Gas boilers, which provide a source of thermal energy for an autonomous heating system, are the most convenient and efficient option.

They are able to work in automatic mode, do not require constant human participation, and are economical and efficient.

The striking representative of the group of gas heating boilers are the Italian Beretta units, which demonstrate excellent performance in combination with affordable prices.

Beretta boilers are reliable and stable in operation, they are constantly monitored by their own self-monitoring system of the state of parts and assemblies.

Consider the most common malfunctions of these units and how to solve the problems that arise in connection with them.

The main malfunctions of gas boilers Beretta

The design of Beretta boilers is a reliable and durable engineering solution that takes into account all the loads and effects on the parts and assemblies of the unit.

The most probable malfunctions occur in the most critical units experiencing maximum temperature or dynamic loads.

According to experts, the most common malfunctions include:

- Lack of flame on the burner, causing blocking of the boiler. This problem occurs most often, since it can be caused by various reasons, from clogging of the burner nozzles, to the cessation of gas supply to the main.

- Failure of the control board - burnout of parts or failure due to the ingress of condensation. This is one of the most frustrating problems for the user, since replacing the control board is a very expensive procedure.

- Boiler shutdown due to exceeding the admissible flue gas pressure. Here, the reasons can be both clogging with soot or the appearance of ice at the exit from the chimney, as well as an increase in wind, which creates excessive pressure in the chimney.

- Failure of any self-diagnosis sensor. The boiler control system recognizes such situations as an equal error and immediately takes appropriate action.

- Low water pressure in the supply pipe of the heating circuit. If make-up does not help to solve the problem, then a leak or failure of the expansion tank is possible.

IMPORTANT!

The listed problems are among the most common, but this does not mean that they are obligatory - during operation, any accidents are possible, and the described situations may not appear at all.

How to run self-test

The self-diagnosis system is a network of sensors located on all important and critical parts and assemblies of the boiler..

They do not need to be started, since they operate in a continuous mode, from the moment of switching on to stopping the operation of the unit.

Therefore, the start of the self-diagnosis of the gas boiler as a separate function is not possible.... Moreover, if it occurs to someone to stop the operation of the system, then no result will work - it is impossible to stop the process by standard methods, and the disconnection of the sensors is regarded by the control board as the same error causing the boiler to block.

The self-diagnosis system is an integral part of the gas boiler operation process, which ensures the safety of the equipment and notifies the owner or repairman about the localization of the defective unit.

Central heating problems

The solution can be a single-circuit or double-circuit boiler. The first type is capable of providing a heating process.With the help of a double-circuit device, it is possible to provide not only space heating, but also heating the coolant for solving household problems. If you decide to purchase a Beretta double-circuit gas boiler, then it is worth remembering that its installation will be a rather troublesome and time-consuming process.

Error codes and their decoding

Consider the main error codes (pictures) of Beretta boilers:

| The code | Decoding |

| A01 | Boiler shutdown due to lack of flame on the burner |

| A02 | Boiler blocked by thermostat signal (overheating) |

| A03 | Exceeding the permissible flue gas pressure |

| A04 | Low pressure of the heating agent in the heating circuit |

| A05 | DHW temperature sensor failure |

| A06 | Heating circuit temperature sensor failure |

| A07 | Thermal relay does not open |

| A11 | Parasitic flame (a flame is detected when the burner is off) |

| A24 | Fan failure |

| ADJ | The setting of the upper and lower limits of the boiler output is required. |

| E33 | Incorrect phase and neutral connection of the power supply |

| E35 | Pressure switch failure |

| E37 | False flame, chimney problems |

| E38 | Smoke sensor short circuit |

| E39 | Broken smoke sensor contacts |

| E40 | Unstable supply voltage |

| E42 | Short circuit of the pressure sensor of the direct line of the heating circuit |

| E43-44 | Opening of contacts or short circuit of the pressure sensor on the return line of the heating circuit |

| E46 | Overheating of the coolant |

| E48 | The fan is peddling |

NOTE!

Errors of type "A" require a restart of the boiler, and errors of group "E" disappear after the cause has been eliminated without the need for a restart.

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs during the operation of the Beretta boiler.

Let's consider the most common errors and possible ways to fix them.:

- A01. Blockage due to lack of flame. There are several possible reasons - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are heavily clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the extract air pressure, add fluids to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, accumulation of soot. Weather factors are possible - strong gusty wind.

- A 04. The drop in coolant pressure may be caused by a lack of fluid. Check the system for leaks, if found, repair.

- A05. Malfunctions of the DHW line thermistor are eliminated by replacing the sensor.

- A06. A defective heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent, do not work if the phase wire is incorrectly connected.

- E46. Exceeding the permissible temperature of the coolant indicates problems in the circulation of the liquid. CHECK the operating mode of the circulation pump.

- The bell symbol (bell, p) flashes. This is a signal from the chimney pressure sensor, indicating that there is an obstruction to the exit of smoke, the formation of ice or frost at the exit of the chimney.

IMPORTANT!

The Beretta boiler error is reset by pressing the shutdown button and restarting the boiler after 5-6 seconds.

Reviews about the rules for the design of the boiler room

When purchasing wall-mounted gas boilers "Beretta", they must be installed in rooms to which certain requirements are imposed. When installing a boiler in a private single-family house, the boiler room or furnace can be located on any floor, including the basement, roof, attic or basement. The restriction applies only to living quarters, as well as to a bathroom and a bathroom, where the boiler is prohibited.Consumers emphasize that it is important to determine the volume of the boiler room, taking into account the thermal power of the equipment, the capacity of water heaters, as well as flow tanks.

User's manual

Operation of Beretta boilers is carried out in automatic mode, which does not require constant human participation.

The user is only required to adjust the heating mode according to his own feelings, transfer the boiler to winter or summer mode (turn off or start the heating circuit), maintain the cleanliness of the case and periodic maintenance (by the service personnel).

All serious problems are solved only by calling the wizard - elimination of constantly occurring errors or incomprehensible phenomena that occur with the boiler in operating mode.

In addition, the user independently fills the system with water (or make-up as needed).

The process consists in supplying liquid through the make-up valve and filling the system until the water pressure reaches 1-1.5 bar. This is below the working pressure, but when heated, the water will expand and, due to the increase in volume, the pressure will reach the desired value.

Download instruction

Download instructions for gas boilers Beretta.

The boiler starts up automatically when the required temperature of the coolant in the system is set.

Do not pour water into a hot boiler due to the risk of destruction of the heat exchanger... Wait until the boiler cools down, and only then pour water.

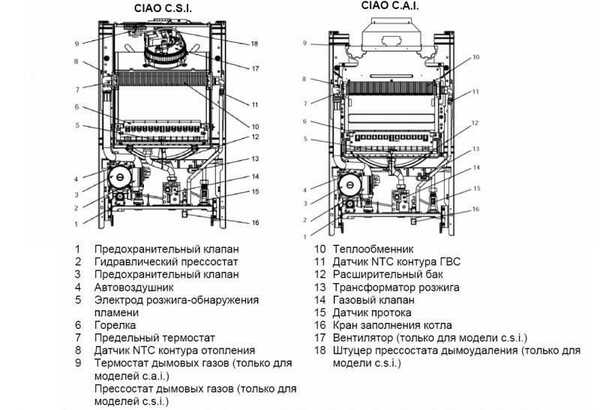

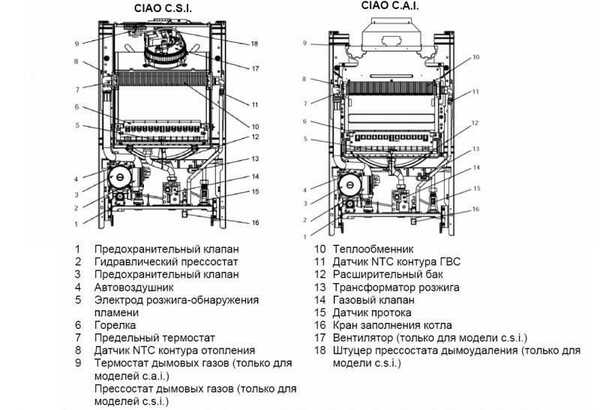

Review of the gas wall-mounted boiler Beretta Ciao CSI

Beretta Ciao 24 CSI are wall-mounted gas boilers with forced smoke exhaust and air intake, designed for heating and production of domestic hot water.

The main components and functionality of the wall-mounted boiler Beretta Ciao 24:

Microprocessor board that controls inputs, outputs and alarms.

Electronic modulation provides smooth power control in DHW and heating mode.

Electronic ignition with ionization type flame control.

Smooth automatic ignition.

Built-in gas pressure stabilizer.

Device for pre-setting the minimum water temperature in the heating circuit.

OFF-RESET switch for restart after stopping by alarm, selection of Summer mode, selection of Winter mode, heating circuit temperature controller.

DHW temperature regulator.

NTC sensor for monitoring the temperature in the heating circuit.

NTC sensor for monitoring the temperature in the DHW circuit.

Circulating pump with auto-air valve.

Automatic by-pass of the heating circuit.

Coaxial heat exchanger for heating the heating water and DHW.

Expansion tank 7 L (24 CSI), 8 L (28 CSI).

Heating system make-up tap.

Pressure gauge for monitoring the water pressure in the heating system.

Space for a 24 V room thermostat.

The Beretta Chao boiler was prepared for connecting the following accessories: an outside temperature sensor, which allows the function of weather-dependent regulation, a remote control.

Anti-jamming function of the circulation pump, which is activated automatically every 24 hours after the last pump cycle.

Closed combustion chamber.

Flame control device, ionization type, in the event of a loss of flame, it shuts off the gas supply and gives a light signal.

Hydraulic pressure switch that controls the water pressure in the heating circuit.

Limit thermostat that controls the boiler overheating.

The smoke exhaust pressure switch, which monitors the operation of the fan and the smoke exhaust system.

Safety relief valve 3 bar, installed in the heating circuit.

Frost protection.

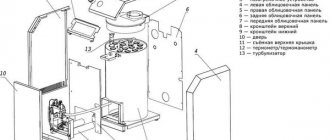

Fig. 1.Assembly parts for wall mounted boilers Beretta Ciao 24 CSI

1 - Boiler filling valve, 2 - Safety valve, 3 - System drain valve, 4 - Circulation pump, 5 - Auto air vent, 6 - Ignition transformer, 7 - Burner, 8 - Ignition-flame detection electrode, 9 - Limit thermostat , 10 - Heat exchanger, 11 - NTC sensor of the DHW circuit, 12 - Fan, 13 - Tube for measuring vacuum, 14 - Flue gas flange, 15 - Flue gas pressure switch, 16 - Expansion tank, 17 - NTC sensor of the heating circuit, 18 - Gas valve , 19 - Hydraulic pressure switch, 20 - Flow sensor

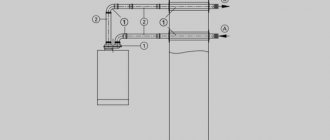

Fig. 2. Hydraulic diagram of the gas boiler Beretta Ciao 24

1 - Water inlet from the water supply system, 2 - Water outlet to the DHW circuit, 3 - Direct heating system pipeline, 4 - Heating system return pipeline, 5 - Drain valve, 6 - Safety valve, 7 - Circulation pump, 8 - Auto air vent, 9 - Expansion tank, 10 - Heating circuit NTC sensor, 11 - Heat exchanger, 12 - Burner, 13 - DHW circuit NTC sensor, 14 - Hydraulic pressure switch, 15 - Bypass, 16 - Flow limiter, 17 - Flow sensor, 18 - Filter, 19 - the make-up valve

Installation of gas boilers Beretta Ciao 24 CSI

Beretta Chao boilers do not use air from the room in which they are installed during operation. Therefore, there are no additional ventilation requirements for these rooms. Various configurations of flue gas extraction and air intake are possible for this type of boiler.

For the correct installation of the wall-mounted boiler Beretta Ciao 24, it must be borne in mind that:

It should not be installed over a stove or other cooking equipment;

It cannot be installed in residential areas;

It is forbidden to store flammable substances in the room where the boiler is installed;

If the wall is sensitive to heat (eg a wooden wall), it must be protected with appropriate thermal insulation.

In order to be able to access the inside of the unit for routine maintenance, during installation, leave a minimum distance to walls and objects.

The device is supplied with a mounting bracket as standard.

To install the Beretta Ciao 24 CSI boiler, follow the steps below:

Fasten the bracket to the wall and use a spirit level to check that it is in an ideal horizontal position.

Mark the top holes (6mm diameter) that are needed to secure the bracket.

Make sure that all dimensions are accurate, then use a drill with a drill, the diameter of which is indicated above, make holes in the wall.

Attach the bracket to the wall using wall plugs.

Electrical connection of boilers Beretta Ciao 24 CSI

The connection to the mains supply must be made through a separate circuit breaker with a contact gap of at least 3 mm. The boiler is powered by 230V 50Hz alternating current.

The consumed electric power of the boiler is:

100 W (Ciao 24 CSI) - 120 W (Ciao 28 CSI)

To access the terminal block, follow these steps:

- Turn the main switch to the off position.

- Unscrew the screws that hold the cladding.

- Slide the cladding base forward and upward to detach it from the frame of the Beretta Ciao 24 boiler.

- Unscrew the screw securing the instrument panel.

- Pivot the instrument panel towards you.

- Remove the cover that covers the terminal block.

- Pass the power cable and the room thermostat that you want to connect.

The room thermostat has a safety low voltage input (24 V DC). The ground wire should be a couple of centimeters longer than the others. It is forbidden to use gas and / or water pipelines as grounding for electrical appliances.

The manufacturer cannot be held responsible for any possible damage that may be caused by a lack of grounding of the boiler. If you need to replace the power supply wire, use HAR type H05V2V2-F, 3 x 0.75 mm2, maximum outer diameter 7 mm.

Gas connection to the wall-mounted boiler Beretta Ciao 24 CSI

Before connecting the Beretta Chao boiler to the gas network, make sure that:

Applicable standards have been complied with;

The type of gas corresponds to that for which the device is designed;

The gas pipeline is cleaned of dirt.

To avoid unnecessary pressure losses, the gas connection must be made with a rigid connection with a diameter of at least ¾ '. Before the gas enters the boiler, a shut-off valve must be installed (not included in the scope of delivery).

We recommend installing an appropriately sized filter on the gas line if the gas line contains foreign particles. After completing the installation, check the tightness of the connections in accordance with the current installation standards.

Filling the heating system

After completing the hydraulic connections, you can proceed to filling the heating system. This operation must be performed with a cooled system.

To fill the system, carry out the following sequence of actions:

Unscrew the air vent cover two or three turns.

Make sure the cold water inlet valve is open.

Open the filling valve and keep it open until the pressure on the pressure gauge reaches a value between 1 and 1.5 bar.

When the system has finished filling, close the make-up valve.

An automatic air separator is installed on the Beretta Ciao 24 boiler, so no additional operations are required to release air from the system.

The burner will only ignite if the venting phase has been completed.

Flue gas removal and air intake

The Beretta Chao boiler must be connected to coaxial or separate chimneys and air ducts, which must be led out through the roof or outer wall.

Effective and safe operation is only guaranteed if original flue and air ducts are used for units with a closed combustion chamber.

This equipment is not included in the standard package and is supplied by separate order. When installing chimneys and air ducts, make sure that all connections are made correctly, in accordance with the attached instructions.

It is allowed to connect several boilers to one collective chimney, provided that all of them have a sealed combustion chamber.

Firing up the gas boiler Beretta Ciao 24 CSI

To ignite the Beretta Ciao 24 boiler, you must perform the following operations:

Switch on the power supply to the unit.

Open the gas cock in front of the device.

Set the mode switch to the required position:

Summer mode: the boiler will be in standby mode until a request for heating water in the DHW circuit appears.

Winter mode: set the switch inside the zone divided into segments, in this case the boiler will start operating in heating mode and, when a signal appears, it will automatically switch to the DHW heating mode.

Set the room thermostat to the desired value (approx. 20 ° C).

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

OPERATION AND REPAIR OF BOILERS

Have you faced problems with central heating or hot water supply for a long time? These issues can be solved by installing a gas boiler.

Does not start (does not light up) - reasons and solution

The failure of the boiler at startup can be caused by various reasons, which can be determined either by the corresponding error code, or by checking the status of the boiler independently. The simplest option is the absence of gas in the main line.

This problem is external, it can only be solved by contacting the gas service.... The gas supply valve on the unit itself may be closed. There is one more reason for failure in ignition - polarity reversal of the power wires. It is shown on the display as code E33.

The solution to the issue is to reconnect the wires... Such a situation may arise even after a certain period of normal operation of the boiler, if any work was performed on the power supply panel and the phase and neutral were reversed by mistake.

If you cannot find the reason for the failure to ignite the boiler, you should contact a service workshop.

For reference

If you decide to install a gas boiler "Beretta", then keep in mind that when installing it, it is important to take into account some factors. So, if the device has a closed combustion chamber, then the volume of the boiler room is not standardized. It is not necessary to have a window. For the removal and supply of oxygen, it is important to ensure the flow of air in the required volume.

Thus, if you installed a boiler with a capacity of 23.3 kilowatts, then the gas will burn in a volume of 2.5 cubic meters per hour. In order to ensure complete combustion of a given volume, 30 cubic meters of air per hour is needed. If you do not guarantee a sufficient supply of air, then the gas will not burn completely, as a result, a harmful substance will begin to concentrate, its inhalation can negatively affect human health. If carbon monoxide is inhaled for as little as 15 minutes, death can occur. Oxygen must penetrate not only from the outside, but also from other areas of the house. This can be ensured by the presence of a gap that will be located between the door and the floor surface. It is also recommended to install a grill at the bottom of the door.

How to check the sensors

All sensors of the Beretta boiler are part of the self-diagnosis system. They not only perform control functions, but are themselves objects of observation.

This means that in case of failure, short circuit or wire breakage of any sensor, the corresponding error code will immediately appear on the display of the boiler control panel. The system polls the sensors automatically at the moment of switching on, no special actions are required from the user.

Most of them are thermistors that respond to changes in the temperature regime or the indicators go beyond the limits set by the operating mode. The design of the elements is simple, replacement, if necessary, is not difficult and does not take much time.

It is not recommended to change any elements of the boiler yourself, you need to call the master from the service center.

What else should you pay attention to

Be sure to provide a gas analyzer to be located in the boiler room. With this device you can prevent gas leaks. The device must be equipped with an electric valve. The latter is designed to shut off the gas supply if necessary.

, a gas boiler of which you can purchase at specialized points of sale, indicates the possibility of placing the equipment in the basement of an exclusively single-family house. With regard to multi-storey buildings, the installation of the device in the basement is prohibited.

How to repair the Beretta gas water heater if it does not burn and does not heat? In this article, we have collected the main causes of breakdowns, gave advice on how to eliminate them.

The Beretta company has been manufacturing heating equipment for 60 years. Flow-through heaters are an economical way to get hot water, but the equipment breaks down with long-term operation.

The pump does not work - what to do

If a failure of the circulation pump is noticed, it is necessary to stop the operation of the system and call the wizard.

There can be several reasons for failure, from power supply problems to mechanical problems.... The first reason is determined by testing and checking the condition of the pump motor.

The second reason can be detected by checking the condition of the moving parts of the pump, the absence of difficulties when rotating or moving parts of the mechanism, breakdowns or wear of gears and other elements.

The decision to repair or replace the pump is made based on the result of an examination of the performance and condition of the unit parts.... If the forecast for repair work is favorable, the pump is restored, otherwise a complete replacement is required.

How to flush the heat exchanger

Beretta boilers are equipped with either separate or bithermic (combined) heat exchangers. In the first case, flushing gives a greater effect, the second type of heat exchangers is difficult to flush due to the design features.

There are two ways to flush:

- Mechanical... Requires disconnection of the heat exchanger from the boiler. The results of this rinsing are not particularly successful, since it is extremely difficult to mechanically clean the inner surfaces.

- Chemical... It does not require dismantling the heat exchanger, but it is done using a special device. It has a fairly high efficiency, is able to remove scale and extend the service life of the unit.

For flushing, special reagents are used that dissolve scale and remove it from the inner cavity of the heat exchanger tubes. The procedure should be performed every 2-3 years, depending on the quality of the water. To perform the work, you need to invite a specialist from the service center.