It is impractical to cut pipes with a hacksaw with an impressive amount of work, since it takes a lot of time. In addition, perfect accuracy is unlikely to be achieved with such a tool. To speed up the process of dividing a tubular product into individual elements, a pipe cutter for steel pipes will help, the use of which guarantees good quality of the edges, and, consequently, the reliability of the tightness of the joints.

Steel pipe cutter with damaged handle.

Distinctive features of the equipment

Modern pipe cutting devices are classified according to the following parameters:

- Tool dimensions and total weight. These characteristics are of key importance if the separation is carried out directly at the pipe joints.

- Type of drive. Based on the tasks set, you can use both manual and mechanical pipe cutters. To work with tubular products of large diameters, electrical devices are predominantly used.

- Separation technology. With the help of some tools, cutting of steel is carried out by means of roller knives, others are equipped with a chain, and still others are cutting machines.

- The material from which the working parts of the cutting elements are made. The hardness of the knife or chain must in any case be higher than the hardness of the steel being cut.

- Maximum permissible operational capabilities, determined by the size of the pipe section.

- Technological purpose of the equipment. While some devices are designed exclusively for work with plastic and metal-plastic products, others can be used for cutting non-ferrous metals and alloys.

Super-Ego, up to 1.1 / 4. Dimensions - 280x120x40mm, weight - 1.1 kg.

When choosing a manual pipe cutter for steel pipes, experts also recommend taking into account its brand, since the technical characteristics of models from little-known manufacturers often do not correspond to the parameters stated in the description.

Manual roller pipe cutter

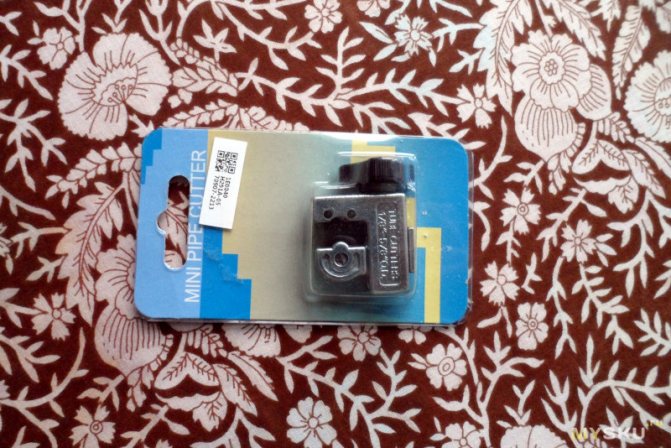

Hello everyone. In today's review, we will focus on a handheld roller pipe cutter that I purchased on eBay at the request of a friend. Most often, when we are faced with the question of separating a metal or plastic tube, we go for a hacksaw for metal. But there are times when this option is unacceptable. My friend is engaged in the repair and installation of small cooling systems (for example, repairing air conditioners in cars, systems installed on a PC, and so on). In such a limited space, it is unrealistic to use a hacksaw already due to the fact that it is simply impossible to crawl with it to the desired tube. In addition, when using the blade during cutting, chips / sawdust are formed, the ingress of which into the system is fraught with the most sad consequences. It was for these two reasons that he needed a manual pipe cutter. And since they are more expensive with us, it was decided to purchase this tool online.

It took about a month for the parcel to get from China to Belarus, after which it was safely received at the local post office. The package was sent with a full track, so all information about the package's travel is available at this link.

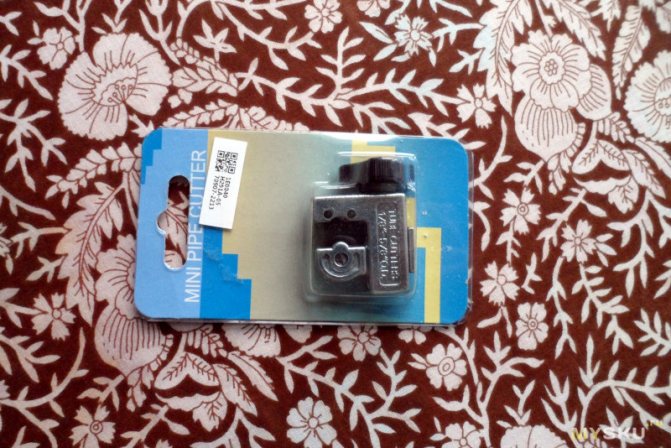

The pipe cutter is delivered in its original packaging, which is a plastic blister with a cardboard insert.

There is no information on the package. All information is located directly on the instrument.Information on the compatible diameters of the tubes to be cut is located directly on the tool. They are here within 1/8 ″ -5/8 ″ (if in our opinion, then 3-15 millimeters). Yes, not a lot, it is not suitable for replacing water pipes, but for the purposes facing a friend, the very thing

The device of the roller is simply disgraceful - it is a kind of miniature clamp on the stationary part of which two rollers are mounted, and on the movable part there is a hard-alloy disc with a pointed edge. Both rollers and the cut-off disc rotate without problems, nothing sticks anywhere, does not "bite". Moving the cutting disc is carried out by rotating the plastic wing, which is the weakest element of the structure - in case of excessive load, it will break first. But given the fact that this pipe cutter is not intended for large diameters, I want to believe that nothing like this will happen.

In general, the quality of the instrument's workmanship does not cause any complaints, everything is more or less decent. But metal processing leaves much to be desired, and this is immediately evident - just look at the back of the tool. Apparently in China they are not familiar with finishing

There is nothing more interesting in the appearance and structure of this tool, which means you can proceed to checking its performance.

A bent tube with a diameter of about 10 mm was used as a test tube to be cut.

The tube is not one-piece, it has a cut along its entire length, which somewhat complicated the task, since when the pipe cutter approached the cut, it shrank slightly. Unfortunately, there was no other at hand.

The principle of operation of the pipe cutter is simple - we put it on the tube, adjust the roller so that it starts to cut a little into the tube. After making a few turns of the instrument around the tube, we tighten the disc a little. We repeat these steps until the tube is completely cut. This is what the cut looks like at the very beginning.

And this is how the already cut pipe looks like:

As you can see, there were no problems with cutting it. It took quite a bit of time, and even less effort. Due to its compact size, the pipe cutter turned out to be quite convenient to use. no traces or damage remained on it after the test check (except for a shiny strip around the circumference of the cutting wheel).

In conclusion, I want to say that the pipe cutter has shown itself to be a workable tool that copes with its task without any problems. The comrade was 100% satisfied with the purchase. As far as I know, from the moment it was received, this tool “won” about a dozen tubes of different diameters and its condition has not changed during its operation.

So, to summarize, this hand held pipe cutter is a cheap working tool with a narrow range of applications. But if you need something like that, then this option may well be suitable.

That's all. Thank you for your attention and your time.

Structural differences of pipe cutters

By design, tubular cutting equipment is divided into three main categories:

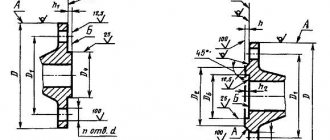

Pipe cutter for stainless steel.

- the roller pipe cutter is originally designed to work with steel pipes. Consisting of one to three cutting elements, the mechanism also includes guide rollers. For pipes with a diameter of up to 100 mm, as a rule, three-roller devices are used. A tool equipped with one roller is suitable for cutting a product with a cross section of less than 50 mm.

NEO 19-83 mm. Alloy steel cutters. Weight - 0.8 kg, dimensions - 140x360x30 mm. Country of origin - Poland.

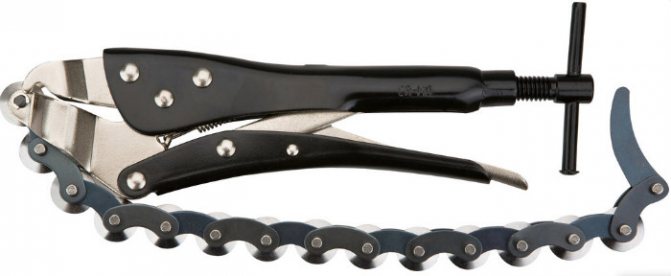

- The chain cutter is less in demand when working with steel pipes, since its main purpose is to cut concrete, ceramic and other particularly fragile materials.However, it copes quite well with single-layer tubular products made of thin steel, up to 30 mm in diameter. The device has a fairly simple design, which includes a tensioning mechanism and several chains. In addition, such equipment assumes the presence of pivoting levers;

- a pipe cutter is mainly used to create individual elements from plastic pipes with a maximum allowable section of 100 mm. The design of the tool, which externally represents a steel clip, contains extra strong discs that can be adjusted to a specific diameter. It is through these parts that the pipe is cut.

RIDGID 472-S 83165 (8-12) Pipe Clamp Pipe Cutter.

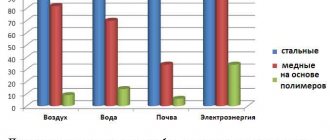

Features of working with copper pipes

Due to its structure and properties, copper pipelines are used in heating, water supply, air conditioning and gas transportation systems. They possess:

- flexibility;

- strength;

- corrosion resistance;

- durability;

- the ability to eliminate bacteria.

The main feature of working with copper pipes is the observance of precautions to maintain the round shape of the products:

- Excessive force from the installer can cause the thin structure to buckle or break.

- When transporting coils with copper pipes, they carefully carry out loading and unloading operations and protect the material from the possible fall of heavy objects.

- When working with copper lines, considerable attention is paid to connecting fittings, installation methods and compliance with diameters. Given the ductility of pipes, they can be connected without the use of couplings using the socket method.

We recommend that you familiarize yourself with: How to build a columnar foundation from asbestos pipes with your own hands

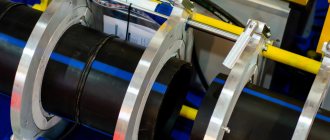

Manual and electrical cutting devices

Compactness and ease of use are two main criteria for hand-held tools, which are excellent for relatively small volumes. It is enough to fix such a pipe cutter for steel pipes on the product, and then perform the separation by turning the handle.

To work with pipes of large diameter, which need to be processed in significant quantities, it is advisable to use an electric pipe cutter. This allows you to significantly reduce the time of work. In the production of such equipment, materials are usually used that are characterized by increased wear resistance.

There are also hydraulic pipe cutters for steel pipes, powered by liquid pressure, and pneumatic devices equipped with several different types of cutters, designed for both plastics and metal cutting.

How to choose a pipe cutting tool

To select a device for performing work, the conditions, complexity and requirements for the quality of the end surface of the cut workpiece are compared.

If it is necessary to perform work in a confined space or at a small distance from the wall, it will be advisable to use a chain pipe cutter. With frequent use of a tool for installing copper pipelines, electrical devices are chosen.

When using thick-walled pipes of refrigeration or other equipment, preference is given to a tool with several cutting rollers.

An important selection criterion is the size of the pipelines to be laid. Some modifications of tools cannot cut very short workpieces due to technological features.

It is important! Special attention is paid to the material of the cutter wheel and handle. For copper pipes, a high strength steel handle and titanium-doped cutting edges are the right solution.

The installer's experience also influences the choice.In the absence of experience, vibration generated when cutting pipes will have a negative impact on the quality of the end face. In such situations, hand tools are preferred.