Gas prospects

The use of gas for heating houses and apartments is one of the most promising trends in the development of engineering communications today. Boiler equipment manufacturers have offered so many options that you can choose the right unit for absolutely any room. An example is the BAXI boilers.

Gas boilers BAXI can be installed in any room. They are suitable both for installation in apartments and for heating a large country house. Naturally, the room where the mini-boiler room is installed must meet the existing requirements:

- The room must be at least 15 cubic meters in volume.

- Ceiling height - at least 2.2 meters.

- Good ventilation, capable of providing three times air exchange.

The existing requirements for the organization of the chimney can be disregarded if you choose a BAXI boiler with a closed combustion chamber for heating your home. Such a unit is a full-fledged mini-boiler room that has all the necessary elements and does not harm the ecology of the house. The models of this manufacturer differ in power indicators, so that BAXI boiler units can be used for heating and supplying hot water to a wide variety of premises.

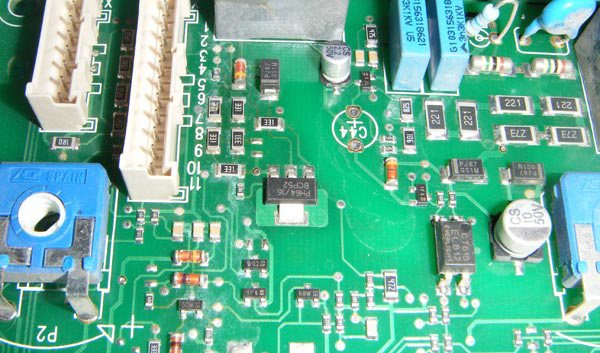

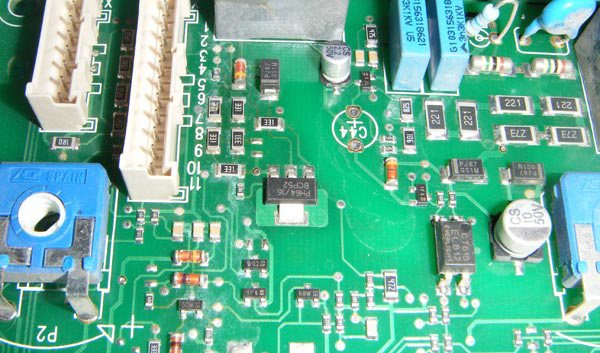

The ninth reason. Error in the control panel (board)

If all the previous causes were eliminated by you or the indicated malfunctions were eliminated, and the Baxi tank issues an E01 error, you should contact the service center to diagnose the board itself. This board contains all the modules it needs, one of which may break, and everyone else will start screaming about the E01 error. From this it follows that the problem may lie, again, in a bad assembly method or bad parts supplied at the factory during the soldering of the main board itself.

Installation nuances

At first glance, the installation of the appliance, especially the indoor wall models, may seem very simple. In practice, this is not entirely true. BAXI boilers use gas as a fuel, and it, with all its undoubted advantages, remains dangerous. Gas equipment requires a professional attitude. One, even the smallest installation error can lead to serious consequences. The equipment should only be installed by qualified personnel with the required access.

Even a short list of the consequences that can lead to interference with gas equipment looks frightening. The most frequent ones are:

- Freezing of the system in winter.

- Explosions.

- Fires.

- The release of carbon monoxide into the air of residential premises.

Front panel display

Of course, BAXI boilers, like any modern gas equipment, are equipped with security systems, but even automation cannot always cope with mistakes made by a non-professional. If we talk about less tragic consequences, the main problem of self-installation is the incorrect operation of the boiler. For example, the equipment does not turn on and issues error codes, despite the fact that all elements are in working order.

Gas boilers BAXI - volatile equipment. They cannot work without being connected to the mains. The connection requirements are very simple, they do not differ from the rules for installing conventional electrical household equipment.... The unit is connected to a 220V network, and must be grounded... It is also better to entrust the grounding to specialists. Even if the lack of grounding does not lead to serious consequences, it can affect the functionality of the equipment. Often, the device gives out error codes and the burner does not light up due to trivial errors in the electrical connection.

In the event that it is not possible to fully ground the equipment (there are also such cases), it is necessary to install a stabilizer that provides galvanic isolation. In some cases, the potential can pass through the gas pipe. This situation is already becoming dangerous, and the connection must be made through a special adapter with dielectric properties.

How to eliminate error 01 on the Immergaz gas boiler?

___________________________________________________________________________

The Immergaz boiler unexpectedly stopped working, the display shows an error with code 01. I cleaned the burner, reset the unit parameters, although there is no sense. The boiler starts up after restarting, the burner ignites and goes out. Then the ignition cycle is performed again and an error appears. Where to look for a malfunction? The gas valve is broken. If damage is found, the gas valve needs to be replaced. The ionization electrode is not functioning correctly or is out of order. Examine it for carbon deposits. Adjust the distance between the burner device and the ignition electrode, if necessary. The gas valve is broken. Check gas valve coils for potential short or open. If any violations are found, change the gas valve.

The gas valve is stuck. Attach a rubber hose to the union located on the front of the valve and apply the ultimate pressure. Incomplete ignition power. Perform ignition power control using the service menu. Malfunction or malfunction of the control board. The ignition transformer stopped working. Reboot the device. If the error starts over, the control board must be replaced.

Check the grounding. The cladding must be potential-free. Excessive moisture serves as a source of blockage for the device. Clean the combustion chamber, ionisation electrode and burner from condensation. Malfunction of the ignition electrode. The control board has detected a flame, but there is no combustion. Inspect the ignition electrode wiring. Poor contacts and breaks are possible. The electrical circuit from the ignition electrode to the control board is checked for a short circuit. The ignition electrode is touching the gas burner. Inoperative control board. It needs to be changed.

___________________________________________________________________________

Similar questions

- How to reset the error code A5 on the Arderiya gas boiler

- How to eliminate error code 108 at the gas boiler Ariston

- How can I reset the error code E10 at the Baksi boiler

- Why the Beretta gas boiler can heat up and buzz strongly

- Why does the Bosch gas boiler pressure drop?

- For some reason, the Buderus boiler does not function in hot water supply mode

- Why does the pressure drop in the Celtic gas boiler?

- Why did the Daewoo double-circuit boiler begin to buzz and heat up

- How to eliminate the E4 error in the Electrolux boiler

- Because of what the Ferroli gas boiler does not work on hot water supply

- Because of this, the Immergas boiler constantly turns on and off when heating

- Why did the Junkers wall gas boiler begin to buzz and warm up?

- For what reason, the Navien boiler gives out error 10, how to fix it

- For this reason, the gas boiler Neva Lux gives error 03, how to fix

- How to eliminate error F22 on a gas boiler Proterm

- Because of what the Rinnai boiler does not function on DHW

- For what reason, the Vilant gas boiler shows error F36, how to fix it

- For what reasons the Wisman gas boiler shows the error code F4

- The gas boiler Electrolux decreases pressure, what is the malfunction

- What is the malfunction, if the Ferroli gas boiler shows the error code F05, how to fix it

- For what reason, the Arderia boiler began to give an E2 error, how to fix it

- For what reason, the gas boiler Ariston constantly began to turn on and off in heating mode

- For some reason, the Baksi gas boiler does not hold pressure

- For what reason, the Bosch gas boiler began to issue error code C6, how to fix

- The pressure of the Buderus boiler drops, what is the malfunction

___________________________________________________________________________

___________________________________________________________________________

- Why did the Arderia boiler often start to turn on and off when heated?

- What is the problem, if the Ariston gas boiler shows error 607, how to reset it

- How to fix the error code F28 on the Vilant boiler

- Because of what the Wisman boiler does not function for hot water supply

- How to eliminate error 43 on the Rinnai boiler

- Because of what the boiler Neva Lux began to heat up and buzz loudly

- Because of what the Proterm boiler does not work on DHW

- How to eliminate error 01 on the Immergaz gas boiler

- For some reason, the Navien boiler does not work in hot water supply mode

- How to eliminate the E1 error on the Electrolux boiler

- How to fix the error with code F37 on the Ferroli boiler

- How can I eliminate error 6A on the Buderus gas boiler

- Because of what the Daewoo gas boiler stopped holding pressure

- Why the Bosch gas boiler does not function on hot water supply

- What is the malfunction of the Baksi boiler, if it gives an error E01

- The Beretta gas boiler does not hold pressure, what is the reason

- What is the malfunction of the Arderia gas boiler, if it began to give error A6

- In the gas boiler Ariston, the pressure decreases, what are the reasons

- For what reasons the Rinnai boiler can warm up and buzz

- Why did the Wisman boiler constantly turn on and off when heating up?

- For this reason, the Arderia boiler does not function in the DHW mode

- For what reasons, the wall-mounted boiler Ariston began to issue an error with code 501

- What is the problem if the Baksi boiler gives an error E03, and how to fix it

- Why does the Buderus boiler give out an error 3C, how to reset it

- Why does the Proterm boiler often turn off and on when heated

- What is the malfunction of the Ariston boiler, if it shows error 607

- How can I eliminate the error with code 10 on the Navien boiler

- What is the problem with the Electrolux boiler, if it issues an error code E3

- How to fix error F36 on the Vilant gas boiler

- What is the problem with the Proterm gas boiler, if it gives an error F25

- How to eliminate an error with code F5 on a Wisman gas boiler

- What is the problem with the Ferroli boiler if it shows an error code F05

- How to fix the E03 error on the Baksi boiler

- What is the breakdown of the Bosch boiler if it shows error C6

- What is the breakdown of the Buderus gas boiler if it issues an error code 3C

- What is the problem if the Rinnai boiler gives an error 99, and how to fix it

- For what reason, the Beretta boiler gives out error A03, how to fix it

- Why does the Junkers boiler constantly turn off and on in heating mode

- Why does the Daewoo boiler constantly turn off and on when it heats up

- Why does the Bosch boiler constantly turn on and off when it heats up?

- Because of what the Thermon boiler often turns off and on when heated

- Because of what the Celtic boiler, when heated, constantly turns on and off

- What is the malfunction of the Westen gas boiler, if it gives an error E01

- How to eliminate error with code A01 on Coreastar gas boiler

- How to fix an error with code F1 on a gas boiler Senor Duval

- How to eliminate error code A6 on a Celtic gas boiler

- What is the malfunction of the Elsotherm boiler, if it began to issue an E1 error

- For what reasons, the Bugatti gas boiler began to give error E01

- How can I eliminate the error with the E2 code on the Motan boiler

- Why does the Immergaz boiler pressure drop?

- For some reason, the Kiturami gas boiler stopped holding pressure

- The pressure in the gas boiler Korea Star drops, what are the reasons

- Why Mora's cauldron does not hold pressure

- The pressure in the Navien boiler decreases, what is the malfunction

- In the gas boiler Proterm, the pressure drops, what are the reasons

- Because of what the Rinnai boiler does not hold pressure

- For what reasons, the Ariston boiler gives out error code 101

- How to fix error F20 on the boiler Proterm

- For what reasons the Daewoo gas boiler shows an error with the E3 code

- How to fix error code 16 on the Navien boiler

- For what reasons, the Electrolux boiler gives an error E2

- How to eliminate error F20 on the Vilant gas boiler

- What is the problem with the Beretta boiler if it began to give error A02

- How to eliminate the F2 error on the Wisman boiler

- For what reasons, the Neva Lux boiler shows error code 02

- How can I fix error A03 on the Ferroli boiler

- For what reasons, the Baksi gas boiler shows an E02 error

- How can you fix the E9 error on a Bosch gas boiler

- For what reasons, the Buderus gas boiler gives an error 2E

- How to fix the E3 error on the Oasis boiler

- For what reasons the Rinnai boiler shows error 16

___________________________________________________________________________

___________________________________________________________________________

- Heating boilers piping

- STS boilers

- Solid fuel boilers KBT

- Pellet boiler Peresvet

- Steel floor boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the gas boiler Termet

- Repair of Thermon boilers

- Repair of boilers Nova

- Boiler service Hermann

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Maintenance of Daewoo boilers

- Boiler malfunctions Demrad

- Mora boiler malfunctions

- Boiler repair Westen

- Immergaz boilers malfunctions

- Types of solid fuel boilers

- Combined boiler models and designs

- Oil and double-circuit boilers

- Cast iron boilers for coal

- Boilers with simulating burners

- Imported boilers for heating systems

A little more about electricity

In addition to the need for grounding, there are other nuances when connecting boilers:

Baxi luna 3 comfort 240 fi

- Gas boiler equipment provides stable operation in the range of 170-250 V. When the voltage drops, the boiler turns off, when the voltage rises, the varistor burns out.

- The sinusoid in the mains must be free of interference. Such devices do not tolerate power surges well. Experts recommend connecting additional voltage stabilizers. It is not necessary to use UPS for installation of gas heaters.

- The connection must have a separate machine.

- For phase-dependent models, it is important to ensure that zero and phase are matched.

The meaning of error E01

The e01 code is one of the most problematic. Indicates the absence of a burner flame, although in fact it may be, but of low intensity. In any case, the ionization sensor does not fix it - the control board gives a command to block the Baksi - the boiler stops when an alarm is signaled. Therefore, the cause of the e01 error must be sought in external factors or elements of ignition and flame control.

* The recommended algorithm of actions described below, based on the principle from simple to complex, is identical for all Baksi gas boilers, regardless of modification.

Method for finding the cause of error E01

Step 1 - testing the gas line

- A typical project for private buildings assumes that shut-off valves (a tap or a valve), a shut-off valve, a meter and a filter are installed on the pipe before the boiler. If the facility has a gas stove, it is not difficult to make sure that the “blue fuel” is coming in: just light the burner.

What can be done when there is no flame?

- Check the position of the controls of the locking elements of the circuit. Perhaps the owner had previously shut off the pipe, leaving the house for a long time, and forgot about it. When the industrial voltage is cut off, the shut-off valve is activated. Gas pipelines are equipped with normally closed devices; cocked manually. These are the most common causes of the E01 error on the Baksi boiler. There is nothing to be done with the counter - it is sealed. We'll have to call a representative of the resource supplying organization for verification.

With an autonomous gas supply, the reducer may freeze or break. Here a specialist is not required - the problems are solved independently.

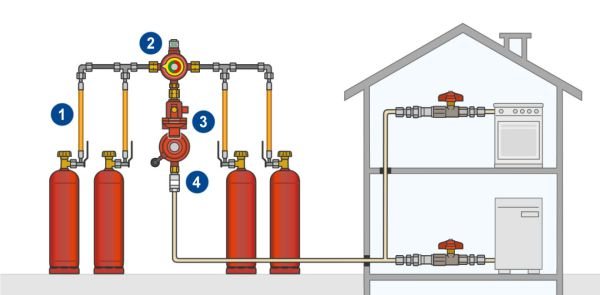

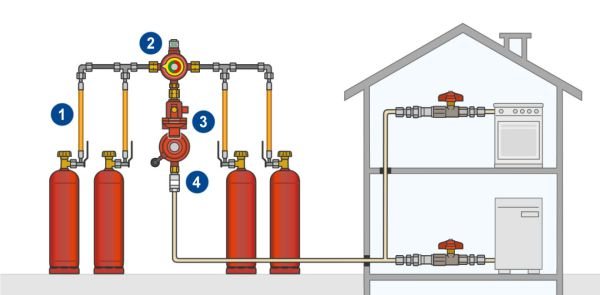

Autonomous gas supply to a gas boiler

- Insufficient pressure in the pipe is another likely cause of the E01 error. If its value is below the critical value for the Baksi boiler, then the valve will block the gas supply path to the burner. Professionals use a differential pressure gauge for diagnosis.

User can determine the pressure level on the same plate. It is necessary to light all the burners without exception and evaluate the intensity of the tongues of flame, their stability. Probably, in the gas tank or in the cylinder group, the maximum production of the “blue fuel” reserve.Alternatively, the main filter is excessively dirty. Often, his banal cleaning neutralizes the E01 Baksi error.

Step 2 - troubleshooting the boiler

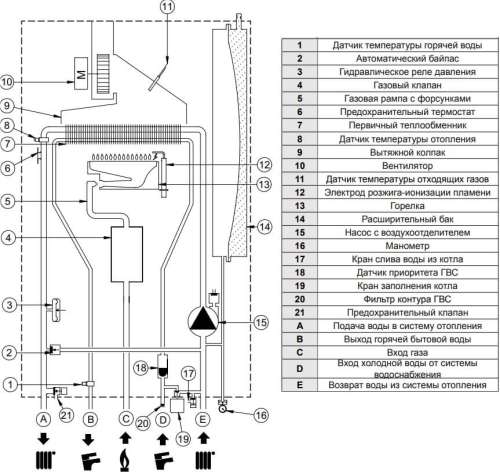

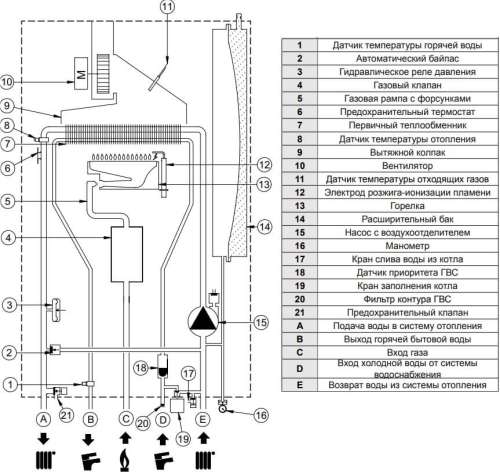

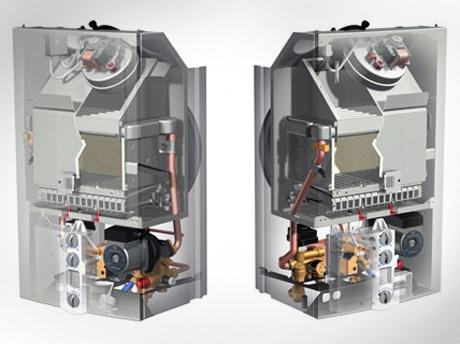

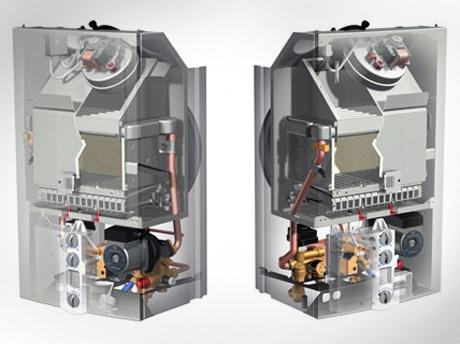

Boiler diagram Baxi

- Ionization sensor. The absence of a signal from it to the control board is caused by a number of reasons. It is not difficult to check and eliminate on your own.

- Chain problem: lack of contact, short circuit or breakage of wires. If, during an attempt to ignite the boiler, characteristic clicks are heard, but the spark is not visible, it is definitely a breakdown of the insulation.

- Electrode contamination. Depending on the Baksi series, it is either combined with the ionization sensor, or they are spaced apart. Cleaning from soot, soot, dust allows you to remove the boiler error E01. Any alcohol-based liquid can be used to remove build-up.

Boiler ignition electrode Baxi

- Weak spark. There are several reasons: incorrect position of the electrode ("knocked down" when cleaning the Baksi burner), the gap does not correspond to the factory setting, a problem with the transformer.

In practice, some "craftsmen" on the advice of the so-called experts bend the electrodeto increase the intensity of the spark. It is absolutely impossible to do this! The size of the gap is indicated in the documentation for the Baksi boiler, you just need to find the appropriate section in the instructions and bring everything back to normal. But you should not bend the electrode pin (it is fragile), but the element of its fastening.

- Dampness. If Baxi is installed in a room with excessive humidity, condensation may form during the equipment decommissioning period. Hence the error e01. Drying the inside of the boiler (with removal of the casing) with a stream of hot air eliminates the problem.

- Burner. It must be serviced regularly. If the boiler is installed in a room with increased dustiness, then more often than recommended by the Baksi manufacturer. The nozzle openings are gradually clogged with dust, soot, the intensity of the gas jet decreases, and an E01 error appears. Cleaning the burner is done with a soft brush and a vacuum cleaner - nothing complicated.

Baxi gas boiler burner

- Oxygen deficiency. This problem is fixed by other sensors, but when the air supply channel is blocked, this becomes one of the reasons for the E01 Baksi error. It is mainly observed when a coaxial chimney is connected to the boiler as a result of icing: it will have to be warmed up.

Closed access to the chimney

- Gas valve... The procedure for setting it up is specified in the instructions on the Baksi. The malfunction can be determined by the continuity of the windings. Resistance (in kOhm) should be: at 1–2 pins 2.85, at 4–5 <1.35. It is not difficult to replace it yourself, but there will be difficulties with the adjustment: you will need the above-mentioned differential pressure gauge. It does not belong to the category of household appliances, and therefore you have to contact a specialist.

- Gas valve VK 4105G M - M MainFour (5702340) Baxi Baxi

More details

- Gas valve HONEYWELL VK4105M 5033 (5665220) Baxi Baxi

More details

- Gas valve SIT 845 SIGMA (5653610) Baxi Baxi

More details

Gas valves for heating boilers Baxi

In fact, this is all that the user can do to restore the operation of the Baksi boiler when the E01 error appears on the display. It is also caused by other malfunctions: in the diode bridge, ignition unit, gas fittings (valve), elements of the electronic board (capacitors, relays). But testing such boiler units and eliminating problems is the lot of a professional. At home, the control module is not checked or repaired: only in a specialized workshop.

On a note!

The new Baksi board costs between 8,300 and 10,100 rubles (depending on the boiler series). Its diagnosis and restoration in a service center costs about 3,400 - 3,800 rubles. for 2018

Electronics

The heart of the boiler is sophisticated electronics. It is she who ensures the normal operation of the device and turns it off in the event of a malfunction. The automation will inform the owner of the problem by displaying an error code.These alphanumeric codes are essentially a description of the problem. They talk about what is disturbed in the operation of the unit, and how the situation can be corrected.

Before talking about the most common error codes, it is worth recalling that self-intervention and repair attempts are not the best solution. Troubleshooting without specialist intervention is permissible only within the limits limited by the manufacturer's instructions.

What is the E01 error associated with Baxi boilers?

The flame sensor electronics are designed to shutdown the boiler in the following situations:

- lack of gas supply or insufficient pressure in the main gas pipeline system;

- failure of the ionization sensor;

- violation of the integrity of electrical connections or problems with contacts;

- failure of the control board;

- incorrect connection of the input power supply (boilers are phase-dependent);

- low pressure in the heat exchange system;

- problems with the pump.

How to fix Error E01

How to fix possible errors Baxi e 01 can be found in the operating instructions, which spell out options for the occurrence of problems and ways to fix some of the faults yourself. If you carefully read the instructions for operating the gas boiler, you can understand that an elementary turn of the power plug by 180o (change the phase) allows you to start the ignition system. But this is one of the things that anyone can do. But there are actions that still only need to be done by a Gas Master with the necessary experience.

For example, cleaning the contacts can restore the function of the flame monitor. Eliminate the problem of lack of starting the pump can be "banal" cranking. A similar situation with the pump occurs when the boiler is first started, or if there is debris in an already operating system, it can also be accompanied by an e01 error for the Baksi gas boiler. Low pressure in the heat exchanger can be caused by a low level of liquid used as a heat transfer medium and the ingress of air into the system.

If, after using the above options and restarting, the boiler does not restart and does not turn on in normal mode, and the E01 error appears on the display, then you cannot do without calling the wizard. Correction of malfunctions associated with the lack of gas supply, low pressure, the gas valve responsible for adjusting the gas supply should be carried out by specialists who are familiar with the specifics of the operation of gas equipment. Checking of electronics, control systems of safe operation, adjustment of control systems should be performed by a specialist with extensive practical experience in performing similar work with gas boilers "BAXI" of various modifications. In the case of boilers with combined ignition, a possible cause may be a failure of the electrical circuit of the control board. Replacement of failed elements should be carried out with similar samples, even though some samples of models of different designs are considered interchangeable.

You can find plenty of tips on how to fix the problems that have arisen. That's just, according to the reviews of specialists providing services for the maintenance and repair of heating equipment, attempts to independently correct the problems that have arisen lead to the complete failure of individual components and equipment as a whole.

Automation

Automation for boiler equipment is very diverse. Some of it is pre-installed by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of the equipment.

The simplest example is a sensor that monitors normal gas flow. When the gas is turned off, the sensor is triggered, the boiler is automatically turned off. Restarting will take place after the gas supply is resumed.

Systems ensuring operational safety also include:

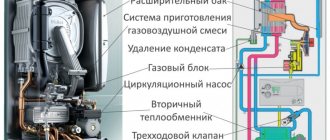

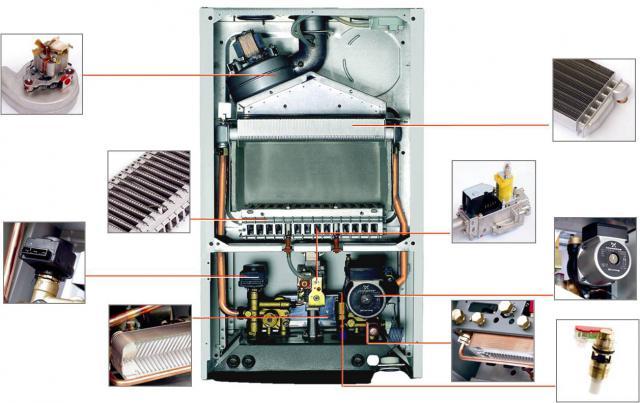

Boiler device

- Frost protection (starts to work if the temperature outside is below 5 degrees).

- Protection against blockage of circulation pumping equipment.

- Protection against blockage of the three-way mixing valve in the event of prolonged downtime.

- Protection against limescale build-up in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the mains.

- Parasitic flame control.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, additional electronics can be installed:

- Outside temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather-dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Reasons for the error during the operation of the boiler

In most situations, error E01 speaks only of a few of the reasons presented. The most common one is that there is no ignition inside the burner, and a signal is sent to the main screen of the control panel, directly from the sensor designed to control the flame. It is an ordinary electrode - a sensor that determines if there is a flame inside the tank, and, in a situation where it is not there, the boiler is blocked. The error also occurs regardless of whether the gas is supplied completely or there are malfunctions in the combustion system. Below are the main reasons why error E01 appears in the Baxi tank.

- There is no gas supply to the tank, insufficient pressure inside it, or a breakdown in the valve through which air is supplied.

- The power supply for the boiler was connected incorrectly, and the phases of this very connection are violated (as a rule, all tanks are phase-dependent).

- Loss of signal from the control panel to which the ionizer is connected.

- Dirt or breakage on the flame sensor panel inside the tank (most common mistake).

- Breakdown of the control board.

- Lack of draft or blockage of the air supply line to the tank to ensure proper combustion.

The boiler control system refuses to work properly only after three attempts to start the tank. After that, it will be necessary to dump the tank. To do this, you need to press the R button on the control panel (from the English Reset) when the errors are eliminated. The user can himself try to check and eliminate some of the causes that arise in the event of a boiler breakdown, such as air access to the inside of the tank, malfunction due to contamination. Below we will analyze all the reasons why the Baxi boiler has an E01 error and what to do in such a situation.

Errors and their codes

Breakage of pneumorel

All error codes can be roughly divided into two groups:

- Complete blocking of equipment operation.

- Switching the device to standby mode.

A complete lockout in most cases will require a manual restart of the unit. It turns on in case of serious malfunctions that can bring danger to health and life of people.... Such failures include lack of traction, overheating of equipment, lack of gas supply, etc. In rare cases, the error can self-eliminate without human intervention, and the automation will turn on the device on its own.

Error E01

E01 is one of the most common mistakes. This code is displayed when the flame monitor is triggered. The reasons for the appearance of the failure can be:

- Lack of gas supply.

- Lack of match between phase and zero in phase-dependent models.

- Lack of contact with the flame sensor.

- Malfunction or contamination of the sensor itself.

- Malfunctions in the ignition system.

- Failure of the gas valve, electronic board.

- Insufficient air supply for normal combustion.

- Insufficient gas pressure in the system.

Gas-burner

When the E01 code appears, you need to check the correctness of the sensor connection, the gas supply (often its absence is due to trivial reasons, for example, the gas valve is shut off).If these items are normal, you can press the R button for 2-3 seconds. If the actuation was accidental, the equipment operation is normalized In case of repeated operations, contact the service center. Perhaps the problems with the E01 code are related to the electronics, and the intervention of a non-professional into it is fatal to the boiler.

Error E10

E10 is another common problem. Unlike error E01, it is associated with sensors that monitor the circulation of water in the system and the operation of pumping equipment. Automation will work in the following cases:

- Lowering the pressure of the coolant in the system.

- Lack of contact between the board and the pressure switch.

- Faulty pressure switch.

- Malfunction of the sensor of the pumping equipment.

- Pump malfunction.

- Clogged filter system in the heating circuit.

- Clogged heat exchanger.

Cause of error E10

It is also not always advisable to fix the E10 error on your own. Of course, if the pump does not work, the only way to solve the problem is to replace it, which is quite possible to do without the intervention of specialists. You can clean the filter system yourself. All other failures should be eliminated by a professional.

Errors E96, E97, E98

The appearance of errors E96, E97, E98 says only one thing - an urgent intervention of a specialist is required. Unlike other malfunctions (E01 or E10), intervention in the operation of the boiler in the event of such malfunctions is strictly not allowed. The prohibition of intervention is simply explained - these three codes appear when the electronic board is inoperative.

The most common error codes for Baxi boilers

The most common Baxi gas boiler error codes are the following codes:

- error e01 - the reason lies in a malfunction of the flame control sensor;

- error e03 - the traction sensor is to blame;

- error e25 - malfunctions of the temperature sensor;

- error e35 - a problem with the flame control electrode.

Boiler error Baksi 03e

Below we will consider the causes of these and other errors in the operation of the unit and recommendations on how to eliminate them.

A00

Error a00 is not an error itself and is lit on the display when the "Info" function is active. This code periodically changes to the indicator of the temperature at the boiler inlet Baxi Luna 3 and Baksi Luna 3 Comfort -, Baksi Ekofor 24,

E00

Error e00 indicates a malfunction of the electronic board. For repair, you must call the service technician.

E01

There is no ignition at start-up or gas supply on Baxi Mainfour 240F (Mine For 240F), Baxi Main 24 FI (Main 24 FI), Eco Four Baxi, etc. The error was caused by the triggering of the flame monitor. Press and hold the "R" button for three seconds. If ignition does not occur, contact the service department. The reason may be a malfunction of the ignition system, electronic board, improper setting of the gas valve, malfunction of the chimney, or a drop in gas pressure in the line.

E02

The thermostat has tripped. If, after pressing and holding the "R" button for a few seconds on the Baksi Luna 3 Comfort wall models, nothing happens, the e02 error is on, you should also call the wizard by the service organization. It can be caused by overheating of the water, an incorrect signal from the sensor, the fact that there is no contact between the sensor itself and the coolant, weak circulation of the coolant.

E03

For the Baxi Mine 5 and Baxi Mainfour 24 model, the cause of the e03 error may be an incorrect setting of parameter F43. For other models, this is a malfunction of the thermal relay or draft sensor. The reason may be clogging of the flue ducts, violation of the rules for installing flue ducts during the installation process, breakdown of a fan or pneumatic relay.

The same result will be in the absence of contact between the board and the fan, the board and the pneumatic relay. Check if the chimney is clogged, if there are contacts on the above devices. If it is impossible to diagnose the cause, call the wizard.

E04

The signal is given by the flame sensor about the periodic loss of the flame on the burner. This error e04 can be caused by a breach of the tight contact between the wire and the ionization electrode, a malfunction in the chimney, clogging or improper positioning of the electrode, voltage fluctuations in the electrical network, and a malfunction of the electronic board.

E05

The signal comes from the temperature sensor of the heating circuit. When the boiler issues such an error e05, most likely either the sensor itself has broken, or the electronic board has burned out, or there is no contact between the sensor and the board. Check for a contact on the board and on the sensor.

Boiler temperature sensor

E06

Malfunction of the temperature sensor of hot water supply in a double-circuit boiler. Error e06 is caused by a breakdown of the sensor, lack of contact between the board and the sensor, and a malfunction of the board. You need to check your contacts.

E10

Appears in the absence of a signal from the hydraulic pressure switch, triggering of the water pressure sensor. For the Baxi Main Four, Main 5, Baksi Ekofor 24 F, Eco Four Baxi, Fourtech, Luna-3, Luna-3 Comfort models, the e10 error means that the water pressure in the system has dropped, the relay does not work, there is no contact in the relay board.

12E

The appearance of the error code 12e in the Baksi slim 1.150 i units indicates the absence of a signal from the differential hydraulic pressure switch. Violation is possible if the heating system is blown, the membrane is damaged, the pump is blocked, the microswitch is faulty. Check the diaphragm, pump, bleed the air from the system

E25

Temperature rise too fast, more than one degree per second. Error e25 occurs if the batteries in the system of double-circuit units are air-in, the pump, the heating circuit sensor has broken, the board is faulty, or there is no contact between the board and the pump connection cable. To eliminate it, you need to check the serviceability of the above devices.

Mayevsky's crane for bleeding air from the battery

E26

Exceeding the set temperature by more than 20 degrees. Error e26 occurs for the same reasons as e25, and similar methods of elimination.

E27

Incorrect location of the temperature sensor in double-circuit boilers. Error e27 is caused by a breakdown of the sensor or its incorrect installation. How to fix this breakdown - check the operation of the sensor and its position.

E32

Error e32 signals the formation of a large amount of scale in the heat exchanger. To eliminate it, you need to descale the heat exchanger. To clean it with a reagent, you need to remove the heat exchanger, first draining the water from it and turning off the water and gas supply valve.

E35

A parasitic flame appears until the flame sensor is applied to open the gas valve. Error e35 appears when water appears on the electronic board, the gas valve is depressurized, the parameters in the electrical network do not meet the requirements of the instructions for the unit, or the board is out of order. Most often, in this situation, the installation of a stabilizer and grounding helps.

Heating boiler board

E40

Chimney blockage or too low gas supply pressure. There can be many reasons for the e40 error, the main ones are the lack of gas supply, violation of draft in the chimney, insufficient air, improper operation of ionization sensors, exhaust gases, failure of the gas valve, the board does not work. You can check the chimney yourself, it is better to entrust the rest of the diagnostics to a specialist.

E41

Error e41 has the same reasons and solutions as e40.

E42

Signals loss of flame. Error e42 occurs when the chimney is clogged, there is no contact between the board and the fan, the fan is faulty, the rules for installing the chimney are violated. With your own hands, you can check the draft in the chimney, for everything else it is better to call a specialist.

E96

The e96 error lights up on the Baxi Main Four display when the mains voltage drops. In this case, restarting the unit can help.If the situation repeats itself, invite a specialist from the service company. On a Baxi SLIM device, this code occurs when a control panel malfunction occurs. here only a call of a specialist can help.

Baxi Main Four boiler

E97

If the setting of the frequency of the supply signal to the board does not match, the e97 error lights up. To eliminate, change the frequency.

E98

Error e98 occurs when the control unit malfunctions, usually sticking of the contacts of the gas supply valve relay. A professional call will help here.

E99

Error e99 is similar to e98, as well as its solution.

128

When the flame goes out during the operation of the boiler, the error e128 is displayed. This happens when the ionization current parameter is below normal. In this case, you will need the help of a specialist.

E133

When the gas supply is cut off, the e133 error appears on the baxi-luna-ht-1-450 display. To resume the operation of the device, press and hold the "Start" button for several seconds.

168

The system issues an error e168 when the power supply is unstable, usually when it surges upward. To identify a specific malfunction in this case, the presence of a specialist is required.