- Purpose of the heating project

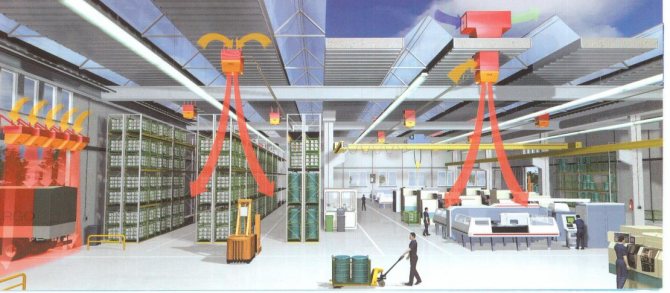

- Heating of large rooms

- Heating types

- Design and installation of heating in the shopping center

Send a quick request Most often, in practice, in shopping malls they use air heating, which is provided using fan coil units (indoor units of the air conditioning system), rooftops (for large rooms without partitions), fan heaters (for rooms with low design requirements). Traditional hot water heating based on radiators in shopping malls is quite rare. This is due to the fact that radiators can interfere with the installation of shelving or be completely closed. That reduces their heat transfer or simply won't fit into the design of the project.

INTECH-Klimat is ready to implement professional solutions for climatic and other engineering equipment. We will perform a full cycle of turnkey works: design, selection, delivery, installation and maintenance. Call now: +7

... Submit your application

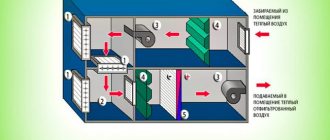

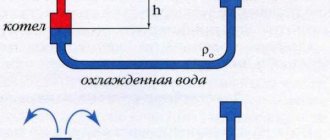

Now more and more often you can find shopping center heating project using re-application of heat. One of the methods is based on typical construction solutions, because almost all shopping centers have a spacious hall or an escalator lift. The design of a heating system with re-use of heat is based on the laws of physics, or rather, on the fact that all heat rises upward. Warm air collects and accumulates under the ceiling and escapes through the roof. Installation of heating in shopping malls involves the forced selection of heat energy from the specified zone and its supply to consumers in the lower zone.

An equally effective method that a heating and heat conservation design firm can lay down is the installation of air-thermal curtains over the exits to the street. Thus, cold air masses are cut off from the outside, which saves a significant amount of energy. This solution is very effective in shopping centers, where the doors are opened quite often.

Organization of thermal protection of the house

In places where heating will be done in the basement of a private house, it is necessary to insulate the outer walls, especially parts that will be in direct contact with the ground. This will help keep the interior warm and prevent condensation from forming.

In basements without heating, insulation with heat-shielding materials is made, as for a heated one, only additional layers can be added in the ceiling of the room in addition to prevent the penetration of cold into the upper floors.

With external thermal insulation, the basement gains the following benefits:

- There are no cold bridges through which the wind and frosty air enters the room;

- When condensation forms, it does not have time to inflict a destructive effect on materials and the room;

- The usable space inside the basement does not get smaller;

- It is convenient to inspect the structures, which allows you to notice in time their damage by fungus or mold, as well as defects due to harm from insects and rodents.

Among the shortcomings, it should be noted:

- It is necessary to protect the layers of thermal insulation from damage to the mechanical properties for the period of the entire use of the house, at the cost of protective devices significantly higher than the layers of the thermal insulation material themselves;

- It is difficult to protect against damage from the actions of insects, pest control is done with poisons and other toxic substances, which is not always applicable in a residential building;

- When facing with bricks, cold penetration is possible, which will reduce the degree of heat in the room.

Even during the design of the structure, protective work is planned against the following factors:

- The impact of groundwater, which, when it enters the basement, is difficult to dry, especially in terms of the enclosing structures;

- Moisture in the concrete mix during pouring for a long time enters the room, imparting dampness and a musty smell;

- Capillary rise of water from different sources through capillaries in the materials from which the basement was built is possible;

- The air of the room also forms moisture through condensation, the inner layer of thermal insulation is not able to ensure absolute tightness, therefore condensation can appear on the walls of the basement. It is also formed from gases from the soil, which can penetrate the entire perimeter of the basement;

- For internal insulation of a room, materials are often used, the level of water penetration of which is quite high, and when wet, their characteristics decrease. Then it is necessary to protect them with individual waterproofing works;

- Internal thermal insulation layers make it difficult to drain the basement. Moisture from soil, concrete and capillary water from base materials is very difficult to remove and requires long drying. It is required to make high-quality waterproofing;

- Walls that are below ground level are cold, and the warm and humid air of the basement somehow affects them from the inside, which leads to the formation of moisture with the subsequent destruction of materials.

When equipping a structure that protects against damage, additional layers of thermal protection can be made, both outside and inside. But they have the same disadvantages as the base, only they increase the estimate significantly.

Advantages and disadvantages of electric heaters

Many people cannot get enough of infrared heaters due to their striking advantages:

- ideal for work in dusty and dirty rooms, as well as for buildings with an increased level of fire hazard;

- the possibility of using not only as a general and partial heating system, but also as special equipment for drying;

- a spot heater is used in paint and varnish industries, for heating steel before processing, for arranging an anti-icing floor system;

- electric heaters are actively used in educational and medical institutions.

We recommend: How to install an infrared ceiling heating?

The downside is the high price for electricity. You can slightly reduce heating costs by installing industrial temperature sensors.

Payment for heating the rented basement

The amount indicated is determined on the basis of an invoice issued by the landlord with copies of utility bills attached. When using the second method, the variable part, i.e. the cost of utilities can change every month depending on changes in tariffs or the amount of services consumed, which excludes economic losses for both the lessor and the tenant. At the same time, the provisions of clause 3 of Art. 614 of the Civil Code of the Russian Federation on the inadmissibility of revising the rent more often than once a year are not violated (for additional information, see clause 11 of the Information Letter of the Presidium of the Supreme Arbitration Court of the Russian Federation of January 11, 2002 N 66). 33.1.2.

Heating selection according to the characteristics of the room

Before you do the heating of the workshop with your own hands, you need to find out several important characteristics. First of all, the optimal temperature regime in the room. The choice of the heating system directly depends on this.

When drawing up a heating scheme for a carpentry shop or other production areas, the following parameters must be taken into account:

- Ceiling area and height. If the distance from the floor to the roof is more than 3 meters, then convection (water, air) systems will be ineffective. This is due to the large volume of the room;

- Thermal insulation of walls and roofs.The heat loss of the building is the first thing to consider when choosing. The heating system for the workshop must be not only efficient, but also economical. In this case, it is best to use zoned heat sources. They will maintain a comfortable temperature level in a certain area of the room;

- Technological requirements for the optimum temperature in the workshop. For example, the heating of a woodworking workshop must keep the air heating at a constant level. Otherwise, it will affect the quality of the product. If the raw material is metal, then a comfortable temperature is needed only for workers.

To conduct this analysis, you will need to study the advantages and disadvantages of each type of heating. Let's consider the most efficient heating of a production hall, which differs depending on the circuit and the components used.

Convection heating system registers, radiators or convectors

Heating devices in such a system are radiators, convectors or registers made of smooth steel pipes.

Advantages: the ability to create an electrically independent heating system; relatively low price of equipment and materials.

Disadvantages: extremely low efficiency of the system due to the fact that warm air from the registers immediately rises up, and not down, and leaves the working area; heating equipment takes up a lot of space on the surfaces of walls and floors, thus, the usable area of the room is reduced and used irrationally; high system inertia (large volume of heated water in pipes); the location of the heating devices at the bottom can lead to their accidental damage in the course of economic activity; with poorly conducted commissioning, the system is poorly regulated; extremely low aesthetics of the register system, which does not meet modern requirements; the possibility of injury and burns in direct contact with the register surface.

Considering all the above facts, we can conclude that radiators or registers are advisable to be used only for heating low-rise rooms (with ceilings up to 3 m high). Otherwise, the running costs will be significant.

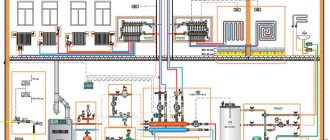

Air heating system using stationary gas air heaters

Air heating using gas air heaters is carried out by means of air (recirculation and / or supply air). It is fed into the unit with the help of a fan, after which it is heated and supplied to the room either directly or through a duct system, passing around the combustion chamber and through a heat exchanger, and the combustion products are removed through the chimney.

Advantages: the ability to use relatively inexpensive natural gas; the air duct system allows for the highest quality air mixing in order to reduce the temperature gradient and deliver it to the desired area; the heating, ventilation and air conditioning system based on indirect gas air heaters can also be decentralized (from the boiler room); the possibility of combining heating, ventilation and air conditioning in one system, due to which it is possible to achieve low metal consumption; greater efficiency and economy due to the absence of an intermediate heat carrier - water, which excludes the possibility of "defrosting" and leakage; low inertia of the system (air heating occurs in 20–40 minutes) and, as a result, a rapid change in temperature during the day; the possibility of placement inside the heated volume without preparing a separate room (boiler room); does not burn oxygen in the room; there are no attachments in the heated rooms; no harmful and toxic emissions in the premises; no heat transfer pipelines or additional cable systems.

Disadvantages: in the case of using main natural gas, heating will require a complex and branched gas supply system, which is extremely expensive both in installation and in design.

Workshop air heating

Fierce competition between manufacturers of a particular type of product forces the owners of industrial facilities to reduce the cost of their products by maintaining the optimal level of costs for the production process and organization of product sales.

The problem of choosing the most economical option for heating production areas plays an important role in reducing costs.

Air heating of warehouse, industrial and utility premises is one of the most effective and cost-effective options for a heating system, allowing you to maintain the required temperature throughout the entire operating cycle.

In this article, we will consider the features of the design, installation and operation of air heating of industrial premises of various profiles (warehouse, workshop, etc.).

Composition and principle of action

Air heating is a heat generator or a water heater that heats the air, and a system of branched air ducts designed to transport air flows to the heated areas of a workshop or warehouse.

Inside industrial premises, heated air is distributed due to the operation of a fan or distribution heads, directing the air flows in the required direction.

Industrial air heating can be presented in the form of a mobile option for heating local areas of the workshop - portable heat guns that successfully perform the task of operational heating of certain areas.

Air recirculation additionally solves the issues of compliance of air parameters in the serviced or working area of industrial premises with sanitary and hygienic requirements and standards.

Advantages and disadvantages

Air heating of industrial and warehouse premises has a number of competitive advantages over other schemes of the heating system:

- High efficiency (up to 93%), no intermediate links (pipes, radiators, etc.).

- Maintaining a constant level of microclimate inside industrial premises due to the possibility of integrating climate and heating systems.

- Small inertia, allowing in a short period of time to warm up the premises to the required level.

- Significant savings in financial resources and reduction in production costs.

The obvious advantages may overshadow some of the disadvantages:

- The need for regular maintenance, the complexity of modernization.

- The need to equip with a backup power supply.

What air temperature should be from the batteries during the heating season

To conclude an agreement, you must apply with an application to any heat supply organization located in the applicant's city. It is necessary to sign a contract before the provision of utilities,

but not later than one calendar month from the date of acquisition of the right to use the premises.

Together with the application to the heat supplying organization, the following should be sent:

- Internal passport of the Russian Federation from the applicant.

- Company registration documents - for example, Articles of Association; the documents must indicate the name of the organization, the details of the enterprise, the place of the state. registration and contact details.

- Extract from the USRN on the premises indicating: the address of the building, the total area of the non-residential premises, the type of activity performed in the premises (production / commercial activity).

- A document certifying the applicant's right to act on behalf of the company - a power of attorney or an order to appoint a manager.

- An act from organizations checking the date of sealing the metering device, as well as the schedule for future inspections of metering devices.

Moreover, it is necessary to pay attention to the fact that all copies of documents must be notarized, otherwise the parties will not be able to conclude an agreement. Notarization of documents, in addition to an extract from the USRN (in 2020, obtaining an extract for legal entities costs 350 rubles), is the basis of expenses during the preparation of documents - notaries charge from 1,500 to 7,500 rubles for notarization of all documents, depending on the region and pricing policy notary

Notarization of documents, in addition to an extract from the USRN (in 2018, obtaining an extract for legal entities costs 350 rubles), is the basis of expenses during the preparation of documents - notaries charge from 1,500 to 7,500 rubles for notarization of all documents, depending on the region and pricing policy notary.

Infrared heating

If there is no opportunity to install liquid or air heating, or if these types of systems do not suit the owners of industrial buildings, infrared heaters come to the rescue. The principle of operation is described quite simply: an infrared emitter generates thermal energy directed to a specific area, as a result of which this energy is transferred to objects located in this area.

In general, these installations allow you to create a mini-sun in the work area. Infrared heaters are good because they heat only the area they are directed to and do not allow heat to dissipate throughout the room.

When classifying infrared heaters, first of all, the method of their installation is considered:

Infrared heaters also differ in the type of emitted waves:

- shortwave;

- medium wave;

- light (such models have a high operating temperature, so they glow during operation;

- longwave;

- dark.

It is possible to divide IR heaters into types according to the energy resources used:

- electrical;

- gas;

- diesel.

IR systems that run on gas or diesel are much more efficient, which makes them much cheaper. But such devices negatively affect the air humidity in the room and burn out oxygen.

There is a classification by type of work item:

- halogen: heating is carried out due to a fragile vacuum tube, which is very easy to disable;

- carbon fiber: the heating element is a carbon fiber hidden in a glass tube, which is also not very durable. Carbon heaters consume about 2-3 times less energy;

- Ten;

- ceramic: heating is carried out by ceramic tiles, which are combined into one system.

Infrared heaters are well suited for use in all types of buildings, from private homes to bulky industrial buildings. The convenience of using such heating lies in the fact that these structures are capable of heating individual zones or areas, which makes them incredibly convenient.

IR heaters affect any objects, but do not affect the air and do not affect the movement of air masses, which eliminates the possibility of drafts and other negative factors that can affect the health of personnel.

In terms of the speed of heating, infrared emitters can be called leaders: they must be launched while at the workplace, and there is almost no need to wait for heat. Such devices are very economical and have a very high efficiency, which allows them to be used as the main heating of production halls. Infrared heaters are reliable, capable of operating over a long period of time, take up virtually no useful space, are lightweight and require no effort to install. In the photo you can see different types of infrared emitters.

This article examined the main types of heating for industrial buildings. Before installing any selected system, it is necessary to calculate the heating of industrial premises. The choice always rests with the owner of the building, and knowledge of the tips and recommendations for calculating the heating of the room will allow you to choose a really suitable option for the heating system.

Disadvantages of other devices

Heating in industrial buildings is often based on classic radiators and bulky registers made of large-diameter pipes. But if the room has a large area, then heating it will be somewhat difficult - high ceilings and too large a distance between the walls affect. Let's see in what other ways we can heat industrial premises:

The use of diesel heat guns requires a lot of space, and the high noise level and the need for ventilation make this method rather inconvenient in many rooms.

- Using gas heat guns is an excellent way out of the situation, allowing you to pump heat into large rooms. The downside is that these devices require a source of liquefied gas;

- With the help of diesel heat guns - these devices are often used for industrial premises, but they require good ventilation, which is necessary to remove combustion products;

- Using convectors is not the best option, it is only suitable for small workshops. The thing is that the height of the ceilings in this case should not exceed 3-3.5 meters. A different type of heater should be used in taller buildings.

Therefore, the best industrial space heater is an infrared device that works by means of infrared radiation.

Another disadvantage of the cannons is the increased noise level - they buzz perceptibly. Also, they are not environmentally friendly.

Infrared heating of industrial premises

Another way to create good working conditions for workers is by using infrared radiation. Devices generate ray energy, which is transferred to surrounding objects, heating them. Then this heat enters the air. The method has a significant disadvantage: uniform energy distribution is not always possible. It can be significantly warmer under the ceiling than at lower levels.

The heating element for infrared heating can be different:

- halogen - if a shock or fall occurs, the tube may break;

- carbon fiber - energy consumption is reduced by almost 2.5 times;

- ceramic - a gas-air mixture burns inside the heater, which is why the device heats up and gives off heat to the environment.

Use regular iron stoves for your home. where you live permanently is not very convenient. There are options that require less time from you.

Every year it is necessary to prepare the boiler room for the heating season. In this case, there will definitely not be any problems in winter.

Do not forget about the ceiling heating system, which is often used to heat industrial buildings. With the help of special devices, not the air is heated, but the walls, ceiling, floor. There is no circulation, therefore, the risk of getting a cold or sore throat for workers in a department or workshop is reduced. A number of advantages are distinguished in the ceiling heating system, such as: long service life, takes up little space, is distinguished by simplicity and speed of installation, and has a low weight.

SNiP standards for heating industrial premises

Before proceeding with the design of a particular system, think about which industrial heating boiler to choose, you need to study the following rules and follow them.It is imperative to take into account the heat loss, because not only the air in the room heats up, but also equipment and objects. The maximum temperature of the coolant (water, steam) is 90 degrees, and the pressure is 1 MPa.

When drawing up a project for heating, staircases are not taken into account. It is allowed to use boilers and other gas-fired equipment only if oxidation products are removed closed and there is no danger of an explosion or fire in production.

In a multi-storey building, heating risers are replaced by the ZhEK employees.

After the completion of the work, the heating system is filled with water and a control check.

Each of the listed heating methods has its own advantages and disadvantages. It is necessary to choose the best of the methods based on the technological processes that are carried out in a particular workshop. Workers cannot be indoors if the air temperature there is below 10 degrees. Warehouses usually store finished products. To maintain its quality, you need to maintain an optimal microclimate.

Interesting on the topic:

- Preparing the system for the heating season

- Pipes for different heating systems

- Polypropylene pipes for heating: pros and.

- Heating pipe insulation

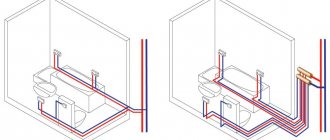

Water heating of industrial facilities

Water heating is appropriate if there is a private boiler room nearby or if there is a central water supply. The main component in this case will be an industrial heating boiler that can run on gas, electricity or solid fuel.

The water will be supplied at high pressure and temperature. Usually, with its help, it is impossible to qualitatively heat large workshops, therefore the method is called "on duty". But they reveal a number of advantages:

- air circulates calmly throughout the room;

- heat spreads evenly;

- a person can actively work in conditions with water heating, it is absolutely safe.

The heated air enters the room, where it mixes with the environment and the temperature is balanced. Sometimes it is necessary to reduce energy costs. To do this, filters are used to clean the air and reuse it for heating industrial buildings.

How to transfer a residential object to a non-residential premises

If the owner of an apartment in an apartment building wants to turn it into a non-residential premises, then for this you need to fulfill several conditions:

- a separate entrance is being set up. For premises with an area of more than 100 m 2, an emergency entrance is also made;

- there should be no registered citizens in an apartment that changes its status. Before starting the transfer procedure, they are discharged;

- the object should not have any encumbrances. The property must not be mortgaged, mortgaged (not yet repaid), or leased out on a long-term basis;

- the room is located on the ground floor or above other non-residential buildings (this was mentioned above);

- no transfer is carried out in buildings in emergency and planned for demolition;

- change of status is made only for the whole apartment. A separate room cannot be turned into a non-residential premises;

- the reason for the ban on obtaining non-residential status may be the finding of an apartment in a building recognized as a cultural and historical monument.

To transfer an apartment in an apartment building to a non-residential premises, you need to collect a package of documents.

All documents with the exception of the application can be submitted as notarized copies. The relevant authority is given 48 working days to make a decision. Receiving a rejection is not yet a final decision. It can be challenged in court.

Do IR heaters harm the industry?

Air heating of workshops and factories of infrared gas and electric types, under the conditions of the correct choice of the system and adherence to the recommendations, is completely safe for people and the environment. Human beings can be harmed by shortwave emitters. You also need to strictly observe the correct installation of IR systems in the production area.Usually the manufacturer notes the dangerous installation location. Subject to all safety requirements, ICs are considered safe and have a positive effect on humans. In terms of their technical parameters, IR emitters have no analogues.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- What are the pros and cons of infrared heating?

- Installation rules for infrared floor heating

- Advantages of heating with infrared heaters

- How is infrared film heating installed?

- How to calculate infrared heating?

- Varieties of infrared heating panels

Selecting a heating option

Only after that you have to choose which type of heating is most suitable. To measure the area of the basement, as well as temperature fluctuations, you will need:

- roulette;

- pencil;

- note paper;

- thermometer;

- barometer.

Temperature and humidity readings should be recorded over several days to determine which one is right for you. After that, analyze the indicators that will show you what is the humidity in the basement, how much heat is required for heating. There is equipment that not only heats, but also dries the air, or vice versa, humidifies it. In addition, you will have to take into account the structure of the foundation of the room, repairs in the room, the presence of doors and windows.

It is also important how the basement is isolated from general communications. If there is a possibility of a tie-in to the general heating, remember that there may be problems with calculating the payment, since it is not always possible to calculate the correct numbers. However, there are options where individual heating is not suitable for your particular basement.

Heating with electricity

Heating a workshop or warehouse with electricity is direct and indirect. Direct heating with electricity is the use of an electric heater in the warehouse itself and the supply of electricity to it. In most cases, this method is a temporary solution and is not applied in practice due to the high cost of electricity.

Indirect heating is radiator heating or air heating, where the coolant (water) is heated centrally in an electric boiler, and then the water enters the heat exchangers. Indirect heating is used only when gas and district heating are not available on site.

It is not difficult to notice that the design of a workshop heating requires not only knowledge, but also experience in the implementation of similar objects. That is why you can contact our company and order a turnkey industrial heating project for a workshop.

Gas or electricity

It is recommended to use the mains voltage in the basement not higher than 42 V.

So, an important factor in determining which basement heating you choose will be the purpose of the room. If you plan to equip a living space in the basement, you will need full heating to keep it warm even in the worst frosts. Options for steam heating and a gas boiler will be relevant here, if the design provides for it. If the ventilation is broken at the basement, then first you need to finish it, plaster all the cracks from where air can come from the outside.

If you are planning an office plan or a store, you can opt for a heating system on radiators that work from the electrical network and are capable of heating rooms with a fairly large area. Such heating in the basement will also dry the air, so it is ideal for rooms with high humidity.

But with this choice of heating, you should pay attention to the power of the electrical network, where the radiator will be connected. If the office will be heated, where there are already so many electrical appliances and electronics, such a voltage will not be able to withstand the network and it will become necessary to install additional equipment, which will incur certain costs in addition to paying for electricity

If the humidity in the basement exceeds the permissible standards, then in addition to heating, you should also worry about drying the air, since moisture destroys the basement as a whole and negatively affects the quality of the air you will breathe. So on the basement floor it will turn out to equip comfortable conditions.

If you have plans to store something in the basement, use it as a warehouse, and the relatively low temperature does not interfere with storage, you can use an ordinary battery, moreover, its installation will not require special changes in the design of heating throughout the house.

Infrared heating is an alternative to boilers and radiators. This option has several advantages: short-term installation work, ease of equipment installation. You can equip it quickly, conveniently, simply and efficiently.

In any case, when installing any heating, you first need to consult with certain responsible services. You can only install a heater in the basement on your own; in all other cases, you will need the help of specialists, professionals in their field. Calculations that will be associated with the installation of heating in the basement are also best left to professionals.

The question of the material for the equipment is also important. From what material is it better to choose the pipes to be installed, which batteries are best to choose, or what type of radiator will be of better quality? All these are individual parameters for each specific basement, and only correct calculations and observations of air and humidity can show this.

Peter Kravets

Reading time: 4 minutes

A A

Basement heating is of interest to both the owners of multi-storey buildings and private country cottages. Often they are equipped with bars, billiard rooms, cafes, recreation areas, gyms, saunas or small cinemas.

Types of infrared gas heaters

Infrared ceiling electric heaters for industrial sites are divided into two groups:

- light emitters - designed to warm up factories with a ceiling height of at least 4 meters. Such models are one of the most productive and powerful in their segment. The heat engineering calculation of power is carried out taking into account that for every 20 cubic meters, a power installation of 1 kW is required. Hinged heaters for 5 kW will quickly cope with the heating of 100 cubic meters. The method of operation of the device consists in the absorption of a gas mixture and air in a special burner at a temperature of 800-1000 degrees. A gas outlet channel is used to eliminate combustion products;

- dark emitters - the process of gas absorption is carried out at a temperature of 350-400 degrees. As a result, the metal tube, which is the emitter, does not glow red-hot, which contributed to the reason for the name of the heating devices. When fixing heaters of this type, it is necessary to take into account that the emitters are larger in size than their light counterparts. For factories and workshops, devices of light or dark types are chosen. The choice depends on the technical parameters of the building itself and on the type of production activity.

Recommended: Is there any health hazard from infrared heating at home?

Basement ventilation

The basement of a multi-storey building serves as the main source of the ventilation system. Since there is a ventilation duct on each riser of any floor, which ensures the normal circulation of air masses in the apartment. There are ventilation outlets in the apartment in the kitchen and sanitary area.

Sometimes special hoods are placed on them, which help to draw out unpleasant odors. Also, the normal functioning of the ventilation ducts that come from the basement ensures gas escape in the event of a leak for domestic reasons.Therefore, verification of such a system is very often carried out by experienced specialists of the relevant service.

The ventilation ducts in the basement provide not only the function of extracting unpleasant odors, which can form as a result of dampness or fungal diseases on the walls of the basement. They still provide such rooms with fresh air to a large extent, which is also necessary for a longer period of operation. There are two types of ventilation in the basement: natural and artificial.