Mechanical models

The valve and the thermal head are the main elements, without which it is impossible to imagine almost any thermostat. In this case, the latter performs the function of a sensitive element. These parts do not need external energy in order to work properly.

In turn, the thermal head also has several components. This is a regulator and actuator, a liquid element, sometimes elastic or gas parts are found as an alternative to it.

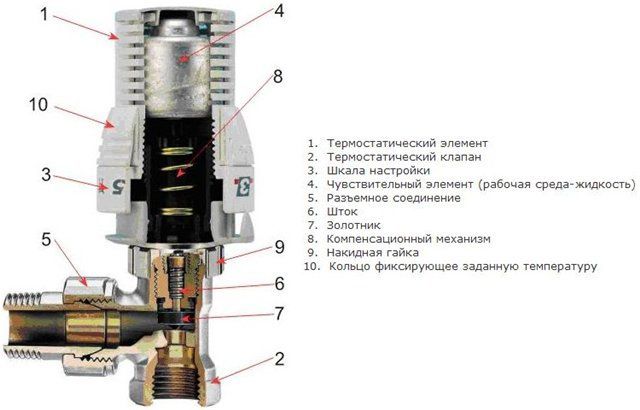

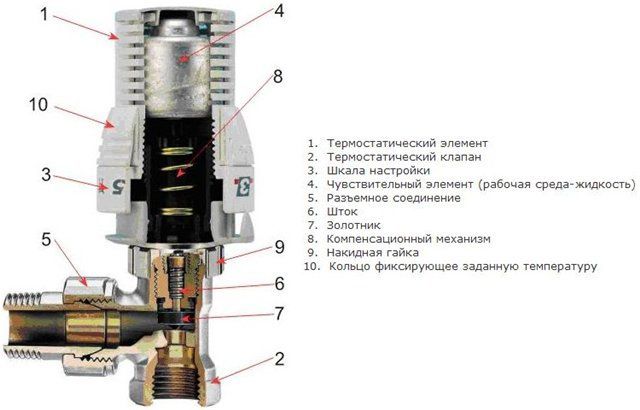

Internal organization

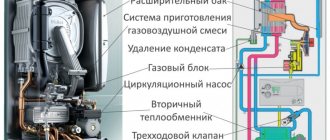

When choosing a temperature regulator, it is necessary to take into account all the factors that may affect the operation of the device in the future. Its main parts are as follows:

- scale with adjustment;

- fixing the set temperature, ring;

- mechanism of compensatory action;

- union nut;

- stock;

- spool;

- detachable connection;

- sensitive element;

- thermostatic element;

- thermostatic valve.

Principle of operation

The volume of the heating medium changes when the temperature in the heated room changes.

The bellows also changes its volume. It is because of this that the movement of the control spool begins. Its movement is proportionally related to how the temperature regime changes.

The thermostat has a special valve stem that moves due to a sensitive element that reacts to the environment.

Benefits

Thermoregulators can reduce heat energy consumption by 10-20%. Those systems that have not only individual thermostats, but are additionally equipped with regulators at the heating source, save 25-35% of thermal energy.

In addition, a pleasant microclimate is constantly maintained in the room, especially if automation is used to control the coolant.

Additional benefits

Other advantages of using temperature control devices include versatility and high accuracy. The versatility lies in the fact that the thermostats are suitable for installation in any type of heating system.

This equipment is used with gas, electric and solid fuel boilers.

High accuracy of adjustment is manifested in the fact that even a mechanical device stops the supply of heated water to the battery at the correct time, not to mention devices with electronic filling.

The latter can be adjusted in such a way as to maintain a specific, comfortable temperature at certain times. Often, an electronic thermostat even has a weekly programming function. The advantages also include the following qualities:

- durability - the devices are made of corrosion-resistant steel. Particularly interesting is Russian-made equipment, which in terms of hydraulic and strength properties corresponds to domestic realities;

- a wide range of brands and models - today thermostats are manufactured by many companies and supplied from abroad. High competition helps to reduce the cost of products.

About installation and its features

A thermostatic valve is installed on the supply part of the regulator pipeline. It is important to maintain a horizontal position for the head of the heating device. Exposure to direct sunlight, heat in large quantities is unacceptable.

Radiators cannot perform their functions normally if they are covered with curtains or covered with furniture. In such a situation, a zone appears with an almost complete lack of sensitivity.This means that there is no contact with the environment.

Otherwise

If it is impossible to install the heating system in another way, you will have to use remote control sensors, which have a sensitive patch element. The so-called mini-heating regulators are also intended for integration into niches.

Experts recommend installing a special shut-off valve on the return flow of the heating radiator. Then you do not have to disconnect the entire heating system from the riser, if you need to clean the battery, dismantle it.

The pump thermostat must be fully open when the heating season ends. After that, excess sediment will not form on the valve seat, the device itself simply turns counterclockwise.

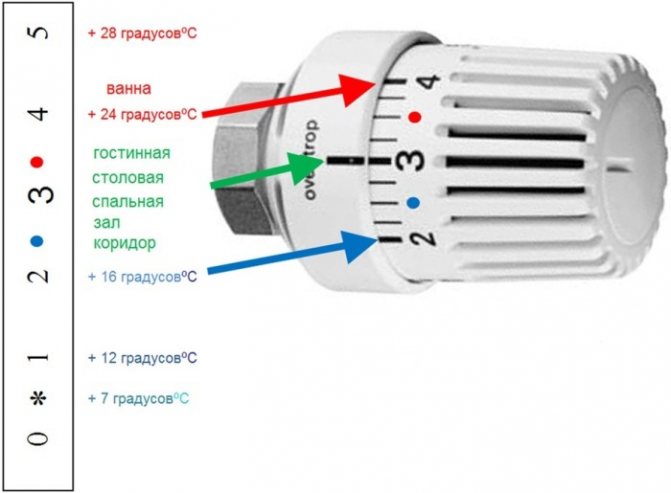

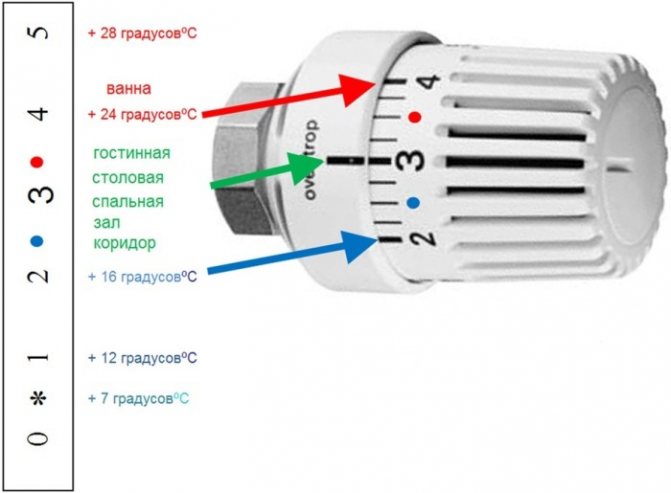

There are several thermal modes with which different types of pump devices can work.

- summer - 28 ° C;

- bathroom - 24 ° C;

- living room - 20 ° C;

- bedroom - 16 ° C;

- inner corridor - 11 ° C;

- frost protection - 7 ° C.

It is imperative to set the thermostat for the pump before starting active operation. At this stage, additional hydraulic resistance is created. It is necessary to smoothly adjust the throttle mechanism in order to achieve the desired result of the pump operation.

The battery check valve and inlet valve are equally good at helping to do the same.

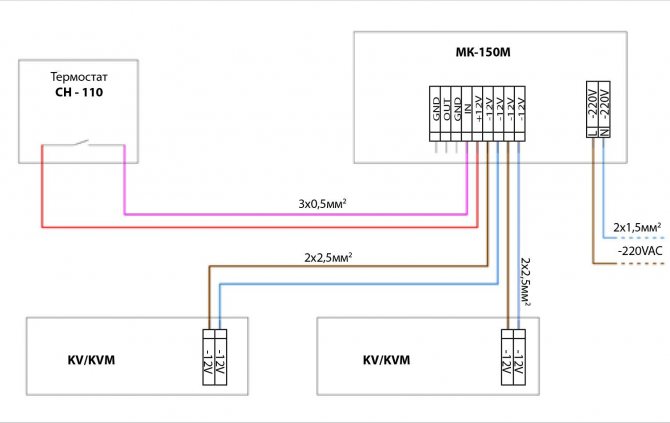

Diagram of connecting the circulation pump to the mains

The circuit for connecting the circulation pump to the mains is as follows

Note. necessarily in the pump connection diagram there must be either a differential circuit breaker (as in our diagram) or a bundle of a protective circuit breaker and an RCD (Safety Disconnect Device)

This is required, first of all, to protect a person from electric shock, in the event of a pump malfunction or improper connection.

As you can see, there is nothing complicated in the circuit, for the operation of a household circulation pump, a phase and zero (working zero) are required, and in addition, an indispensable safety element is grounding (protective zero). Therefore, there are three contacts in the terminal box of the pump, which are labeled accordingly.

Detailed photo instructions for connecting to the circulation pump to the mains, according to this scheme - HERE (link will open in a new window).

Most circulation pumps in heating systems are connected according to this standard scheme. The main disadvantage of which is that the pumps have to be turned on and off manually each time, therefore they are often turned on at the beginning of the heating season and turned off at the end. Disadvantages of this connection method. I think, it is obvious that unnecessary energy consumption and a decrease in the resource of the pump operation.

To automate the operation of the circulation pump in the heating system in order to reduce energy costs and increase the overall service life of the pump, you can connect it through a thermostat.

At the same time, the thermostat measures the temperature of the heat carrier and, if it is low, the circulation pump does not turn on so as not to drive cold water through the system in vain (or another heat carrier), and when the temperature of the heat carrier near the boiler reaches the required level, the pump starts.

Electronic type models

They are also briefly referred to as ET. These are automatic devices that help maintain the set temperature. They can be used with any type of pump if required.

An electronic thermostat can automatically control system actuators such as valves and pumps, mixers, boilers.

How does it work?

The presence of an external or built-in thermal sensor in the design becomes mandatory. It is installed in a place free from direct influence of other heating devices. This part is used to adjust the device.

The thermal sensor gives the ET information about the temperature being maintained in the environment. Currently, digital and analog versions of ET are produced.

The first ones have more functionality, due to which they have become widespread.

In turn, digital type models are divided into two types:

- with open;

- or closed logic.

Types of thermostats

Mechanical thermostat

The place of installation and the characteristics of the thermostat are determined even during the planning of the heating system. The heat supply parameters are calculated in advance and on the basis of these data the system components are selected.

The thermostat for a heating radiator in this case is no exception. But in addition to technical qualities, operational ones should be taken into account. These include the following factors:

- The degree of automation of the device... It determines how often manual tuning is needed for normal operation;

- Installation features... Some models of room thermostats for heating can be mounted in a strictly defined position;

- Accuracy of the control element... What changes in hot water temperature will trigger the device;

- Additional modes... Almost every electric thermostat for heating can be configured for daily or weekly operation according to strictly defined system parameters.

Consider the most common types of thermostats for heating a house, depending on the design features and performance.

Some boiler models have built-in thermostats. This must be taken into account when designing the control mechanisms of the heating system.

Mechanical thermostat for heating

Mechanical thermostat design

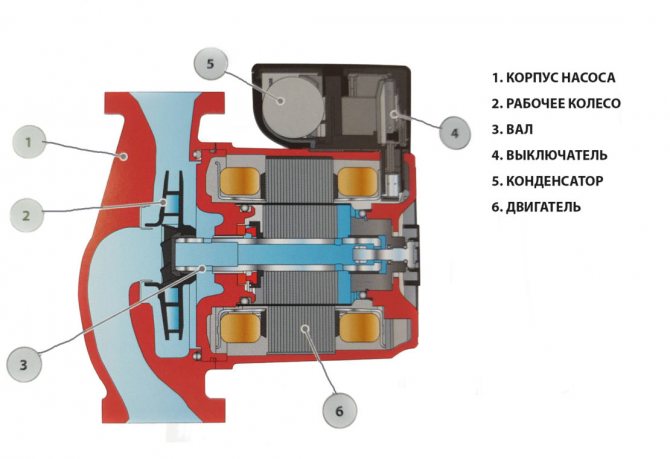

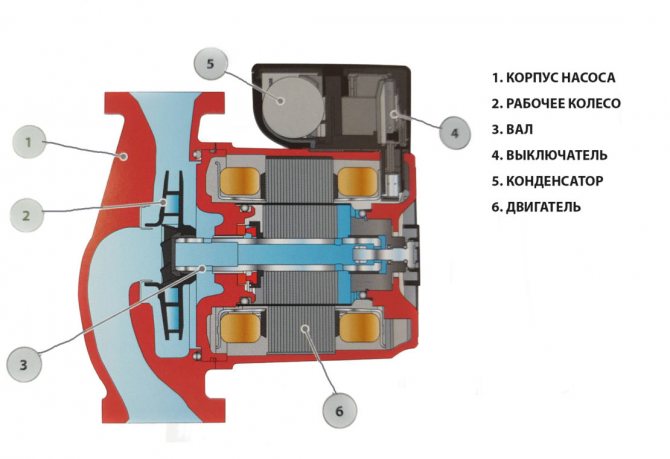

The easiest way to control the heating of a radiator or a section of the system is to purchase a mechanical thermostat for heating boilers, which can also be installed in the radiator piping. Its design is not particularly complex. It includes a locking mechanism and a mechanical control unit.

Under the influence of temperature, the working element expands, which is filled with the working fluid. Its body begins to press on the stem, which, when lowered, limits the flow of hot water in the pipe. A decrease in the working diameter of the line leads to a decrease in the heating of the radiator.

Such thermostats in the heating system can be installed only after becoming familiar with their features:

- Place of installation. It can be installed on both the inlet and outlet. It all depends on the task at hand. If it is necessary to regulate the degree of heating of the radiator, installation is performed in front of it. To limit the flow of coolant from the battery, it is mounted after it;

- Location. For correct operation, the thermostat on the heating battery must be installed on the side so that hot air does not affect the control element;

- The thermostat parameters are pre-calculated for a specific heating system.

The defining characteristic of mechanical thermostats for heating boilers is their capacity.

The control element is set before starting the heating system. To do this, it is necessary to stabilize the pressure in the pipes and set the required thermostat response value for the heating boiler.

Two and three way valves

Two-way valve for heating

They are versatile devices that can perform several functions.Their difference from the above-considered thermostats for a heating radiator lies in the absence of a control component that operates from a change in the temperature of the water.

A simple mechanical thermostat for heating boilers only works in the local zone. Those. actually does not take into account the indoor and outdoor temperature. Automated valves do not have this disadvantage. This is due to the peculiarities of their design, which consists of the following components:

- Mechanical gate valve - crane;

- Servo mechanism installed on the control valve stem.

The servo mechanism can be connected to any external control element - programmer or temperature sensor. Depending on external data, the valve stem is adjusted, which limits the flow of coolant in this section of the line.

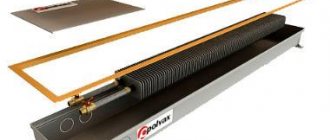

In addition to the function of the thermostat on the heating radiator, the valves can be used in the following heating elements:

- Water heat-insulated floor... Are part of the mixing unit;

- Collector heating system... Regulate the supply of coolant to a specific section of the line.

If you need a thermostat for a heating pump, two and three-way valves will be the best option. In addition to the function of adjusting the volume of hot water, in some cases they can stabilize the hydrodynamic distribution in the system.

Some valve models have a built-in temperature sensor and at the same time have the ability to connect to an external thermometer.

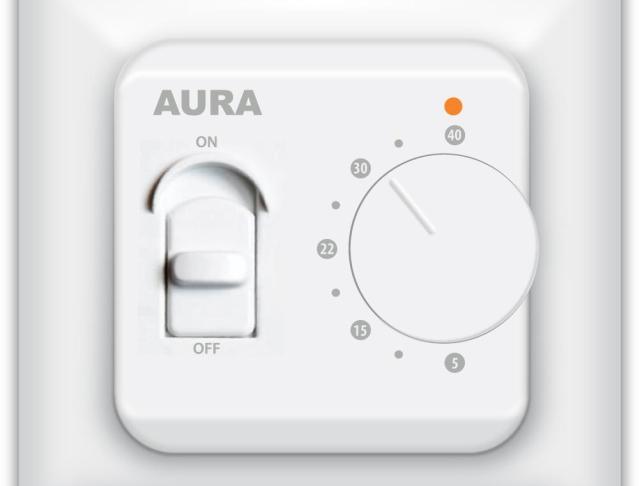

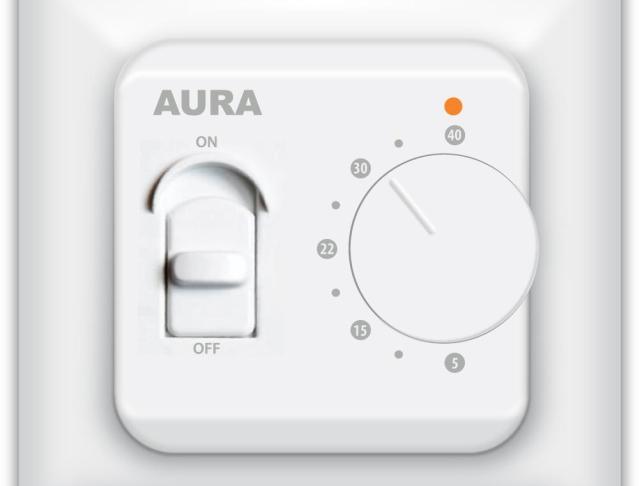

Electronic thermostat for heating

Electronic thermostat programmer

To automate the operation of heat supply, it is recommended to install an electronic contact thermostat for heating. Often they are not mounted on a battery or radiator, but have a remote design. It can be installed anywhere in the room.

The simplest models of room heating thermostats have one remote temperature sensor and a control element. It is installed in a certain part of the system and, according to its readings, the parameters of the boiler or the control valve are changed. However, for efficient operation, it is recommended to use more complex models of overhead thermostats for heating with programmer functions - daily or weekly.

To choose a thermostat for a heating battery, you should first familiarize yourself with their types:

- With bimetallic spiral... When exposed to hot air, it expands and closes the contact. As a result, the adjusting mechanism is triggered and a signal is given to open (close) the valve. The mercury sensor performs the same function;

- With timer... This is an optional component that can be configured to change the heating parameters depending on the time of day. This thermostat is suitable for heating a small house;

- Programmable... In these models, the mechanical part is connected to the electronic control unit.

The last type of electric thermostat for heating is convenient for organizing autonomous heat supply. It can be connected to several components - a boiler, servomechanisms on radiators and a circulation pump.

After installing the thermostat for the heating pump, it is mandatory to calibrate it. The actual data from the manometer thermometer is checked against the readings of the device.

Closed logic

The closed logic of the device for the circulation pump means that there is a rigid internal structure. The algorithm of work remains constant over time, does not change depending on the state of the environment.

For circulation pumping equipment, this is quite possible. There are only a small number of programmable parameters that can be changed.

Installation of Vilo pumps

Vilo pumps are very popular on the market today. They have good technical characteristics. A wide variety of sizes of threaded and flange connections allows you to choose just such pumping equipment that is ideal for installation in an existing heating system. And the heating radiator itself will not be involved in the work.

It is worth considering how to connect the pump to Vilo heating. Installation of VILO units is not difficult. The Wilo pump can be installed directly on the pipeline. There are different models. If the room has a small area (up to 750 square meters), then you should give preference to the Wilo-Star-RS model. The pumps in this series are equipped with three-stage switches. For power supply, a current with a voltage of 230 volts is needed. The device can operate at a temperature of the working fluid from -10 to +110 degrees. In this case, the ambient temperature should be no more than +40 degrees.

Installation of this unit assumes horizontal placement of its shaft. The terminal box has two cable outlets. Therefore, the Wilo heating pump can be connected to the power supply from either side. Thanks to the spring-loaded design of the terminals, the cable is very easy to connect.

Thus, connecting a pump for heating is not difficult work. And you can do it yourself. The main thing is to choose the pumping equipment correctly, know the installation features and follow a number of rules during the installation of the device.

Open logic

There are also freely programmable open logic instrument types. They are also often found in pumping products of the circulation type. Such devices can be easily configured for any environmental conditions and temperature conditions.

But it is rather difficult to manage them, special qualifications are required. Therefore, they have not become widespread, closed logic is most often found in circulating devices.

You should not save on the purchase of a thermostat for a heating system, because this product significantly increases productivity and efficiency.

Summarizing

Heating radiators with a thermostat allow you to create a truly "smart" heating system that adapts to changes in weather conditions. Meanwhile, regulators for batteries are far from the only way to regulate the operation of a heating system. The proposed material is an attempt to generalize the existing methods of regulating heating in the house.

The video shows an example of connecting a thermostat to a boiler.

Did you like the article? Subscribe to our channel Yandex.Zen