Penofol properties

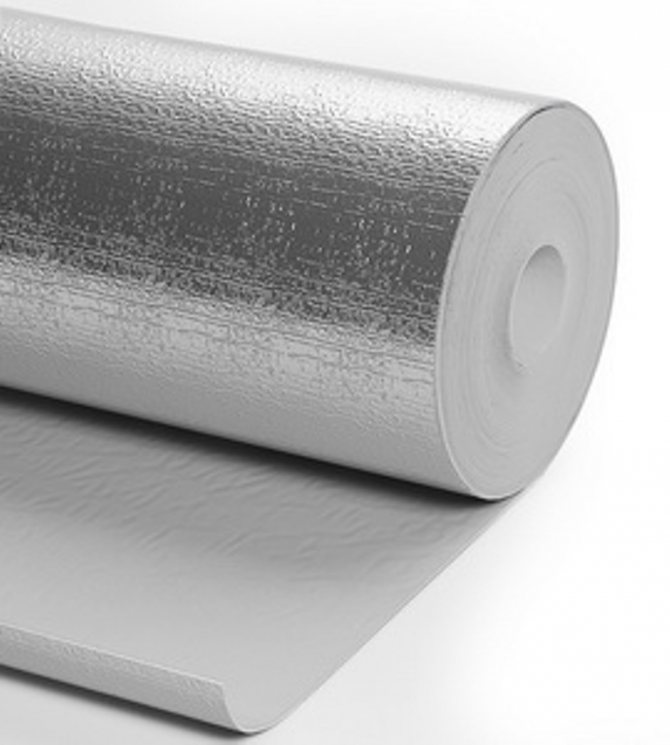

Foiled penofol is an insulating material with a reflection effect, which has a multilayer structure. The main purpose is to remove drafts or wind flows from building structures, to eliminate condensation or moisture, steam that rise up the tiers. Also, the material isolates external noises or sounds. It is a universal type of insulator, since it increases sound insulation, vapor barrier, protects against moisture and retains heat. Such features are due to the structural organization of the material and the technology used in production.

The bulk of the material is foamed polyethylene... In this case, the pores formed on it are closed and filled with air. Such polyethylene foam is used in the form of skeins with different densities, thicknesses and different internal structures. Either on one or on both sides, based on the purpose of the material, polyethylene is covered with aluminum foil. Before application, it is processed and polished to a high gloss with a maximum reflectivity (up to all 97% and even more). More often, the foil is applied using heat welding, which provides better adhesion of the material.

The thickness of penofol is from two to ten millimeters, the foil is only from 12 to 30 microns. The thickness of the material can be increased to 40 mm, if it is necessary to create especially strong thermal insulation, for example, in an arctic climate.

Penofol is based on the well-known principle of "Dewar vessel" in physics. At the beginning of the last century, James Dewar established that every substance has some kind of resistance to heat transfer. Whatever this indicator is, the material can only suspend or make the movement of heat slower, however, not stop it at all. In this case, heat waves are collected in the substance and energy is accumulated inside the substance, after some time, a supersaturation is created, after which any material becomes a source of heat itself.

Experimenting further, Dewar isolated several substances that did not absorb thermal energy, but reflected. Among those were all the precious metals (platinum, silver and gold), as well as polished aluminum. At the same time, heat rays are reflected from surfaces by almost 100%. These reflectors themselves are excellent heat conductors and should be used in conjunction with heat sinks.

A common thermos is arranged in approximately the same way, and Dewar's research became the basis for the creation of space suits and materials for thermal insulation with a reflective effect.

The use of both double-sided and single-sided insulators reduces the cost of heating the premises in winter, and in warm summer weather does not allow the house to heat up too quickly.

What insulation for walls is better to choose

So, you decided to significantly reduce the heat loss of your apartment or residential building and did what almost all the owners of the living space do in this case - you insulated the doors and installed double-glazed windows.

And immediately felt the improvement in energy saving, the cost of paying for heat decreased.

However, many ordinary people do not stop at this and continue to search for opportunities for more significant energy savings, asking neighbors and acquaintances of builders what else can be done to achieve the goal.

You will find the most complete answer to this question in our article.So, if you seriously set out to make your apartment or house as energy-efficient as possible, in addition to insulating doors and installing double-glazed windows, you must also insulate the walls by covering their surfaces with insulation materials of various types and types.

This is a very effective measure, it allows several times to reduce heat loss, which has been proven by practice and laboratory research. So there is a solution to effective energy saving.

Now the question arises, which of the many types of insulation is best used? The question asked is really quite relevant and serious, therefore it is necessary to approach it with full responsibility.

Heat insulating materials

Indeed, today's building materials market is filled with a huge variety of insulation products. However, this does not mean that each of them can be used for wall surfaces. Therefore, we will list those heat-insulating products that specialists use today to insulate walls everywhere:

- Polyfoam, aka expanded polystyrene;

- Mineral wool;

- Fiberglass wool;

- Penoplex;

- Penofol.

The first three named materials are well known to most of the inhabitants; they have been successfully used for a long time in performing heat-insulating processes.

But penoplex and penofol appeared on the construction market relatively recently, although even in a short period of time they have already managed to show themselves as excellent heaters with excellent operational and physical and technical characteristics.

And, nevertheless, the vast majority of builders and ordinary people, when it is necessary to insulate the walls in their houses and apartments, for many reasons, prefer foam and mineral wool.

And the main reason pushing people to such a choice is the cheapness of these materials.

Based on this, we have set ourselves the goal of acquainting you as fully as possible with the indicators of these two heaters - foam and mineral wool.

Styrofoam

What is this material and what is it made of? Polystyrene granules are used as a raw material for the manufacture of foam. During the production process, they undergo several processes or stages of processing:

- I will heat up.

- Thermal swelling.

- Formation.

At the last stage of the process - shaping - not only is the final product shaped, but a certain density of the material is also created, in accordance with which the thickness of the manufactured product, that is, panels, will subsequently be laid. This is a very significant indicator that largely affects the quality of the product, the cost of the process and the size of the room to be insulated.

But the greatest role in this material is assigned to air bubbles, which are formed directly inside the polystyrene granules in the manufacture of foam. First, the air bubbles are isolated from each other.

Secondly, as has long been known, it is air that is the most powerful heat-insulating material.

So, having delved into the above two reasons, expanded polystyrene foam type without any stretch can be attributed to the category of products with excellent performance, it is almost completely vapor-proof and moisture-proof material with very high thermal insulation properties.

As you can see, there really are significant reasons why foam has become a popular and most commonly used thermal insulation material. And if you add the extraordinary lightness of this insulation product (foam is 98% pure air), then in terms of competitiveness, foam gives odds to all other types of thermal insulation materials.

Extruded polystyrene foam

A kind of the same foam, additionally subject to technological processing, or more precisely, melting with extrusion.

What does it mean? After the polystyrene granules undergo this industrial processing, the properties of the foam change, and primarily due to this effect, the foam becomes much more elastic.

All of us, to a greater or lesser extent, had the opportunity to be convinced of the fragility of this insulation product, and this is due to the property of quick separation of polystyrene balls from one another. So, the melting process creates a strong bond between the balls.

The layman, of course, is interested in the cost of both types of insulation. So, extruded polystyrene foam is much more expensive than its foam counterpart.

However, we will immediately make a reservation that the high price of the product is justified, this material costs a lot of money, because it has excellent thermal insulation characteristics, it can be effectively used for floor insulation, it has a high coefficient of compression and strength.

As a rule, this material is used, as we said, for floor insulation, although it is quite common on wall surfaces.

When should foam be preferred?

This insulator is successfully used to insulate a wide variety of surfaces - walls and floors, ceilings and roofs and on other surfaces.

But let's make a reservation right away that polystyrene is not an absolute panacea if insulation is necessary in all cases. There are times when styrofoam will not give the expected effect.

For example, experts have made an unequivocal conclusion that foam works best when insulating surfaces outside. And it is according to this principle that builders perform thermal insulation of country houses.

Of course, there is no doubt that polystyrene foam can be used to reliably insulate the apartments of the upper floor when it is installed from the inside. But in this case, you will have to strictly follow the recommendations and installation technique of insulation products, in addition, this will entail additional consumption of materials, which, in general, will affect the estimated cost of insulation.

Also, when using insulating materials from the foam line, the environmental friendliness of the material must not be overlooked. Despite the fact that manufacturers guarantee its complete safety for humans, there are different opinions on this matter.

Some ordinary people believe that polystyrene is exposed to high temperatures and, if present, releases substances harmful to the human body.

However, there is also an opposite point of view, which has an “iron” foundation. Firstly, scientists have long proved that expanded polystyrene is an absolutely environmentally friendly material, even the fact that it is used in the food industry for the manufacture of containers for a certain category of products testifies to this.

The second, purely psychological moment for those who doubt the cleanliness of the insulation - the foam laid on the surface will necessarily be separated by a steam-terrier and finishing material from the room space.

And this, you see, is a very impressive protection, thanks to which a person can feel completely safe.

Mineral wool

What raw materials are used to make mineral wool? The source material from which this type of insulation is made is rocks from the basalt group (for this reason, mineral wool is called basalt wool).

Sometimes mineral wool is made from molten blast furnace slag, which is used as the main or additional raw material.

Mineral wool is comparable to asbestos, but unlike it, wool is absolutely harmless and does not emit any harmful substances.

Mineral wool owes its popularity to such significant positive indicators as high thermal insulation properties and increased moisture resistance. It is these two properties that are so necessary for the thermal insulation of the material that made cotton wool a popular insulating material.

I would like to dwell a little more on the parameter of thermal insulation of mineral wool, because it has a dual characteristic. Firstly, the insulation does an excellent job of protecting against the penetration of external cold.

Secondly, cotton wool is often used as a barrier against heat leakage.

For example, it is used to insulate boilers, pipelines with hot heat carriers, furnace outlet pipes and in many other cases when it is necessary to save heat in a variety of structural elements.

What makes the insulation able to withstand such heavy loads? And the fact is that mineral wool is able to withstand temperatures up to +800 degrees Celsius. And at high temperatures, it will begin to melt, but will not burn. As you can see, this is another serious argument in favor of mineral wool.

True, when using cotton wool for thermal protection, it is necessary to use a special version of the insulation with a foil coating.

When should mineral wool be preferred?

Where can you use this type of insulation? In many cases, but usually, mineral wool is used when necessary:

- Insulation of facades with their subsequent coating with plaster or siding;

- Insulation of wall surfaces and partitions;

- Insulation of the roof and floor;

- The need for use in frame construction.

It should be noted that the manufacturer has taken into account the possibility of using mineral wool in different situations, therefore, this heat-insulating material is produced in the form of mats of standard sizes and in rolls. Also, the layman can pick up insulation according to the indicator of the thickness and density suitable for him, according to which the material is marked.

Outcome

So, you have in an accessible form received the maximum information about two excellent thermal insulation materials - foam and mineral wool, which are most often used as insulation for various surfaces of apartments and houses.

In addition to what has already been said, we consider it obligatory to note the simplicity of the installation work with these materials, almost any man in the street, in the absence of a builder's experience, is quite capable of independently performing insulation work with foam or mineral wool.

True, it must be borne in mind that if the installation of foam plastic can be carried out directly on the wall surface using an adhesive mixture, then for laying mineral wool on the wall surface it is necessary to make a working frame.

It represents a series of vertical slats or bars of appropriate thickness, which are assigned the role of fasteners, between which insulation wool is placed.

Of course, if we compare the cost of insulating materials and the costs of their installation, then the advantage is on the side of the foam, its use will be much cheaper for the layman. And this despite the fact that the foam itself is several times cheaper than mineral wool, which automatically puts it in a leading position in sales.

As you can see, there are some pluses in favor of foam, everything is fine and cloudless. If not for one thing - a mouse! Even one small rodent will very quickly take a liking to polystyrene and make it its permanent habitat. This means that it will gnaw through the insulation up and down.

After such vandalism, you can say goodbye to the thermal insulation of your apartment or house.

Therefore, even before purchasing this or that insulation, use the qualified advice of a specialist who, after examining the premises and the accompanying nuances, will be able to give recommendations on the use of this or that insulation.

Penoplex and penofol

It makes no sense to compare this line of insulation materials with previous heat insulators, because they are in different price ranges, and the newly introduced insulators are much more expensive than their counterparts made of foam or mineral wool, as well as their subspecies. However, we should pay tribute to the fact that penoplex and penofol belong to the category of heaters of the modern generation with excellent operational and technical characteristics.

And the flagship among them is penofol, made in the form of a multifunctional insulating material, which, thanks to its three-layer design, is capable of simultaneously waterproofing, thermal insulation and vapor barrier of a room.

This insulation is glued to the wall surface with the help of special glue, in contrast to the foam, which is fixed to the wall surface with fungal self-tapping screws.

In addition, penoplex is produced in the form of even and smooth panels, which greatly simplifies the preparation of the wall surface for its subsequent finishing.

Source: https://SovetPoRemonty.ru/steny/kakoj-uteplitel-dlya-sten-luchshe-vybrat.html

Pros and cons of penofol

When using penofol for insulation, the following advantages can be distinguished:

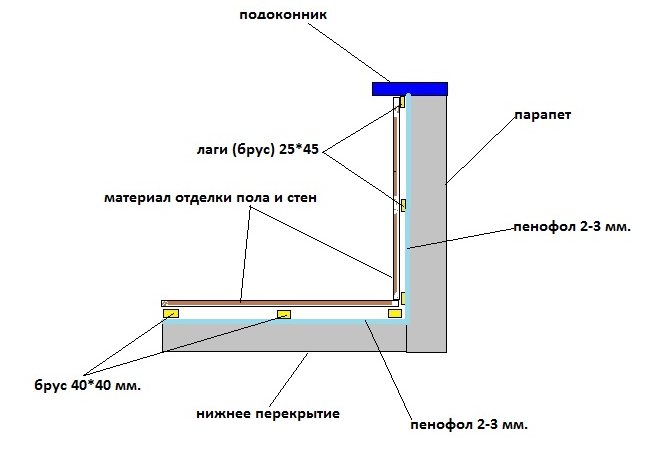

- Penofol possesses versatility of use - the material can be used during construction and repair work, outside or in the internal insulation of premises. For example, for balcony insulation.

- It has minimal vapor permeability from the side of the insulation, which makes it possible to apply penofol without additional vapor barrier material.

- It gives good insulation from noise, it is often used in houses, in workshops against acoustic noise.

- Compared to other insulators, the material is quite thin. Penofol on two sides 4 mm thick can replace mineral wool laid out with a thickness of 8.5 cm, a pine interlayer of 1.8 cm or as much as 3 cm of expanded polystyrene with extrusion.

- Penofol easy to mount... This material is lightweight, it makes it possible to install thermal insulation without assistance. For work, no extra tools are needed, the sheet of material is simply cut with a knife, you can fix it with a stapler for furniture, small nails, or tape.

- Penofol made from environmentally friendly materialsthat meet all sanitary requirements. The substances from which it is made are used to store food, and some of the manufacturers even warn that penofol will protect against increased radiation.

- This heat-shielding material is hardly flammable, which significantly increases the level of fire safety in an insulated room.

- It is too thin for rodents who like to make minks in other insulation can start in it.

- Penofol is convenient to transport, the canvas is collected in rolls, they can later be hidden in the trunk of a passenger car.

Even taking into account the huge variety and number of advantages of foil-clad penofol, it also has a number of disadvantages:

- The material is quite soft, which limits its possibilities.It will not work for wallpapering or plastering.

- For fixing, you may need to purchase specialized glue. True, there are self-adhesive material options.

- Experts recommend not using this material as an insulated external insulation for buildings. It can be attached to reflect heat energy or to protect the entire structure from internal moisture in a separate layer.

Advantages and disadvantages

Penofol is used to protect against cold, dampness and extraneous sounds in the room. The main advantages material:

- Low thermal conductivity.

- Virtually zero vapor permeability, making the material an excellent barrier to evaporation.

- Fire safety, it belongs to the class of hardly combustible substances.

- The material does not melt at high temperatures (up to +110 degrees).

- Penofol does not absorb moisture and reliably protects elements of the frame and floors from its penetration.

- Small thickness.

- Convenient transportation, sheets of material are rolled into rolls and take up little space.

- Strength and durability.

- Ease of fastening sheets of material.

- Affordable price.

Material disadvantages:

- Lack of rigidity.

- Penofol is not advised to be used for wall insulation for wallpapering or painting.

- When attaching penofol, you need to protect the electrical wiring and avoid breakdowns.

- Poor adhesion to the insulated surface.

- It is necessary to use a special adhesive or fasteners.

- It is not recommended to use penofol as an independent insulation for installation on external walls.

Attention: Penofol is used as an additional layer to reflect heat energy and protect the structure from moisture.

Penofol types

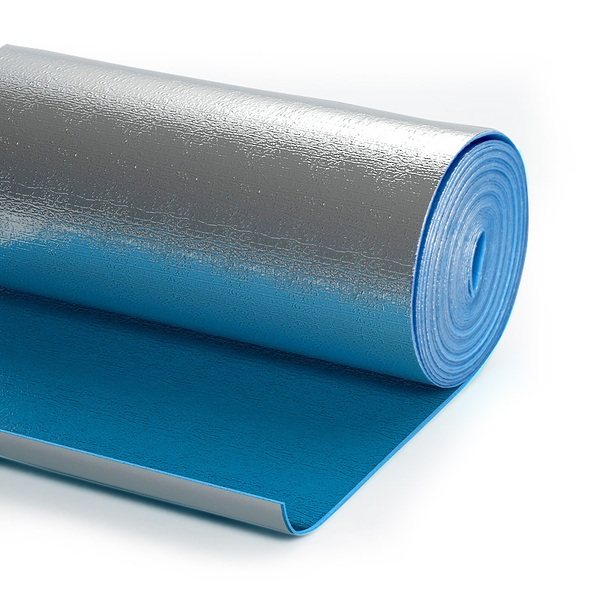

For different functionality, manufacturers offer different penofol options. The generally accepted classification subdivides three types:

- A type - one-sided penofol (aluminum film is applied to one side of polyethylene after foaming). This type is used more often as an additional heat insulator with foam;

Penofol type A - B type - penofol foil on two sides, has universal application, including for autonomous isolation;

Penofol type B

- C type - self-adhesive. On one side there is a reflector layer on aluminum, on the opposite side there is a moisture resistant adhesive on polyethylene foam, which is protected by a sticker. Such penofol is more convenient for finishing areas that are difficult to reach. During installation, no special installation tools are required.

Penofol type C

In addition to these standardized types, the developers have also prepared modifications that occupy a separate niche in the building materials market:

- ALP type - penofol with lamination, there is a plastic wrap on the foil side. This type of material is used to insulate agricultural buildings, operated in a not too aggressive environment;

- M or R types - one-sided foil with corrugated "top";

- AIR - penofol used for the preparation of air outlet structures;

- Super NET (from the word "Network") - the main task of this type of penofol is body insulation and protection from steam for air outlets, pipelines or heating mains.

Comparison of heaters by thermal conductivity

Expanded polystyrene (styrofoam)

Plates of expanded polystyrene (polystyrene)

It is the most popular thermal insulation material in Russia due to its low thermal conductivity, low cost and ease of installation. Polyfoam is made in plates with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% of air. The material has various densities, low thermal conductivity and moisture resistance.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for insulating various premises. But the material is quite fragile and quickly ignites, releasing toxic substances during combustion. Because of this, it is preferable to use polystyrene in non-residential premises and for thermal insulation of unloaded structures - insulation of the facade under plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not affected by moisture and decay. It is a very durable and easy to use material that can be easily cut with a knife to the required size Low water absorption provides a minimum change in properties at high humidity, the boards have high density and resistance to compression. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other heaters, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to the assurances of the manufacturers, an extrusion sheet 50 millimeters thick replaces a 60 mm foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and additional waterproofing can be dispensed with.

Mineral wool

Isover mineral wool slabs in packing

Minvata (for example, Isover, URSA, Technoruf, etc.) is made from natural materials - slag, rocks and dolomite using a special technology. Mineral wool has low thermal conductivity and is absolutely fireproof. The material is produced in slabs and rolls of various hardness. For horizontal planes, less dense mats are used; for vertical structures, rigid and semi-rigid slabs are used.

However, one of the significant disadvantages of this insulation, like basalt wool, is its low moisture resistance, which requires additional moisture and vapor barrier when installing the mineral wool. Experts do not recommend using mineral wool for insulating wet rooms - basements of houses and cellars, for thermal insulation of the steam room from the inside in saunas and dressing rooms. But even here it can be used with proper waterproofing.

Basalt wool

Rockwool basalt wool slabs in packing

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, has good performance in thermal insulation and sound insulation of premises. It is used for both internal and external thermal insulation.

When installing basalt cotton wool, protective equipment (gloves, respirator and goggles) should be used to protect mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs are not compacted or caked, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

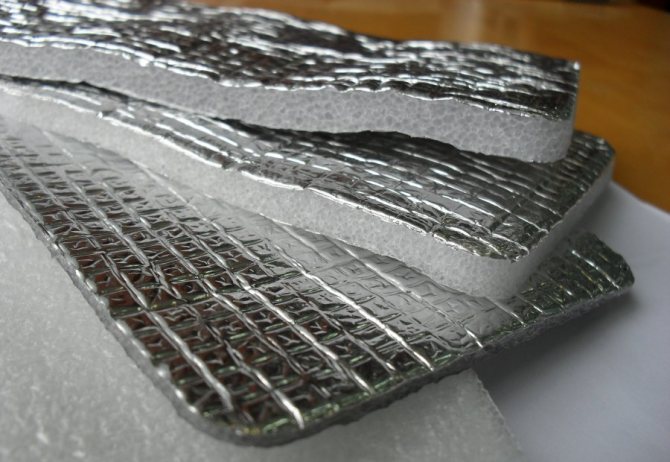

Penofol, izolon (foamed polyethylene)

Penofol and Izolon are roll insulation with a thickness of 2 to 10 mm, consisting of foamed polyethylene. The material is also available with a layer of foil on one side to create a reflective effect. The insulation has a thickness several times thinner than the previously presented insulation, but at the same time retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Penofol characteristics

This material has the following performance characteristics:

- operating temperatures are in the range from -60 ° С to + 100 ° С;

- thermal reflection on the surface reaches 95 - 97%;

- thermal conductivity indicators depend on the conditions in which the material is used and fluctuate between 0.037 and 0.052 W / m ° C;

- moisture absorption per volume is from 0.35 to 0.7%, this value guarantees high-quality protection of the frame or floor from possible moisture ingress;

- if the thickness is 4 mm, then the specific weight will be 44 or up to 74 kg / m3 (this indicator strongly depends on the type of material);

- vapor permeability is no more than 0.001 mg / m h - penofol is an excellent protector against fumes;

- ultimate compressive strength - up to 0.035 MPa;

- specific heat capacity is 1.95 J / kg ° C;

- the sound is absorbed - not less than 32 dB.

More technical characteristics of foil-clad penofol can be found in the table below.

| Specifications | Penofol types | Units | ||

| Type A | Type B | A type C | ||

| Optimum temperature | from - 60 ° C to +100 ° C | ° C | ||

| Thermal reflection coefficient of the surface | ≥ 95-97 | % | ||

| Thermal conductivity coefficient (I) in dry condition at 20 ° С | ≤ 0,037-0,049 | ≤ 0,038-0,051 | W / m ° C | |

| Water absorption by volume | ≤ 0,7 | ≤ 0,6 | ≤ 0,35 | % |

| Specific gravity (with a thickness of 4 mm) | 44 + / — 10 | 5 4 + / — 10 | 7 4 + / — 10 | kg / m3 |

| Dynamic modulus of elasticity (Eq) - under load 2 Kpa - under load 5 Kpa | 0,26 0,77 | 0,39 0,72 | 0,26 0,77 | MPa |

| Compression ratio (Eq) - under load 2 Kpa - under load 5 Kpa | 0,09 0,20 | 0,03 0,12 | 0,09 0,20 | units |

| Heat assimilation coefficient (S) with a period of 24 hours | 0,51 | 0,45 | 0,51 | W / m² ° С |

| Vapor permeability | ≥ 0,001 | mg / m h Pa | ||

| Compressive strength | ≥ 0,035 | MPa | ||

| Reduction index of the reduced level of impact noise | A3003-17 | A3005-19 | A3010-21 | dB (A) |

| Specific heat | 1,95 | J / kg ° С | ||

Why choose "Tepofol": customer opinions

"Tepofol", reviews of the masters about which you can read in the article, can be used in heated buildings and houses without heating. Thanks to the opinions of professionals, we can conclude that the material is characterized by high thermal insulation performance. And the foamed structure of polyethylene increases the sound insulation capacity, which is expressed in noise absorption of 32 dB. Due to the fact that the water absorption of the described product is only two percent, this makes it possible to use it as a thermal insulation and a waterproofing layer.

Among other things, if the surfaces are insulated, they will not lose their ability to breathe. Also for this reason, according to buyers, this insulation can act as a vapor barrier. If you count, it turns out that the consumer saves three times. The use of "Tepofol" has a positive effect on the indoor microclimate of the room. An optimal temperature is maintained in the building, a person does not experience the effect of suffocation, because the penetrating ability of the material is quite high. "Tepofol" foil-clad has a small thickness. That is why he is not able to take up the volume of the room. Due to the thermal insulation qualities, the thickness of the wall can be reduced, and the costs of the work can be reduced.

View gallery

Penofol application

A universal type of material is well suited for insulation of multi-storey buildings or a summer house in the country. The material is known and popular in both renovation and fundamental construction.

Penofol is widely used in construction:

- With thermal insulation:

- in hangars or warehouses, heated or cold;

- living quarters;

- for refrigerators, vans or railroad cars, in cars;

- saunas or baths;

- during the construction of children's medical institutions;

- industrial buildings and administrative complexes;

- during the construction of shopping centers, shops, and so on;

- when insulating different types of pipelines;

- for chambers of refrigeration units;

- in water supply, heating or ventilation systems;

- for insulation of equipment and technology (boxes, boilers, etc.).

- For insulating parts of structures:

- when processing ceilings or floors;

- for insulation of window or door systems;

- processing of external and internal walls of buildings;

- for overlapping in basements and unheated types of premises;

- heat, hydro or vapor insulation of mansards or roofs, roofs of various types;

- in the shielding of heating radiators.

It must be remembered that penofol helps not only to keep the rooms warm in winter. If you lay it at the bottom of the roof, then it will prevent the penetration of the summer heat.

Tools and materials

To carry out insulation of a house with penofol, you will need following tools:

- screwdriver;

- a hammer;

- construction stapler;

- painting knife.

Materials (edit)required for work:

- penofol sheets;

- wooden bars 1.5-2 cm wide;

- plywood, drywall, panels, siding, depending on the surface to be insulated;

- flooring, wallpaper, paint;

- self-tapping screws.

How to choose penofol

It is recommended to consider the following criteria for choosing penofol:

- On the the price the thickness affects, as well as how many layers of aluminum have been applied to the reflective surface. The standard size is from three to eight or even ten mm. Penofol with one side - a reflector with a size of 3 or 4 mm by type A may cost about up to 55 rubles / m². 10mm by type B is considered much more expensive and more durable of all, the cost for it can reach from 100 to 130 rubles / m².

- In stores, you can stumble upon the "Penofol 2000" label. This is an analogue of the standard material, but cheaper (it costs from 35 rubles / m²). In terms of strength, according to experts, it is much inferior to the classic insulation.

- The best ratio between the cost of the substance and the operational data shows penofol with a thickness of 5 mm at a cost of approximately 70 rubles / m².

- When you need to insulate the roof or basement rooms, in the basement, on the balcony, for saunas, or walls and ceilings, you can use A-type of foam foam. When applied on wood floors, it is best to take the B-class C-class is used for metal structures and car insulation.

Feedback from experts on areas of use and application features

Thermal insulation "Tepofol", reviews of which you can find in this article, is used for noise, moisture, heat and waterproofing surfaces in saunas, baths, as well as attics. We can use the material for walls, floors and air ducts. According to experts, this insulation is often used to form heat-reflecting screens behind heating batteries. The area of application depends on the thickness of the material, the variety of layers and their number. The more difficult the conditions of use, the more outstanding the characteristics of the insulation will be. For example, as experts emphasize, it is best to purchase Tepofol insulation of maximum thickness to insulate the facade and roof. A reflective surface will be placed on both sides of it.

"Tepofol", reviews of which, perhaps, will allow you to make the right choice, is also used in the arrangement of floors. The higher the load on the coating, the more impressive thickness the material should be chosen. Professionals advise home craftsmen to purchase "Tepofol" with a self-adhesive layer. It adheres well to most substrates. Therefore, working with the material is extremely simple. When installing thermal insulation, the reflective layer must be placed on the side of the warm object.

View gallery

How to lay penofol with your own hands

The best insulating effect is achieved if you adhere to the following rules:

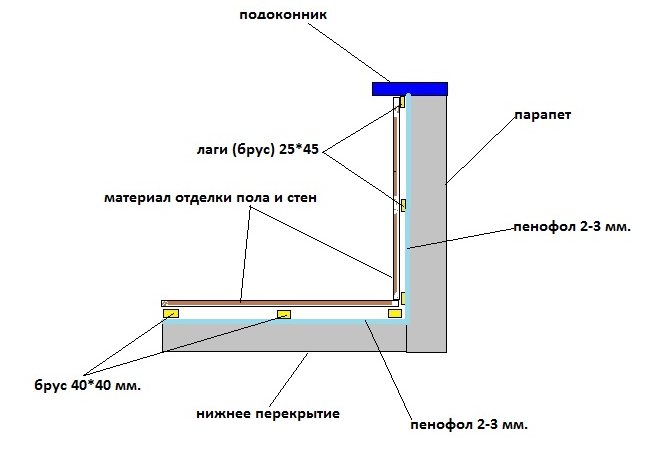

- Between the structural element and the insulation itself, you need to leave some distance for ventilation, no more than a couple of centimeters.

- If you mount one-sided penofol, the layer with the foil must be directed to the side where the heat will come from.

- It is better to join the sheets of material joint to joint, which gives uniformity in the reflection of heat. But if, for example, a loggia is insulated, joining by the overlap method to a width of up to 10 cm is also permissible.

- When the joints of sheets of materials are sealed, tape should be used, also foil-clad.

It is very important to remember that this material must be fastened taking into account the fact that the reflective aluminum foil conducts current. Therefore, if there is a wiring nearby, it is necessary to insulate the wires well.

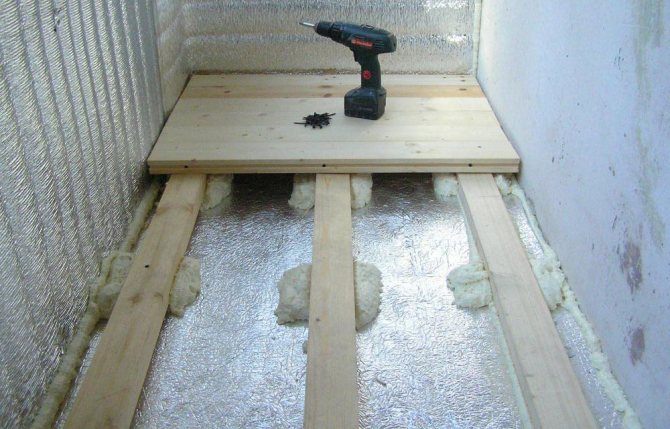

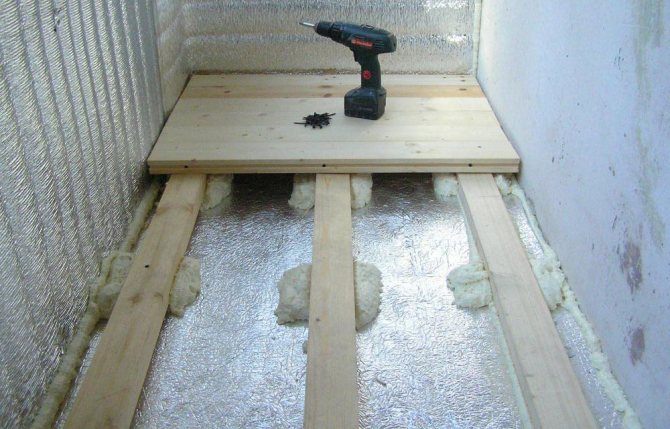

An example of using penofol for insulating walls and floors

After a material suitable for the operational requirements has been selected, additional waterproofing can be used, protection from steam or heat can no longer be used. It will also be possible to save on the installation process and materials necessary for high-quality insulation and surface insulation. You can also watch several videos on this topic.

Penofol insulation technology for internal walls

Depending on the characteristics of the room and the method of thermal insulation, the appropriate type of Penofol is selected. Some of them can be mounted autonomously (type B), others serve as waterproofing of a more powerful insulation (type A), and still others act as the basis of the heat-insulating layer (type C). This material successfully allows the surface to breathe without accumulating moisture. It relieves walls from the appearance of mold and mildew that arise after steam ingress.

Preparatory work before thermal insulation of walls with Penofol

Before you start laying Penofol, be sure to check the quality of the electrical wiring in the room. Unlike other thermal insulation materials, it contains aluminum foil, which is known to have good electrical conductivity. Protect the wires to prevent the insulation from coming into contact with bare cables. It goes without saying that the work surface is prepared - they clean off the debris, carry out cleaning with an emery cloth. If necessary, fill up the cracks with a filler solution. It is also advisable to buy a primer paint and paint over the wall, which will allow you to get a perfectly flat surface. Of the tools and devices for work, we need:

- Well sharpened knife;

- Furniture (construction) stapler with staples;

- Ruler;

- Level;

- Pencil;

- Construction trowel;

- A hammer;

- Working deep container for solution;

- Emery cloth of varying grain size;

- Screwdriver;

- Roulette;

- Dowels;

- Electric drill.

Instructions for installing Penofol on walls

Armed with the necessary tool and using the help of another person, they carry out the following actions:

- Initially, a wall-mounted wooden frame is constructed. Its task is to enhance the effect of the use of heat-insulating material. For fixing the bars, dowels are taken, which are hammered no wider than 1 m from each other.

- Penofol is fixed on the frame with a furniture stapler. For this, the material is cut into strips with a sharp knife. The strips do not overlap, but end-to-end, so that condensation does not form along the joint line. Seams can be glued with special tape.

- After that, another frame is attached, at a distance of 2 cm. This is done in order to allow air circulation. Now it can be covered with cladding panels, putty or wallpaper on top.

A vapor barrier film is not laid, because the material itself is considered vapor-tight. However, it is not capable of replacing waterproofing. A common mistake associated with improper installation of insulation: some craftsmen mount Penofol directly on the ceiling or wall, leaving an air gap on only one side. This leads to a decrease in its thermal insulation characteristics. Important! When installing Penofol, its foil part must necessarily look inside the room, and not at the wall. This is a prerequisite for additional heat reflection.

Finishing the walls

After laying the heat insulator, cover it with crate and wood boards on top, you can start finishing the surface. You need to start by leveling it: any defects that may interfere with the reliable attachment of the plaster or the gluing of a roll of wallpaper are removed. It is best to smooth out unevenness with emery, starting with coarse-grained and ending with fine sandpaper, which makes the surface even and smooth. Most often, a plaster solution is applied to the finished wall, which can then be painted or decorated in other ways. The most common are cement-based or gypsum-based plaster mixes. At the same time, gypsum is not subject to shrinkage over time, it has good plasticity and bonding properties. It does not require the use of a reinforcing mesh.If you don't have enough experience in plastering walls, you can purchase plastering signaling devices that will be limiters - they allow you to measure the thickness of the layer and protect against irregularities. After fixing the signaling beacons on the working surface, you can start preparing the solution. Take a bucket or other container, fill it with water about a third. Add the solution gradually and stir constantly to achieve a homogeneous mass. The mortar should be of such a consistency that it does not run off the spatula, and its density will depend on how thick the plaster layer should be. If the walls in the room absorb moisture strongly, they must be additionally moistened. For these purposes, a household spray gun is well suited. This is done so that the solution retains its moisture content, otherwise it will crack after drying. The plaster is applied to the wall by applying it with a spatula. If such skills are difficult to master at first, then you can apply the solution to a wooden trowel and level it on the surface. Alignment is performed from bottom to top. If plastering is carried out in the area of the slopes of window and door openings, then it is better to apply the solution with a slight overlap. Using the rule, you can remove the excess solution. Its sharp edge is directed perpendicular to the plaster beacons. You should start from the lower border. Gradually, the instrument is raised higher and higher and the excess solution is removed, throwing it up. After that, the final smoothing of the wall is carried out. This is done several times to achieve a flat surface. In order to make sure that the surface is flat, the rule is applied at different angles. The resulting bumps are scraped off with the sharp edge of the instrument. It remains to pull the beacons out of the wall with a screwdriver. Now you can grout or paint the plaster. On this, the insulation of the walls with Penofol from the inside can be considered complete.

Reviews about the material

Last year, house buildings were erected on the site, and, among other materials, they decided to use Teplofol. Where bets were placed on him, it was warm even in the most severe cold. I consider the advantages of light weight, strength, but softness. I did not notice any shortcomings.

I check any insulation for exposure to high temperatures. In the case of Teplofol, I decided to do the same. Already before melting, it began to exude an unpleasant odor, on the basis of which a conclusion was made about its toxicity under certain conditions. Despite its many advantages, I would recommend using it in a limited way.

Convenient material with a lock connection, making its rolls very easy to install. The result is an insulating surface without gaps, which, moreover, perfectly insulates the building, even when installed outside. Moreover, working with him is a pleasure.

We live on the first floor of an old high-rise building. The floors are not very thick, and cold air actively penetrates into the basements in winter, so the cold in the apartment was very serious, and without really good insulation it was difficult. We decided to try Teplofol, as there are many positive reviews about it, and besides, it is very inexpensive. A year has passed since the floor was insulated, and last winter we were finally able to relax. Especially true for those who have small children who love to play on the floor.

When building the house, I used mineral wool, but it did little to insulate. I decided to additionally apply Teplofol. Self-assembly at first did not help to improve the situation, but after contacting professionals and reworking everything changed - the house became really warm. Earlier I read that the material can be used independently, but my experience in this matter was unsuccessful. Therefore, if you nevertheless decide to use it, then it is better to contact the professionals.

Types of reflective insulation for home

Insulation for walls can be either ordinary foil or insulation with foil on one or both sides. The principle of operation of such a system is based on the reflection of infrared rays. The foil itself can be insulation, but it is more appropriate to call it “reflective insulation”.

Insulation can be:

- Styrofoam;

- Closed cell polyethylene foam;

- Mineral or stone wool.

All heaters can be sold both in layers and in rolls. The safest is considered to be filtrated insulation with stone wool. It is mainly used for baths, since the material is non-toxic and does not allow moisture to pass through. Due to these properties, reflective thermal insulation can be used for chimneys and any other heating surfaces.

Polymer insulation cannot be used for surfaces with temperatures above 85 degrees.

Reflective insulation can vary in thickness and quality of materials used in its manufacture.

Plastic or polyethylene begin to lose their properties at temperatures above 90 degrees. In addition, polymers are used only for internal use. The exception is the pipe boxes. When cladding a house, the effectiveness of polymers as insulation is not observed. But sound insulation and wind barrier are provided.

Properties and characteristics of Tepofol insulation

Tepofol has the following properties:

• low thermal conductivity (0.37-0.39 W / m ° C);

• inertness to microbiological processes;

• vapor permeability (0.011 mg / mchPa);

• soundproof qualities (absorbs sounds up to 32 dB).

The specific gravity of the material per cubic meter is 44 kg. This indicator is ideal for frame structures, the foundation part and load-bearing walls are not burdened with additional load.

Tepofol helps to create a comfortable microclimate in the home and maintain it regardless of the season. The operating temperature range at which the insulator retains its properties is from minus 60 ° to plus 100 °.

What is Teplofol

Briefly, this material can be described as follows - polyethylene foam. The material is thin and usually accompanied by aluminum foil. It is used in various areas of insulation, including walls in private houses, as well as roofs and floors. It is often used to insulate air ducts, ventilation ducts and, of course, pipes. In the case of the latter, Teplofol, due to the strongest reduction in the level of vibration and noise, also contributes to the absence of condensation, which often occurs when there is a high temperature difference and the surrounding space. Finally, being mounted on a radiator, the teplofol will be able to increase its productivity by a third.

Polyurethane foam (PPU)

Polyurethane foam is usually sprayed using special equipment. Foaming fill is sometimes used. This material has many varieties. For example, the foam rubber known to all is also polyurethane foam. But for thermal insulation, a tougher and more durable PU foam is used. Polyurethane foam also consists of this substance and is applied in a similar way. But the foam from the cylinder forms only half of the closed cells, and the professional insulation is more than 90%, therefore it is better able to insulate. The advantages of PPU are as follows.

- This material is one of the most effective in insulation. In terms of thermal insulation properties, it surpasses expanded polystyrene. Solidifying in an even layer without seams and joints, it excludes the appearance of "cold bridges".

- Rigid PU foam is not afraid of water, which cannot penetrate into closed cells.

- Polyurethane foam does not require fasteners, which can also reduce thermal insulation properties. The insulation quickly hardens, firmly adhering to almost any surface and filling all the gaps.

- PU foam can be applied to surfaces of different shapes, which makes it possible to insulate complex objects.

- The material is environmentally friendly and does not burn well.

- The service life is approximately 30 years.

There are not many disadvantages of polyurethane foam, only two.

- A special installation is required for application. You need to contact a specialist to insulate the balcony.

- If the PUF surface remains open, it loses its properties under the influence of ultraviolet radiation. It is necessary to cover the insulation with finishing materials.

Polyurethane foam is a reliable insulation

Choice

It is necessary to first determine the main goals of insulation.

To perform insulation quickly, without difficulty, you will need roll raw materials with a thickness of at least 5 mm.

Work in rooms with a high level of humidity, periodic temperature jumps is better when using foil-clad polypropylene.

Regardless of the type of penofol, you need to carefully check it. It is not recommended to take stitched rolls, poorly polished foil. Poor quality raw materials will entail consequences.

You need to consider packaging with a footage of 9-18 sq. m, issued by well-known, well-established brands. If you cannot find such information on your own, you need to contact the builders for advice. Experts do not advise contacting consultants in the store with such questions, as they strive to sell a certain product, and not the best one.