas water heaters built-in hydrogenerator allows for automatic ignition of the flame when opening the tap with water.

Repair of the gas column Neva

Most of the models of Neva gas water heaters have shown themselves to be simple and affordable water heating devices. They are far from the reliability of European models, but their repair costs an order of magnitude cheaper, and almost always you can do it yourself.

Failure and subsequent repair of the spark plug according to the rules is considered an atypical case of breakdown, therefore, after completing the repair work, it will be correct to look for the cause of the defect. Most often, plastic burnout occurs due to condensation flowing through the ventilation system to the gas burner body.

How to repair the heat exchanger flare nut

One of the most common defects of Neva gas columns for almost all models is the low quality of the heat exchanger metal. According to the rules, the heat exchange circuit through which the water flows must not come into contact with aluminum parts, for example, a gas burner or a regulator block. Any such contact can cause electrochemical corrosion of the copper walls, and then the repair will be simply useless.

In addition, the rules for tightening the union nuts, with which the heat exchanger is attached to the regulator and the outlet pipe, are not always respected. With each removal and repair of the heat exchanger, the nuts cut a thin, barely distinguishable track in the copper wall. Ultimately, the flared end and part of the copper pipe simply break off for the tenth time.

In this case, it is necessary to cut and level the breakdown site, install a new nut with an external thread and connect the heat exchanger to the regulator block with an ordinary flexible hose. Any other repair option, as practice shows, turns out to be short-lived.

Repair of a microswitch in the gas column starting system

A situation similar to the Oasis on dead batteries also happens with the Neva gas water heater. When you try to start the Neva, the indicator board lights up, but the gas burner does not ignite. Sometimes the column can be turned on 4-5 times.

In this situation, repair of the microswitch is required, due to premature wear of the part or improper adjustment of the unit.

The switch is located next to the water pressure control unit. When the column is started, the membrane on the block squeezes out the stem, which unlocks the switch contact. Unlike Oasis, all parts of the block, including the stem, are made of brass, so there is no corrosion, the microswitch itself must be repaired and replaced.

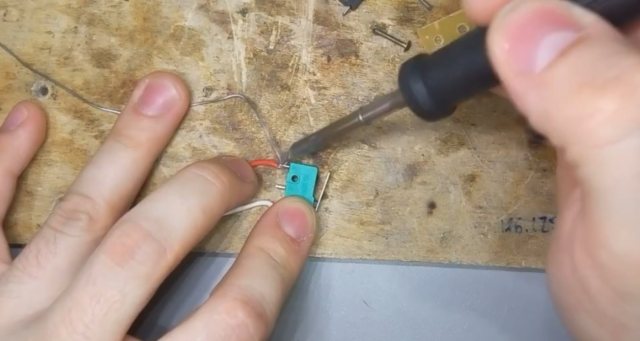

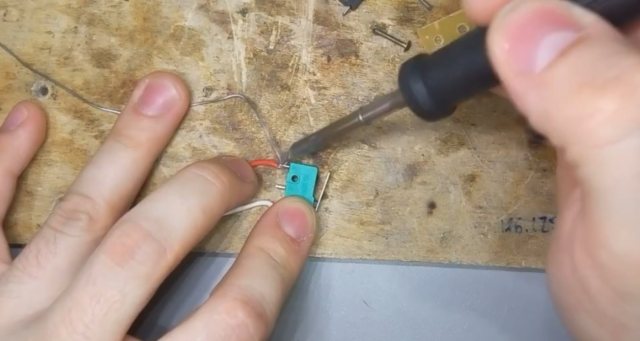

To carry out repair work, you must disconnect the connector, unscrew the two M3 screws and remove the switch body from the bar, as in the video

Replacing the micrik is easy. You can buy an original part for 400-500 rubles. in a specialized salon or purchase an analogue for 50 rubles. in any radio parts store. There is no difference for repair, in both cases they will sell a part from Chinese consumer goods.

In order to carry out the repair, you will need to unsolder two cores of the wire with a connector from the switch legs, put on a heat-shrinkable tube and solder to the contacts of the new part.

At the final stage of the repair, the switch is fastened with old screws to the mounting plate on the block. Next, you need to adjust the position of the microswitch housing so that the rod completely releases the contact when moving. This is done using mounting screws. One of the screws bends with a radius, respectively, by rotating it, you can move the switch body in the desired direction.

Distinctive features of the Repair kit for the water unit of the gas water heater Junkers WR-10:

Delivery for you anywhere in Russia

... delivery. ... Russian Post (). Product weight in package:

1 kg - specify for

In the heating equipment store, you can buy a repair kit for a water unit for a Junkers WR-10 gas water heater at a price of 900 rubles!

Similar Products to Repair Kit for Water Heater Unit Junkers WR-10

Replacement of jets for gas stoves for cylinder gas "Hephaestus". Instruction.

According to numerous requests from our clients

.

Publication date 04/10/2016

In order to bring us as close as possible to the feelings of an installer who replaces the nozzles for cylinder gas on a gas stove, we have chosen a Brest 300 gas stove that has been in use for more than one year. And in practical life, it is quite often the old ones that are transferred to liquefied gas. gas stoves, which are taken to the dacha or to country houses. When replacing the jets, several important discoveries await us, which can only be talked about when we visually begin to approach the intended goal. This will help a number of necessary photos that had to be taken in order to fully illuminate the implementation of the task.

The Junkers gas water heater is a product of the German concern Bosch. Like all German technology, these devices are easy to use, reliable, durable and use natural gas economically.

The Junkers brand was merged in 1932. And the history of the brand began back in 1895, when the German engineer Hugo Junkers, an inventor and industrialist, opened a factory for the production of water heating devices. Junkers himself patented about two hundred inventions - this is a record for his time. The company has introduced piezo ignition since 1968. Then a column with ignition from 2 batteries was released. 10 years later, Junkers launched the world's first wall-mounted combi boiler with continuous power regulation. The brand is known for its turbocharged speakers - not many manufacturers make them. Bosch Thermotechnology is the world's largest manufacturer of heating equipment, occupies a leading position in Europe.

disadvantages

Even the famous German quality cannot completely eliminate the disadvantages arising from the design features of water heaters. Disadvantages of Junkers speakers:

- Almost all modifications are distinguished by increased noise.

- After a few years (5-6), the heat exchanger begins to fail - leaks may appear.

- We have to seal the joints, and the gaskets that are supplied with the Junkers models are not enough to eliminate leaks.

Masters say that the cause of problems with the heat exchanger is scale. The instruction manual recommends: for the equipment to function properly in the conditions of the Russian water supply, it is necessary to install an additional water filter. This will increase the service life of the apparatus up to 10-12 years. Not all consumers are attracted by such a solution - they have to regularly change cartridges. Many users also do not want to take a bath in water that has passed through a magnetic filter.

Benefits

Despite the serious disadvantages of Junkers water heaters, they are in demand in the domestic market, as they offer potential buyers a large list of advantages:

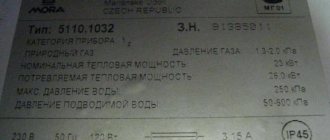

- Adaptation to domestic gas pipeline systems. In the Russian network, the pressure is 13 mbar, in Europe - 20 mbar.

- Work at water pressure from 0.1 atm.

- High productivity - water is heated at a rate of 11-17 l / min.

- There is a flame modulation system - the power automatically changes, ensuring the stability of the temperature of the heated liquid.

- Reliable security system.

- Reasonable price.

- The warranty is 1 year. The service life is 10-13 years.

How much are? The price of the Junkers model depends on the size - all other characteristics of the models are the same. The manufacturer offers two versions: mini and standard. The cost is from 7,000 to 11,000 rubles.

How to choose?

The main difference in the Junkers models is the ignition method. Water heaters have not been kindled with matches for a long time, there are more perfect ways to get fire:

- Piezo ignition is used in P series devices - the most popular option. The device turns on at the touch of a button. Such versions have another important plus - you can set the water temperature. The igniter burns constantly.

- In heaters of the "B" series, electric ignition is provided - in this case, the device ignites from the batteries.This option is more expensive, but gas is also consumed more economically - you do not need a constantly burning igniter. The device turns on automatically when the coolant starts to move. These versions allow you to save fuel and comfortably use the device.

- In the “G” series devices, the Hydro Power technology is used for ignition - a special generator, there is no burning igniter.

Security

Gas is a source of increased danger. Gas equipment, having a multi-stage safety system, prevents possible emergencies. All processes are controlled by automation, which, at the slightest hint of a problem, will prevent danger and block the flow of gas. The German speakers provide protection:

- from the extinction of the fire;

- from lack of traction;

- from reverse thrust;

- from overheating.

Model overview

BOSCH Therm 4000 O WR 10-2 B (B series)

This model provides electric ignition with two batteries, automatic start, reliable security system:

- traction controller;

- ionization flame adjustment;

- safety valve.

Water pressure and temperature are set taking into account the flow in the pipes. There is a self-diagnosis with fault indication. According to consumer reviews, this model has been serving well for 10 years or more. The cost is about 18,000 rubles. Management is mechanical. Characteristics:

WR 10-2P ("P" series)

This device uses a piezo ignition, the igniter is always on. Separate setting of water pressure and flow. The WR10-P, 13-P and 15-P versions have a thermoelectric device that controls the combustion intensity. Copper radiator is installed, there is no tin and lead in the alloy. Convenient control panel. There is an indication of the state of the gas burner device. The piezo ignition button is at the bottom of the device. Water flow and power are regulated separately. The burner is made of stainless steel. Water reinforcement material - glass fiber reinforced polyamide. The cost is 13,000 rubles. Body color is white. Characteristics:

WR 15-G ("G" series)

This ignition device is equipped with a hydrodynamic generator using the Hydro Power technology. It works at a pressure of 0.35 and can work at 3 points of water intake. The manufacturer offers modifications: 10-G, 13-G and 15-G. Characteristics of the WR 15-G model:

Express instruction manual

After the installation of the equipment, carried out by specialists, the buyer of the gas water heater should read the instructions. The service life of the device depends on the correct operation. Rules for the user:

- Installation and maintenance is a professional business.

- Periodic cleaning of the igniter and radiator is required.

- It is undesirable to set a very high heating temperature - this contributes to the accelerated formation of scale.

- If the water is very hard, the device needs a special device to prevent the formation of limescale.

What are the problems?

More than half of all breakdowns occur due to violation of operating rules. All other faults are associated with problems in the electrical network, poor water quality and corrosion. If a factory defect is found, the device is sent to a service center for free fixing of the problem. Paid repairs cost about 1000-2000 rubles. It is more profitable to take the water heater to the service, since calling the master will cost more. The most common malfunctions:

- The device cannot be ignited. The igniter lights up and goes out after a couple of seconds. The reason is a breakdown of a thermocouple, valve or sensor of combustion products.

- The water is not heated. The probable cause is a breakdown of the heat exchanger. It may have built up a lot of scale.

- The device makes noise and overheats. The reasons are the same as in the previous paragraph.

- Loss of water. Reasons - the heat exchanger is damaged or it's time to change the oil seal.

- Claps are heard during operation. The reason can be either too high or too little gas pressure.In any case, professional cleaning and adjustment is required.

- Smell of gas. This problem needs to be taken into account especially carefully. The first step is to close the gas valve and immediately ventilate the room, then call the gas service.

To fix the problem yourself, you need:

- establish the exact cause of the breakdown;

- buy original spare parts;

- prepare the equipment needed for the repair;

- study the rules for eliminating a specific malfunction and clearly follow the instructions of specialists.

Before turning on the Junkers column after replacing a faulty part, make sure that the fasteners are firmly fixed - gas leakage must be excluded. Self-repair is possible if you have experience and knowledge of the design and operation of the equipment. Only original spare parts should be used. The purchase of new hydraulic fittings will cost 7,000 rubles, the pilot will have to pay 500 rubles, and the thrust sensor - about 1,000 rubles. The cost of an electronic ignition device is 5,500 rubles.

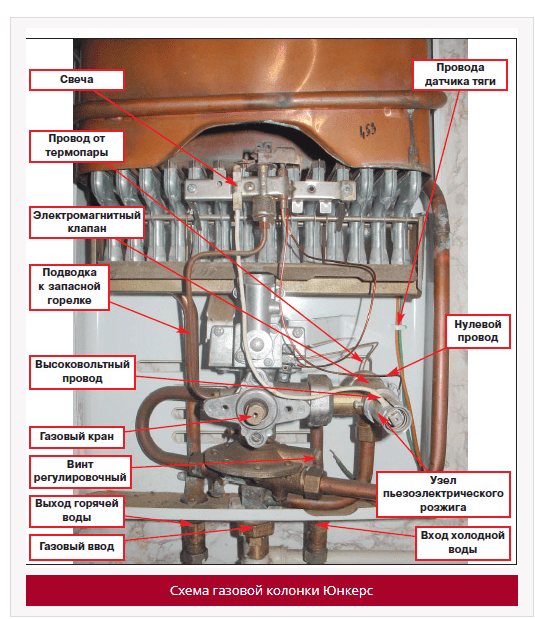

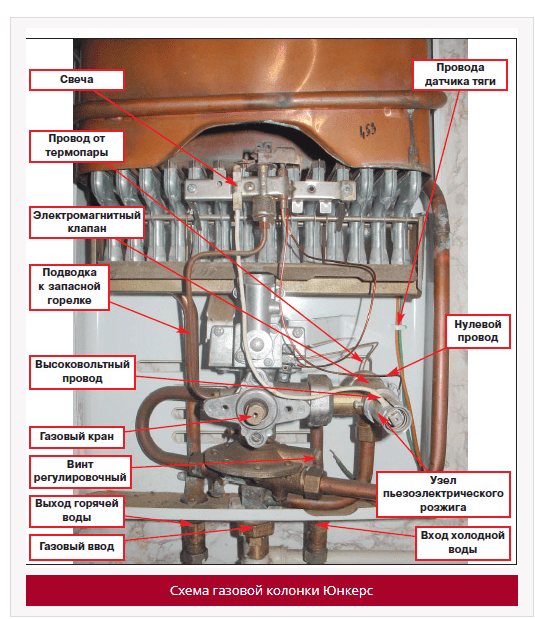

Dismantling the Junkers gas water heater

To repair a unit, perform a maintenance cleaning or replace a part, you need to disassemble the device in parts. The disassembly procedure is as follows:

- Remove the handle located on the water block. Set the gas regulator to the central position, unscrew the self-tapping screws - they are located at the bottom of the case. On "Junkers", instead of self-tapping screws, there may be clips. The housing can now be removed.

- Unscrew the self-tapping screws securing the flue gas hood to the body. Then - screws from the strip screwed to the cap - it is needed to fix the heat exchanger.

- Sequentially remove the traction and temperature sensors, disconnect the wires from them. The columns "Bosch" and "Junkers" have a difference: for the former, the wires from the draft sensor can be easily removed, for the latter, they are fixed by soldering and cannot be removed.

- Detach the cap from the heat exchanger and the housing and remove it. Be careful when removing the pipes. There are rubber seals in the pipes - it is advisable to replace them with new ones during assembly, since they tend to age and dry out.

- Disconnect the wick tube from the burner.

- To remove the burner, unscrew the self-tapping screws and, pressing the thermocouple with a screwdriver, remove it from the burner body.

The Junkers company existed until 1932. From that moment the company was bought out by the Bosch Gruppe, which, however, did not affect the name of the water heaters produced by the division of the main office.

Junkers flow-through gas columns are produced in several modifications, differing in the principle of ignition, as well as in the type of combustion chamber. Instantaneous boilers operating with an ignition burner are popular among the domestic consumer. The average service life of a Junkers column is over 15 years.

Repair of the Junkers gas column

The advantage of domestic gas water heaters is their high resistance to overloads and low quality of water, and first of all, gas. Experts say that German equipment traditionally shows huge service life without repair, but on one condition - the system must be protected from power surges and equipped with protective filter elements that soften the hardness of the heated water.

But even in such conditions, you have to periodically carry out minor repairs with your own hands of the Junkers gas water heater. The reason is simple, automation, ignition and ignition device are very sensitive to dirt, dust and rust in household gas. On dirty gas fuel, the igniter is the first to fail.

To restore the column, you will need to remove the lid and pull out by hand a thin profiled aluminum tube that provides standby operation. The tube is carefully cleaned with copper wire and rinsed with alcohol.Due to the high content of iron pentacarbonyl in the gas, finely dispersed metal dust precipitates on the walls of the gas pipeline, killing the candles and igniter.

Filters practically do not retain pentacarbonyl, so craftsmen often replace an aluminum tube with a copper tube of a larger diameter. The new gas pipeline is wrapped around the heat exchanger, which ensures the decomposition of the carbonyl in the pipe before entering the ignition zone.

In addition, dirty gas makes it necessary to regularly open and clean the gas burner of the column.

Prevention of geyser malfunctions

In addition to troubleshooting, you need to know how to properly disassemble the gas column. These skills are essential for DIY maintenance. Why do you need to know not only the constituent elements, but also the sequence of actions when disassembling the column.

Periodic maintenance throughout the entire operational life of the gas water heater will contribute to correct operation.

Annual cleaning is recommended in the technical documentation by the manufacturer. After all, it is the lack of cleaning with prolonged use that can lead to all of the above problems.

Repair of heat exchangers for gas columns

One of the most severe cases of column damage is considered to be burnout, breakage, or through corrosion of a copper heat exchanger. In the first two cases, the repair is carried out only by replacing the part with a new one. In the case of perforating corrosion, thin, 02, -0.5 mm holes are formed on the walls of the heat exchanger through which water flows out of the circuit.

A defect, as a rule, is detected by intense soot formation, water leakage and a drop in pressure in the circuit when the valve is closed.

To repair the heat exchanger, you will need to remove it from the geyser mount. Next, the copper surface is cleaned of soot and scale deposits and subjected to a hydraulic test.

The easiest way is to identify the place of corrosion by pumping air or water under excessive pressure. For example, the outlet of the heat exchanger is muffled with a rubber stopper, and air pressure is supplied to the inlet by a hand pump. The heat exchanger of the gas column is immersed in a container with water and the location of the damage is determined.

You can repair the damage at home by soldering with copper-silver tin solder. The first is used to restore the hottest spots located close to the flame front. To seal with tin, the copper surface is etched with a solution of zinc in hydrochloric acid, heated with a burner and tinned with a massive piece of solder. For normal operation, the thickness of the tin patch should be at least 0.5-0.7 mm.

After the repair, the heat exchanger is checked twice more - using traditional air injection and holding under the working water pressure after installing the unit on the gas column. The pressure in the circuit must not drop for at least 15 minutes.

Junkers speakers

The Junkers brand is considered to be synonymous with quality and reliability all over the world. The speakers are distinguished by a well thought-out internal arrangement and design. Domestic consumers are offered water heaters of the following type:

- Semi-automatic - the company began to produce speakers back in 1968. The pilot burner is used during operation. Ignition is carried out using a piezoelectric element. The main burner turns on when the DHW tap is opened.

- Automatic - run on batteries or a hydrogenerator. The series includes simple Junkers gas water heaters with an open combustion chamber, as well as multifunctional models with modulated power. The capacity of the burner varies depending on the water pressure.

Only high quality materials are used in the internal structure of Junkers gas flow columns.All water heaters are subject to mandatory testing and certification.

More information on the technical characteristics of Junkers dispensers can be found in the following table:

| Specifications | Column model Junkers | |||||

| Power and flow of water | ||||||

| Max. rated heating power Pn (kW) | ||||||

| Min. rated heating power Pmin (kW) | ||||||

| Heat output (adjustment range) (kW) | ||||||

| Permissible gas supply pressure | ||||||

| Natural gas H G20 (mbar) | ||||||

| Liquid gas (butane / propane) G30 / G31 (mbar) | ||||||

| Gas consumption | ||||||

| Natural gas H G20 (m³ / h) | ||||||

| Liquid gas (butane / propane) G30 / G31 (kg / h) | ||||||

| Number of nozzles | ||||||

| Hot water | ||||||

| Max. admissible delivery head pw (bar) | ||||||

| Water volume switch in extreme right position | ||||||

| Temperature rise (° C) | ||||||

| Flow range (l / min) | ||||||

| Min. working pressure pwmin (bar) | ||||||

| Water volume switch in the extreme left position | ||||||

| Temperature rise (° C) | ||||||

| Flow range (l / min) | ||||||

| Flue gas characteristics | ||||||

| Required draft (mbar) | ||||||

| Flue gas flow mass (g / s) | ||||||

| Temperature (° C) | ||||||

In the labeling of the water heater, detailed information on the principle of operation and the internal structure is indicated. To understand the abbreviations, a table with decoding of designations will help:

- W - Gas water heater

- R - Power regulator

- 10 - Max. water consumption (l / min)

- –2 - Version 2

- P - Piezoelectric ignition

- B - Electronic ignition system with batteries (1.5 V)

- G - Electronic system of ignition from a hydrogenerator

- 23 - Number of designation of work on natural gas H

- 31 - Number of designation of work on liquefied gas

- S…. - Code of the country

Bosch gas water heater repair

Hot-water gas appliances manufactured by Bosch are distinguished by their compact size and enormous saturation of automation. The more components and mechanisms in the design, the more likely it is to break.

Bosch WR10 water heating systems are characterized by two types of breakdowns - arbitrary shutdown after a successful start and leakage of oil seals due to high water hardness.

Arbitrary shutdown can occur for three reasons:

- Drop in chimney draft;

- Contamination of the ignition electrode, as a result of which the automation does not recognize a very small ionization current and turns off the gas supply. The repair is reduced to the usual cleaning of the electrodes;

- Heat exchanger overheating sensor triggered.

The last case is the most relevant. The overheating sensor is a bimetallic plate with contacts. When a certain temperature is reached, the plate bends and opens the contacts.

Before recovery, it is necessary to check the operation of the sensor, for example, short-circuit the contacts directly with a paper clip or copper wire. If the gas water heater continues to work in normal mode, then you need to buy and replace the sensor. Severe overheating means that it will be necessary to adjust and check the gas flow regulator.

Gas water heater wick goes out - reasons

How does a gas column igniter work?

The igniter can work for some time after turning on the water, and it happens that it goes out immediately.

Let's deal with the reasons for equipment failure in these two cases. In general cases, the reasons for equipment failure are as follows:

- faulty thermocouple;

- the igniter is clogged with dust or debris;

- strong air currents knock down the flame;

- there is no draft in the chimney or it is insufficient;

- the traction control sensors are out of order;

- the contact connections of the sensor with the power supply are broken.

- A thermocouple in most cases leads to equipment failure. Technically, this unit is a safety device for the gas flow in case of force majeure in the operating column. If the thermocouple is worn out or burned out by prolonged exposure to flame, it will cause the wick to fade.

- The litter of the igniter does not necessarily occur to the eyeballs.With structurally small holes in the burner wick, a few large inclusions are enough to cause problems with heating the thermocouple to standard temperatures.

- Flame blowing problems occur with improperly adjusted column ventilation. But here it is important to pinpoint the cause without mistaking weak draft for air exchange problems.

Now let's look at the causes of failures depending on the duration of the igniter.

Why does the igniter go out immediately after switching on?

What to do if the igniter goes out immediately after switching on?

- The consumer has time to notice a small glimpse of the wick and that's it - the igniter immediately goes out. Moreover, it is impossible to start up the equipment again.

Interruptions in operation are caused by the failure of the gas supply mechanism - the servo motor / solenoid valve. Site cleaning is a temporary measure. Complete replacement of valves will solve the problem.

- If the wick is triggered and fades out after about a minute, it is possible to ascertain the activation of the security system "gas control". This is done to prevent gas leaks, the ingress of combustion products into the room, or rupture in the event of overheating of the equipment.

The reason lies, first of all, in an increase in the permissible temperature regime. In this case, the protective plates of the bimetallic control sensor are repelled from each other, turning off the gas supply. Due to this, the column in dangerous mode will not work for more than a minute or two.

The wick goes out after a short time of operation of the column

Why does the igniter go out after a while

- Poor or no cravings. It occurs due to a malfunction of the chimneys and the ingress of combustion products - carbon monoxide into the room. Control devices record dangerous leaks, a safety shutdown of the equipment is triggered, and the column is temporarily blocked.

- The equipment smokes. In most cases, the problem is typical for speakers that have been in use for a long time. The norm for gas equipment is annual maintenance. If you neglect this rule, soot accumulates on the gas burner, clogs the heat exchanger, leading to the ingress of carbon monoxide into the room.

- Overheating of the heat exchanger. There are individual technical conditions of use for each speaker. In most cases, the critical heating temperature is + 55 °. Exceeding the safe mode leads to increased evaporation of water and the accumulation of hot condensate. The steam builds up the pressure of the equipment, causing the exchanger tubes to break and break. To prevent this, the manufacturer completes the columns with a sensor for indicating the temperature in the heat exchanger.

- Poor water supply pressure, diaphragm wear. There are brands of gas boilers that are initially sensitive to this indicator. In this case, a "floating" flow, a faulty mixer or shower, low pressure in the heating systems will lead to an emergency shutdown of the igniter.