Types of heating systems

Modern engineering systems, intended for heating country houses, can be:

- One-pipe. These are structurally simple and fairly common systems. Their advantages include low cost and ease of assembly. The disadvantages are uneven heating of rooms located at an unequal distance from the boiler.

- Two-pipe. Systems of this type are excellent for heating large houses and cottages. Their assembly is more expensive than installing one-pipe systems. However, heating the premises with their use can be more efficient.

Also for heating houses systems can be used:

- With natural circulation of the coolant. In this case, water moves along the highways due to pressure drops at the inlet and outlet by gravity. This happens because its density can vary quite a lot depending on the heating temperature.

- Forced circulation. Systems of this type are somewhat more complex to assemble. However, heating radiators included in their design warm up much more evenly than in one-pipe designs. In this case, the movement of the coolant along the highways occurs as a result of the operation of the circulation pump.

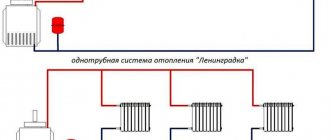

One-pipe heating system

Such systems are usually assembled only in one-story buildings small area. In this case, one line is included in the design, which is simultaneously both supply and return. It can be laid under the floor or directly along the wall. Radiators in such systems are installed on a bypass with a shut-off valve. Such a scheme in the future facilitates their repair or replacement, and also allows you to regulate the air temperature in different rooms. The pipes themselves are installed with a slope of at least 0.005 m per linear meter towards the water flow.

Two-pipe heating systems

Equipment of this type is, as already mentioned, very convenient to operate, but also more difficult to install. There are only two types of two-pipe systems: vertical and horizontal. The first type is usually used in single-story houses. For two- and three-story cottages, a vertical two-pipe heating system is more suitable. In this case, two risers are installed: supply and return. The contours of each floor are connected to them.

Recommendations and Tips

In conclusion, I would like to give a few recommendations that may be useful.

- The installation of piping systems should be carried out taking into account the fact that tension fitting connections must not be laid in the floor and walls. If this happens, then a small free space must be left to place the connections.

- Radiators should be within 70% of the window width. Panel radiators will be able to fulfill this condition. Changing the thickness of the device allows you to change its overall dimensions, and choosing the best option is not difficult

- The installation of smoke exhaust systems should not pass through rooms with a long stay of people. With an external chimney, it should be borne in mind that the distance from it to the windows of living quarters must be at least 800 mm

- When using non-freezing antifreeze liquids as a heat carrier, sectional radiators must not be installed. After a certain time, nipple connections may leak

- The use of a room thermostat with an on-timer allows you to save up to 40% of energy consumed for heating

There is still a huge number of subtleties and nuances. If you do not have experience, knowledge, working skills, then it is better to entrust the installation of heating systems to a trusted Contractor. The usual cost of work is estimated at 30-40% of the price of equipment and materials.

The best option is to conclude an Agreement with a company that will carry out all the turnkey work - develop a scheme or complete a project, complete the equipment and install it. Practice shows that the installation of turnkey heating systems helps the Customer to significantly save money. It is necessary to pay attention to the fact that the Warranty is provided for all materials and works.

Read other articles on this topic

| Heating wiring for a two-story house | Gas consumption for heating a private house - consumption calculation |

| Collector heating system of a private house | Installation of a heating system in a private house |

| How to save on heating a country house | Heating a private house with electricity |

| Heating a private house from metal-plastic pipes | Autonomous heating of a private house |

| Heating system of a private house with natural circulation | Features of heating a country house with electricity |

| Heating options for a frame house | How to heat your home without gas |

| Heating and water supply of a country house: a description of the installation technology | Private house heating project |

| The best heating for a private house | About heating schemes for a private house with a gas boiler |

| Heating a private house made of polypropylene with your own hands | Heating a house with liquefied gas |

| Heating scheme for a two-story house | Heating wiring diagrams from a boiler in a private house |

| How to make heating a private house | Water heating in a private house |

Services on this subject

| Heating design | Turnkey solid fuel heating |

| Turnkey gas heating | Turnkey heating |

| Heating in a turnkey wooden house | Turnkey water heat-insulated floor |

| Installation of a water heated floor | Heating a two-story house |

| Heating installation in a cottage | Heating a country house: options and prices |

| Heating installation | Heating installation in a private house |

| Installation of engineering systems for water supply and heating | Diesel heating of a country house |

| Turnkey autonomous heating | Air heating of a country house |

| Prices for installation of heating in a private house | Design and installation of heating systems |

| Water heating in a private house | Electric heating of a country house: options and prices |

| Heating in a townhouse | Gas heating design |

| Heating design cost | Private house heating calculator |

| Installation of a water-heated floor in a private house | Price for installation of a water-heated floor |

| Installation of a water-heated floor on a wooden floor |

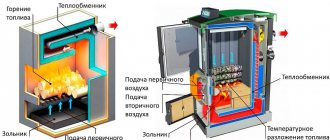

Types of heating boilers

Owners who decide to assemble a heating system for their home should first of all decide on what equipment will be used for this. And first of all, of course, you need to choose a suitable boiler... There are several varieties of such units:

- Gas. This is the most common type of equipment used in most cases. Connecting such a boiler is quite expensive. However, this type of equipment is quite economical in operation.

- Electrical. Equipment of this type costs the same as its installation, it is quite cheap. However, its operation costs the owners of the house much more expensive than gas units.

- Liquid fuel. Such boilers operate on diesel fuel. The owners of the house do not have to spend too much money on the operation of such equipment. However, it is not very convenient to use. After all, the fuel needs to be stored somewhere, and it is obligatory in compliance with all the required fire safety standards.

- Solid fuel. This is the cheapest type of boilers to operate. Such equipment works on wood, coal, briquettes, etc. However, using such boilers is even more inconvenient than liquid fuel ones. Firewood or coal has to be manually loaded from time to time.

Electric boilers are usually used to heat houses only where there are no gas mains. Liquid and solid fuel - in remote areas in the absence of nearby gas pipelines and power lines.

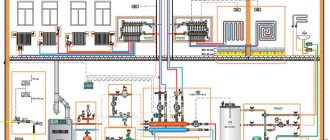

Heating system installation sequence technology

When installing heating systems, it must be ensured:

accurate performance of work in accordance with the project and the instructions of SNiP; density of connections, strength of fasteners of system elements; verticality of risers; compliance with the slopes of the distribution and main sections; absence of curvature and kinks in straight sections of pipelines; serviceable operation of shut-off and control valves, safety devices and instrumentation; the possibility of removing air, emptying the system and filling it with water; reliable fastening of equipment and guards of their rotating parts.

When installing CO, the following sequence of work is applied:

- unloading, picking, delivery of pipe and heating units to the place of installation;

- installation of trunk pipelines;

- installation of heating devices;

- installation of risers and connections;

- system testing.

The installation of main pipelines is carried out after the layout of the mounting assemblies on the supports and hanging them to the building structures by assembling the assemblies on flax and red lead or joining the assemblies with their subsequent welding. Then the lines are verified and fixed on supports and hangers.

After assembling the main pipelines, risers and branches are connected to them to the equipment. First, the heating units are installed in place and verified by level and plumb line, then the heating units are connected using an interfloor insert. Heaters are connected to the interfloor inserts by means of a thread or by welding.

Varieties of radiators

For heating systems of country houses, cast iron, aluminum or bimetallic batteries can be used. The latter variety is the most popular. Cast iron radiators are quite reliable and efficient. However, they do not look particularly aesthetically pleasing. In addition, they are too heavy, and therefore inconvenient in installation. Aluminum batteries look modern and easy to install. But they have one very serious drawback. With prolonged contact with the air dissolved in the coolant, they begin to corrode, as a result of which they quickly fail.

Bimetallic radiators are devoid of all these disadvantages. Their aluminum body is protected by steel from the inside. And therefore, its contact with the coolant does not occur. Consequently, such radiators can be considered much more reliable than aluminum ones. Bimetallic batteries weigh a little, but they look very modern and aesthetically pleasing.

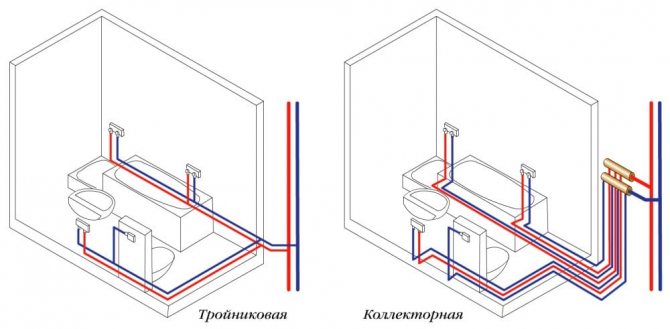

Wiring

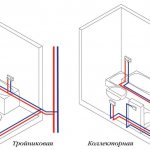

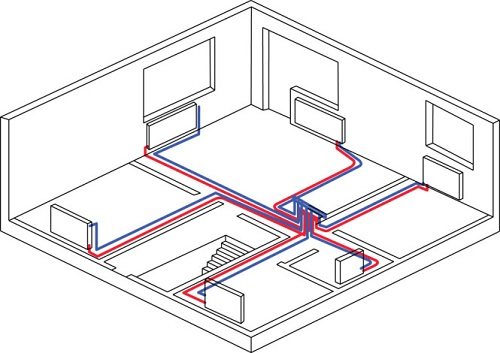

Heating and water supply can be divorced in two fundamentally different ways:

- Tee (series) wiring implies the connection of all devices (heating or plumbing) to a common supply or bottling using tee connections;

- With collector wiring, each device is equipped with its own connection. All devices are connected to a common manifold-manifold (or a pair of collectors - hot water supply and cold water supply or heating supply and return).

Two water distribution schemes - serial and collector

Benefits of Serial Wiring:

- Low material consumption, which means a decrease in the estimate for the installation of heating and water supply systems;

- Possibility of open laying of engineering systems;

Open serial wiring

- Possibility of installing pipelines following from the open laying after finishing the premises.

Advantages of collector wiring:

- In the case of water supply, a constant water pressure on an arbitrary plumbing fixture, regardless of the water flow through the rest of the draw-off points. Simply put - if you turn on the cold water tap in the kitchen, the battle cry of the scalded wife will not be heard from the shower;

- In the case of heating - the same coolant temperature on all radiators. With sequential wiring, the temperatures of the supply and return batteries differ by 20-25 ° С;

- Possibility of switching off and adjusting devices from one point - a manifold cabinet.

Manifold cabinet for heating

Which pipes to choose

Heating mains can be assembled by hand using pipes of the following types:

- Galvanized steel. This type of pipe has such advantages as durability and ease of maintenance. Galvanized lines do not rust and do not need to be painted. The disadvantages of such pipes are the high cost and the impossibility of the device when they are used in the heating system of a large number of joints.

- Conventional steel. Such pipes are inexpensive, but not very convenient to install and fail quite quickly due to corrosion.

- Polypropylene pipes. The material of this variety is easy to install and inexpensive. The disadvantages of polypropylene include the ability to delaminate due to uneven heating of the inner and outer surfaces. Therefore, for heating systems, it is allowed to use only pipes made of reinforced material of this type.

- Crosslinked polyethylene. Pipes made of this material tolerate the temperature difference outside and inside much better than polypropylene ones. However, they also have a rather serious drawback. It is impossible to mount them without using special equipment.

- Metal-plastic. Pipes of this type are most often used for the installation of heating systems. They are completely devoid of any shortcomings. Their advantages include, first of all, strength, elasticity, the ability to withstand any temperature difference and ease of installation.

For systems with natural circulation of the coolant, select pipes as large as possible... If this figure is very large (about 8-10 cm), you may not even include radiators in the system. Their role will be taken over by the highways themselves. But, of course, such a scheme can be used only in those rooms where aesthetics is not attached much importance, or in very small houses.

Boiler equipment in the house

Opening the topic of how to make a heating system with your own hands, it is also worth considering options for heating a house with boiler systems. But since the heating of a house is different and the arrangement of each involves its own methods and consists in different aspects, it is also worth keeping in mind the heating of the stove type.

This type is well suited for a one-story house. But the kiln method is not as widespread as it used to be. This technique assumes the presence of large reserves of fuel, and if the house has several rooms, then the heating will not occur evenly.

Gas boilers

Returning to the boilers, several types must be distinguished. In the first place here are gas boilers, which are in great demand and are distinguished by their incredible convenience and their simplicity. The installation technology of these cats is the most elementary. But, since we are talking about your own house, and some settlements, villages or villages do not always have gas equipment, the use of a gas boiler may be limited to this.

Diesel boilers

Next in popularity are diesel boilers. They run on liquid fuel and are configured using a special system that can be controlled as the owner of the house needs. The advantages of such boilers are hygiene and ease of use.Also, liquid fuel does not take up much space during storage. The diesel boiler works autonomously and allows you to heat the premises for weeks. The only drawback is the smell when the product burns.

Electric boilers

Electric boilers will be convenient for lovers of cleanliness and compactness. They are convenient and simple enough. Such boilers are in demand among home owners, but they are expensive. Just like diesel boilers, they have an autonomous function. Solid fuel boilers have the highest efficiency.

Combined boilers

If you are not sure about any one type of fuel, it is possible to install a combination boiler. This method guarantees uninterrupted boiler operation. However, do not forget that the choice primarily depends on the energy carrier and pipes. In this regard, boilers are quite convenient to use, transport and save. In addition, thanks to boiler equipment, heat in rooms of any size will last longer, and the heating system in a two-story house with your own hands is more convenient.

When heating a residential building, a do-it-yourself closed heating system can come in handy. This system includes boilers. But at the same time, the order of work will be as follows: installation, piping, hanging heating registers. This sequence is essential in order not to make mistakes. The system has minimal costs and due to the uniform circulation of the pump, the room will warm up faster.

Installation of a gas heating boiler

The assembly of this type of heating system is as follows:

- The heating boiler is installed in the place designated for it (or hung on the wall, depending on the model).

- The chimney is being installed. You can also make it with your own hands - bend it out of tin or use old drainpipes. You can also purchase a ready-made version of the chimney in a specialized store.

- The boiler is connected to the gas main. It is forbidden to do this work independently according to the standards. The owners of the house will have to call specialists.

Selecting the type of heating system

Heating home equipment begins with the choice of the type of heating with reference to the main factor - the availability of a certain type of fuel or energy converted into heat. The factor of efficiency when choosing a heating method takes the second place after efficiency.

Let's start with the least expensive method - water heating with a radiator system connected to a heating main. This type of heating is as safe as possible and eliminates the need to purchase / install a heating boiler with automation, narrowing the scope of work to the installation of the heating circuit and connecting it to the heating plant after agreement with the organization operating the heating network. But with the relative ease of installation in such heating, there is a complete dependence on the characteristics of the coolant, the performance of the heating plant and the human factor associated with the personnel serving the heating network.

If there is no heating plant nearby, but the area is gasified, then it is advisable to consider the possibility of installing a water heating boiler using natural gas. The relative cheapness of gas fuel is accompanied, in addition to the need to purchase a gas boiler, the inevitability of a chimney, ventilation and, possibly, even a separate boiler room. In addition, gas is a highly hazardous fuel, so the system needs a high level of operational control.

In a situation where they prefer not to get involved with gas, or there is simply no gas nearby, a water heating system with an electric heating boiler would be a reasonable choice.This method of heating at first scares the cost of electricity, but then pleases with hidden efficiency - the absence of the need for a boiler room, chimney with ventilation, cleaning this communication and constant fears of gas fuel leakage. In addition, boilers for electricity are produced in different types, with and without heating elements, so in this segment there is room for maneuver when choosing.

Another option for solving the issue of heating housing can be a liquid fuel boiler. The most common heating systems with liquid fuel units that consume diesel fuel. This type of fuel, like electricity, is not cheap today, and if we take into account the associated costs for the chimney and ventilation, a diesel boiler is economical only if it is possible to purchase this fuel on a preferential basis.

If the homeowner is a supporter of traditional fuels, for example, firewood, which are also very cheap in this region, then the rational solution would be to install a solid fuel boiler of mine design using the pyrolysis process - separate long burning. For such owners, the preparation of firewood and cleaning the chimney is a familiar occupation, compensated by the environmental friendliness and cheapness of fuel.

There are other heating methods - underfloor heating, baseboard heaters, infrared heating devices, which are successfully used in a small house or, for example, a two-room apartment, but their operation is based on the same electricity or gas.

Having made a choice in favor of one or another heating method, they assess their capabilities in terms of self-installation and, depending on the results of the assessment, proceed to the execution or the next stage - the design of the heating system.

Installation of pipes and radiators

After the boiler is installed, you can start hanging radiators... They are usually fixed under the windows. At the same time, they try to make sure that the distance from them to the floor is at least 7 cm, to the windowsill - 8 cm. There should be at least 3 cm of free space between the wall and the radiator. Fix the radiators to the wall with brackets.

Do-it-yourself piping should be done taking into account the chosen method of connecting the batteries. When installing radiators in country houses, either their diagonal connection or the bottom one is most often used. In the first case, the return pipe is connected to the lower branch pipe of the battery, and the supply pipe is connected to the upper one from the opposite side. In the second, both pipes are connected from below. The actual insertion operation itself produced according to the instructionsattached to the selected type of radiator. A Mayevsky crane or some other similar device is mandatory installed on each battery.

Brazing pipes

Learning to assemble a polypropylene pipeline.

Instructions on how to properly mount a polypropylene heating system are quite simple. But we need a set of tools for welding plastic pipes, which can also be rented in the city of Miass.

The kit includes a soldering iron, a pipe cutter, teflon nozzles and a beveller.

So let's get started:

- We cut the pipe according to the drawing using a pipe cutter;

We carry out cutting.

- At the ends of the pipe, it is necessary to chamfer with an inclination of 15 degrees to a depth of 2 - 3 mm. It is better to do this with a bevelling tool;

We clean and chamfer.

- Install the soldering iron on the stand and set the temperature to 260 degrees... Then we put the fitting on the mandrel, and insert the end of the pipe into the sleeve. We press on both sides until the parts rest against the sides;

We put the parts on the teflon tips of the soldering iron.

- Heating lasts about five seconds, the instructions for the soldering iron should have a heating circuit depending on the diameter... After heating, we remove the parts and connect until the pipe is completely inserted into the coupling;

We connect the details.

- We hold the parts motionless, do not rotate. It is enough to withstand them for about 30 seconds until they fully set;

We are waiting for the material to freeze.

- We collect individual sections on the table, then we connect them by weight at the entrance to the wall and near the radiators.

We carry out soldering by weight.

Important! It is better to first practice on the scraps in order to gain some dexterity and confidence in the actions, since the connections are non-separable.

At the end of the pipes, they are connected to the boiler, a circulation pump is installed on the return. Then the system is pressurized with a special pump. You can read more about this in the articles on our website.

How to include a circulation pump in the circuit

This structural element can be installed directly at the stage of assembling the system or cut into an existing structure with a natural flow of water. Recently, pumps have appeared on the market, which can be installed both on the return and on the supply pipe. However, they are quite expensive. Therefore, most of the owners of country houses prefer acquire less hardy models old model. Since the latter do not tolerate elevated temperatures too well, they are installed strictly on a return pipe on a bypass with three taps. At the same time, in front of the pump itself, a filter for cleaning the coolant is necessarily mounted.

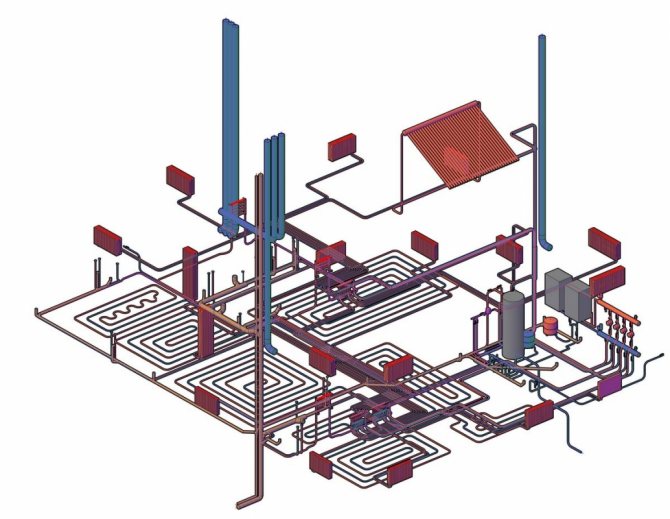

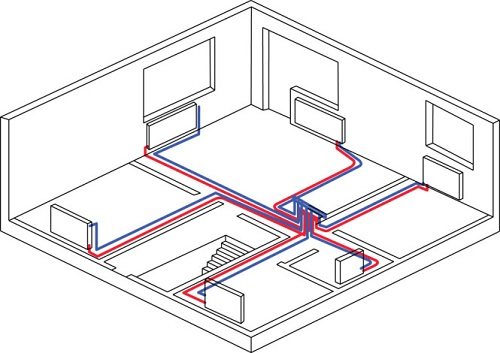

Vertical and horizontal schemes

Horizontal and vertical schemes differ in the arrangement of pipes that connect heating devices to the heating system.

- Horizontal two-pipe system - more suitable for long single-storey buildings. In this case, the most reasonable option is to connect heating devices to a pipeline laid horizontally. Such a scheme is convenient for arranging a panel-frame house or for a house without walls, where the risers are best placed in the corridor or on the staircase.

- Vertical two-pipe system - differs in that devices in it are connected to a vertical riser. The installation of such a scheme will be more expensive, but in operation it is more profitable, since there will be no problems with air congestion. This scheme is suitable for a multi-storey building, because each floor is connected to the riser separately.

Horizontal two-pipe heating system

Both of these schemes are distinguished by good hydraulic and thermal stability. Only for the horizontal scheme, balancing of the horizontal loops will be necessary, and for the vertical one, balancing of the vertical risers.